Composition capable of reflecting sun heat radiation

A technology of heat radiation and composition, which is applied in the field of composition reflecting solar heat radiation, and can solve problems such as hindering the internal temperature from radiating outward, increasing the temperature of open-air equipment with metal casings, human work, and adverse effects on indoor environment comfort. , to achieve the effect of reducing building energy consumption, increasing temperature difference and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Solvent-based solar heat radiation reflective coating

[0017] The solar heat radiation reflective coating comprises the following components by weight:

[0018] Acrylic resin 600 parts

[0019] Butyl acetate 60 parts

[0020] Dispersant 5 parts

[0021] 175 parts of rutile titanium dioxide

[0023] Precipitated barium sulfate 50 parts

[0024] Dissolve the acrylic resin with dispersant and butyl acetate according to the above parts by weight, then add rutile titanium dioxide, zinc oxide and precipitated barium sulfate and disperse at high speed, and mix evenly to obtain the solvent-type solar heat radiation reflective coating. The reflectance of the paint is ≥86%, and the emissivity is ≥85%.

Embodiment 2

[0025] Example 2 Water-soluble solar heat radiation reflective coating

[0026] The solar heat radiation reflective coating comprises the following components by weight:

[0027] 150 parts of water

[0028] Synthetic resin emulsion 400 parts

[0029] 225 parts of rutile titanium dioxide

[0030] Zinc oxide 195 parts

[0031] Precipitated barium sulfate 100 parts

[0032] Dispersant 10 parts

[0033] Defoamer 8 parts

[0034] 1 part pH adjuster

[0035] Coalescing aid 25 parts

[0036] Thickener 5 parts

[0037] According to the above parts by weight, the above components are added and mixed evenly to obtain the water-soluble solar heat radiation reflective coating. The reflectance of the paint is ≥87%, and the emissivity is ≥88%. Since water is used as a solvent, this type of solar heat radiation reflective material is beneficial to environmental protection.

Embodiment 3

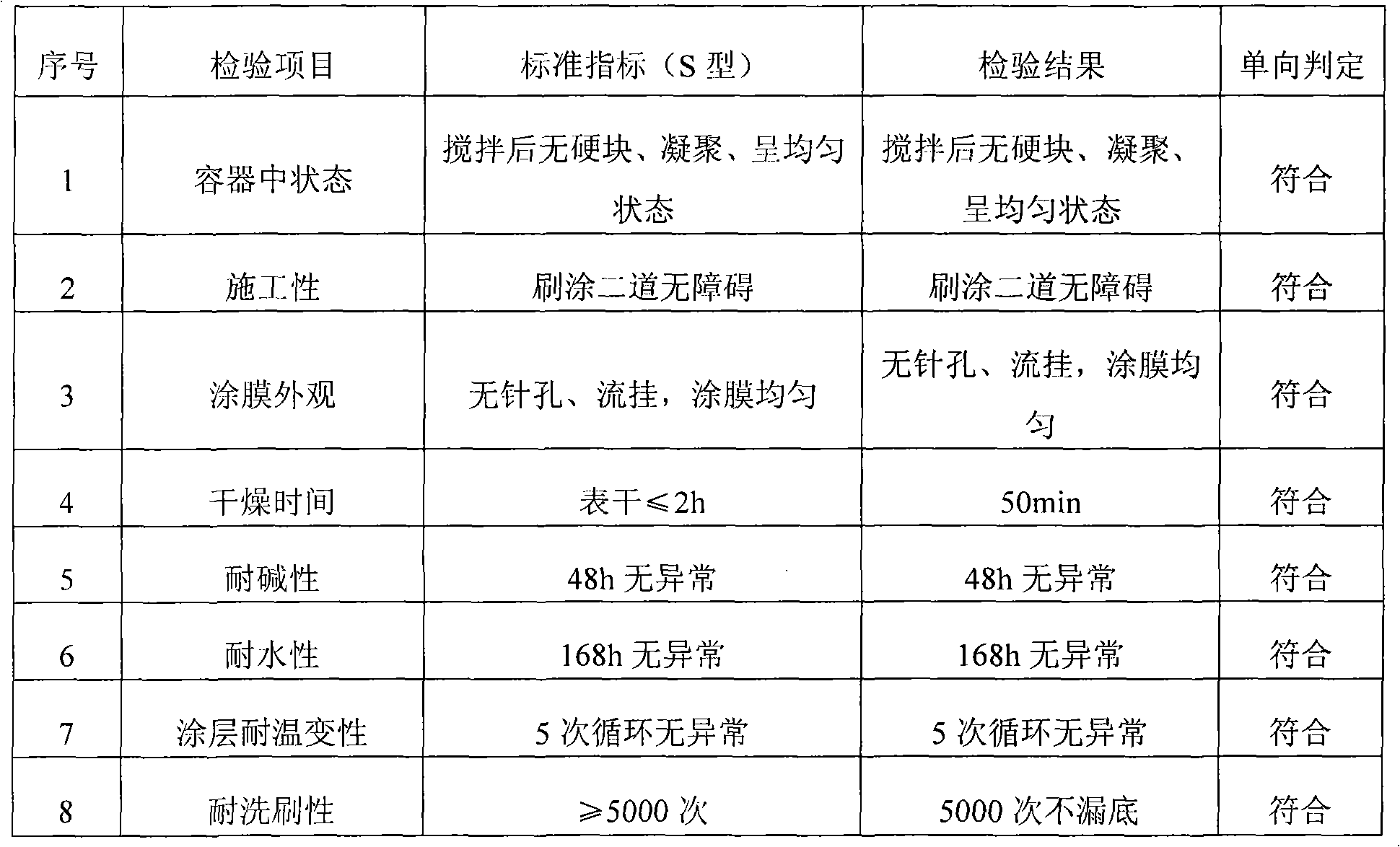

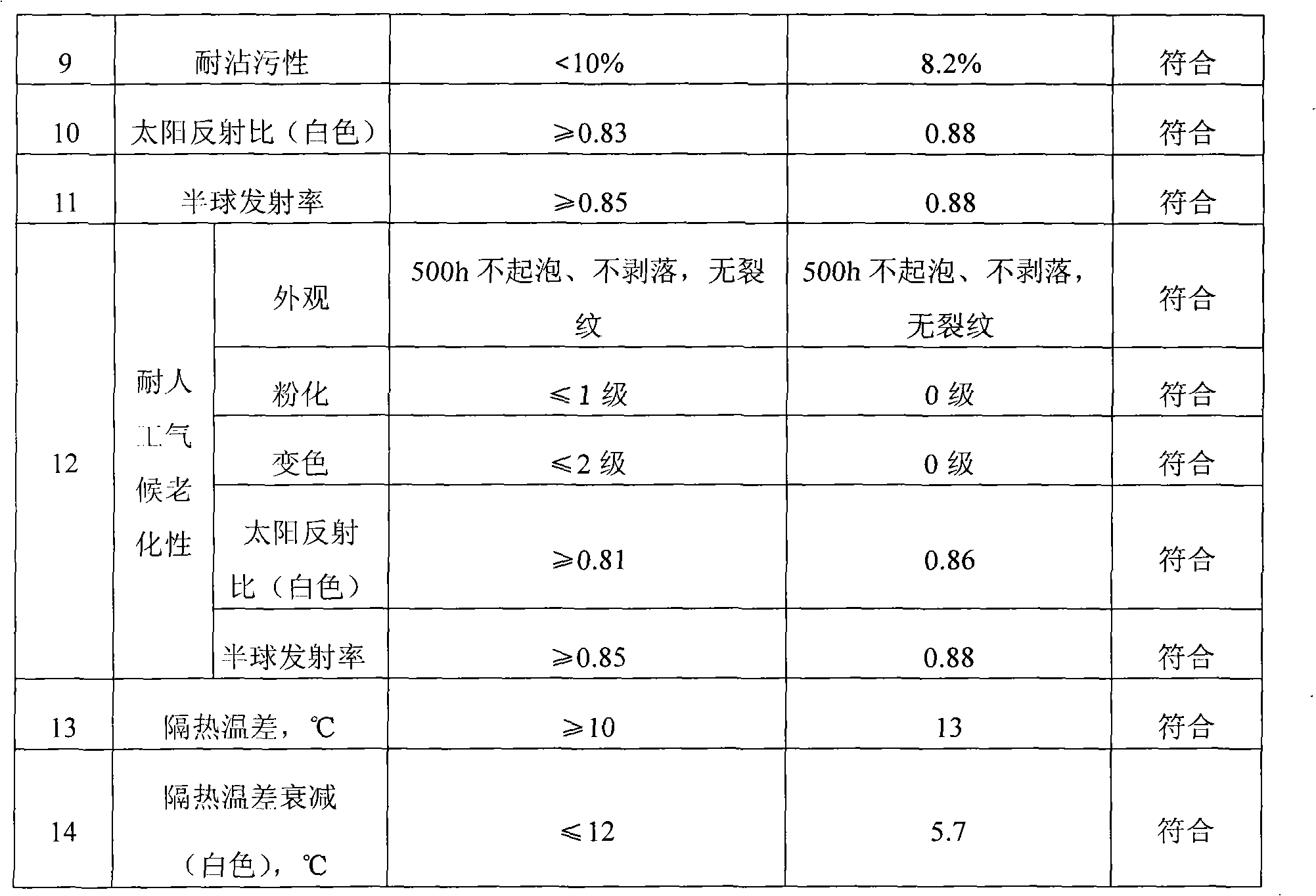

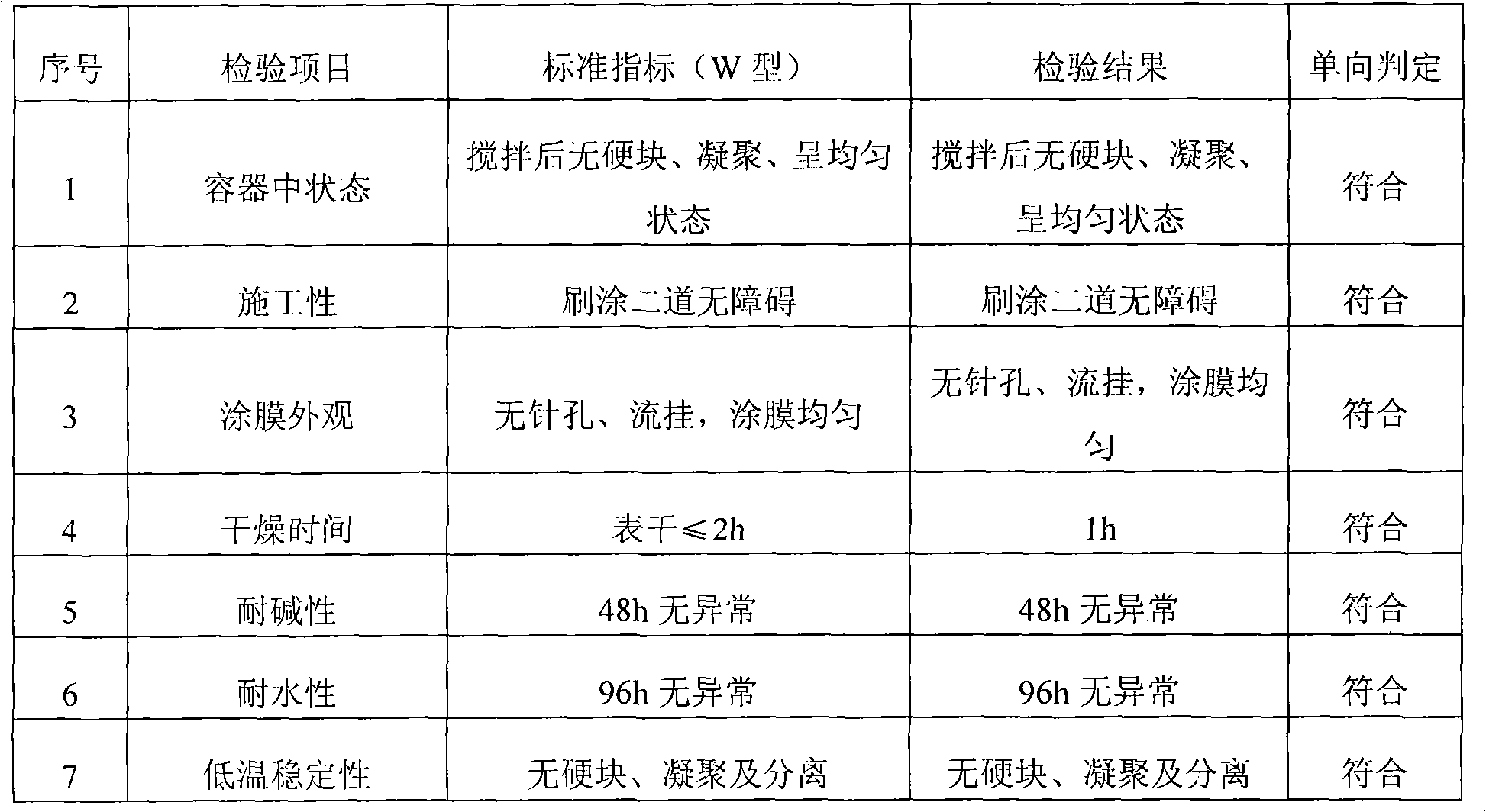

[0038] Example 3 Inspection results of technical indicators of solvent-based solar heat reflective coatings

[0039] The solvent-based solar heat reflective coating disclosed in the present invention is tested in accordance with the JC / T1040-2007 standard and the JG / T235-2008 standard for testing the performance indicators of heat insulation temperature difference and heat insulation temperature difference attenuation, as shown in Table 1.

[0040] Table 1

[0041]

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com