Polypropylene composite material for household appliance shell and preparation method thereof

A composite material and polypropylene technology, applied in the polymer field, can solve the problems of dimensional stability of injection molded parts, difficulty in assembly of the whole machine, difficult to meet the requirements of use, and the effect is not very ideal, so as to shorten the cooling molding time, increase the Effective utilization and shortened storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

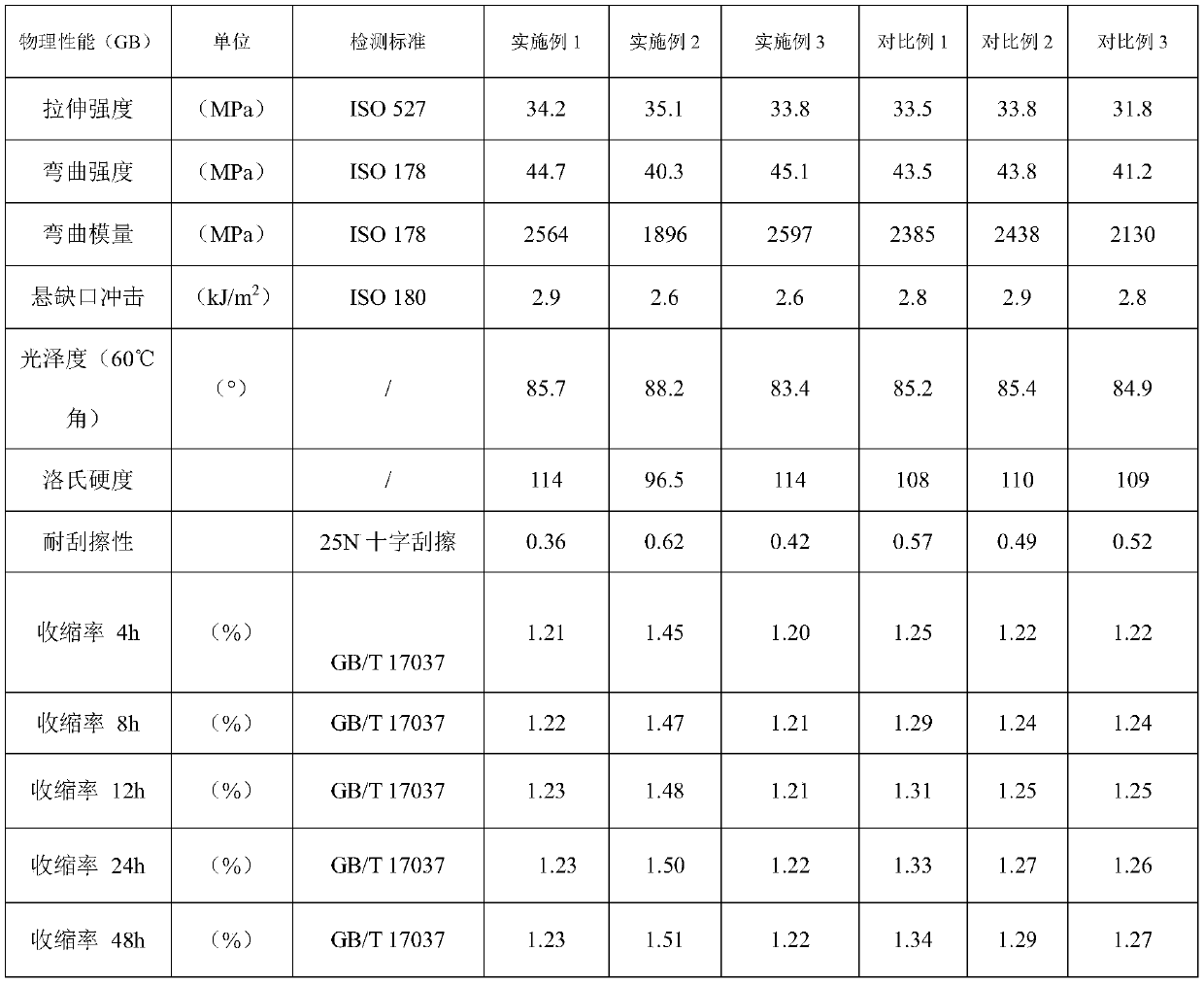

Examples

Embodiment 1

[0031] A kind of polypropylene composite material for home appliance casing, comprises the raw material of following parts by weight:

[0032] 83 parts of homopolypropylene, 12 parts of precipitated barium sulfate, 5 parts of magnesium sulfate whiskers, 2 parts of silicone, 0.2 parts of phosphate metal salt nucleating agent, 0.2 parts of antioxidant 1010, 0.2 parts of antioxidant 168, hard 0.3 parts of calcium stearate, 0.4 parts of N,N-ethylenebisstearamide, and 1 part of titanium dioxide.

[0033] Among them, the homopolypropylene has an isotacticity of 98% and a crystallinity of 90%.

[0034] The preparation method of the polypropylene composite material for the housing of household appliances comprises the following steps:

[0035] S1. Weigh raw materials by weight, mix 12 parts of precipitated barium sulfate with 0.1 part of calcium stearate and 0.2 part of N,N-ethylenebisstearamide;

[0036] S2. 83 parts of homopolypropylene, 5 parts of magnesium sulfate whiskers, 2 pa...

Embodiment 2

[0040] A kind of polypropylene composite material for home appliance casing, comprises the raw material of following parts by weight:

[0041] 96 parts of homopolypropylene, 2 parts of precipitated barium sulfate, 2 parts of magnesium sulfate whiskers, 0.1 part of phosphate metal salt nucleating agent, 0.1 part of antioxidant 1010, 0.1 part of antioxidant 168, 0.3 part of calcium stearate , 0.2 parts of N,N-ethylenebisstearamide.

[0042] Among them, the homopolypropylene has an isotacticity of 97.5% and a crystallinity of 85%.

[0043] The preparation method of the polypropylene composite material for the housing of household appliances comprises the following steps:

[0044] S1. Weigh raw materials by weight, mix 2 parts of precipitated barium sulfate with 0.1 part of calcium stearate and 0.1 part of N,N-ethylenebisstearamide;

[0045] S2. 96 parts of homopolypropylene, 2 parts of magnesium sulfate whiskers, and 0.2 parts of phosphate metal salt nucleating agent were mixed...

Embodiment 3

[0049] A kind of polypropylene composite material for home appliance casing, comprises the raw material of following parts by weight:

[0050] 83 parts of homopolypropylene, 10 parts of precipitated barium sulfate, 7 parts of magnesium sulfate whiskers, 2 parts of erucamide, 0.5 parts of sorbitol nucleating agent, antioxidant 1010 0.2 antioxidant DLTP 0.2 parts, stearic acid 0.3 parts of calcium, 0.4 parts of N,N-ethylenebisstearamide, and 1 part of phthalocyanine blue.

[0051] Among them, the homopolypropylene has an isotacticity of 97% and a crystallinity of 80%.

[0052] The preparation method of the polypropylene composite material for the housing of household appliances comprises the following steps:

[0053] S1. Weigh raw materials by weight, mix 10 parts of precipitated barium sulfate with 0.1 part of calcium stearate, and 0.2 part of N,N-ethylenebisstearamide;

[0054] S2. 83 parts of homopolypropylene, 7 parts of magnesium sulfate whiskers, 2 parts of erucamide, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com