Electronic candle lamp shell and manufacturing technology thereof

An electronic candle and manufacturing process technology, which is applied to semiconductor devices of light-emitting elements, damage prevention measures for lighting devices, lighting devices, etc., can solve the problems of easy oxidation of wax shells, high cost, and many processes, and achieve shortened cooling molding time, improve effective utilization, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

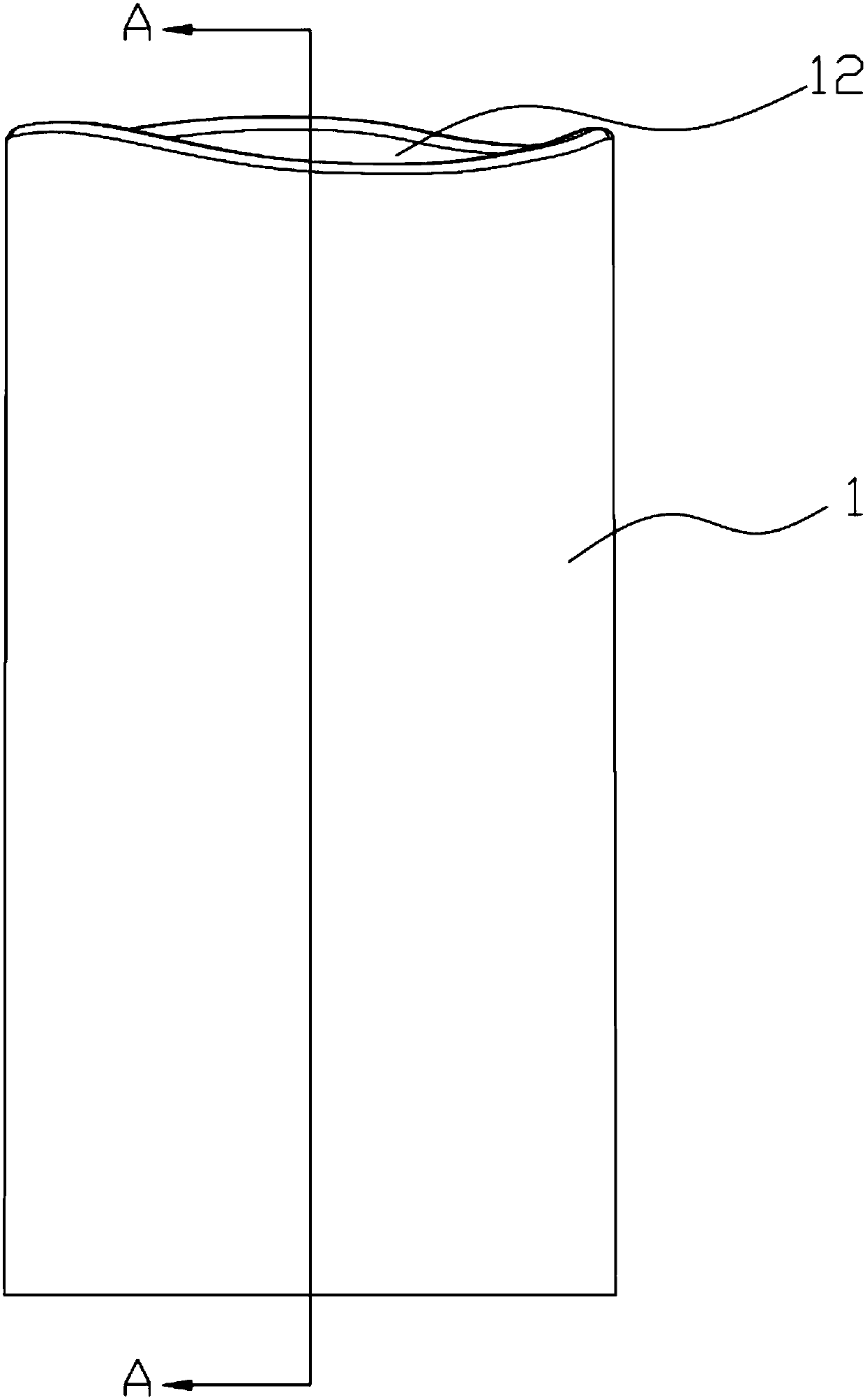

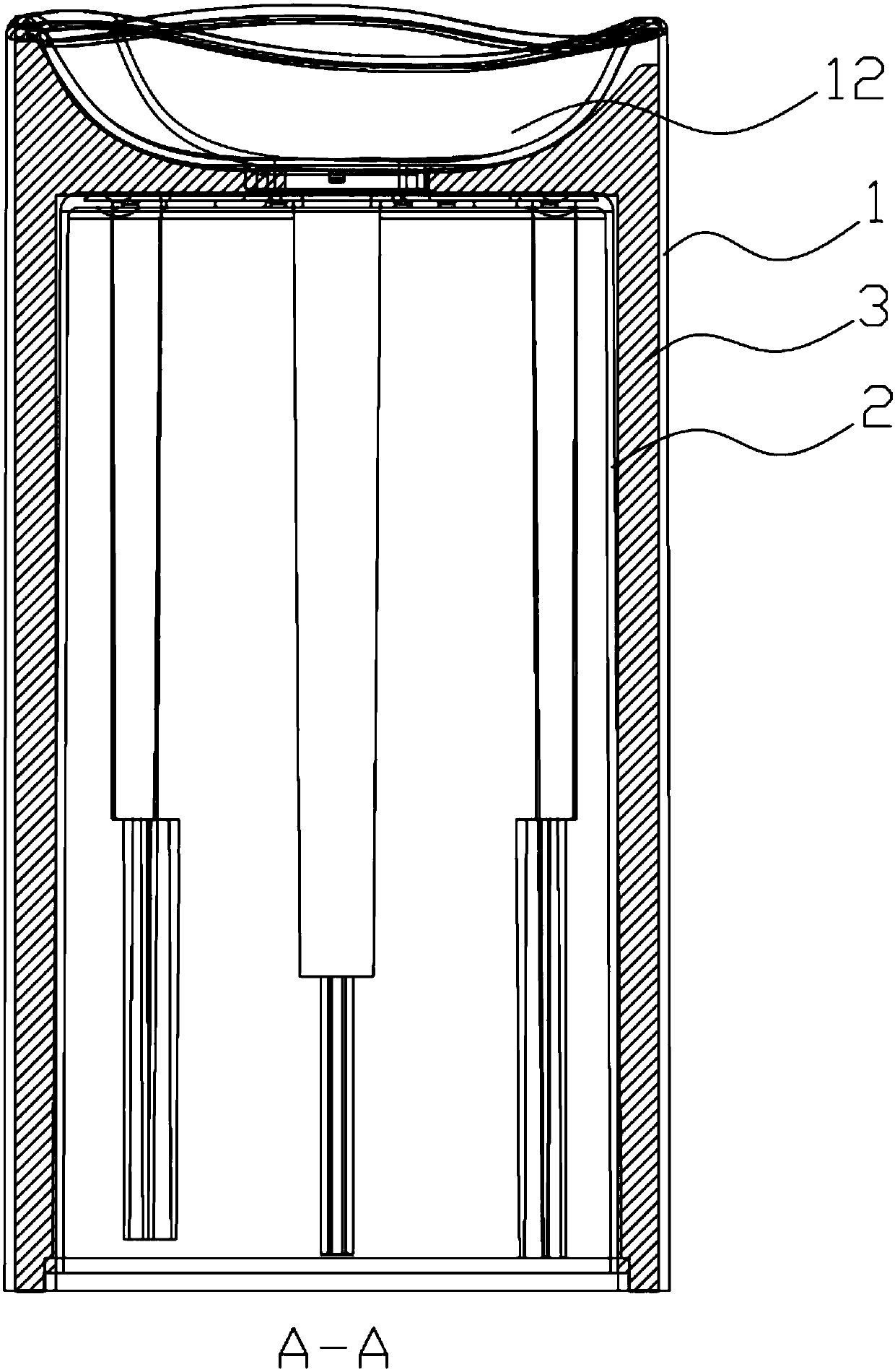

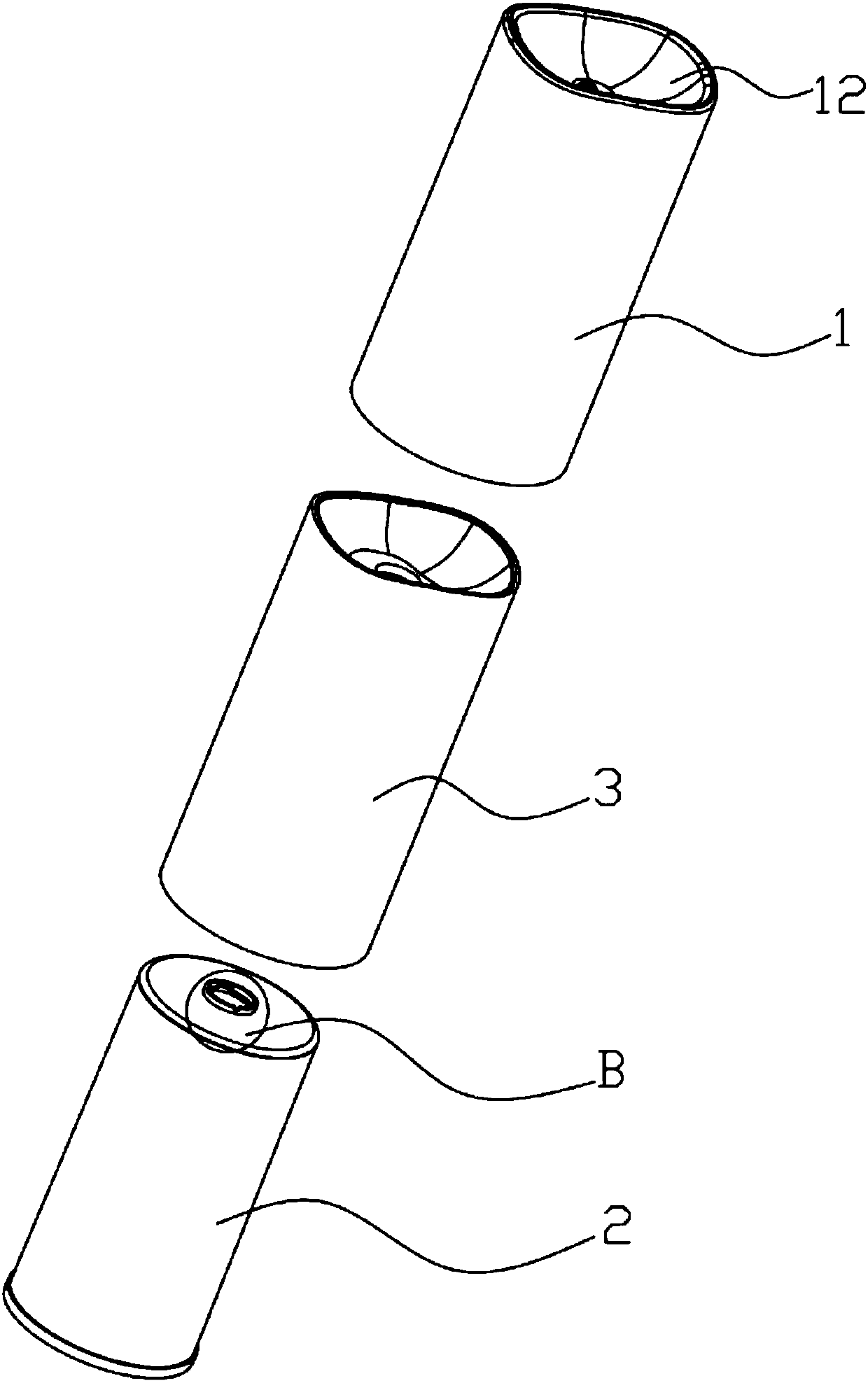

[0025] Such as figure 1 and figure 2 As shown, an electronic candle lamp housing provided by an embodiment of the present invention includes a cylindrical plastic shell 1 and a cylindrical plastic inner shell 2, the plastic shell 1 is set outside the plastic inner shell 2, and the plastic shell 1 It is arranged coaxially with the plastic inner shell 2 , the inner wall of the plastic outer shell 1 and the outer peripheral wall of the plastic inner shell 2 are spaced apart, and the space between the plastic outer shell 1 and the plastic inner shell 2 is filled with wax body 3 .

[0026] Such as Figure 3 ~ Figure 5 As shown, further, the top of the plastic shell 1 is centered with a through hole 11, and the top of the plastic inner shell 2 is fixed with a convex ring 21 that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com