Mould temperature conversion system

A conversion system and mold temperature technology, applied in the field of mold temperature conversion system, can solve the problems that the mold temperature cannot be converted quickly, the injection molding process time cost cannot be effectively reduced, and the cost control is not met, so as to shorten the cooling molding time, Reduce the average energy consumption of the output, which is beneficial to the effect of the qualified rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

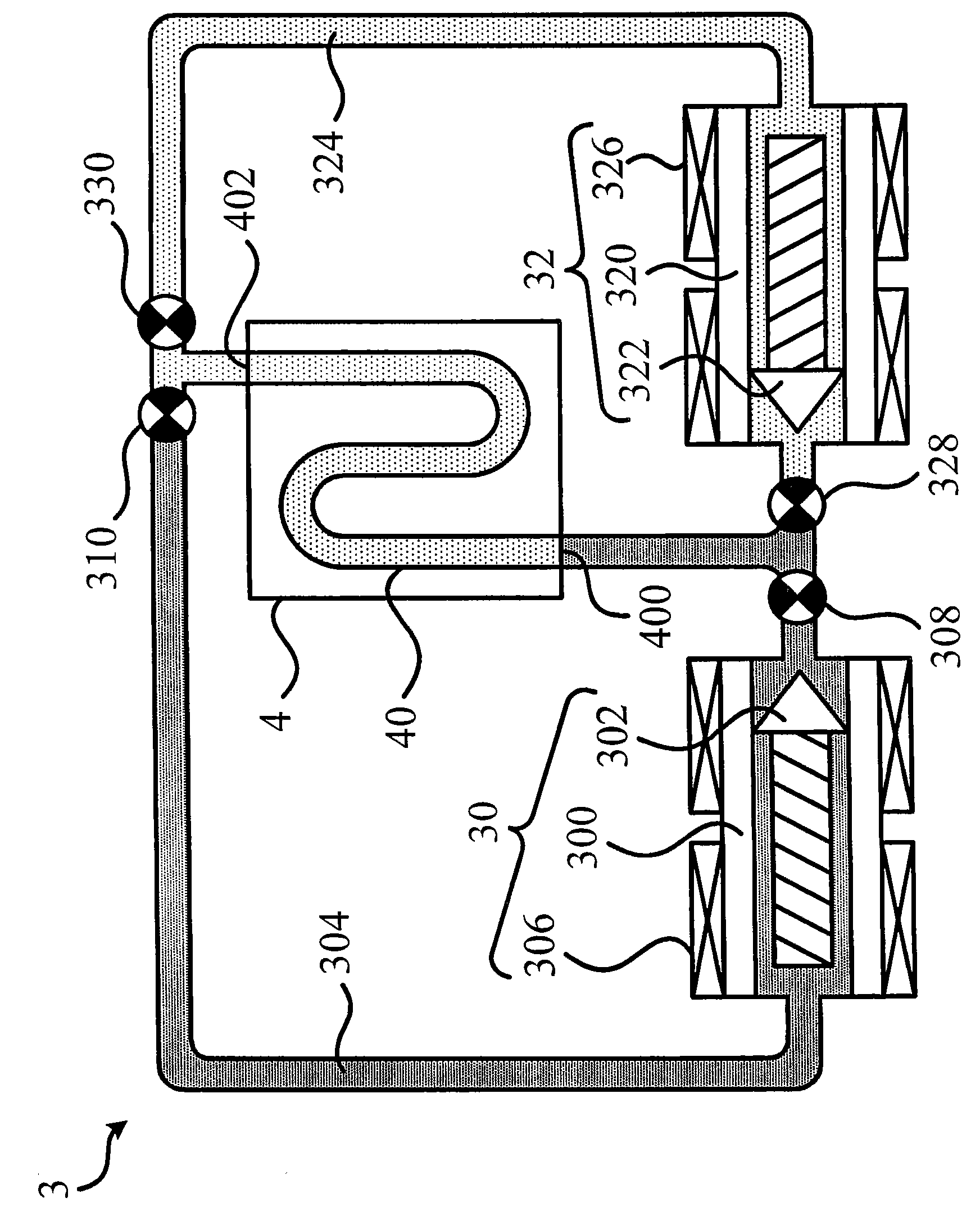

[0021] The object of the present invention is to provide a mold temperature transformation system. The mold temperature switching system utilizes two mold temperature controllers with injection capability to quickly switch the mold temperature. Moreover, the high-temperature liquid and the low-temperature liquid respectively in the two mold temperature controllers can share the same set of water channels and can be recycled to their respective storage tanks. Preferred specific embodiments of the present invention will be described in detail below to fully illustrate the features, spirit, advantages and simplicity of implementation of the present invention.

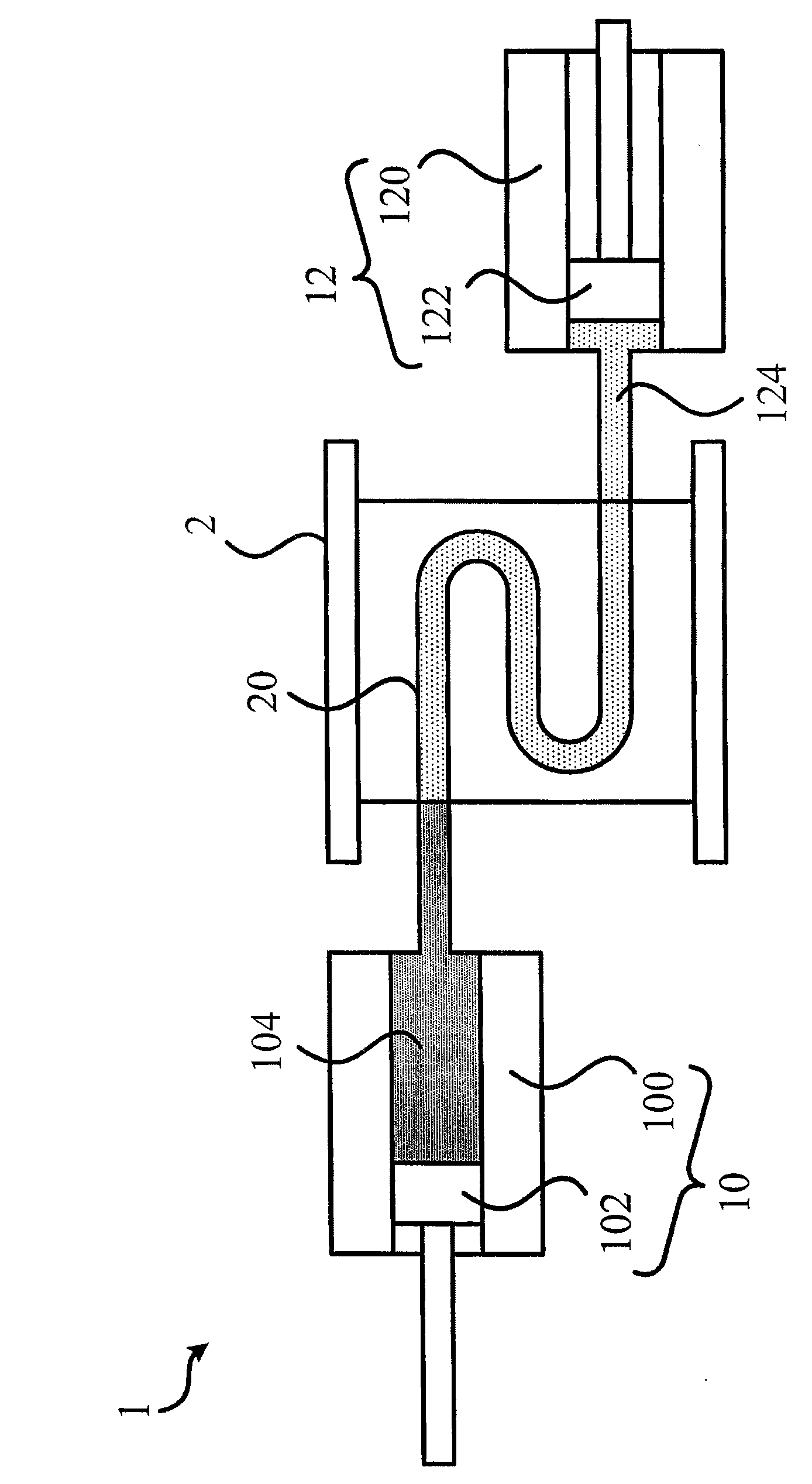

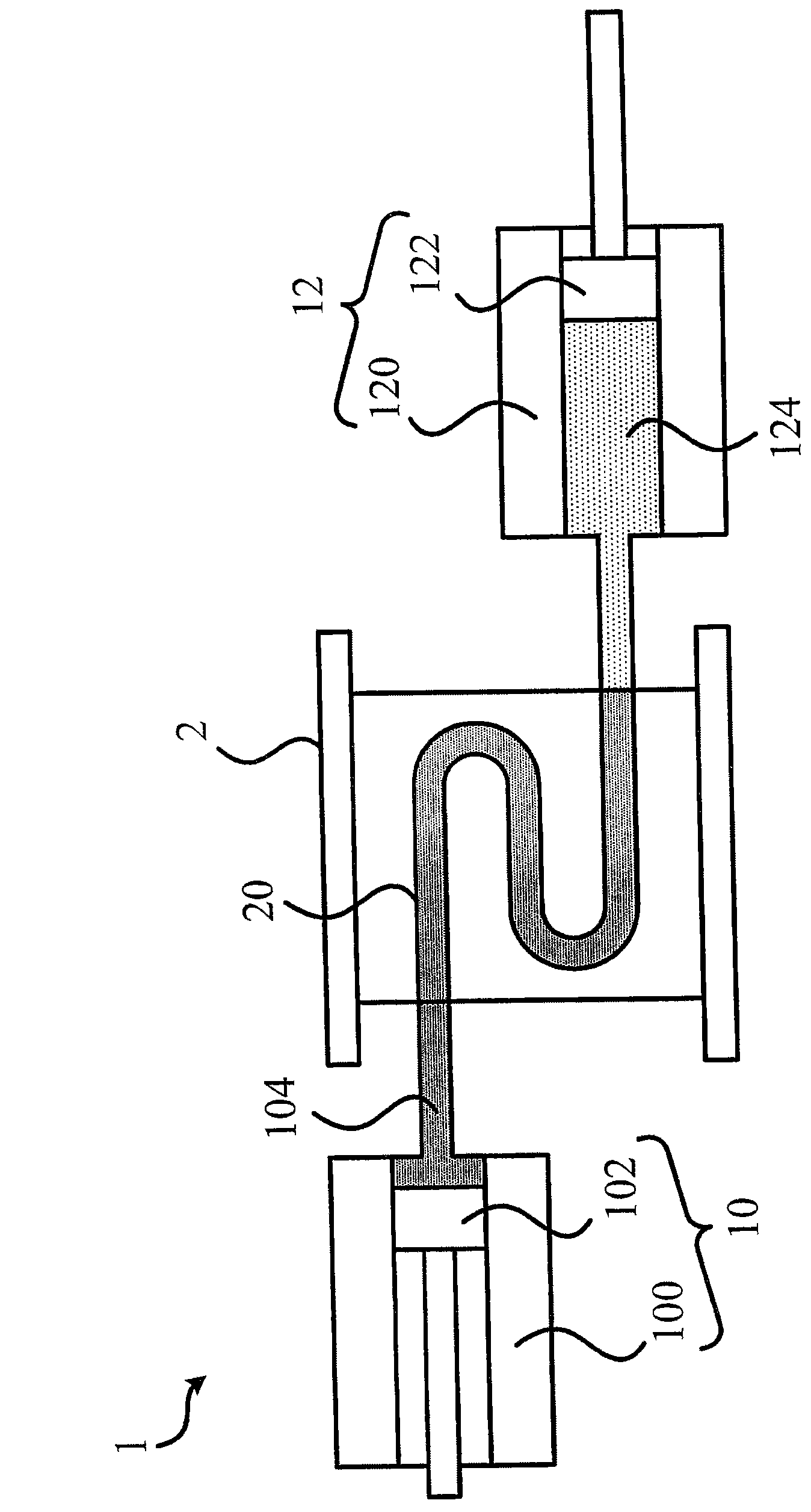

[0022] Please refer to Figure 1A and Figure 1B . Figure 1A Shown is a schematic view of the first operating state of the mold temperature conversion system 1 according to the first preferred embodiment of the present invention. Figure 1B shown as Figure 1A A schematic diagram of the second operating state of the mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com