Waste plastic recovery and granulation method and device thereof

A technology of waste plastic and granulation device, which is applied in coating and other directions, can solve the problems of uneven color, performance and size of plastic particles, easy adhesion of plastic particles, high production cost, and achieve uniform size, no noise pollution, no noise pollution, no Effects of dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The method for recycling and granulating waste plastics comprises the following steps:

[0034] Soak the recovered waste plastics in cleaning agent for 30-60 minutes, then wash them with clean water and dry them;

[0035] The dried waste plastics are pulverized and then melted, and a plastic modifier is added to modify the molten liquid;

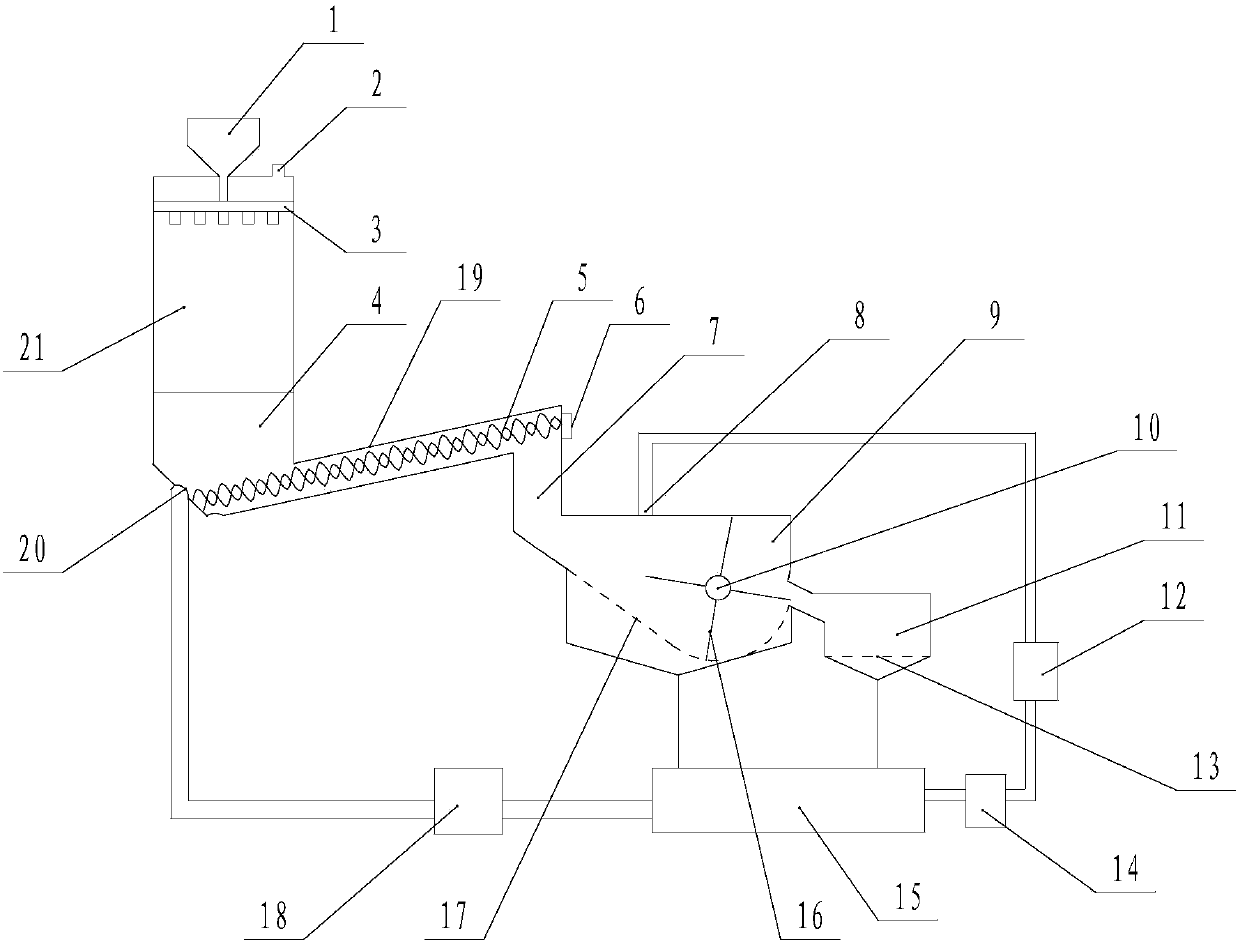

[0036] The modified molten liquid is sent into the prilling tower 21, and after being distributed by the distributor 3, the molten liquid becomes liquid droplets and falls into the water tank 4 to form plastic particles, and the plastic particles enter the cooling box 9 through the feeding pipeline 19, and the cooled The plastic granules are sent into the storage bin 11 by the distributing device 10 to obtain plastic granules recovered from waste plastics.

[0037] The water flowing out of the cooling box 9 and the storage bin 11 enters the water purification pool 15, and after being purified by the water purification pool 15, it is ...

Embodiment 2

[0046] The waste plastic recycling and granulation device includes a granulation tower 21, a cooling box 9, and a storage bin 11. The upper part of the granulation tower 21 is provided with a distributor 3, and the distributor 3 is connected to the injection port 1 to make The lower part of the grain tower 21 is provided with a water tank 4, and the water tank 4 and the cooling box 9 are connected through a feeding pipeline 19. The inside of the cooling box 9 is provided with a distributing device 10, and the outlet of the cooling box 9 is connected with the storage bin 11.

Embodiment 3

[0048] The waste plastic recycling and granulation device includes a granulation tower 21, a cooling box 9, and a storage bin 11. The upper part of the granulation tower 21 is provided with a distributor 3, and the distributor 3 is connected to the injection port 1 to make The lower part of the grain tower 21 is provided with a water tank 4, and the water tank 4 and the cooling box 9 are connected through a feeding pipeline 19. The inside of the cooling box 9 is provided with a distributing device 10, and the outlet of the cooling box 9 is connected with the storage bin 11.

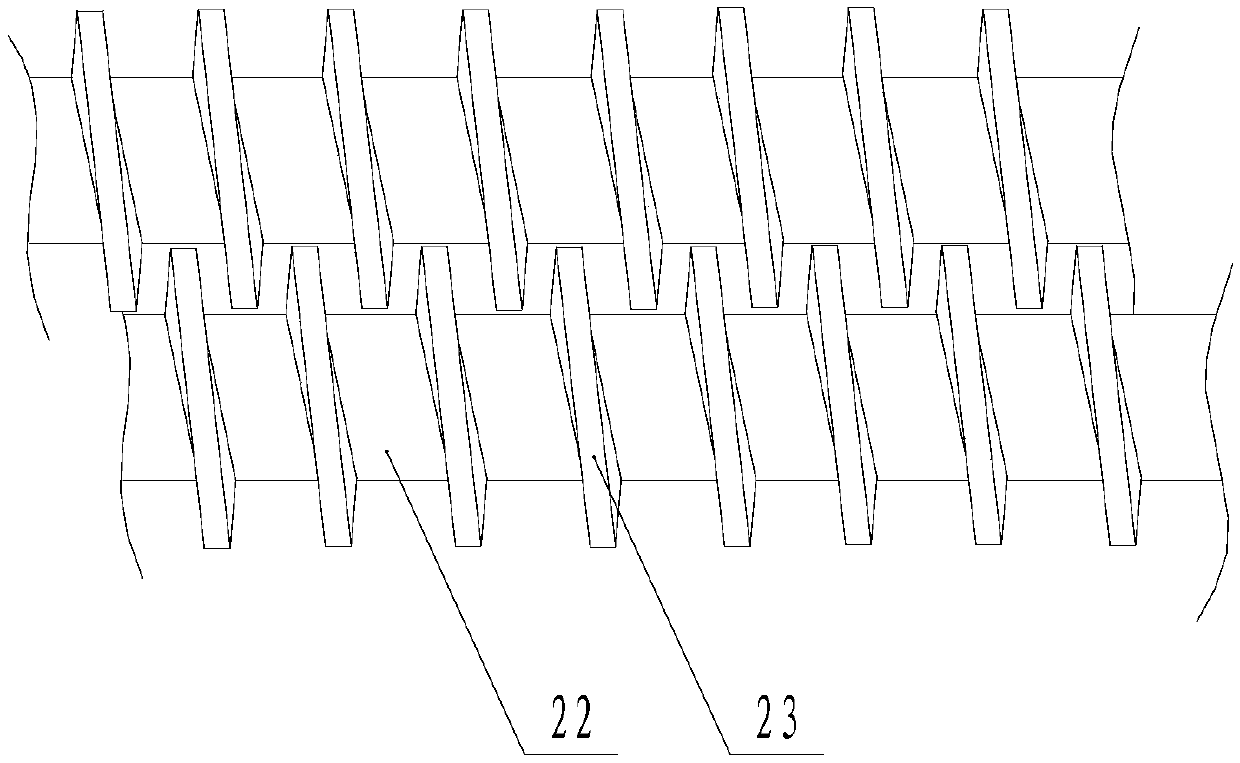

[0049] Furthermore, the said feeding pipe 19 is provided with a double-screw feeding propeller 5 inside, and the double-screw feeding propeller 5 is composed of two screw rods whose helical teeth 23 mesh with each other.

[0050] Further, the feeding pipeline 19 is inclined upward at an angle of 10-30° with the horizontal direction, and the double-screw feeding propeller 5 is driven by the motor 6 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com