Sealing hammer type crushing splitter

A hammer crushing and shrinking machine technology, applied in the preparation of test samples, grain processing and other directions, can solve the problems of unrepresentative coal samples, uneven feeding, low sample preparation efficiency, etc., to achieve compact structure, adaptable The effect of high water content and fast sample preparation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

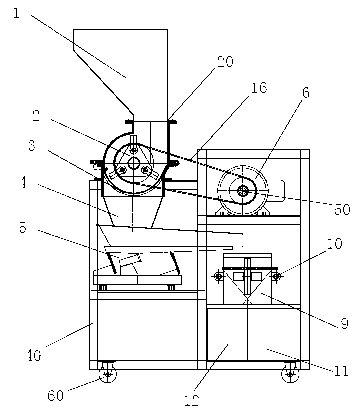

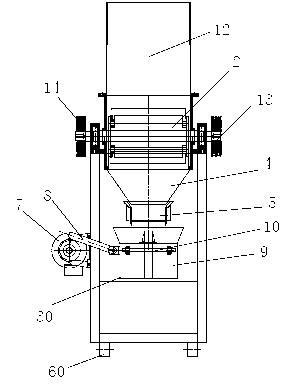

[0013] The present invention includes feeding mechanism 20, shrinking and dividing mechanism 30, frame 40, such as figure 1 As shown, the feeding mechanism 20 is arranged on the middle and upper part of the frame 40, and the shrinkage mechanism 30 is arranged on the lower part of the frame 40; 1. Crushing device 50, sieve plate 3 is fixedly connected to the top of frame 40, feed hopper 1 is airtightly connected to the top of sieve plate 3, electromagnetic vibrating feeder 5 is arranged in the middle of frame 40, gathering hopper 4 is arranged on sieve plate 3 The lower part of the gathering hopper 4 faces the top of the electromagnetic vibrating feeder 5, and the crushing device 50 includes a feed motor 6, a pulley 13, a flywheel 14, a rotating shaft 15, and a rotor hammer 2, and the rotor hammer 2 is arranged on the screen Inside the plate 3, the rotating shaft 15 pas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com