Patents

Literature

50results about How to "Does not rot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Collagen fiber stuffing product and processing method thereof

ActiveCN1730376AHigh heat retention rateHigh static stabilityMonocomponent protein artificial filamentUpholstery fillingTextile fiberEngineering

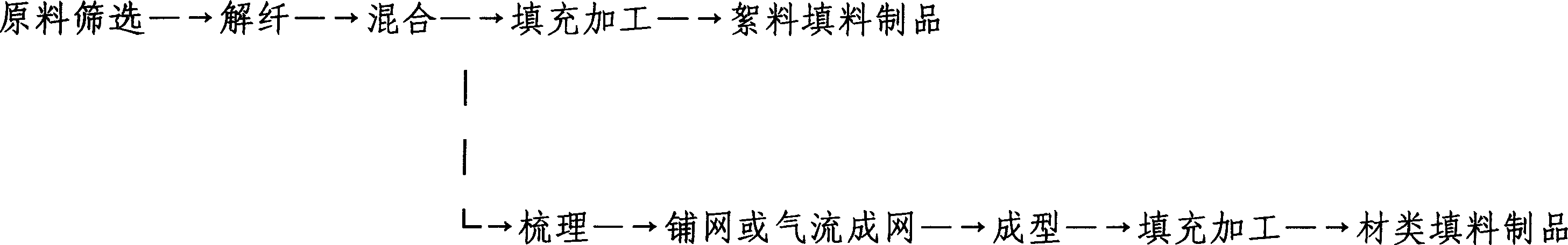

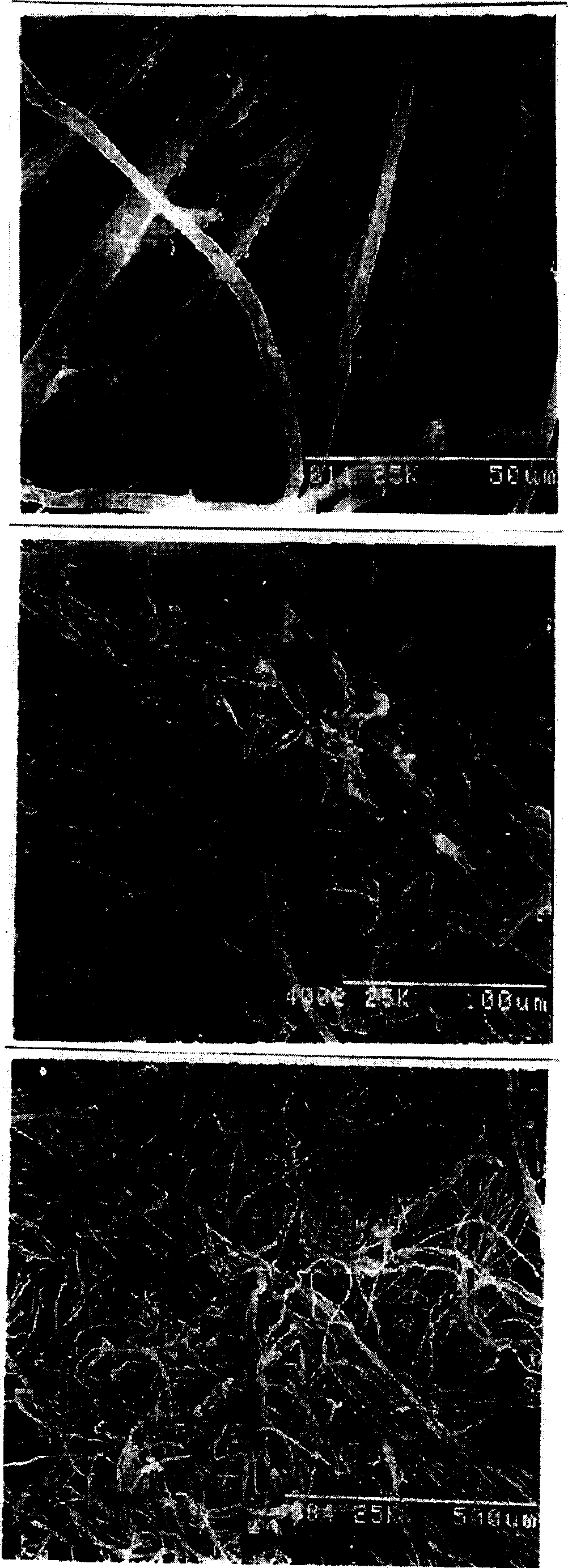

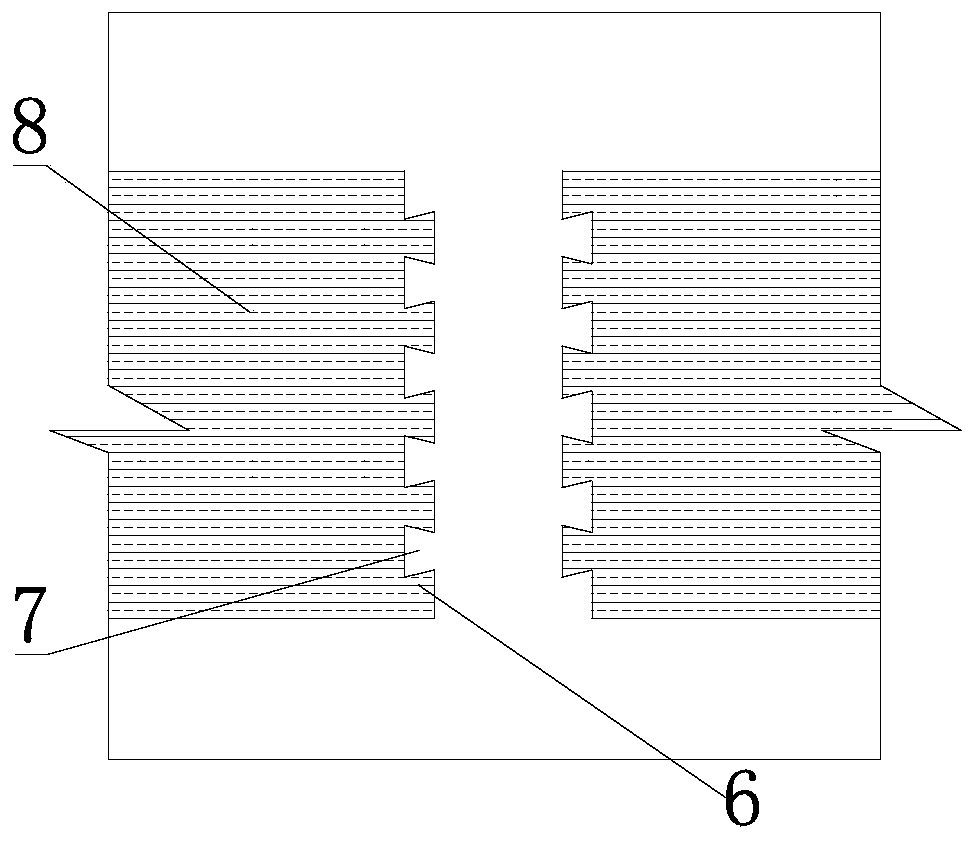

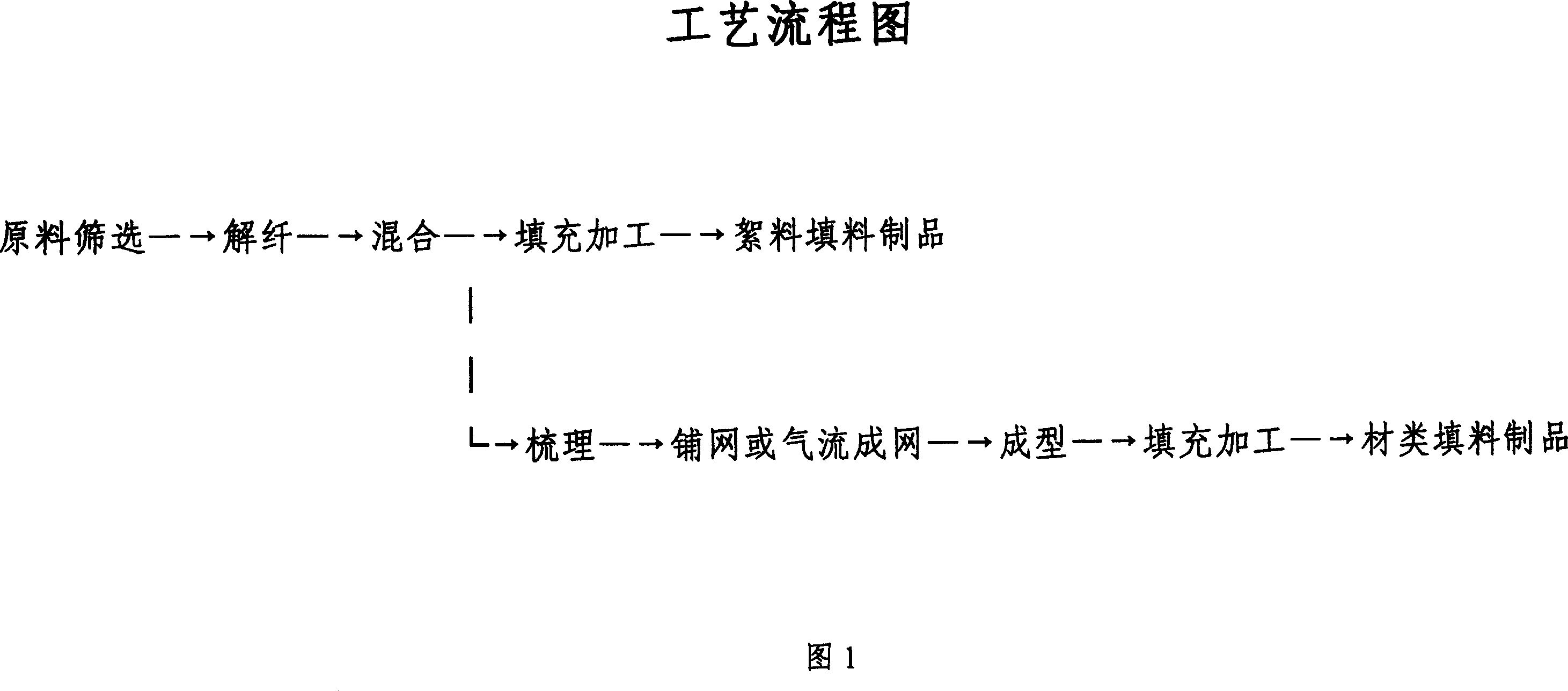

The invention provides a collagen fiber stuffing product which comprises 50%-100% collagen fiber in the stuffing and its Process for preparing. The said stuffing is oakum stuffing mixed collagen fiber deliberating from animal hide with at least another textile fiber; or materials stuffing arise from teasing, bedding web and modeling. The stuffing product in the invention is provided with advantages of well puffy, well rebound, well warming, flameproof and sound absorbing which the current stuffing can not get because it uses collagen fiber as main stuffing. The stuffing produced in the process provided in the invention has no peculiar smell, without putrefaction, without mouldy, and can be used in practice. The product is low cost and settles the problem of leftover bits and pieces of industrial material, so it is environment friendly.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

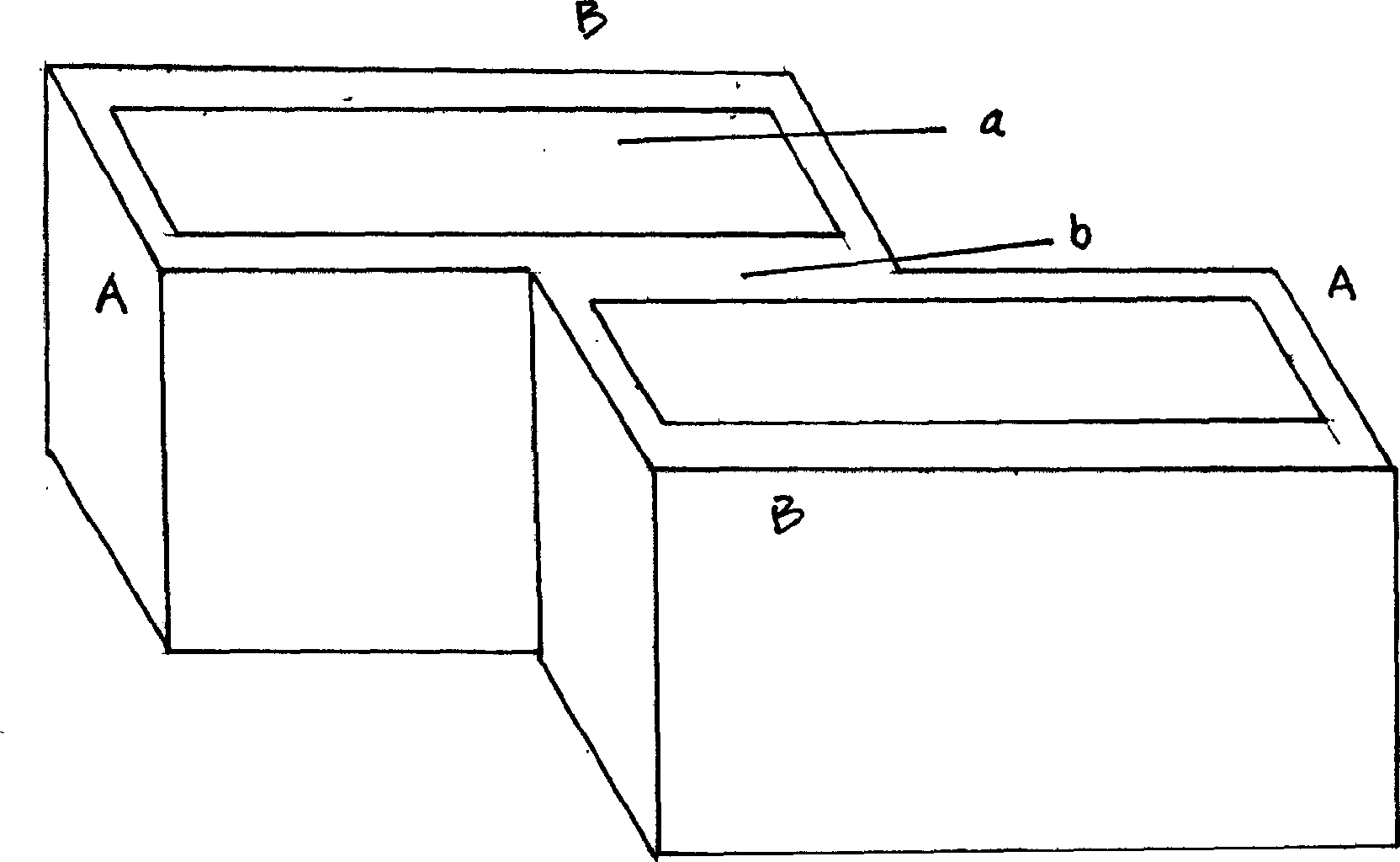

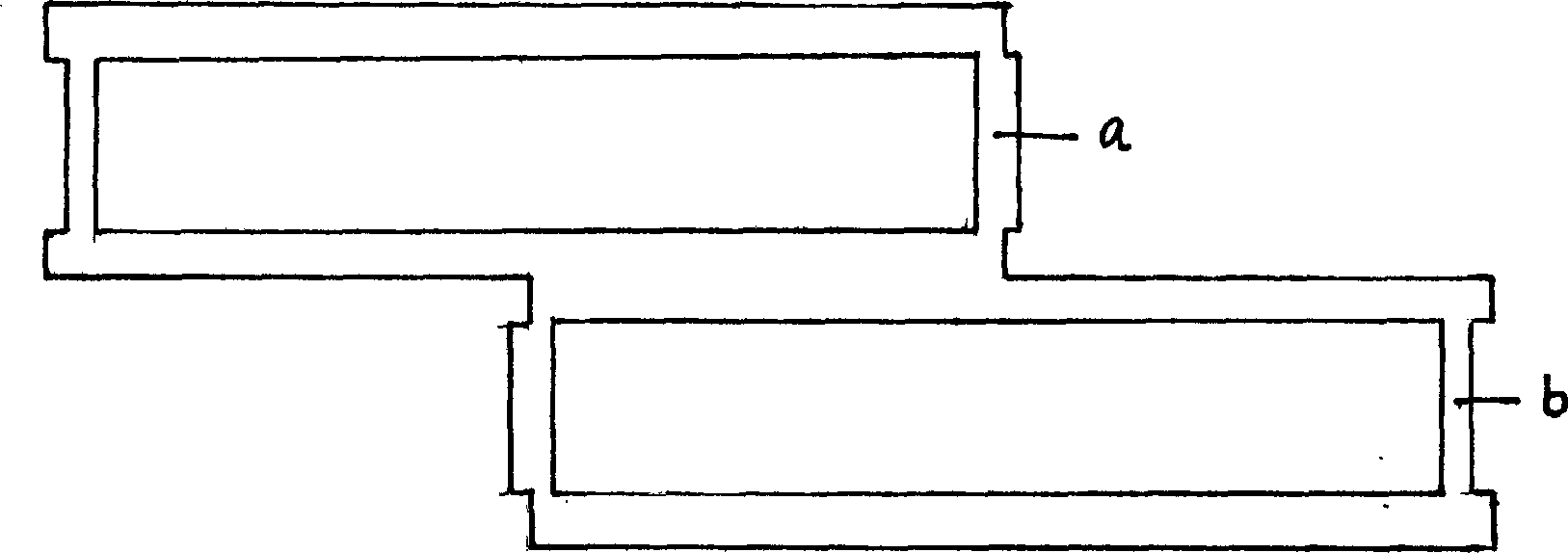

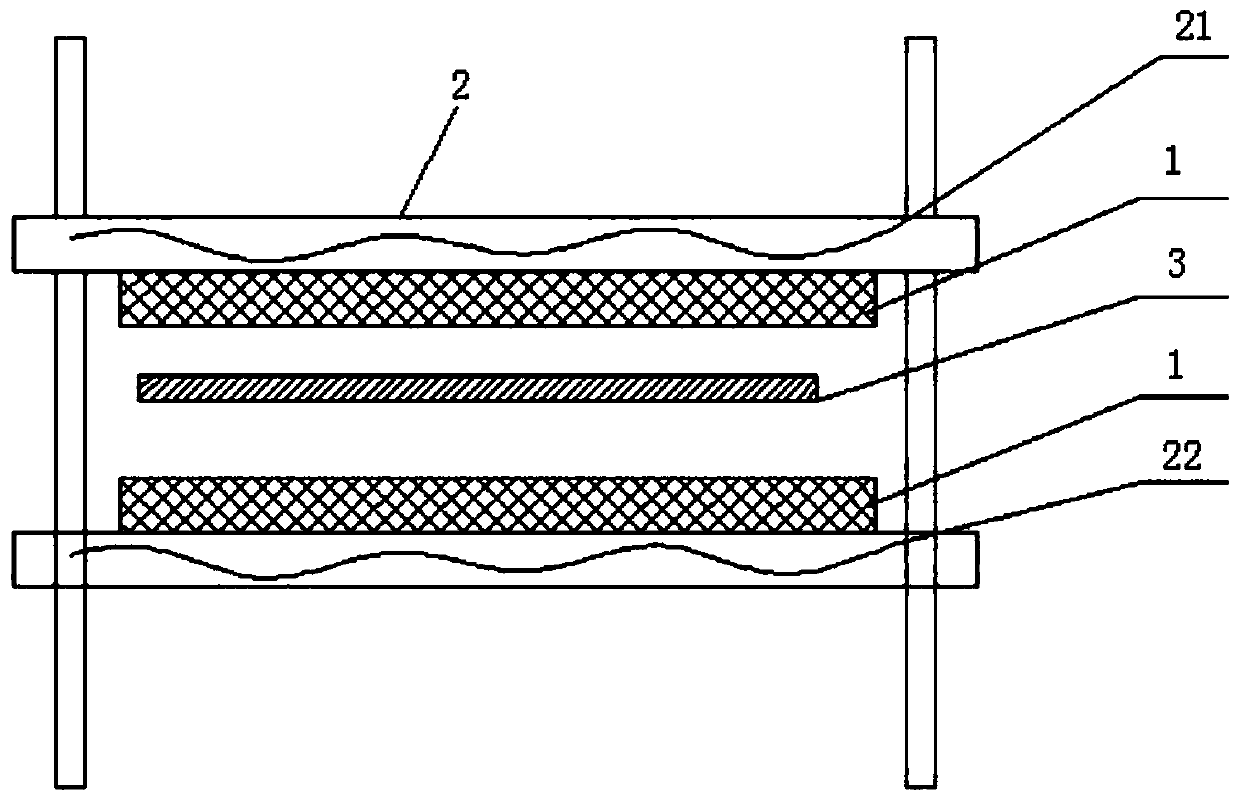

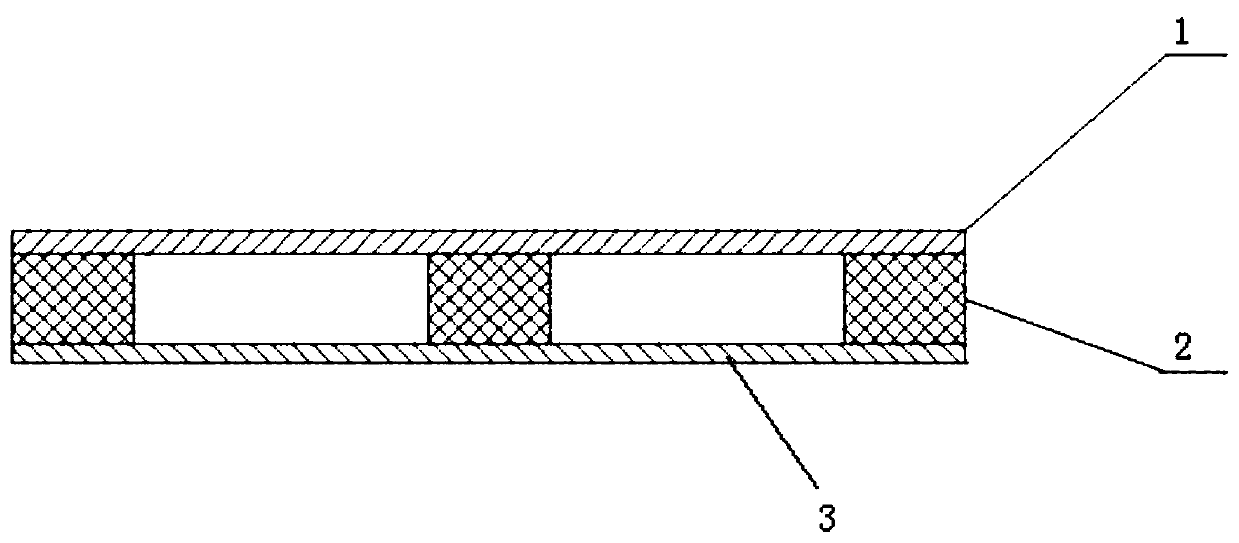

Z-shaped small-sized cement concrete hollow filled non-clod bridge thermal insulation building block and its making method

InactiveCN1702253AHigh compressive strengthStrong collision resistanceWallsThermal insulationAcoustic energy

This invention relates to a Z-shape small cement concrete hollow filled insulating building block, which belongs to the acoustic and heat-insulating material of the architecture field. The technical project is: designing the building outline to Z-shape hollow, filling the straw, chaff or the crushed wheat strew, corn stalk, waste aerated plastics particles which are packed and sealed with the aluminized plastic film. The insulating block obstructs the end wall interlaced through double layer insulating material, and eliminates the self-cold bridge, which increases the insulating property of the wall greatly; in addition, the loose insulating material can absorb acoustic energy and has good deafening effect. The Z-shape block is mainly used in laying the exterior wall and the separated production wall.

Owner:周荣标

Antiseptic fixing liquid composition for cadaver sample and preparation method thereof

InactiveCN101473812ANatural colorTissue flexibilityDead animal preservationChemistryLiquid composition

The invention discloses an antiseptic stationary liquid composition for corpse specimen, mainly comprising a metal complexing agent, a protein corsslinking agent, an osmoregulation agent and a food-grade antiseptic / mildew inhibitor and water; the metal complexing agent is ethylenediamine tetracetic acid disodium salt or ethylene glycol diethyl ether ethylenediamine tetracetic acid, the protein corsslinking agent is glyoxal, malonaldehyde, succinaldehyde or glutaraldehyde, the osmoregulation agent is a mixture, according to any proportion, of more than two substances selected from potassium nitrate, sodium nitrate, potassium chloride and sodium chloride, the food-grade antiseptic / mildew inhibitor is sodium dehydroacetate, sodium diacetate or potassium sorbate. The inventive composition is dedicated to antisepsis and fixing perfusion for animal or human corpses and has the advantages of strong antiseptic performance, good fixing performance and excellent safety without formaldehyde and toxicity. The invention also provides a method for preparing the antiseptic stationary liquid composition for corpse specimen.

Owner:WENZHOU MEDICAL UNIV

Anti-microbial and bacteriostatic preservative film and production method thereof

InactiveCN103205005AWill not remainHas antibacterial propertiesFruit and vegetables preservationBiotechnologyPolyvinyl alcohol

The invention relates to an anti-microbial and bacteriostatic preservative film and a production method thereof. The preservative film comprises, by weight, 50%-80% of polyving akohol with 500 to 2400 degrees of polymerization and 80% to 99% degrees of alcoholysis, 10% to 25% of water-solubility polyhydroxy plasticizer, 1% to 5% of polyoxyethylene, 1% to 5% of capacity-increase compatilizer and 5% to 15% of other assistants. The production method includes dissolving water-solubility polyhydroxy plasticizer in water with total weight consisted of 4 to 8 times formulation, adding polyving akohol, polyoxyethylene, capacity-increase compatilizer and other assistants, heating up above 95 DEG C to make the mixed solution completely dissolved in water, dispersing for 30 to 60 minutes at high speed, cooling to 50 DEG C to 70 DEG C, preparing a solution used for curtain coating and filming, and finally the preservative film can be prepared by a solution curtain coating method. The preservative film has good anti-microbial and bacteriostatic effects and functions to packed and fresh-keeping fruits and vegetables on the premise of no any extra anti-microbial and bacteriostatic chemical assistants.

Owner:SOUTH CHINA UNIV OF TECH

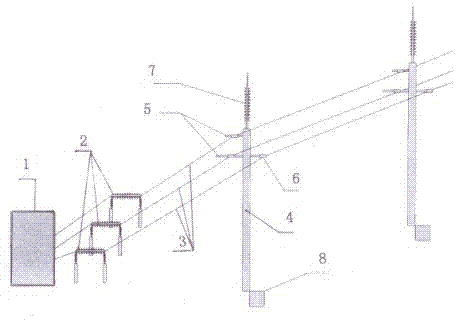

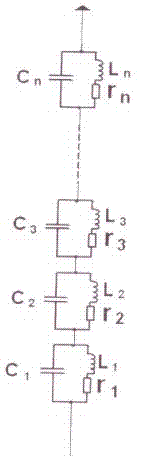

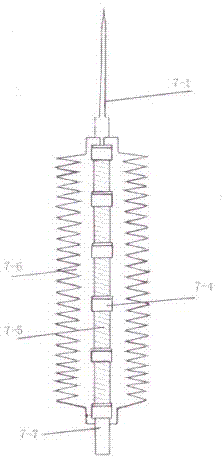

Distribution network integrated lightning protection system

ActiveCN104518475ASmooth shockReduce shockInstallation of lighting conductorsCorona dischargeOvervoltageTelecommunications

The invention discloses a distribution network integrated lightning protection system comprising a transformer substation, and output lines led out of three phases of outlet ports of a transformer substation transformer. Each phase of line is connected in series with an overvoltage isolator. Overhead wires are formed through lead-out of the output ends of the voltage isolators to a pole tower. Pole tower insulating cross arms support the overhead wires, and power transmission wires are fixed via multifunctional wire clamps arranged on the insulating cross arms. A wave-resistant lightning rod is installed at the top end of the pole tower. A simple and rapid grounding device is embedded in the ground of the bottom part of the pole tower so that integrated lightning protection performed on the distribution network lines and the transformer substation is realized with pole tower protection acting as the center and prevention of distribution network lightning tripping and disconnection acting as the key points. Distribution network line dedicated lightning equipment like the wave-resistant lightning rod, the insulating cross arms, the multifunctional wire clamps and the simple grounding device are organically integrated by the system so that the multilayer and three-dimensional integrated lightning protection system is constructed and realized, lightning trip-out rate and disconnection rate can be substantially reduced, and maximum matching of distribution network lightning economical efficiency and effectiveness is realized.

Owner:成都星河科技产业有限公司

Multifunctional plastic additive and preparation method thereof

The invention relates to the field of plastic processing and in particular relates to a multifunctional plastic additive and a preparation method thereof. The multifunctional plastic additive comprises the following components in parts by weight: 70-89 parts of light calcium carbonate powder, 10-15 parts of stearate, 1.0-1.8 parts of mica powder, 3-5 parts of light magnesium oxide powder, 1-2 parts of organic tin, 2-3 parts of glass fiber powder, 1-2 parts of methacrylate, 1.0-1.5 parts of a coupler and 2-4 parts of a lubricant. The preparation method comprises the following steps: pre-modifying the light calcium carbonate powder by stearate, mixing the pre-modified light calcium carbonate powder, the mica powder, the light magnesium oxide powder and the glass fiber powder at a low speed, adding other formulation components, producing a high-temperature and low-speed stirring reaction, and discharging to obtain the multifunctional plastic additive. The preparation process is simple, and the prepared plastic additive can be used for improving the tensile strength, the strength, the pressure resistance and the like of a PVC (polyvinyl chloride) wood plastic composite material and a PVC engineering plastic.

Owner:汕头市亨德利塑胶有限公司

High-strength concrete

InactiveCN107151115AImprove mechanical propertiesHigh strengthSolid waste managementHigh strength concreteCrack resistance

The invention discloses high-strength concrete. The high-strength concrete is prepared from, by weight, 10-12 parts of cement, 35-45 parts of sand, 60-75 parts of coarse aggregate, 13-17 parts of silicon powder, 7-12 parts of rubber powder, 3-5 parts of modified bamboo fibers, 1-4 parts of polyvinyl alcohol fibers and 3-7 parts of polypropylene fibers. By addition of a certain quantity of silicon powder into cement and sand, pressure resistance of the concrete is greatly improved; due to addition of the modified bamboo fibers, the polyvinyl alcohol fibers and the polypropylene fibers, cracking resistance of the concrete is improved while concrete strength is improved as well, and concrete density is reduced to some extent.

Owner:成都市德容建筑劳务有限公司

Preservation of carved or processed fresh vegetables and fruits and special antistaling agent therefor

InactiveCN1853488ADoes not change colorDoes not rotClimate change adaptationFruits/vegetable preservation using acidsAcetic acidSucrose

An antistaling method for the carved or processed fresh vegetable or fruit features that said carved or processed fresh vegetable or fruit is immersed in the antistaling agent which is an aqueous solution prepared proportionally from edible acetic acid, edible, citric acid, cane sugar, calcium chloride, and chitosan. Its advantages are high antistaling effect (6-10 months) and edible.

Owner:TSINGHUA UNIV

Method for making colour-glazed porcelain plate

The invention discloses a glazed ceramic board making method, adopting the steps of: 1) applying glaze on a mud blank ceramic board; 2) simultaneously sintering the blank and glaze; 3) making glaze post- processing on the ceramic board sintered with glaze, such as colored drawing, or pasting decal paper, or tracing design in gold, etc; 4) decorating firing. And it can act as sign boards and other pendants, and as compared with the existing materials, such as wood, metal, plastics, and even white ceramic board, has characters of stainlessness, not decoloring, not rotting, not deforming, easy to care, etc, thus a new variety of porcelain.

Owner:傅涛

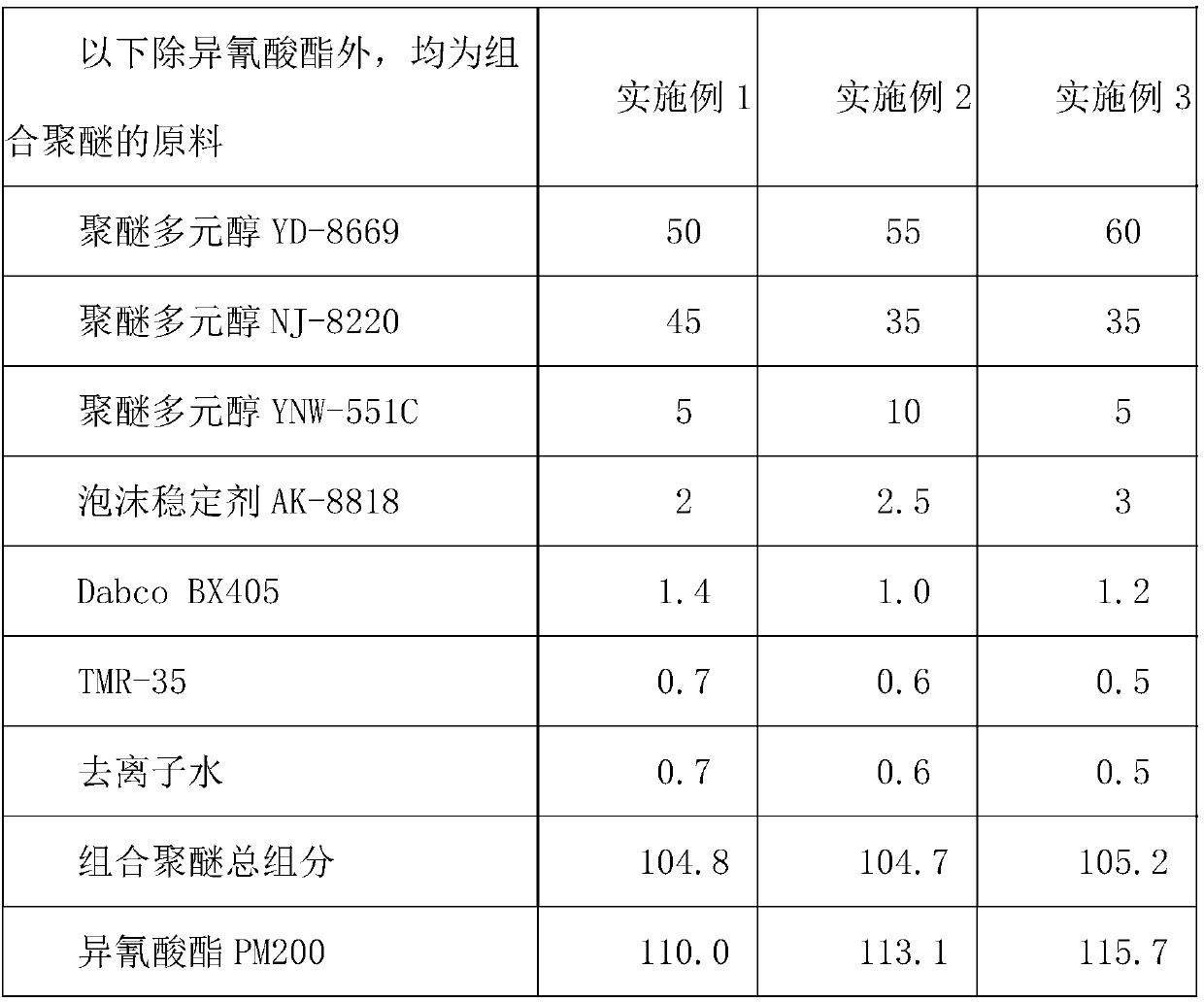

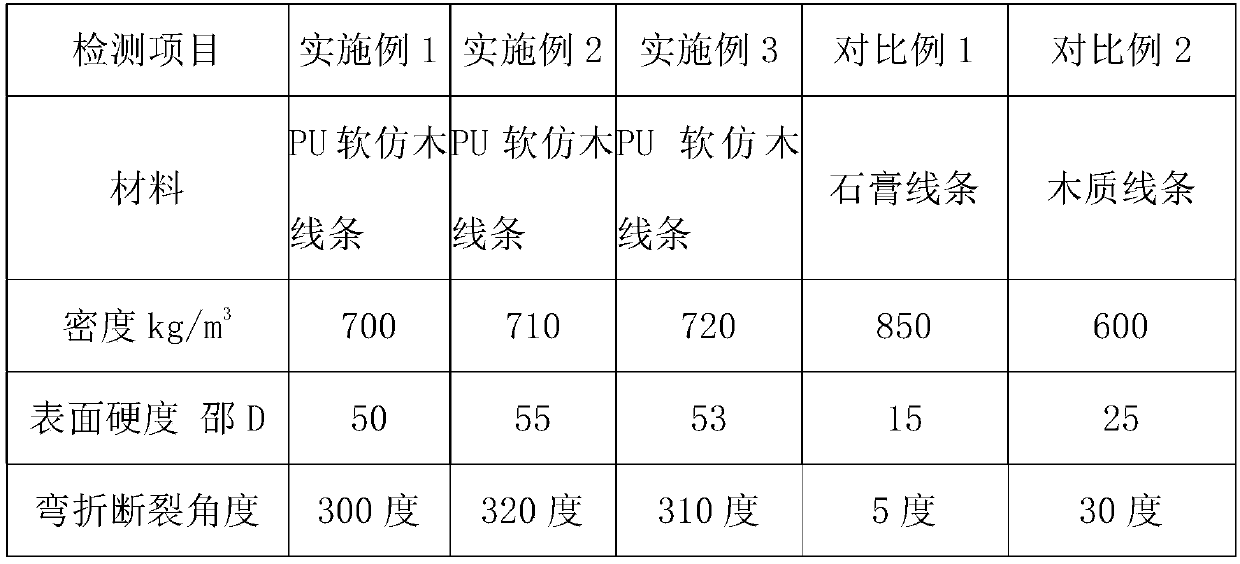

Premixed polyether polyol, polyurethane raw material composition and polyurethane foam for polyurethane imitated wood product and preparation method of polyurethane foam

The invention relates to premixed polyether polyol, polyurethane raw material composition and polyurethane foam for a polyurethane imitated wood product and a preparation method of the polyurethane foam. The premixed polyether polyol is prepared from components in parts by weight as follows: 50-60 parts of first polyether polyol, 35-45 parts of second polyether polyol, 5-10 parts of third polyether polyol, 2-3 parts of a foam stabilizer, 1.5-2.5 parts of a catalyst and 0.5-0.7 parts of a foaming agent, wherein viscosity of first polyether polyol is 3200 plus or minus 500 mPa.s and hydroxyl value is 425-455 mgKOH / g when first polyether polyol is at 25 DEG C; viscosity of second polyether polyol is 1500 plus or minus 500 mPa.s and hydroxyl value is 400-460 mgKOH / g when second polyether polyol is at 25 DEG C; viscosity of third polyether polyol is 500 plus or minus 100 mPa.s and hydroxyl value is 54.5-57.5 mgKOH / g when third polyether polyol is at 25 DEG C. The polyurethane imitated woodproduct prepared from premixed polyether polyol has the advantages of being high in toughness, bendable and suitable for dome, arc-shaped furniture / wall decoration and the like.

Owner:SHANGHAI DONGDA POLYURETHANE

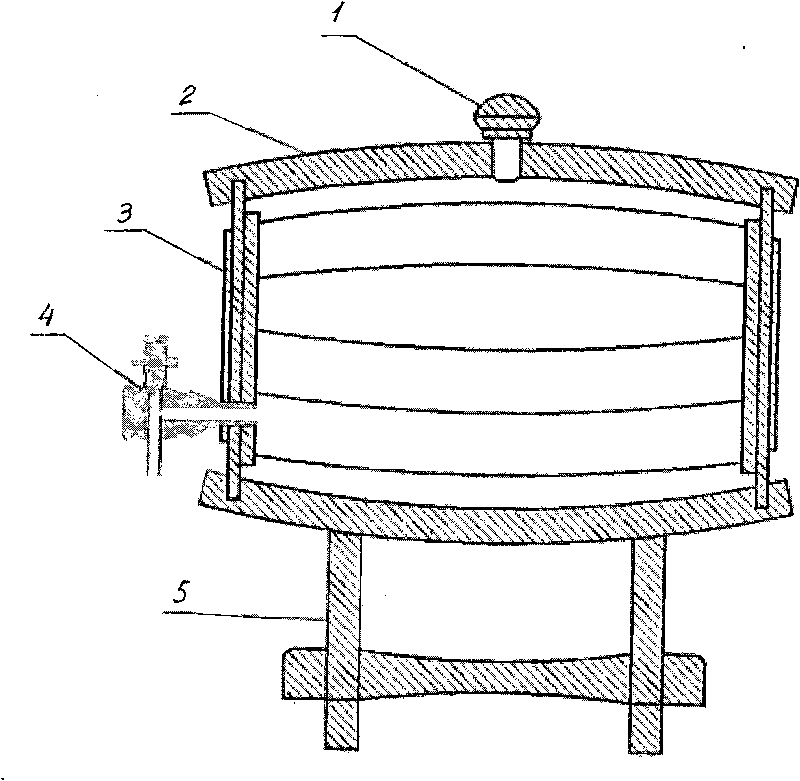

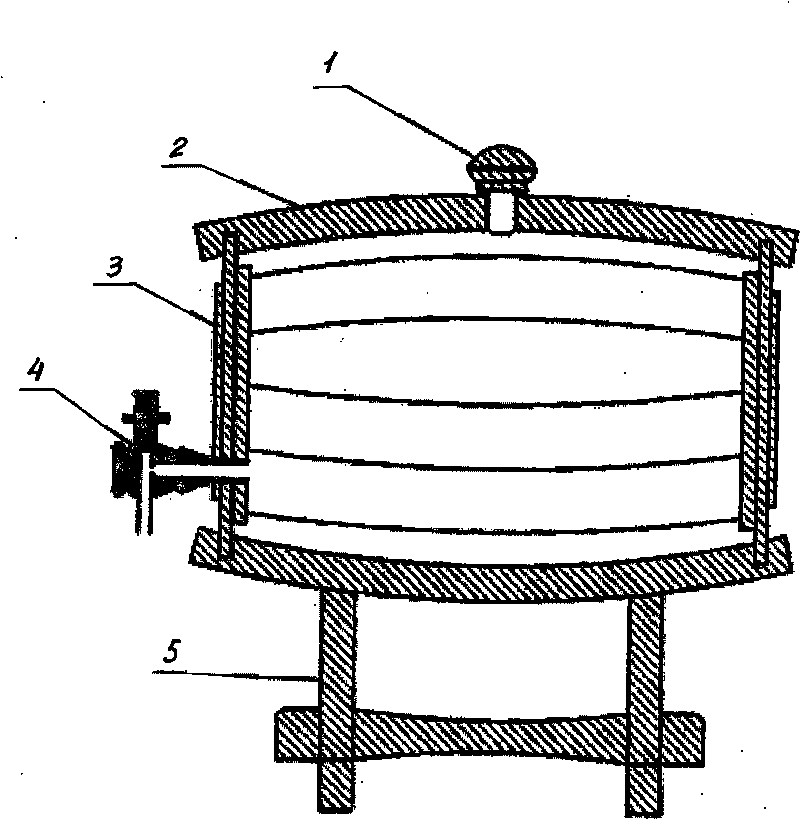

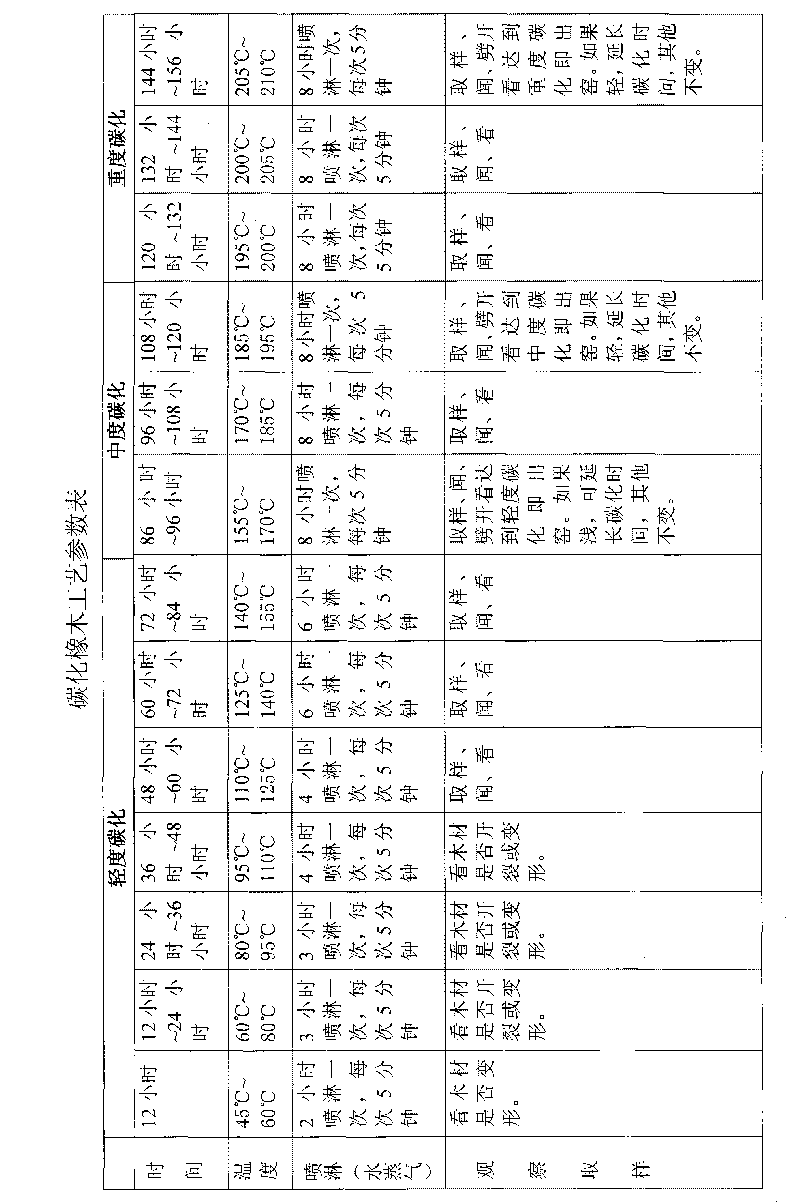

Carbonized oak wine barrel and fabrication process thereof

InactiveCN101758974AFor long-term storageDoes not rotWood dampingRigid containersEngineeringCarbonization

The invention provides a carbonized oak wine barrel and a fabrication process thereof, having the advantages of uniform carbonization, deformation resistance, sun-crack resistance, rot resistance and high oak utilization rate. The carbonized oak wine barrel consists of a barrel rack, a barrel wall, a barrel plug, a wine injection plug and a wine outlet valve, wherein the barrel rack is connected with the barrel wall; the barrel wall is connected with the barrel plug; the wine injection plug is located at the upper part of the barrel wall; and the wine outlet valve is arranged on the lower side of the barrel plug. The fabrication process comprises the following steps: sorting; drying; ripsawing; flat-planing; thicknessing; precise-cutting; carrying out the densification, bending and carbonization treatment by a plate bending machine; subjecting the carbonized materials to the processes of arc-tooth milling, siding milling and lathing; assembling; and subjecting the assembled barrel to the processes of primary-planing, sanding, ferruling, paint-spraying paint and boring. The carbonized oak wine barrel of the invention has the advantage of uniform carbonization, that is, the carbonized oak wine barrel is fully carbonized from inside to outside; the carbonized oak wine barrel of the invention also has the advantages of deformation resistance, sun-crack resistance and rot resistance, so the carbonized oak wine barrel can be stored for a long time no matter before or after the wine storage; and the carbonized oak wine barrel of the invention further has the advantages that the utilization rate of oak is as high as 100%, and the wine stored in the carbonized oak wine barrel of the invention has no unpleasant odor but pure taste.

Owner:王传礼

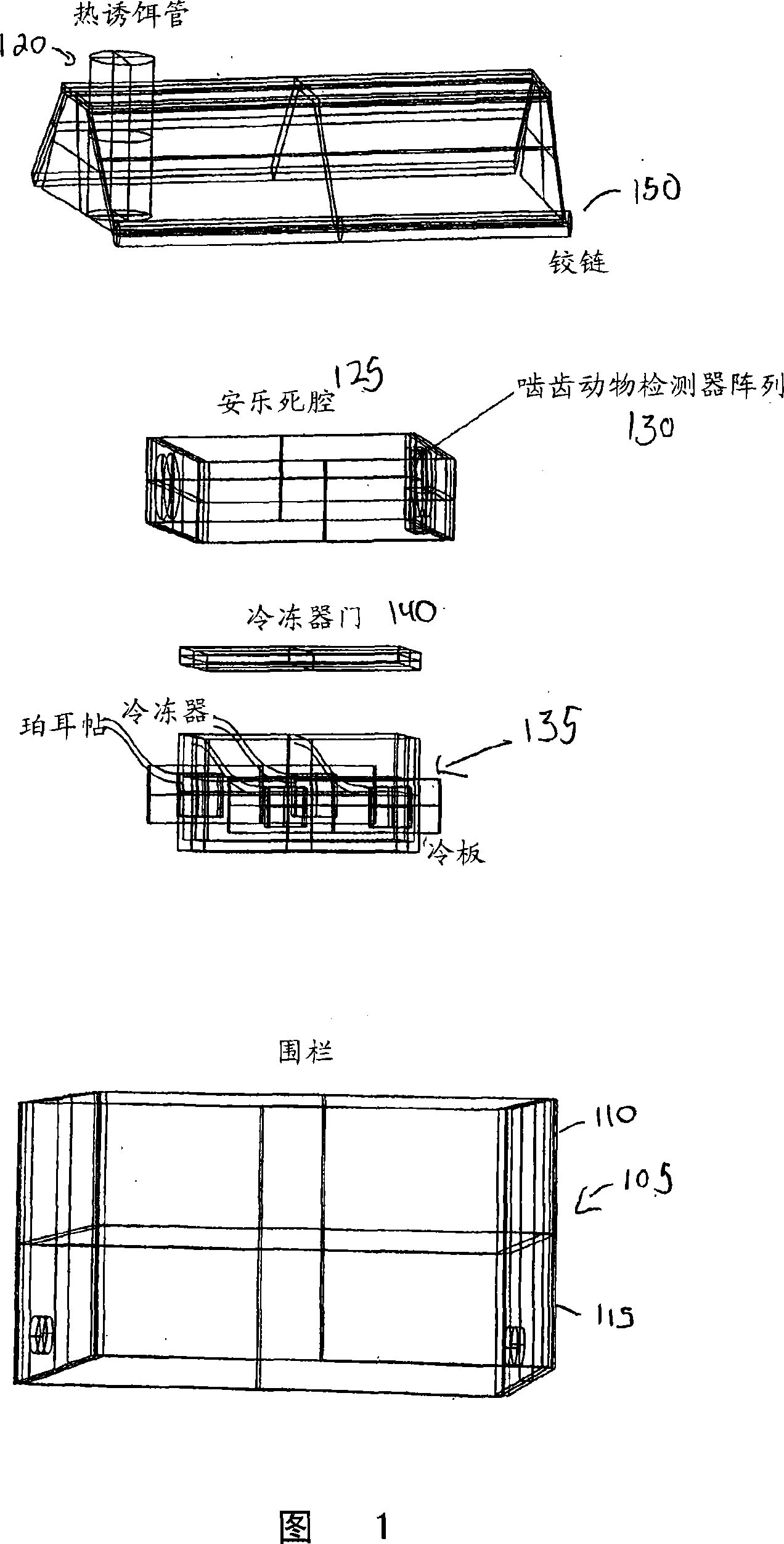

Rodent elimination system

Owner:肯尼思·丹尼尔·雷尔

A cucumber trellis-building cultivation method

The invention provides a cucumber trellis-building cultivation method comprising four major production steps of transplanting cucumber seedlings according to certain specifications, preparing supports, building a trellis and guiding vines to the trellis. The step of transplanting cucumber seedlings according certain specifications comprises two substeps of raising cucumber seedlings and transplanting the cucumber seedlings according to certain specifications. The step of preparing supports includes the preparation of vertical frame rods and transverse pull rods. The step of building a trellis comprises the substeps of inserting the frame rods and tying the frames. The step of guiding vines to the trellis includes two substeps of vine guiding and vine tying. The method solves the urgent technical problems in the cucumber production that ground crawling cucumbers are in contact with ground and thus cucumbers are stained with mud, are liable to rot, are poor in commodity performance and low in yield and the income is low.

Owner:林天国

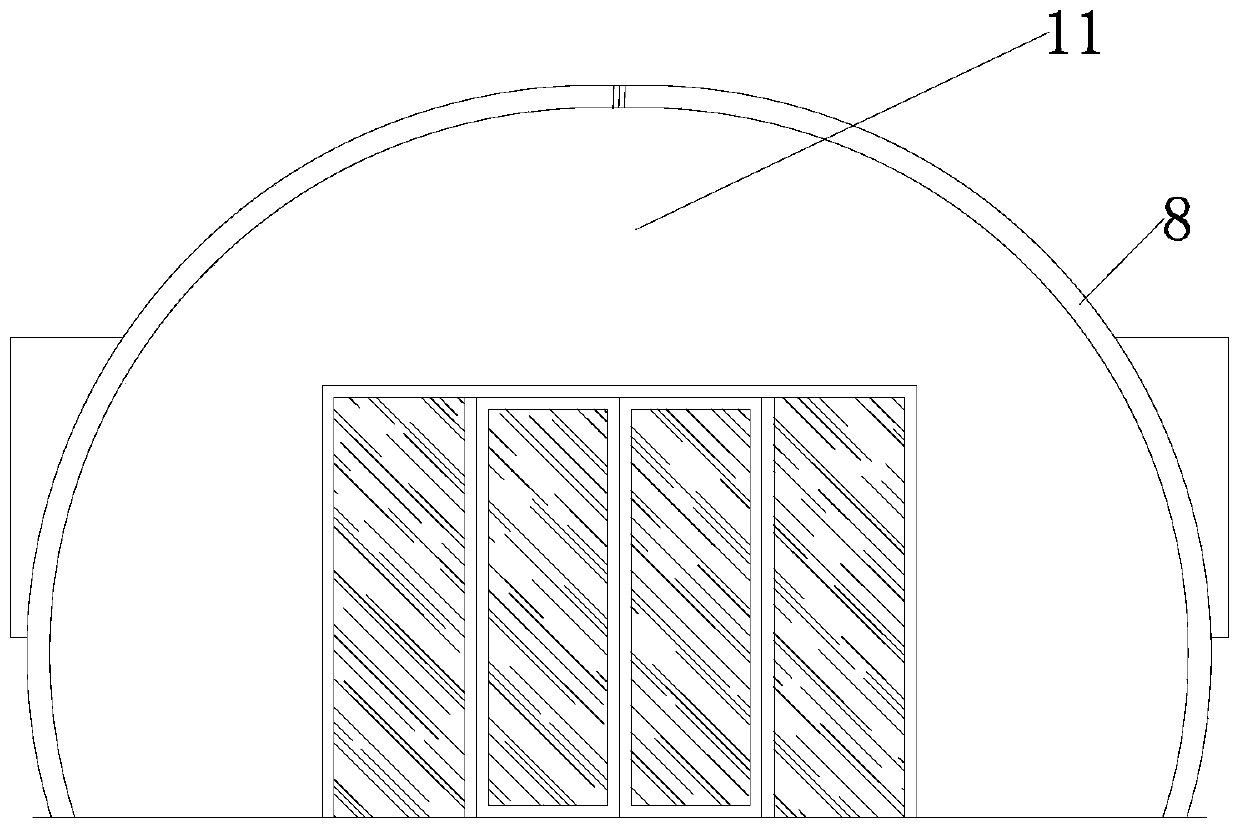

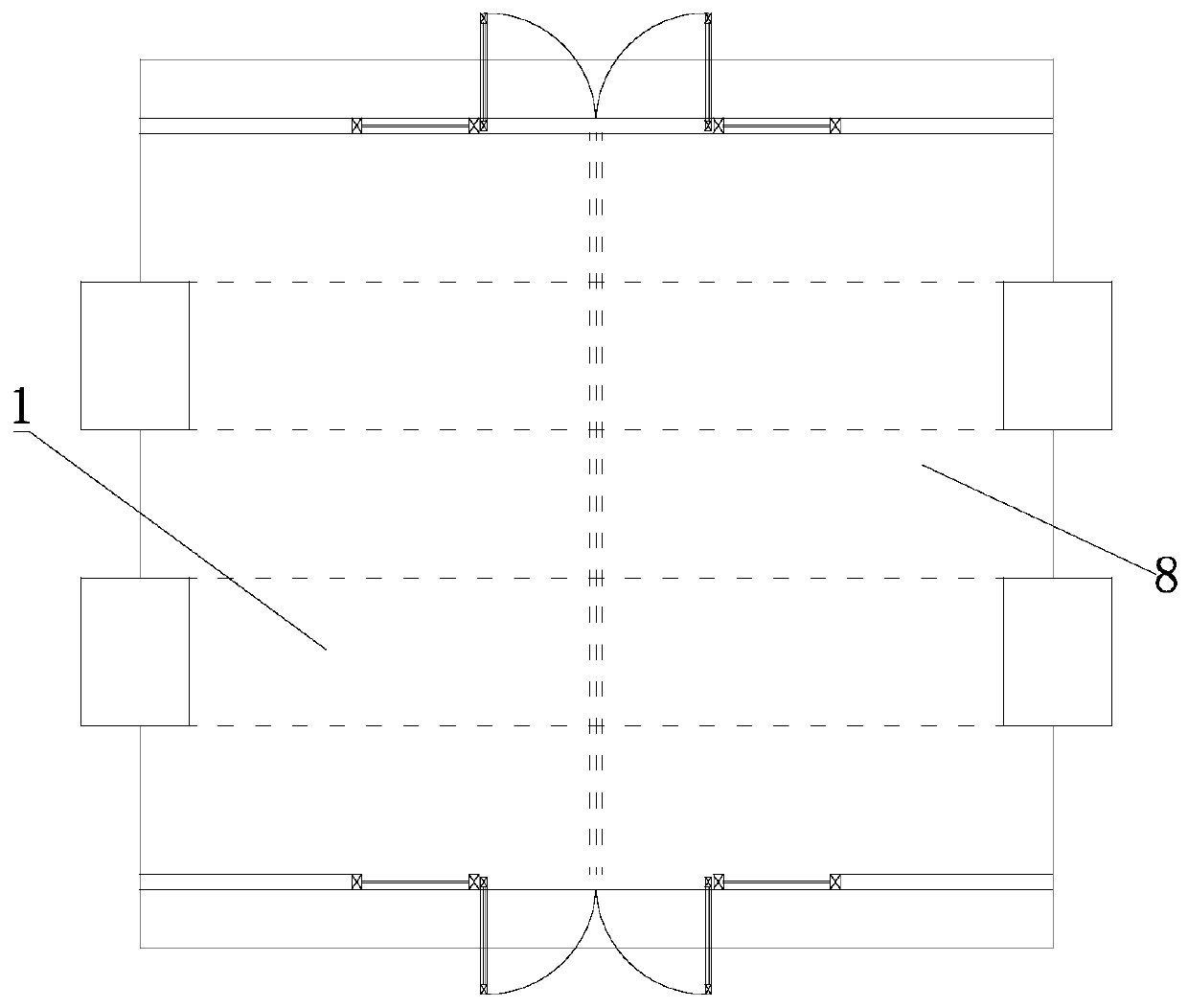

Self-extinguishing EPS foam plastic and house

InactiveCN110105684AImprove insulation performanceImprove sound insulationArched structuresVaulted structuresReinforced concreteRebar

The invention belongs to the field of construction, and discloses a self-extinguishing EPS foam plastic and a house. The house is formed by assembling a plurality of EPS foam plastic modules, and compared with a traditional house prepared from wood or reinforced concrete materials, the house prepared from the self-extinguishing EPS foam plastic has the advantages of being low in construction cost,saving more energy sources, resisting the vibration, insulating heat and sound, not rotting, not rusting, being light and convenient and the like; the labor is reduced by 60%, the construction time is reduced by 50%, the construction cost is reduced by 30%, and the requirements of green construction, environmental protection and high efficiency are met.

Owner:谢宜环

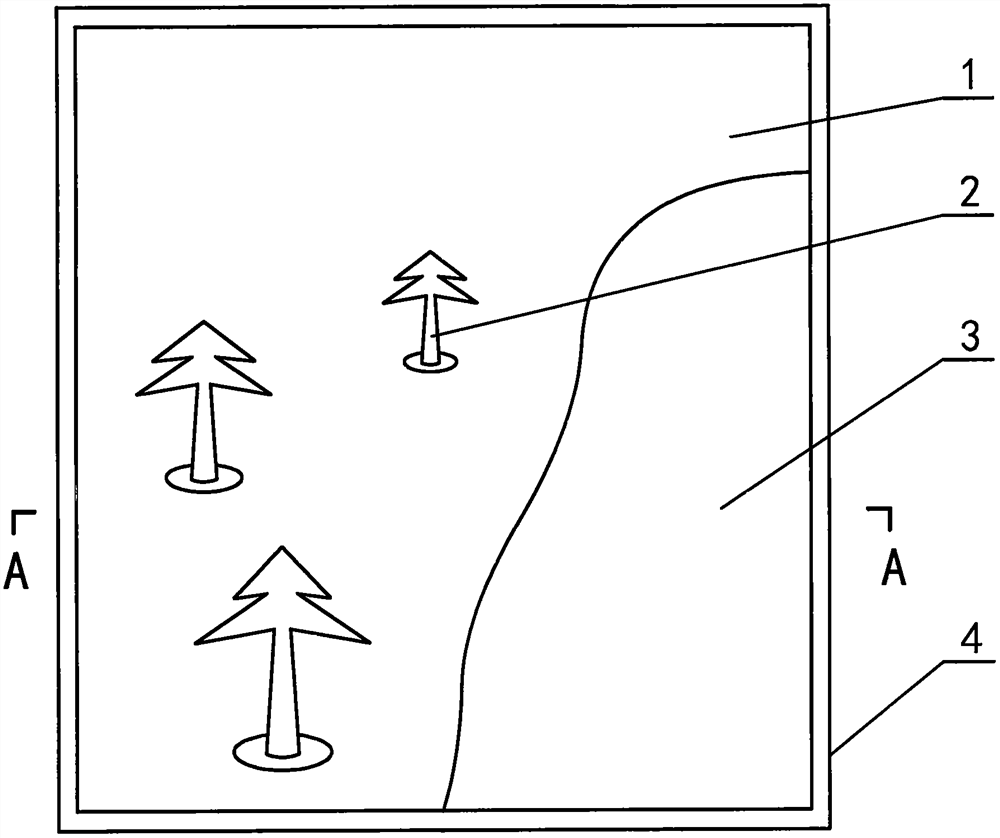

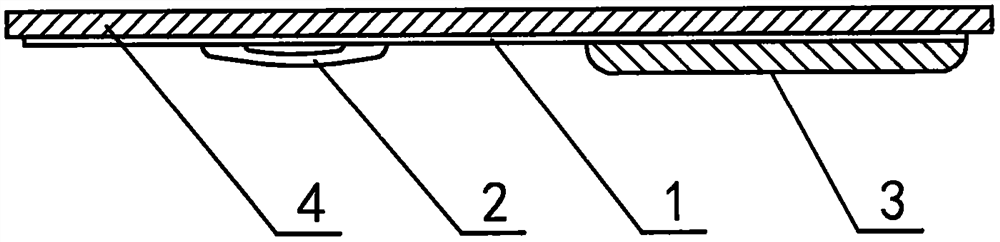

Indoor landscape wall or gallery painted with viable moss on wall surface

InactiveCN110754315AEasy to keep tidyDoes not rotCovering/liningsSelf-acting watering devicesLiving roomCement board

The invention discloses an indoor landscape wall or gallery painted with viable moss on the wall surface. According to the indoor landscape wall or gallery, a modified alkali-reducing cement board isused as a moss attaching substrate, superabsorbent fibers are used as water-supply moisturizing materials, and single or multiple moss cut stem composites, resistant to shade and drought and capable of normally growing on an alkaline substrate, are selected. An effective soft decoration approach is provided for indoor space walls of subway passages and platforms, large comprehensive indoor plazas,offices, living rooms and the like, so as to reduce threats to human health, which are caused by excessive formaldehyde, radioactive radiation and the like generated in prevalent hard decoration of such places, and accordingly, the indoor environment is purified and beautified. The indoor landscape wall or gallery has the advantages that indoor three-dimensional greening conditions are met, the technical factors that existing three-dimensional moss greening technologies are not suitable for indoor spaces and especially not suitable for wall greening in living rooms are eliminated, the moss isplanted on the cement board directly, rot, odor, poison and peeling are avoided, simple management is achieved, an effective approach is provided for improvement of indoor soft decoration and indoorenvironment as well as protection of physical and psychological health of citizens, and the indoor landscape wall or gallery has a broad application prospect.

Owner:武汉长江绿色工程科技股份有限公司

Forming preparation method of degradable nitrile rubber gloves

The invention belongs to the field of high polymer materials. The invention relates to gloves, in particular to degradable nitrile rubber gloves forming preparation method. The invention discloses a forming preparation method of degradable nitrile rubber gloves. The preparation method is simple, convenient and easy to implement, and the prepared gloves have the characteristics of acid and alkali resistance, oil stain resistance, permeation resistance, bacteria resistance, no latex allergy and convenience in use, are lighter, thinner and softer in touch feeling, excellent in elasticity, excellent in physical property and chemical property, free of any natural latex component, free of allergy risk, good in degradability and wide in application prospect.

Owner:安徽攀望科技有限公司

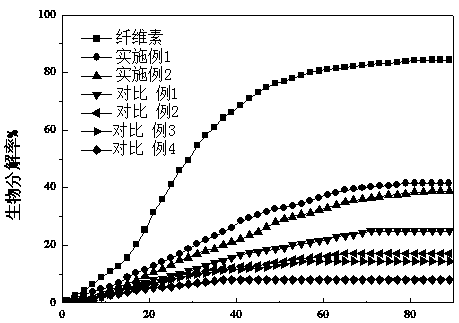

Collagen fiber stuffing product and processing method thereof

ActiveCN100351167CGood static stabilityImprove featuresMonocomponent protein artificial filamentUpholstery fillingTextile fiberPolymer science

The invention provides a collagen fiber stuffing product which comprises 50%-100% collagen fiber in the stuffing and its Process for preparing. The said stuffing is oakum stuffing mixed collagen fiber deliberating from animal hide with at least another textile fiber; or materials stuffing arise from teasing, bedding web and modeling. The stuffing product in the invention is provided with advantages of well puffy, well rebound, well warming, flameproof and sound absorbing which the current stuffing can not get because it uses collagen fiber as main stuffing. The stuffing produced in the process provided in the invention has no peculiar smell, without putrefaction, without mouldy, and can be used in practice. The product is low cost and settles the problem of leftover bits and pieces of industrial material, so it is environment friendly.

Owner:GUANGZHOU WUYUAN NEW MATERIAL CO LTD

Processing technology of walnut shell filtering material

InactiveCN105126771AGood filtering effectImprove the quality of purified waterFatty/oily/floating substances removal devicesOther chemical processesWater contentFilter material

The invention belongs to the technical field of adsorption material preparation, aims to solve the problems that conventional filtering materials cannot absorb harmful substances in wastewater and get agglomerated easily, and provides a processing technology of a walnut shell filtering material. The processing technology comprises the following steps: removing the impurities, disinfecting the walnut shells, washing, drying, grinding, polishing, steaming and washing to remove the grease, polishing the walnut shells in a cylinder polishing machine to remove the projected parts on the surface and reach a surface roughness of Ra0.8; steaming and washing the walnut shells in a steaming and washing machine for 1 to 3 hours; degreasing the walnut shells in a baking oven with a temperature of 85 to 90 DEG C for 20 hours until the water content is less than 8%; irradiating the walnut shells by UV rays with a wavelength of 185 nm for 20 hours to kill the bacteria; and finally screening and grading so as to obtain the walnut shell filtering material. The prepared walnut shell filtering material can absorb suspensions and harmful substances in wastewater. During the application process, the hardness of the provided filtering material is high, the filtering material will not get rotten or agglomerated, the toughness of the filtering material is high, moreover, the filtering material can be easily regenerated, thus the replacement frequency is reduced, the labor and time are saved, and the cost is low. The processing technology is simple, the water quality can be improved effectively, the raw material sources are wide, and the using effect is prominent. The provided novel filtering material can greatly reduce the water treatment cost.

Owner:SHANXI CHANGYUAN AGRI & SIDELINE NATIVEPROD

Medicine mud mask and manufacturing technology thereof

ActiveCN103908142ADoes not rotNo pollutionGaseous substancesReligious equipmentManufacturing technologyRespiratory disease

The invention provides a medicine mud mask. Raw materials of the medicine mud comprise the flowing components, by mass ratio, the ratio of mud, medicine and water is 2 to a range from 0.8 to 1.5 to a range from 0.2 to 0.8; the mud is from mountains with the altitude more than 4600 m; the water is from mountains with the altitude more than 4600 m; the gross weight of the medicine which comprises 10 g of religious holy articles, 240 g of Tibetan medicine, 133 g of Chinese herbal medicine, 255 g of gem and 150 g of aromatic drugs is 788 g. The medicine mud mask has functions in sterilizing, cleaning air, resisting viruses in the air, resisting various respiratory diseases, increasing intelligence and maintaining health, relieving fatigue and the like, has high collection values and can be served as precious gifts to be given to others. The invention also discloses a manufacturing technology thereof. The manufacturing technology of the medicine mud mask comprises steps of preparing the medicine mud, manufacturing a medicine mud mask body, manufacturing a medicine mud mask product and the like. The manufacturing technology of the medicine mud mask is unique in method and the medicine mud mask product cannot be decayed, does not pollute and fade and is convenient to carry along.

Owner:四龙降泽

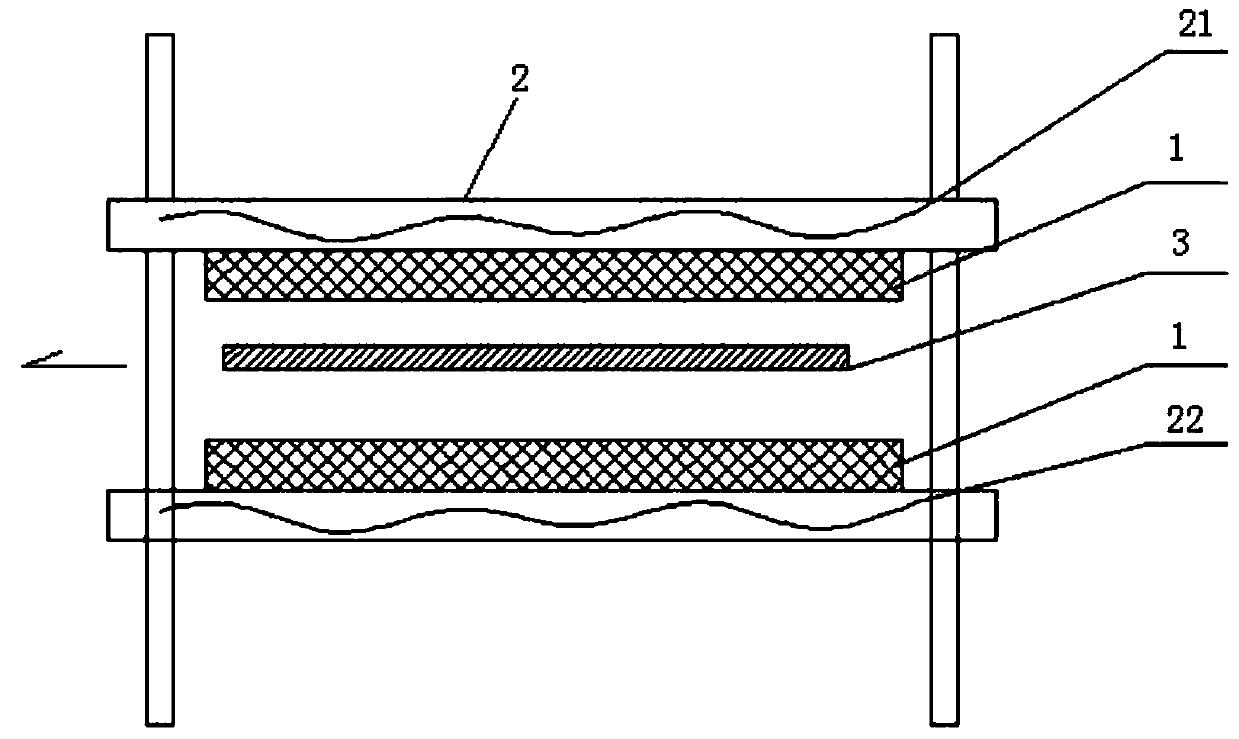

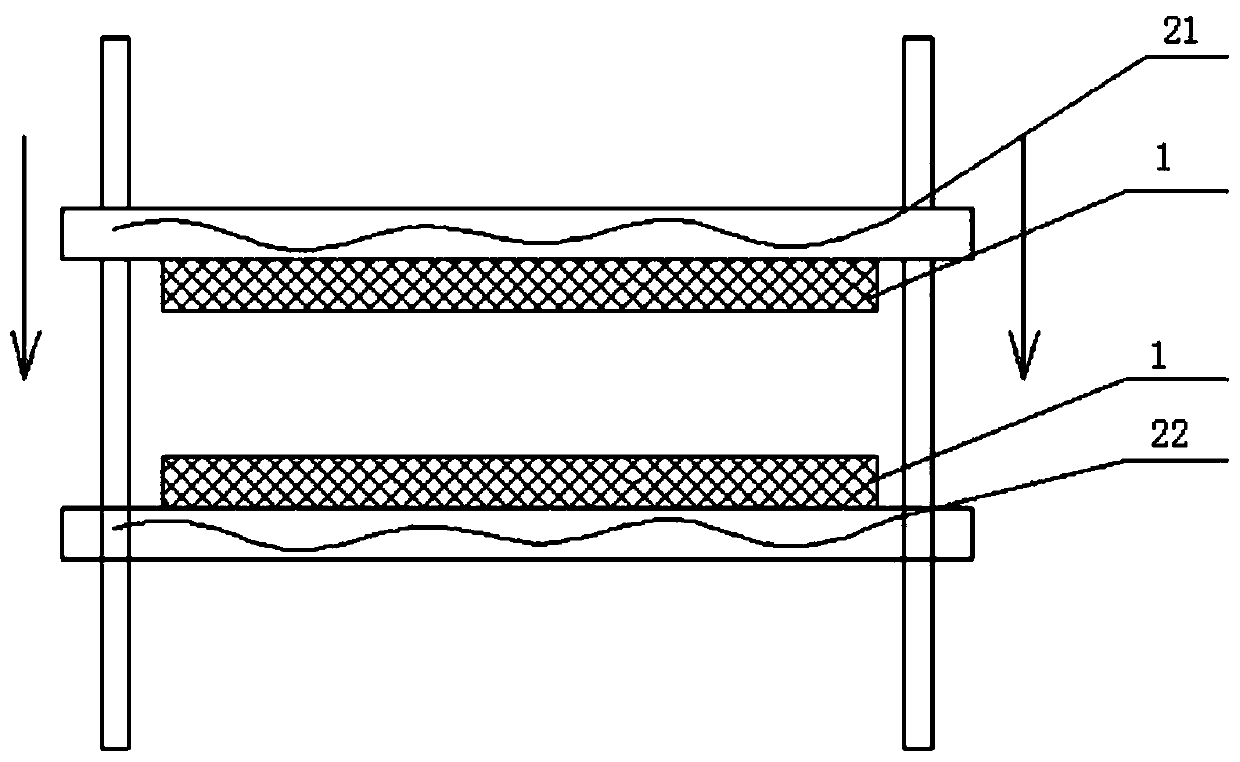

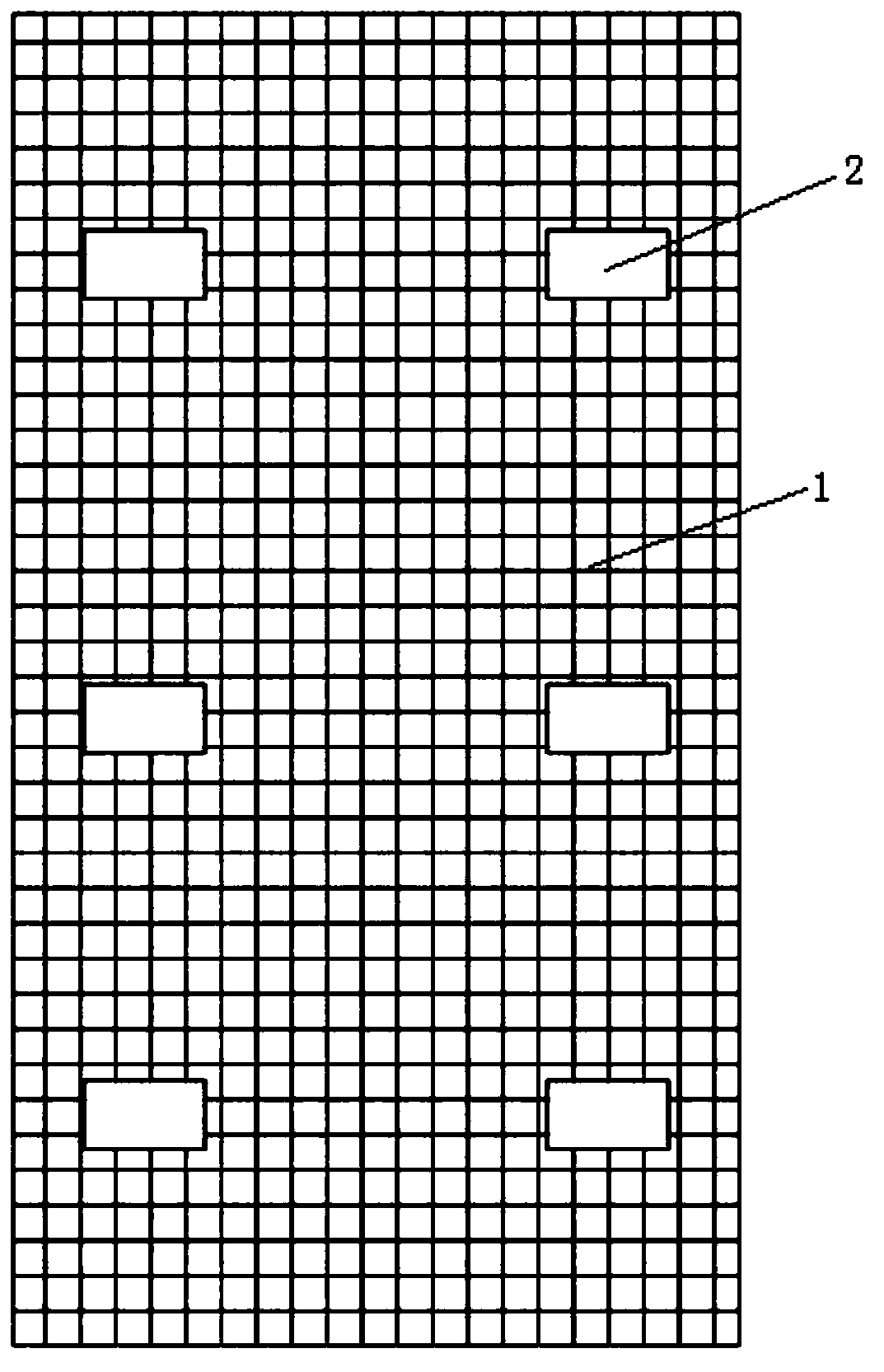

Multifunctional light-weight thermoplastic composite board and manufacturing method thereof

InactiveCN110253973AImprove bending strengthImprove bearing capacitySynthetic resin layered productsLaminationPolytetramethylene terephthalateCarbon fibers

The invention discloses a multifunctional light-weight thermoplastic composite board and a manufacturing method thereof. The multifunctional light-weight thermoplastic composite board is formed by bonding a plurality of thermoplastic composite boards, wherein the plurality of thermoplastic composite plates are bonded and formed by heating and pressurizing mutual connection surfaces. The thermoplastic composite boards are made of thermoplastic composite honeycomb boards, and each single-layer thermoplastic composite honeycomb board is of a sandwich structure, wherein the upper skin and the lower skin are both made of a glass fiber reinforced thermoplastic composite material (CFT), and the middle part is a plastic honeycomb. The glass fiber reinforced thermoplastic composite material consists of continuous fibers and a thermoplastic material (granules or a sheet), wherein the thermoplastic material is one or more selected from a group consisting of polypropylene (PP), polyethylene (PE), polyamide 6 (PA6) and polybutylene terephthalate (PBT), and the continuous fibers are one or more selected from a group consisting of glass fibers, carbon fibers and basalt fibers. The multifunctional light-weight thermoplastic composite board is light in weight, high in strength and good in structural stability.

Owner:惠州市华贵新材料有限公司

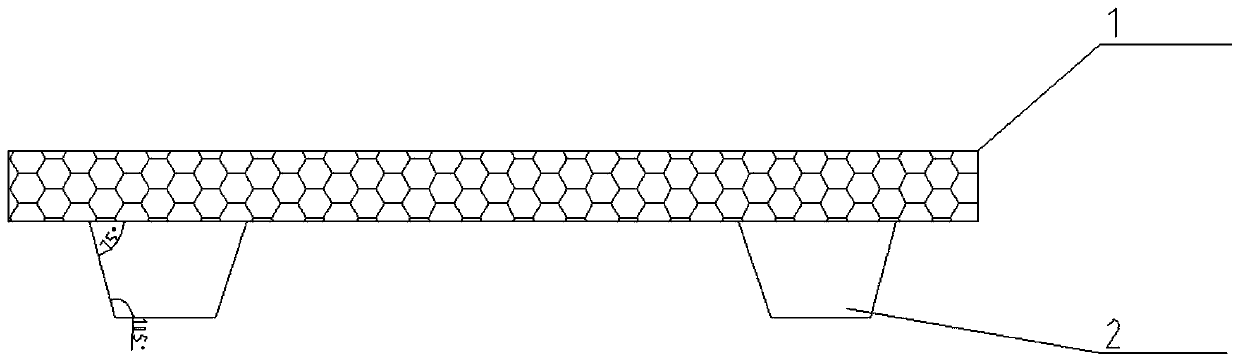

Light thermoplastic honeycomb plate composite material tray and manufacturing method thereof

InactiveCN110203516AEasy to shapeSpeed up the molding processRigid containersSurface layerHoneycomb

The invention discloses a light thermoplastic honeycomb plate composite material tray which is formed by a honeycomb plate panel and a plastic support column through contact surface bonding or welding; from the structure, a thermoplastic honeycomb is taken as a core material, so that tray weight is greatly relieved, elasticity and compression resistance are improved; and a surface layer adopts a continuous fiber reinforced thermoplastic material, so that impact resistance and puncture resistance of the tray are greatly improved. An inverted tower shaped plastic support column structure is adopted, so that the bottom of the plastic support column tilts inwards, and frequent collision during carrying is avoided; and a hollow-out structure is adopted inside the plastic support column, so thattrays are stacked together to save space, the contact area between the plastic support column and the honeycomb plate panel accounts about 20%-30% of the total area of the honeycomb plate area, and bearing ability and bending strength of the panel are strengthened.

Owner:惠州市华贵新材料有限公司

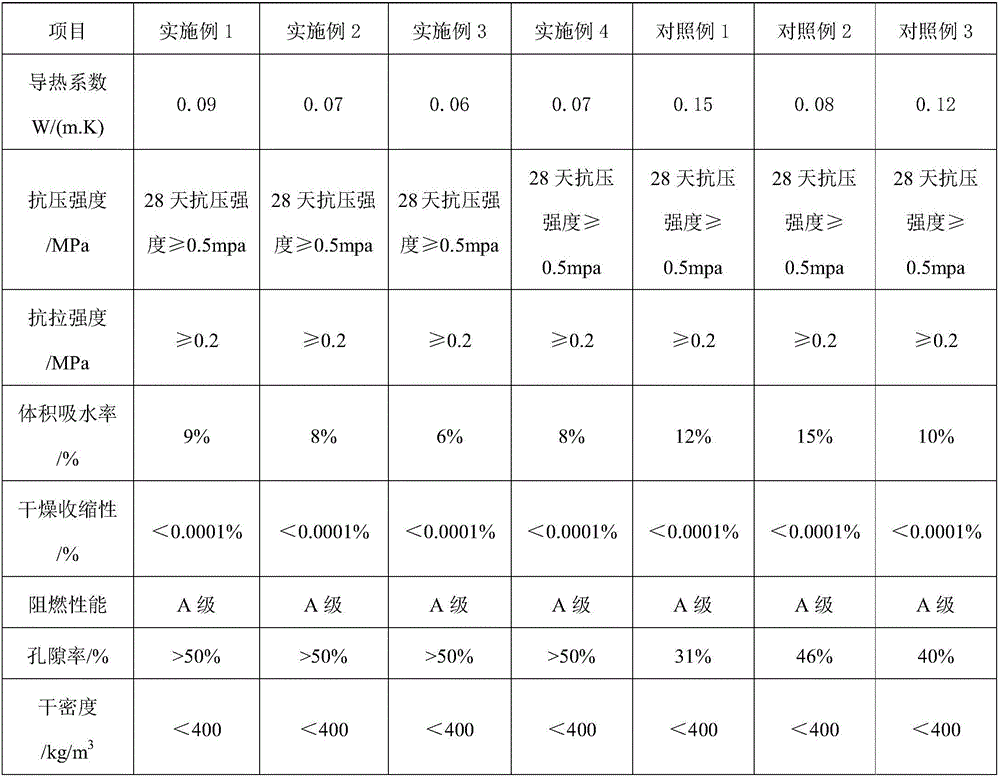

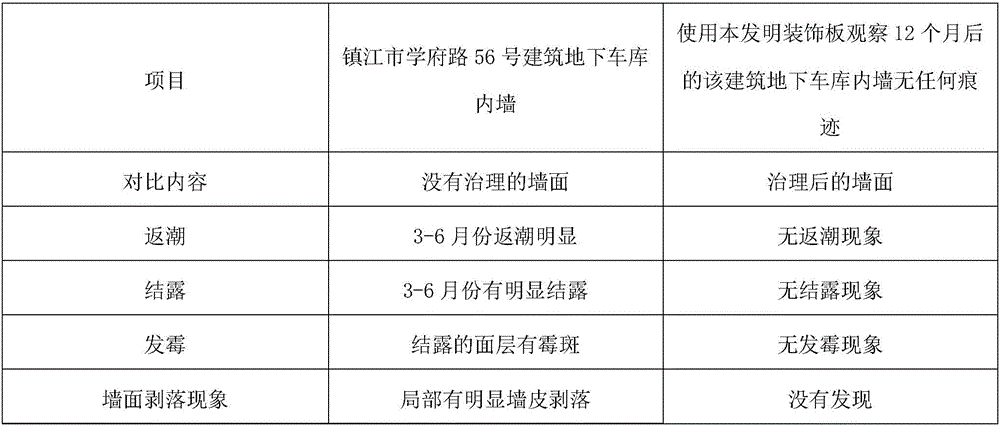

Protection plate capable of preventing internal wall from getting damp and forming dew and preparing method of protection plates

ActiveCN106220055APrevent moisture and condensationMaintain temperature and humidity conditions for a long timeCovering/liningsSurface layering apparatusEngineeringMoisture

The invention discloses a protection plate capable of preventing internal wall from getting damp and forming dew and a preparing method of protection plates. The protection plate is prepared from a heat insulation and breathing component, a condensing and curing component, a bonding breathing auxiliary, a coagulating aiding and hole forming component and an anti-cracking component. The preparing method comprises the steps that the components are combined to obtain a component A and a component B, and then the component A and the component B are stirred evenly to obtain a mixed paste; then, gridding cloth is laid on a base plate, the mixed paste is flatly laid on the gridding cloth, a layer of gridding cloth is then laid on the surface of the mixed paste, finally cutting is carried out according to specifications, natural curing is carried out, and the protection plates are obtained. The protection plate has the effects of preserving heat, preventing damp, removing moisture, regulating the temperature and humidity of an indoor wall and the like; meanwhile, straw powder can be added into the raw material components, and the performance of the product can be further improved while the straw powder is effectively utilized.

Owner:JIANGSU TEYOUNUO NEW MATERIALS TECH

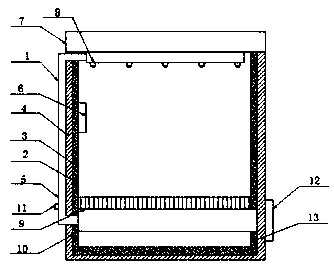

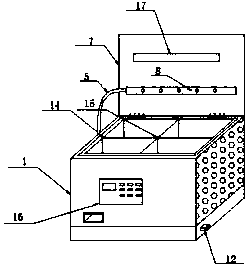

Decorative plate for permanently curing damping and dewing of internal walls and preparation method for decorative plate

The invention discloses a decorative plate for permanently curing damping and dewing of internal walls and a preparation method for the decorative plate. Raw materials of the decorative plate comprise a component A and a component B, wherein the component A contains cement, bentonite, diatomite, gypsum powder, hydroxypropyl methylcellulose, calcium lignosulfonate and polypropylene anti-crack fibers; and the component B contains a certain amount of a mixture of all the ingredients of the component A, water and EPS granules. The preparation method comprises the steps of mixing the component A and the component B, and then, carrying out uniform stirring, so as to obtain a size mixture; and then, laying gridding cloth on a backing plate, then, tiling the size mixture on the gridding cloth, then, re-laying a layer of gridding cloth on the surface of the size mixture, then, carrying out cutting according to specifications, and then, carrying out natural air-drying, thereby obtaining the decorative plate. The decorative plate provided by the invention plays roles in preserving heat, proofing dampness, dehumidifying and regulating and controlling the temperature and humidity of indoor wall bodies; and meanwhile, the decorative plate has the remarkable functions of retarding inflaming, not deforming, not cracking, being sturdy and durable, generating self-breathing, and the like, is free of any odor and is harmless to human health.

Owner:JIANGSU TEYOUNUO NEW MATERIALS TECH

Preparation method of corrugated case with preservation function

InactiveCN107201693AHigh strengthImprove anti-corrosion performanceBox making operationsPaper coatingEngineeringUltimate tensile strength

The invention discloses a preparation method of a corrugated case with a preservation function. The preparation method comprises the following operation steps of (1) putting a formed corrugated case into a drying oven with the temperature of 40 to 45 DEG C, and baking for 30 to 40min; (2) uniformly spraying fresh-keeping agents onto the baked corrugated case, then airing the corrugated case at a ventilated part, and obtaining the corrugated case with the preservation function. The preparation method of the corrugated case with the preservation function provided by the invention is simple in operation method, and can realize continuous industrial production, and the prepared corrugated case not only has an excellent mechanical property, high strength and large load, but also has an excellent preservative and fresh-keeping performance, and can prevent the packaged fruits from rotting for a long time.

Owner:HEFEI LONGFA PACKING CO LTD

Vegetable packing box

InactiveCN108706228AReduced aestheticsReduce nutritionLiving organism packagingDomestic cooling apparatusNutritionEngineering

The invention discloses a vegetable packing box. The vegetable packing box comprises an outer box body, an inner box body and a box cover; the inner box body is arranged in the outer box body; an exhaust hole is formed in one side of the outer box body; the outer side of the outer box body is rotationally connected with the box cover through a hinge; a first protecting layer is arranged on the outer side of the inner box body; a second protecting layer is arranged on the outer side of the first protecting layer; a water pipe is vertically arranged on the other side of the outer box body; the water pipe is connected with multiple atomizing nozzles; a temperature and humidity sensor is fixedly arranged on the inner side wall of the inner box body; a filter plate is transversely arranged at the bottom of the inner box body; a water collecting tank is formed in the bottom of the filter plate; an electromagnetic one-way valve is arranged on the water pipe; a waterproof plug is arranged in an opening at one end of the water collecting tank; an accumulator is arranged at the bottom of the water collecting tank; through arrangement of the first protecting layer and the second protecting layer, external heat is isolated, and internal heat is absorbed; and through the second protecting layer, the external shock is reduced, vegetables in the inner box body are protected, and the beauty and the nutrition of the vegetables are guaranteed.

Owner:南京铭旺食品贸易有限公司

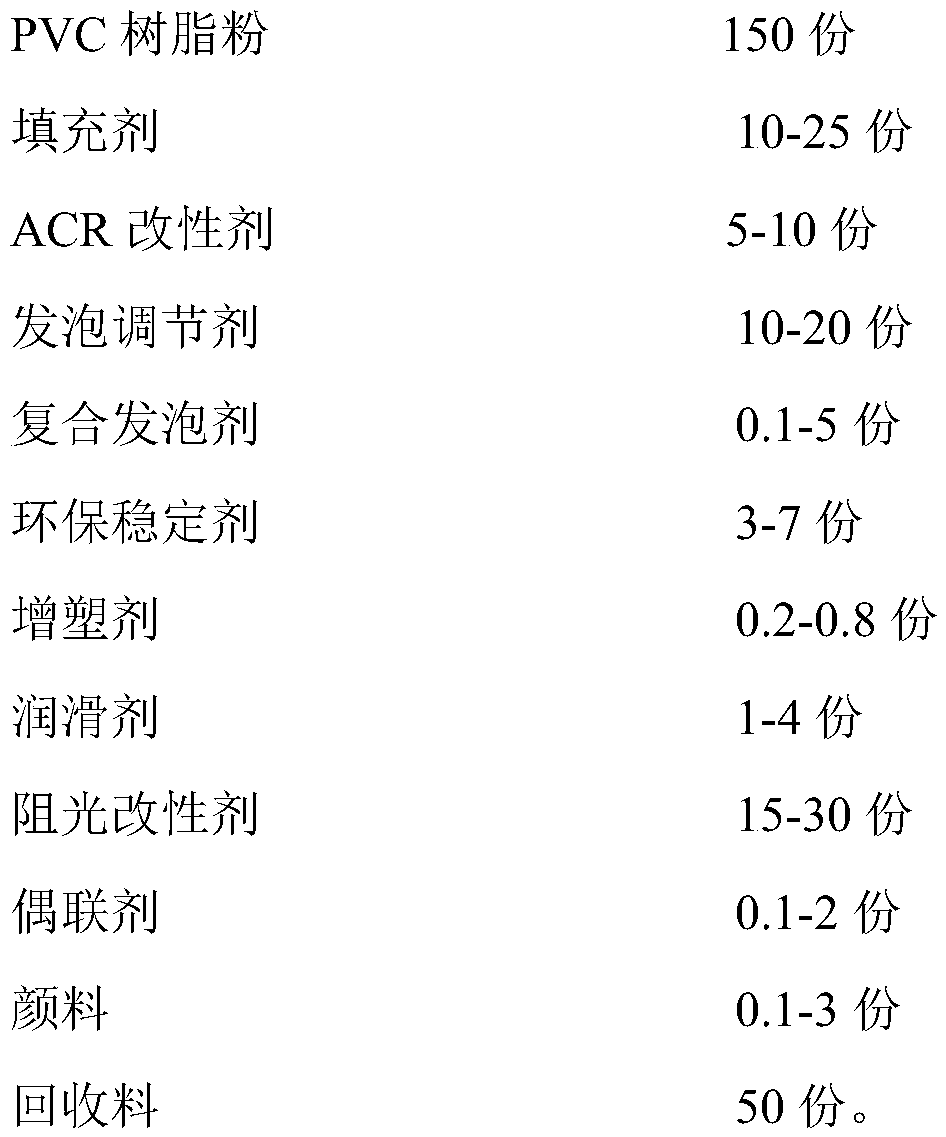

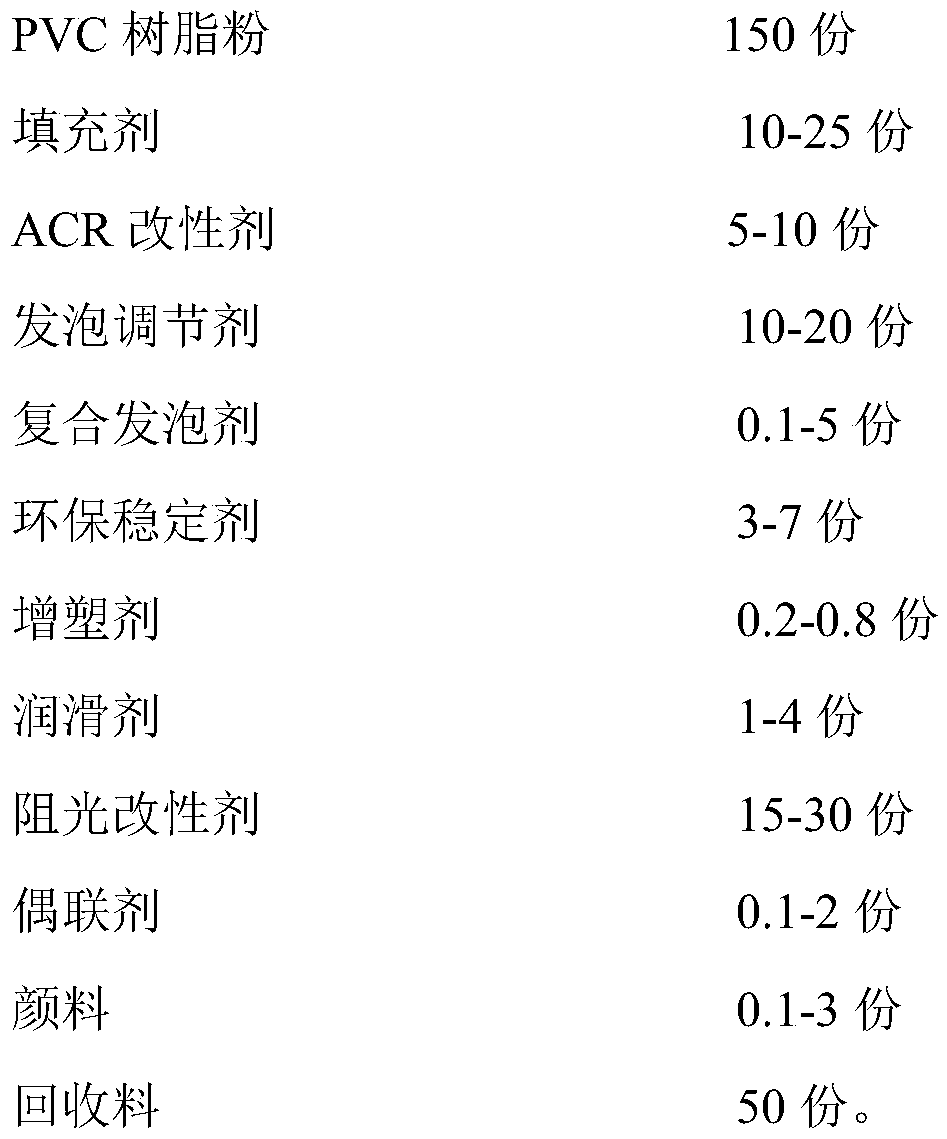

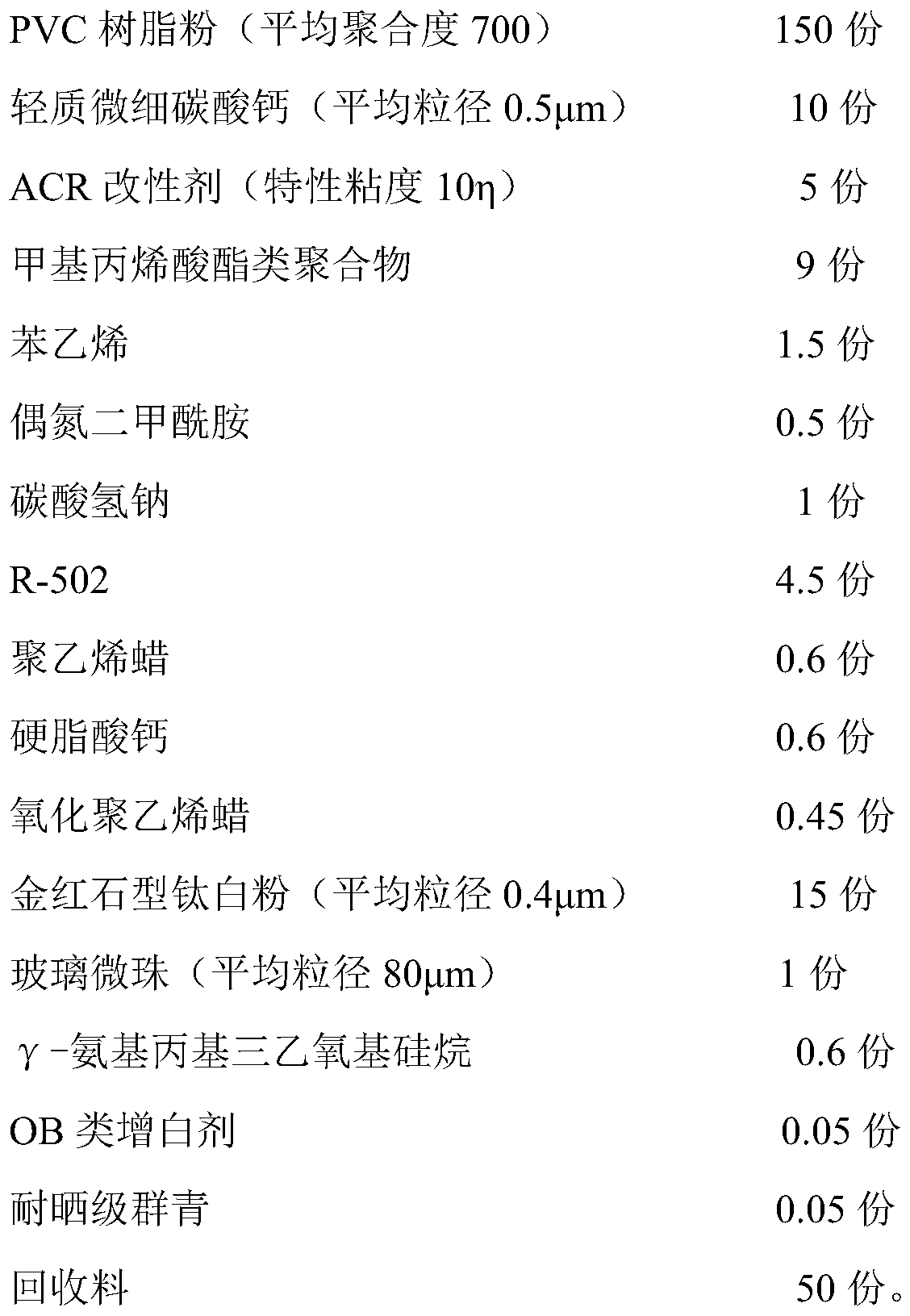

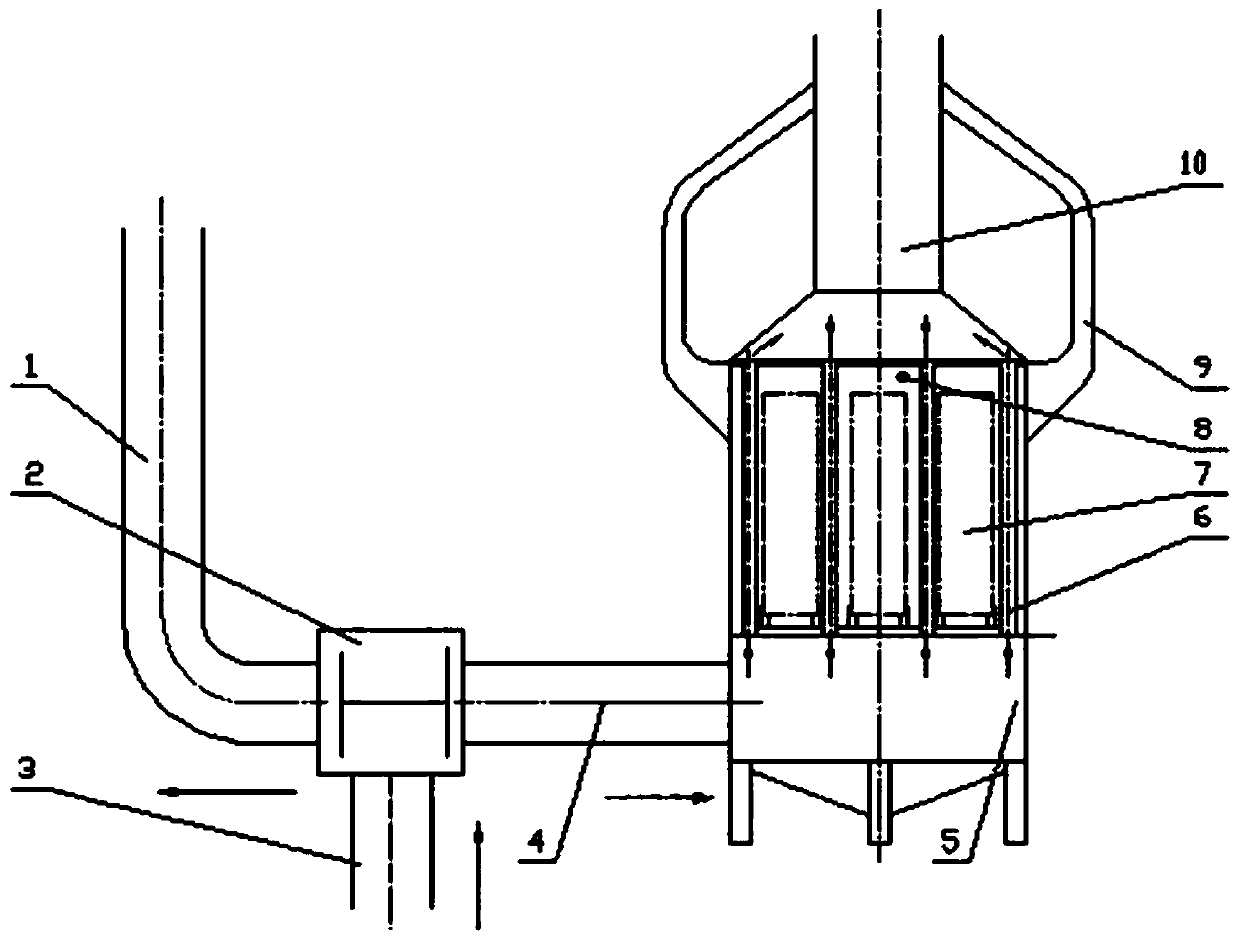

High-weather-resistance polyvinyl chloride light-blocking foam board and preparation method thereof

The invention relates to the technical field of polyvinyl chloride foam boards, in particular to a high-weather-resistance polyvinyl chloride light-blocking foam board and a preparation method thereof. The high-weather-resistance polyvinyl chloride light-blocking foam board is prepared from the following raw materials in parts by weight: 150 parts of PVC resin powder, 10-25 parts of filler, 5-10 parts of ACR modifier, 10-20 parts of foaming regulator, 0.1-5 parts of composite foaming agent, 3-7 parts of environment-friendly stabilizer, 0.2-0.8 part of plasticizer, 1-4 parts of lubricant, 15-30parts of light blocking modifier, 0.1-2 parts of coupling agent, 0.1-3 parts of pigment and 50 parts of recycled material. The high-weather-resistance polyvinyl chloride light-blocking foam board notonly has excellent light-blocking performance, but also has good weather resistance, corrosion resistance and bending resistance, and ensures the advantages of low density and high hardness of the polyvinyl chloride foam board, is convenient to install and use, and can replace a coating material of a traditional lamp box side panel. The invention also provides a preparation method of the high-weather-resistance polyvinyl chloride light-blocking foam board.

Owner:SHANDONG BODO PLASTICS CO LTD

Preparation method of dried black fungi

InactiveCN107897341AImprove food tasteGood lookingFood thermal treatmentFood dryingCartonPlastic film

The invention relates to a preparation method of dried black fungi. The preparation method of the dried black fungi comprises the following steps of: (1) thoroughly washing harvested black fungi, andcarrying out air-drying in a ventilated place for 2 hours; (2), preheating a dryer until the temperature reaches 50 DEG C, carrying out cooling, and evenly arranging the black fungi on a bamboo sieveof the dryer; (3), adjusting temperature, and carrying out shaping; (4), dehydrating the black fungi; and (5), carrying out integral drying, namely maintaining a constant temperature for 6-8 hours andraising the temperature to 60 DEG C, taking the baking sieve out when the black fungi are 80% dried, carrying out spreading-airing for 2 hours, continuing baking with both air windows completely closed so as to have the black fungi dried, finishing baking, timely packing the high-quality dried black fungi by using woven bags with lining plastic film, and carrying out packaging by using cartons. By adopting the preparation method, the processed black fungi have significantly improved taste, and are good in appearance, uniform in color and luster, not liable to decompose or deteriorate, long inshelf lives, purely green as a food and high in edible value; moreover, the dried black fungi have the functions of benefiting Qi, building up a good physique, tonifying the kidney, nourishing the stomach, activating the circulation of the blood and so on. In addition, the preparation method also has the characteristics of relatively simple processes, and low cost.

Owner:蒋艳

Method for promoting nemophila menziesi seed germination

InactiveCN103340040BSimple and fast operationPromote dormancySeed and root treatmentAbscisic acidDividing cell

The invention discloses a method for promoting nemophila menziesi seed germination. The method comprises the following steps of 1, selecting nemophila menziesi seeds, 2, preparing a nemophila menziesi seed immersion solution, and immersing the nemophila menziesi seeds, 3, preparing river sand and paving the nemophila menziesi seeds, 4, refrigerating the nemophila menziesi seeds, and 5, carrying out seed temperature-changing treatment. The method is simple and feasible, has simple processes, improves breathability and water permeability of seed coats of nemophila menziesi seeds, and promotes cell division and differentiation thereby promoting nemophila menziesi seed embryo development and nemophila menziesi seed germination. The method utilize a temperature-changing treatment technology to promote the whole metabolism of the nemophila menziesi seed so that a germination inhabitation material is eliminated, cytokinin synthesis is promoted, and inhibition hormones such as abscisic acid are degraded and transformed and thus dormancy is stopped, nemophila menziesi seed germination is promoted, germination time is short, germination uniformity is obtained, effects are obvious, and nemophila menziesi large-area production seedling is promoted.

Owner:ZHENJIANG SUIHAN AGRI

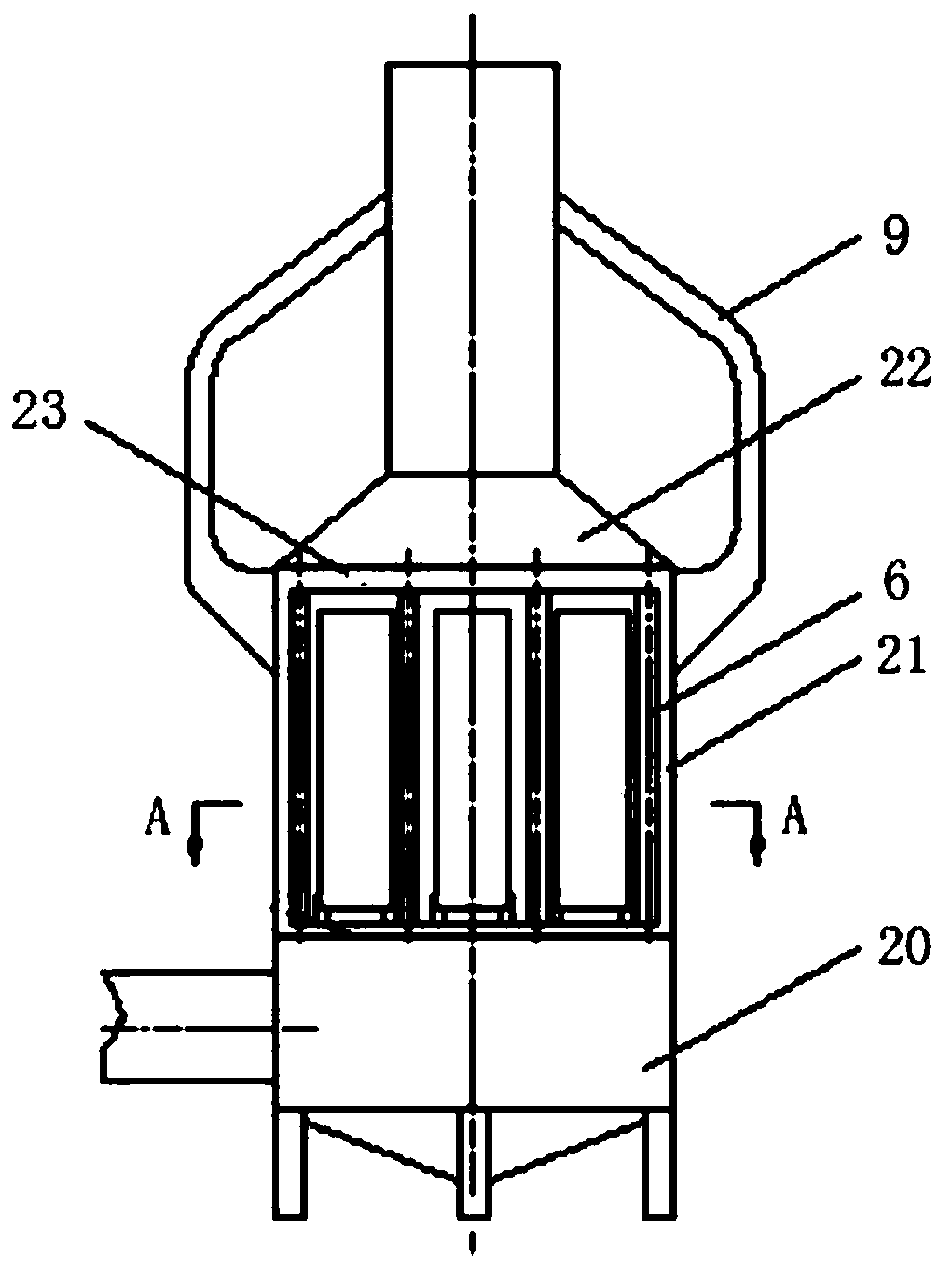

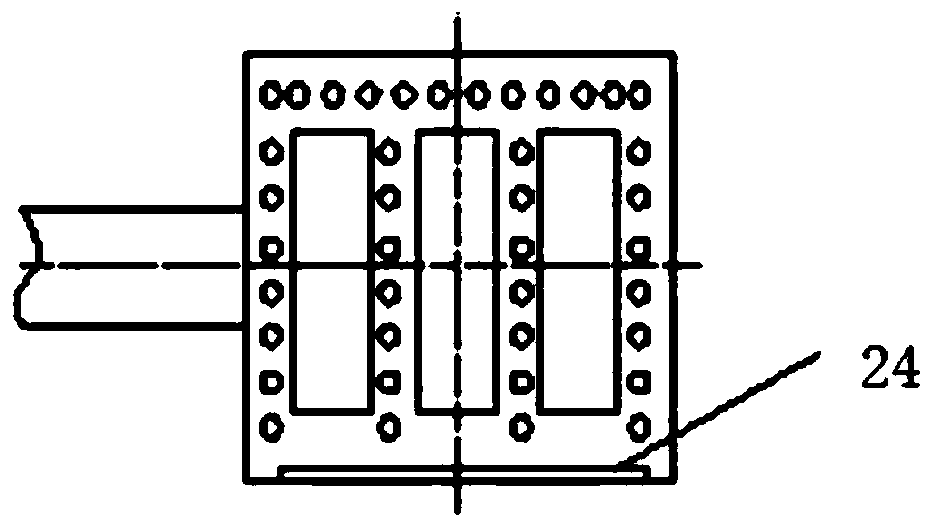

A pyrolysis distillation device for ship kitchen waste

ActiveCN107723005BImprove sanitationNot easy to breedEnergy inputSpecial form destructive distillationEnvironmental engineeringInternal combustion engine

The invention discloses a ship kitchen garbage pyrolysis and distillation device. The device comprises an air intake mechanism, a pyrolysis and distillation furnace, and a garbage box. The pyrolysis and distillation furnace comprises a lower cavity, a furnace cavity, a smoke box, and a chimney successively from bottom to top, wherein a baffle plate is arranged between the lower cavity and the furnace chamber, a baffle plate is arranged between the furnace chamber and the smoke box, and the lower chamber and the smoke chamber are communicated through a plurality of smoke pipes between the lowerchamber and the smoke chamber. The air intake mechanism is connected with the lower chamber. The garbage box is placed in the furnace chamber, an air outlet mechanism for controlling the size of theair outlet of the garbage box is arranged on the garbage box, a first temperature sensor is arranged in the garbage box, and the output end of the first temperature sensor is connected with the air outlet mechanism. Compared with the prior art, the device has the advantages that it has a simple structure and convenient operation, saves energy by utilizing the waste heat of ship internal combustionengine or boiler exhaust gas to treat domestic waste, and improves the energy utilization rate; besides, the reaction product is mainly solid regenerated carbon, has no odor, and is not easily deteriorated, the environmental pollution is small, and the garbage storage space is reduced.

Owner:NANTONG INST OF TECH

Three-dimensional bark and embroidery combined manufacturing method

PendingCN112877936AStrong embroidery skillsDoes not rotEmbroidering machines apparatusComposite materialLawn

The invention belongs to embroidery hand art products, and mainly relates to a three-dimensional bark and embroidery combined manufacturing method combining embroidery and barks. The method is characterized by comprising the following steps: determining that one part is embodied in an embroidery mode and the other part is embodied in a bark process according to an embroidery manuscript pattern theme, firstly embroidering the part to be embroidered, selecting birch barks or under-forest resource vegetation as materials of the other part, trimming into required shapes such as shapes of trees, mountains, houses, lawns, buildings and the like, polishing the back surfaces of the barks to make the barks thin, drawing on the barks with grease paint to form approximately natural color patterns needing to be expressed, then treating with paint, mounting embroidered pieces on a rubber shell plate or a density plate, and then pasting the treated barks or vegetation on designed positions of a base material of mulberry silk, mounting in a photo frame, and thus a complete three-dimensional picture composed of embroidery, barks and the like is formed.

Owner:范丽娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com