Decorative plate for permanently curing damping and dewing of internal walls and preparation method for decorative plate

A decorative board and moisture-returning technology, applied in applications, household utensils, ceramic products, etc., can solve problems such as mildew, damage to steel bars, and troubles for users, and achieve a harmless effect on human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

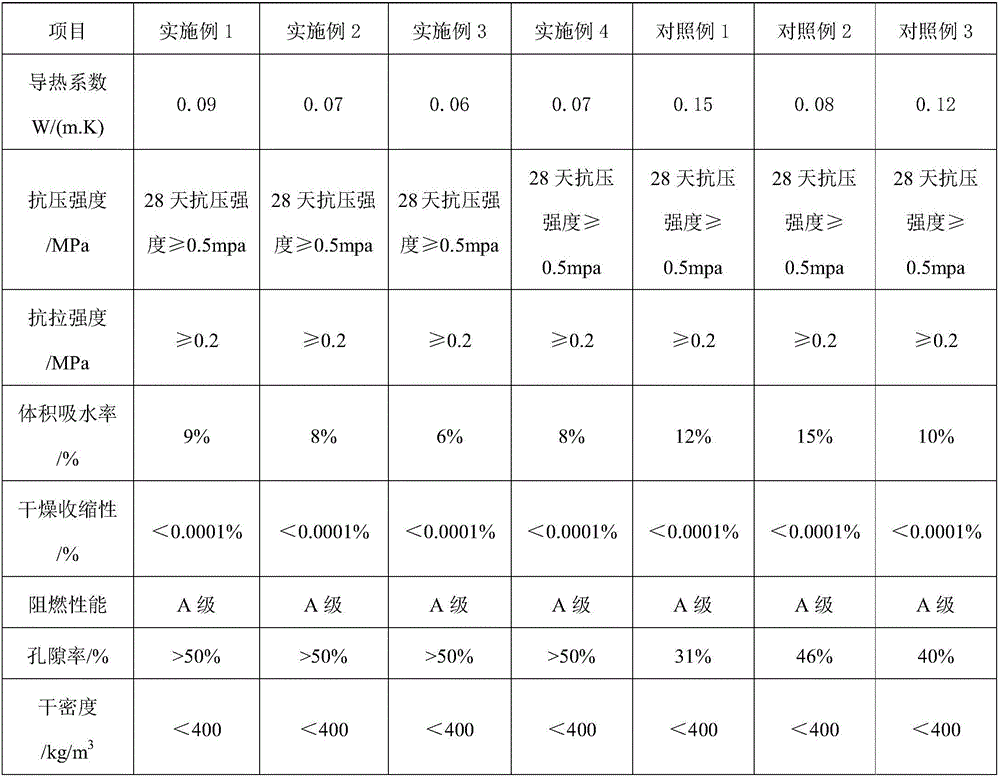

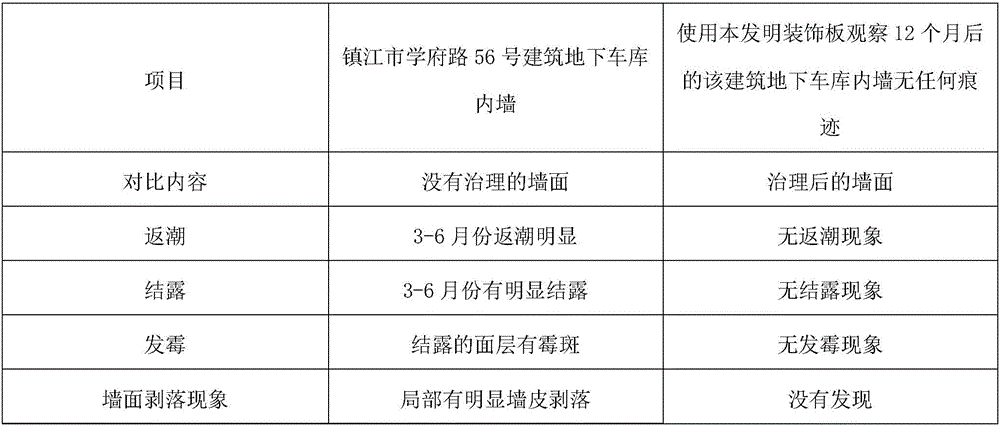

Examples

Embodiment 1

[0025] A decorative board used to radically cure moisture and condensation on interior walls. The raw materials of the decorative board include component A and component B:

[0026] Wherein component A includes the following components in parts by weight: 50 parts of cement, 20 parts of bentonite, 15 parts of diatomaceous earth, 10 parts of gypsum powder, 0.05 part of hydroxypropyl methylcellulose, 0.2 part of calcium lignosulfonate, 1 part polypropylene anti-crack fiber;

[0027] Component B includes the following components in parts by weight: 150 parts of all components in component A are mixed in proportion by weight, 100 parts of water, and 7 parts of EPS particles.

[0028] Among the above components, the particle size of bentonite is 200 mesh, the viscosity is 30, and the filtration loss is less than 15; the density of diatomite is 0.3g / cm 3 , the Mohs hardness is about 1-1.5; the particle size of gypsum powder is 180 mesh; the particle size of hydroxypropyl methylcell...

Embodiment 2

[0035] A decorative board used to radically cure moisture and condensation on interior walls. The raw materials of the decorative board include component A and component B:

[0036] Wherein component A includes the following components in parts by weight: 55 parts of cement, 26 parts of bentonite, 18 parts of diatomaceous earth, 12 parts of gypsum powder, 0.06 part of hydroxypropyl methylcellulose, 0.23 part of calcium lignosulfonate, 1 part polypropylene anti-crack fiber;

[0037] Component B includes the following components in parts by weight: 160 parts of all components in component A are mixed in proportion by weight, 150 parts of water, and 10 parts of EPS particles.

[0038] Among the above components, the particle size of bentonite is 200 mesh, the viscosity is 30, and the fluid loss is less than 15; the density of diatomite is 0.4g / cm 3 , Mohs hardness is 1-1.5; the particle size of gypsum powder is 250 mesh; the particle size of hydroxypropyl methylcellulose is 100 ...

Embodiment 3

[0045] A decorative board used to radically cure moisture and condensation on interior walls. The raw materials of the decorative board include component A and component B:

[0046] Wherein component A includes the following components in parts by weight: 70 parts of cement, 35 parts of bentonite, 22 parts of diatomaceous earth, 13 parts of gypsum powder, 0.08 part of hydroxypropyl methylcellulose, 0.26 part of calcium lignosulfonate, 2 parts of polypropylene anti-cracking fiber;

[0047] Component B includes the following components in parts by weight: 180 parts of all components in component A are mixed in proportion by weight, 180 parts of water, and 12 parts of EPS particles.

[0048] Among the above components, the particle size of bentonite is 200 mesh, the viscosity is 30, and the filtration loss is less than 15; the density of diatomite is 0.5g / cm 3 , Mohs hardness is 1-1.5; the particle size of gypsum powder is 200 mesh; the particle size of hydroxypropyl methylcellu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com