A pyrolysis distillation device for ship kitchen waste

A kitchen waste and chemical device technology, applied in special forms of dry distillation, energy input, coke ovens, etc., can solve problems such as a large number of fly ash and bottom ash, and achieve improved energy utilization, easy popularization, and less secondary pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

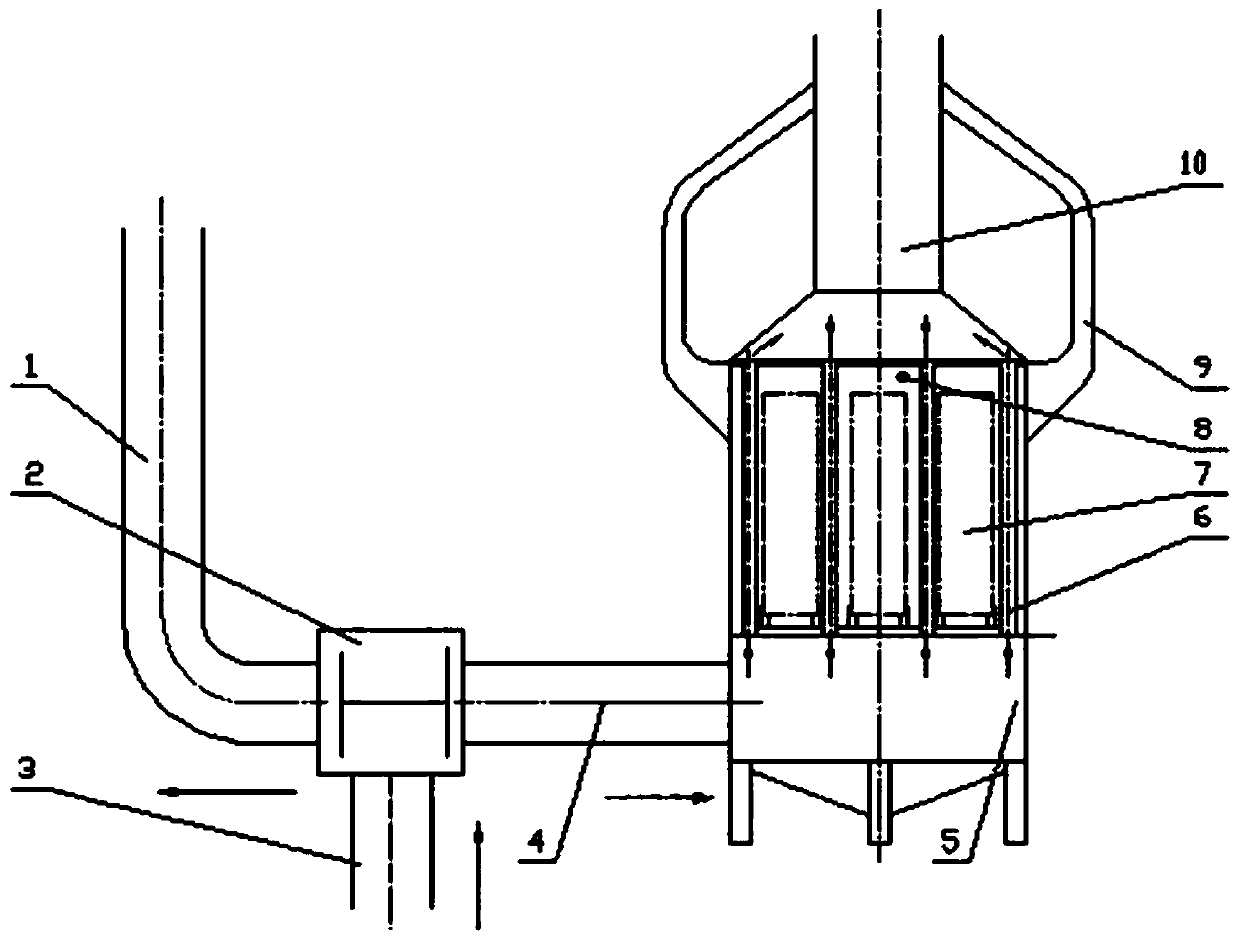

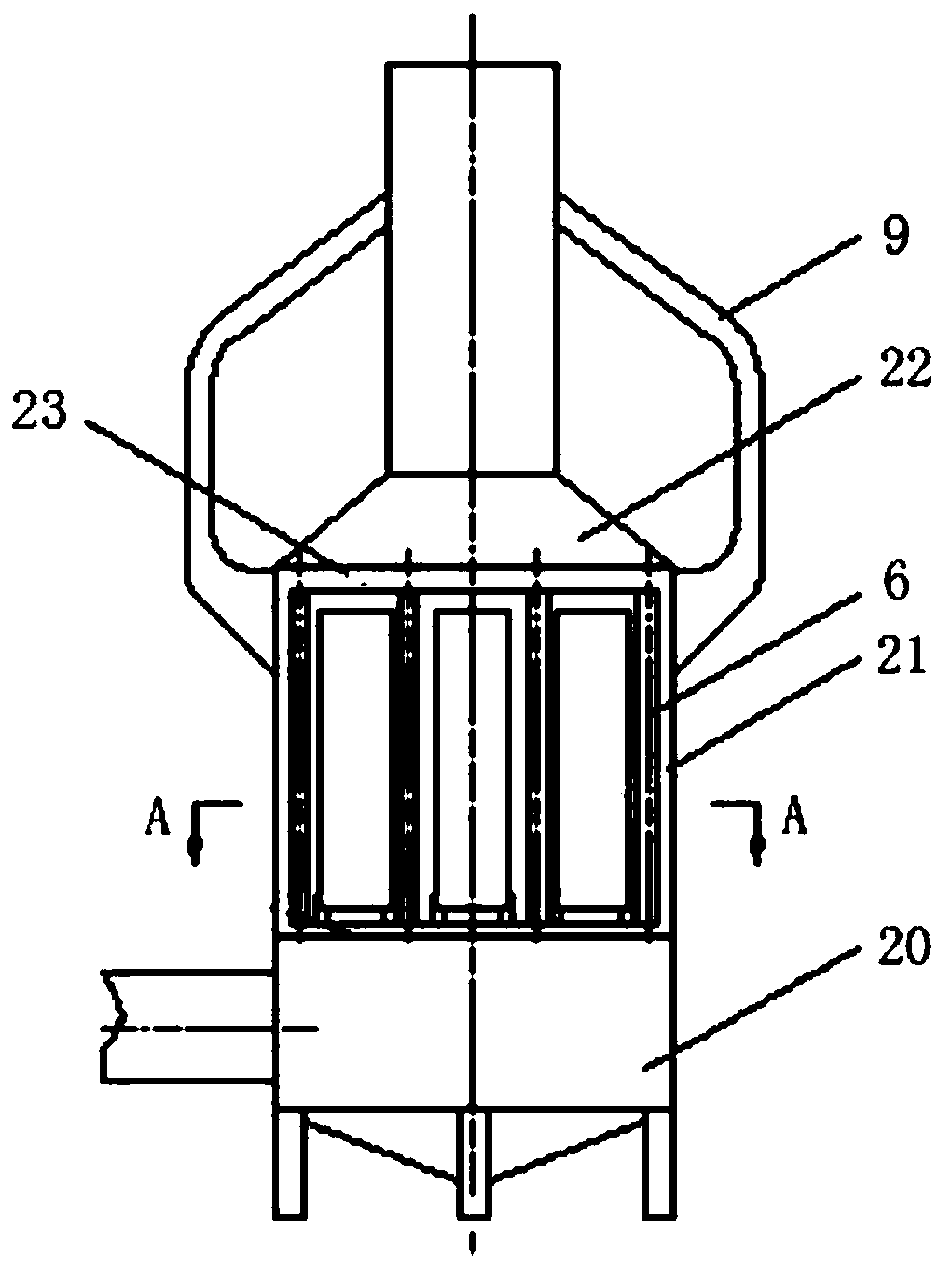

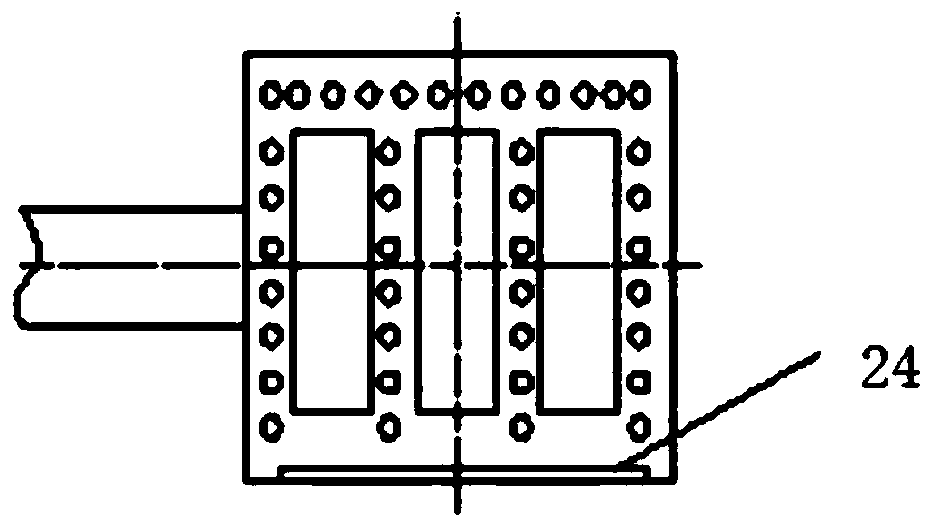

[0028] 2. In order to achieve the purpose of the present invention, such as Figure 1 to Figure 3 As shown, in one of the embodiments of the present invention, a pyrolysis and distillation device for ship kitchen waste is provided, including an air intake mechanism, a pyrolysis and distillation furnace 5 and a garbage bin 7. The pyrolysis and distillation furnace 5 consists of the following A lower cavity 20, a furnace cavity 21, a smoke box 22 and a chimney 10 are provided in sequence on top, a partition 23 is arranged between the lower cavity 20 and the furnace cavity 21, and between the furnace cavity 21 and the smoke box 22, the lower cavity 20 and the smoke stack A number of smoke pipes 6 are connected between the boxes 22, and the air intake mechanism is connected with the lower cavity 20; the garbage box 7 is placed in the furnace cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com