Self-extinguishing EPS foam plastic and house

A foam plastic and self-extinguishing technology, applied in the direction of building components, arch structures, dome structures, etc., can solve the problems of mechanical properties and heat insulation performance decline, hinder popularization and use, and large heat release, etc., to achieve mechanical properties Excellent, reduce construction time, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A self-extinguishing EPS foam plastic, the preparation raw material of the EPS foam plastic includes the following components in parts by weight: PS particles: 90 parts; liquid physical foaming agent: 8 parts; water 130 parts; soap powder: 2 parts .

[0070] Compared with traditional materials, the EPS foam plastic has better heat insulation, sound insulation, flame retardant and shock resistance effects, and at the same time has better mechanical properties.

[0071] The preparation technology of described EPS foam plastics comprises the following steps:

[0072] Step A: Impregnation: Add liquid physical foaming agent, PS particles, water and soap powder into the reaction kettle, and feed nitrogen into the reaction kettle, pressurize to 0.03MPa, and form EPS particles.

[0073] Step B: Pre-foaming: heating the impregnated EPS particles to above 80°C, the EPS particles begin to soften, and the internal blowing agent decomposes to release gas, generating pressure to exp...

Embodiment 2

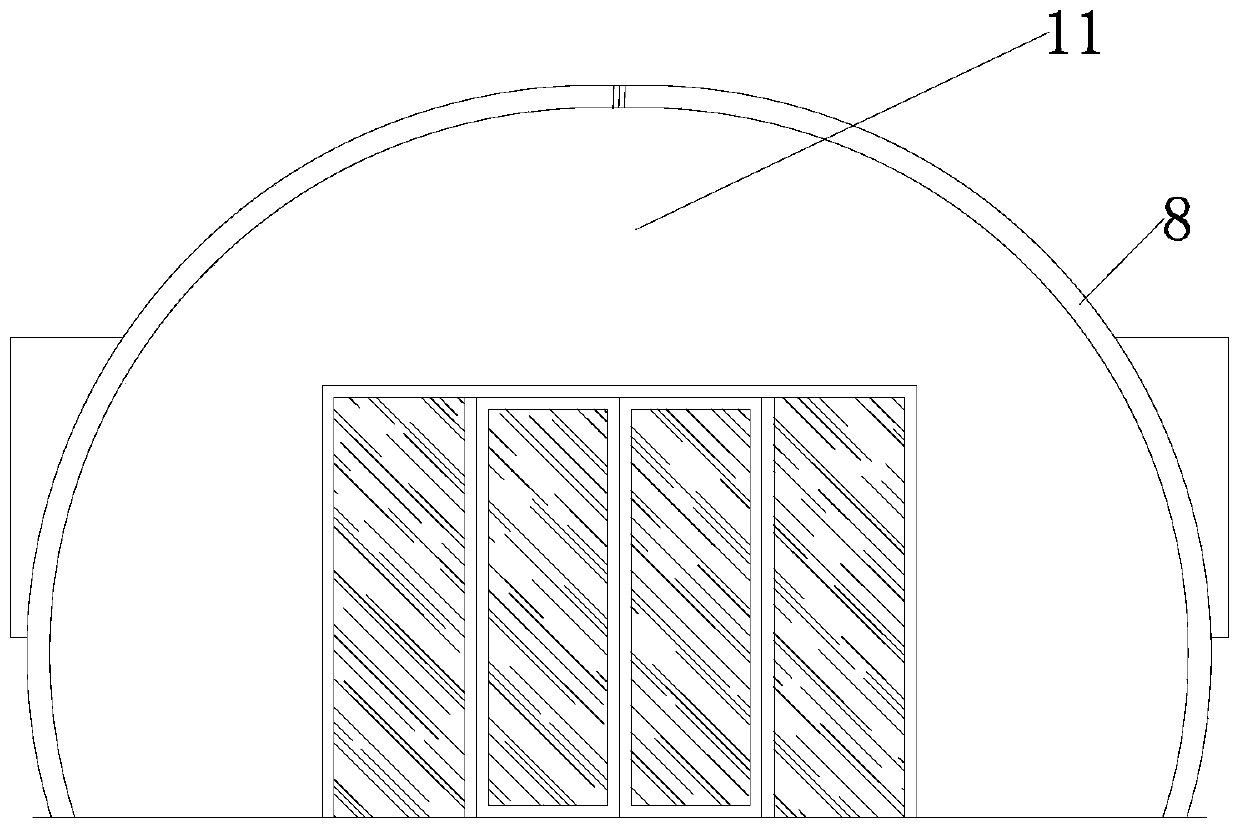

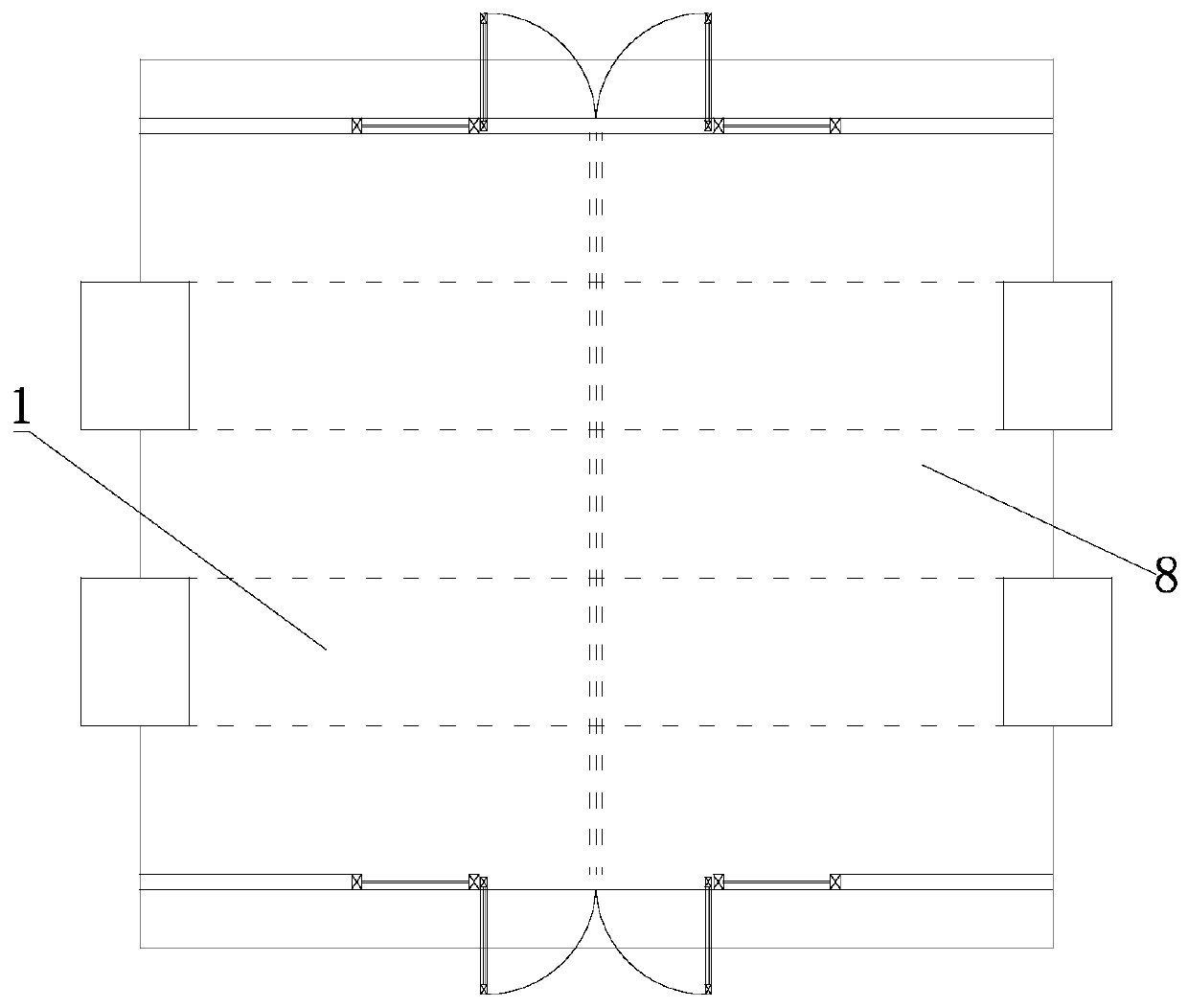

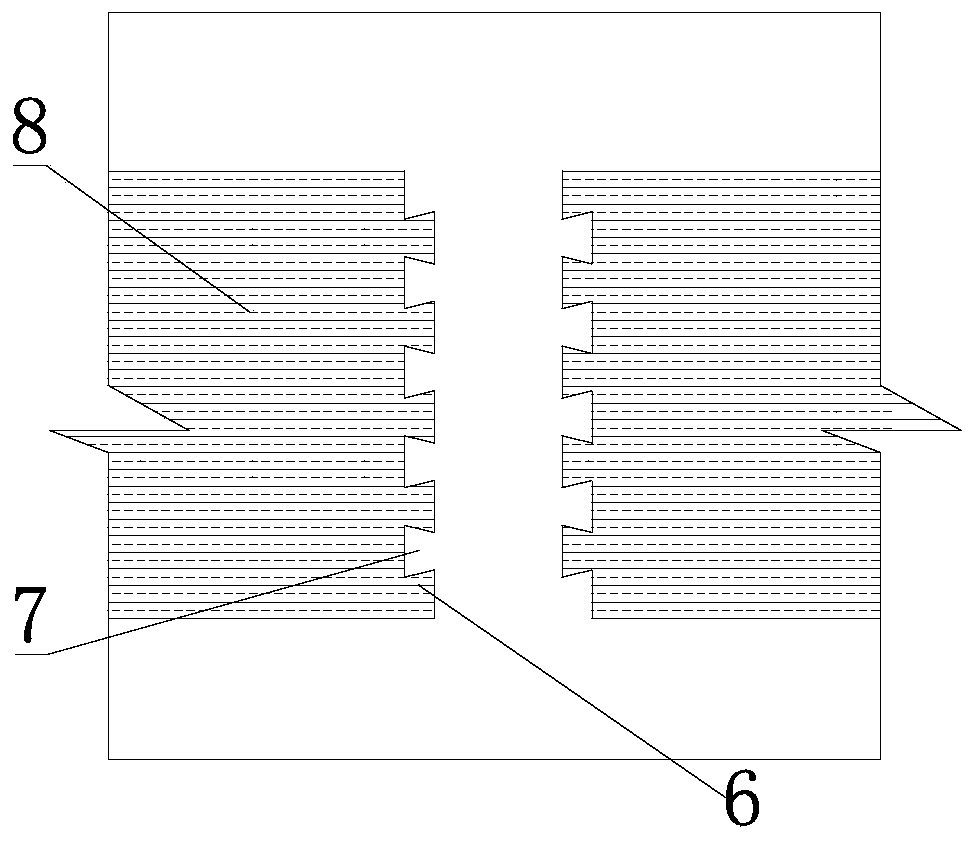

[0084] A house assembled from a plurality of EPS foam plastic modules.

[0085] Compared with traditional timber houses or reinforced concrete houses, houses made of self-extinguishing EPS foam plastics have the advantages of lower cost, more energy-saving, earthquake resistance, heat insulation, sound insulation, no rot, no rust, lightness and quickness, and the like. Reduce labor by 60%, reduce construction time by 50%, and reduce construction cost by 30%.

[0086] The house made of the self-extinguishing EPS foam plastic meets the requirements of green construction and has the characteristics of environmental protection and high efficiency.

Embodiment 3

[0088] A self-extinguishing EPS foam plastic, the preparation raw material of the EPS foam plastic includes the following components in parts by weight: PS particles: 110 parts; petroleum ether: 10 parts; water 200 parts; soap powder: 5 parts.

[0089] Compared with traditional materials, the EPS foam plastic has better heat insulation, sound insulation, flame retardant and shock resistance effects, and at the same time has better mechanical properties.

[0090] The preparation technology of described EPS foam plastics comprises the following steps:

[0091] Step A: Impregnation: Add foaming agent, PS particles, water and dispersant into the reactor, and feed nitrogen into the reactor, pressurize to 0.05MPa, and form EPS particles.

[0092] Step B: Pre-foaming: heating the impregnated EPS particles to above 80°C, the EPS particles begin to soften, and the internal blowing agent decomposes to release gas, generating pressure to expand the EPS particles to form EPS foam, the EPS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com