Multifunctional light-weight thermoplastic composite board and manufacturing method thereof

The technology of a composite board and a production method, which is applied in chemical instruments and methods, synthetic resin layered products, lamination and other directions, can solve the problems of poor thermal insulation and sound insulation, easy to burn and spread, and poor snow resistance pressure, etc. Achieve the effects of good structural stability, compensation for losses and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present application will be described in further detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present application and the present application is not limited to the following examples.

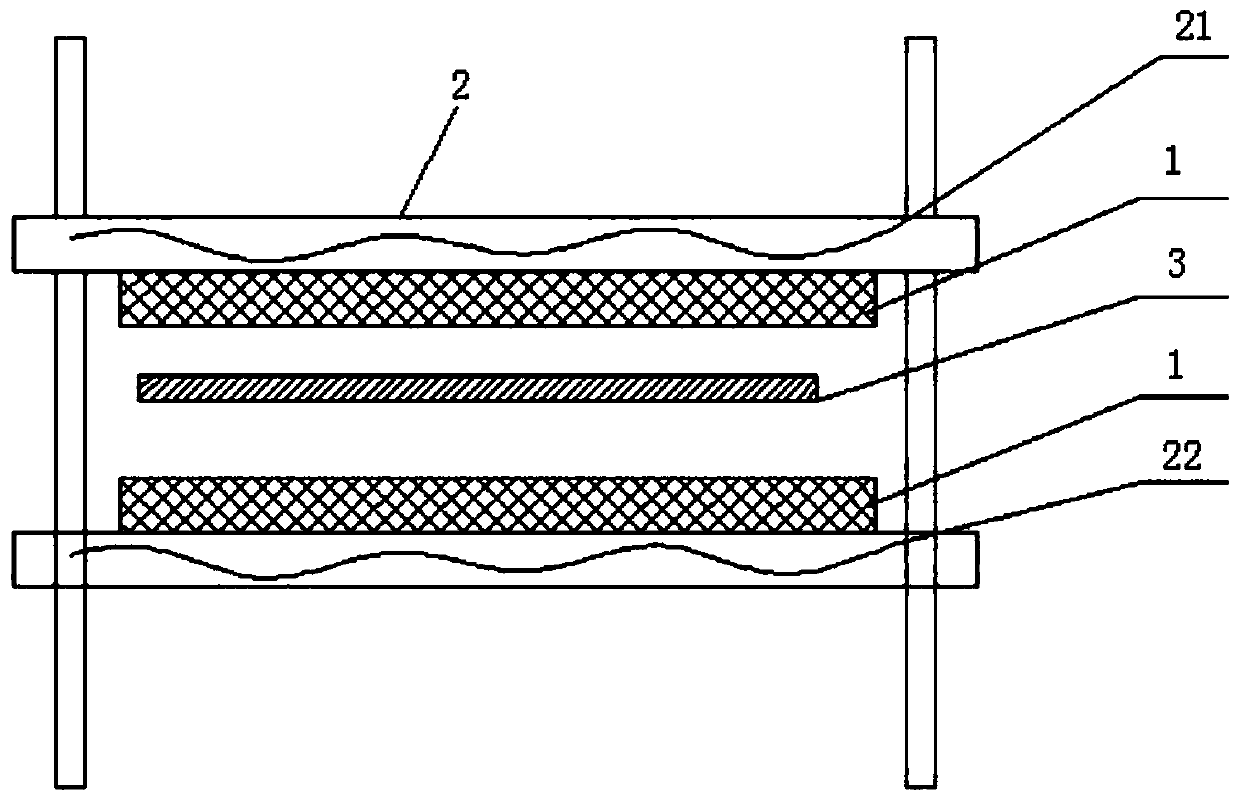

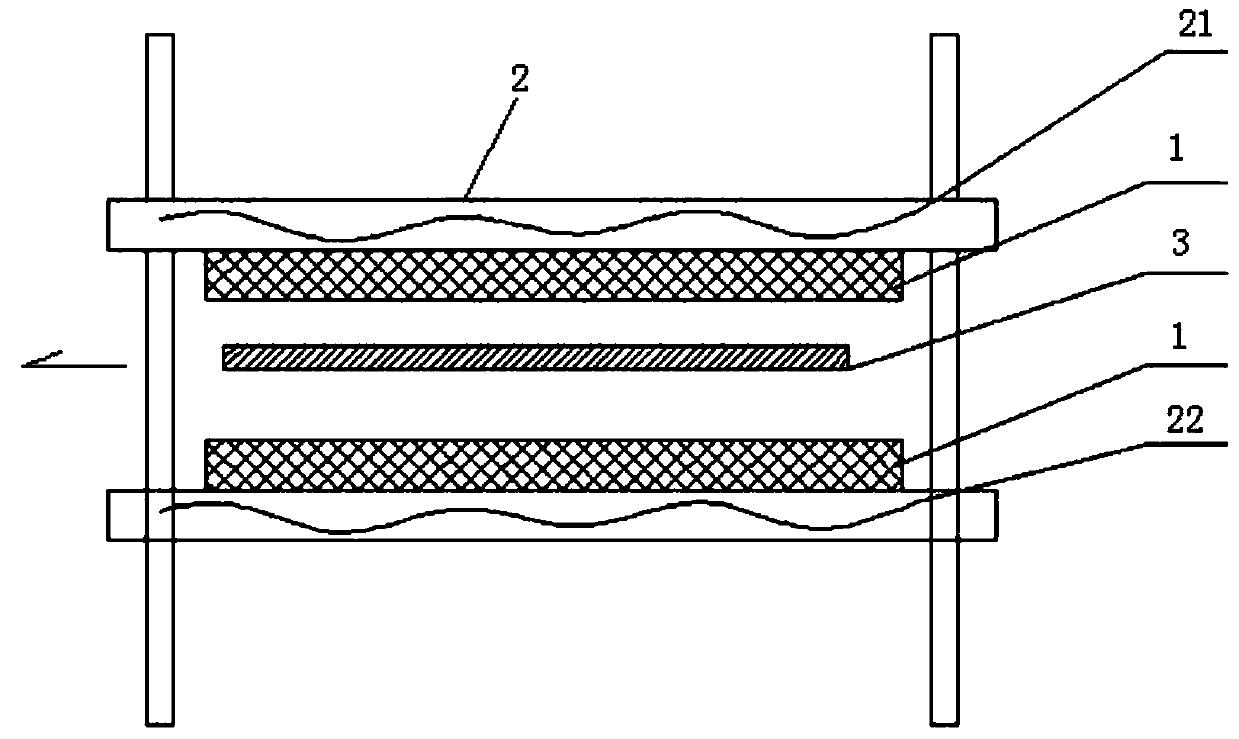

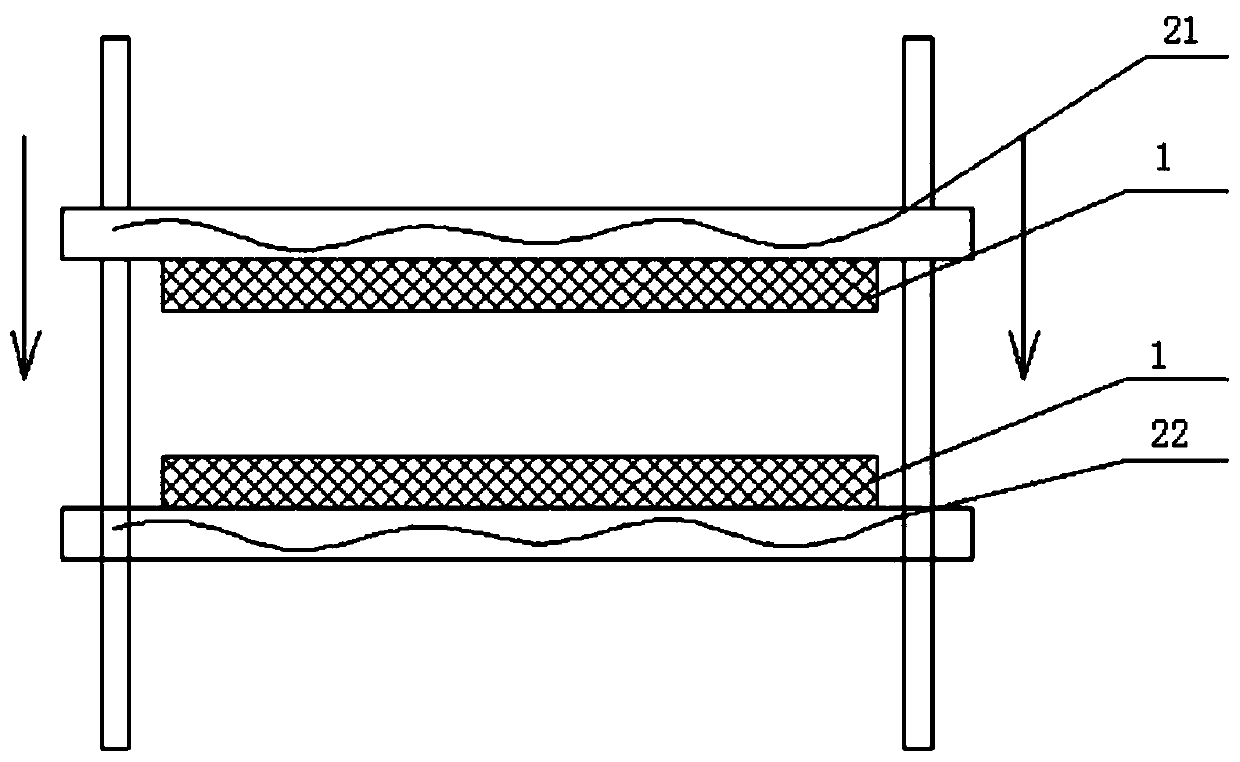

[0040] see Figure 6 , the multi-functional lightweight thermoplastic composite sheet of the present application is formed by heating, pressurizing and bonding a plurality of thermoplastic composite sheets through mutual connection surfaces.

[0041] The thermoplastic composite board is a thermoplastic composite honeycomb board. The single-layer thermoplastic composite honeycomb board 1 has a sandwich structure similar to a sandwich, and is composed of an upper skin 11, a plastic honeycomb 12 and a lower skin 13 connected in sequence.

[0042] The preparation method of the above-mentioned multifunctional lightweight thermoplastic composite board, such as Figure 1 to Figure 5 shown, including the following st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com