Three-dimensional bark and embroidery combined manufacturing method

A production method and combined technology, applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problems of laborious, multi-limited plane embroidery, and long time-consuming embroidery transmission, and achieve the improvement of appreciation level and three-dimensional sense Strong effect and novel structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Embodiments of the present invention will now be described in detail in conjunction with the accompanying drawings.

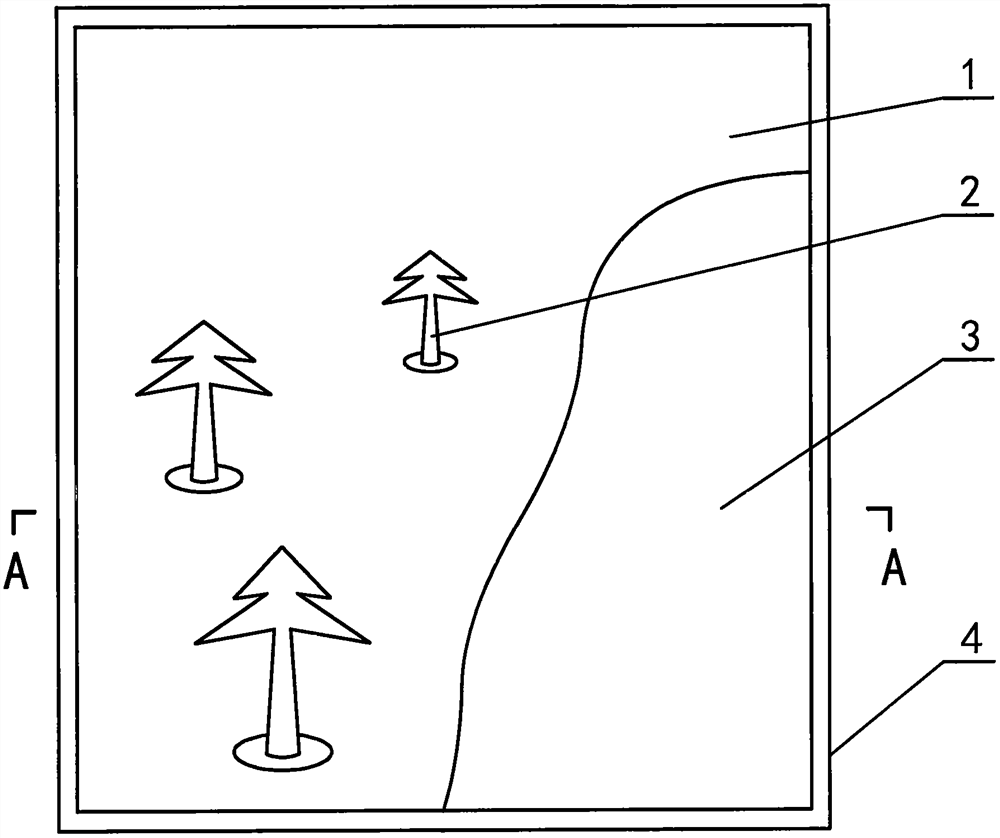

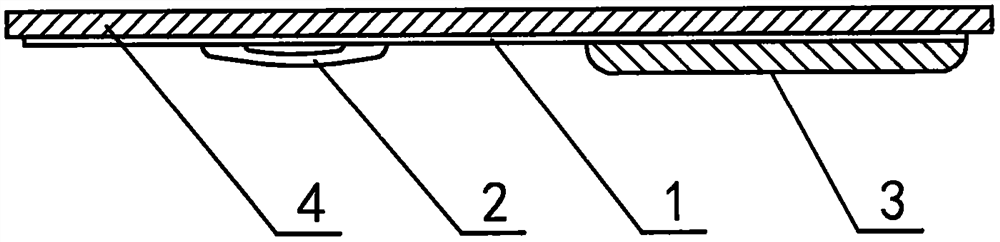

[0016] A production method combining three-dimensional bark technology and embroidery. The semi-finished base material 1 embroidered with mulberry silk is selected from cloth such as mulberry silk, and its function is to fix the embroidery pattern 2 and the bark 3. The bark 3 is made of birch There are many bark processing and production. When making and processing birch bark, first make the birch bark into the shape of mountains, houses, and objects, and polish the back of the birch bark to make it thin. The surface is not slippery and easy to apply glue. Deformation, anti-corrosion and moisture-proof treatment with lacquer, after painting with oil paint on the bark close to the natural color pattern you want to express, then treat it with lacquer to lock the color so that the purpose will not fade, and then mount the embroidered base material on the glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com