High-weather-resistance polyvinyl chloride light-blocking foam board and preparation method thereof

A technology of polyvinyl chloride and foamed board, applied in the field of high weather resistance polyvinyl chloride light-blocking foamed board and its preparation, can solve the problem of affecting the mechanical properties and weather resistance of polyvinyl chloride foamed boards, and the impact of polyvinyl chloride foaming Problems such as the foaming process of the board and the increase in the density of the PVC foamed board, to achieve good opacity and smoothness, which is conducive to dispersion and adsorption, and the effect of reducing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

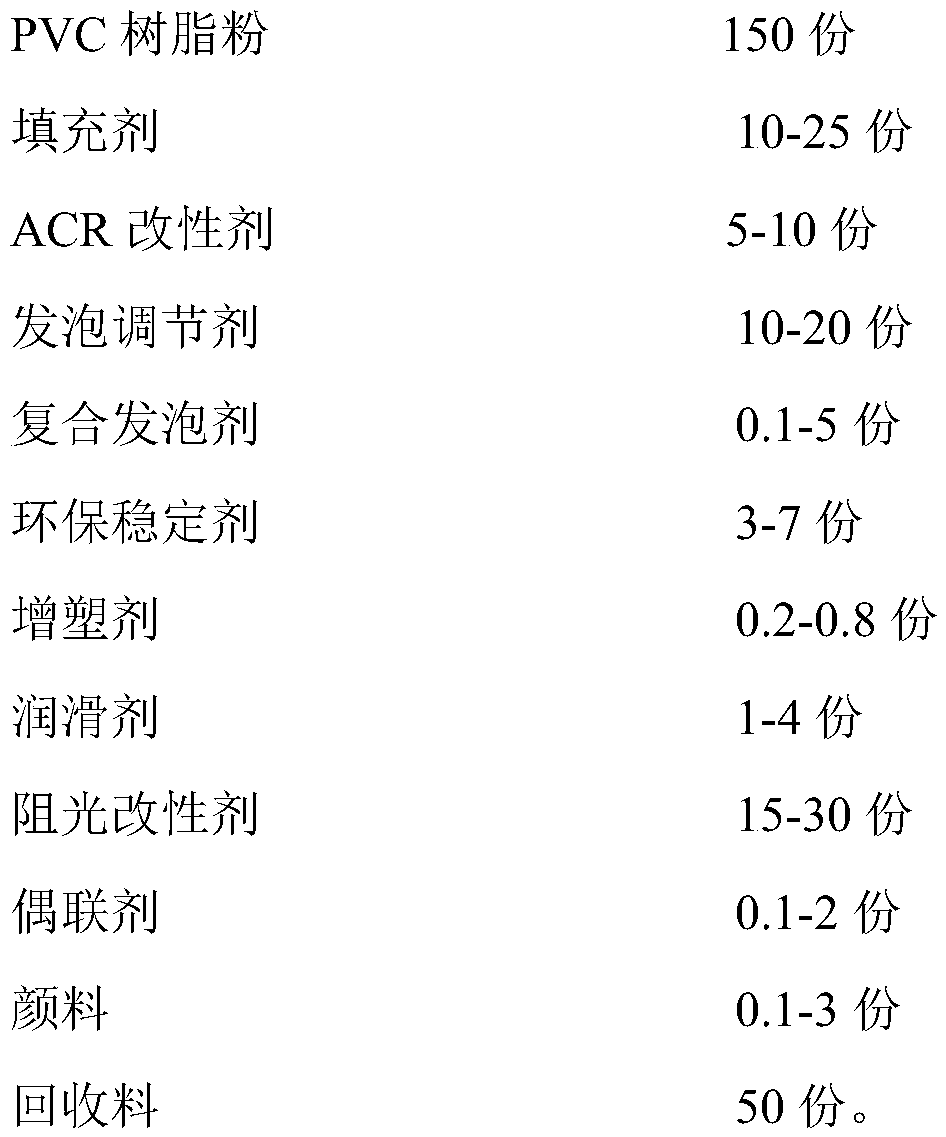

[0039] A highly weather-resistant polyvinyl chloride light-blocking foam board of the present invention is made of the following raw materials in parts by weight:

[0040]

[0041] The preparation method is as follows:

[0042] (1) Preparation of masterbatch: Precisely mix all raw material components according to the formula;

[0043] (2) Hot mixing: add each component into the hot mixing tank in the following order, add PVC resin powder at 50°C and 700rpm; add environmental protection at 60°C and 700rpm Stabilizer R-502; Add polyethylene wax, azodicarbonamide and sodium bicarbonate at 75°C and 1000rpm; add methacrylate polymer, Styrene, ACR modifier and calcium stearate; under the conditions of 100°C and 1000rpm, add light fine calcium carbonate, rutile titanium dioxide, glass microspheres, γ-aminopropyltriethoxysilane, Recycled material, OB brightener and light-fast grade ultramarine; finally heated to 115°C for mixing;

[0044] (3) Cold mixing: Put the hot mixed mixtu...

Embodiment 2

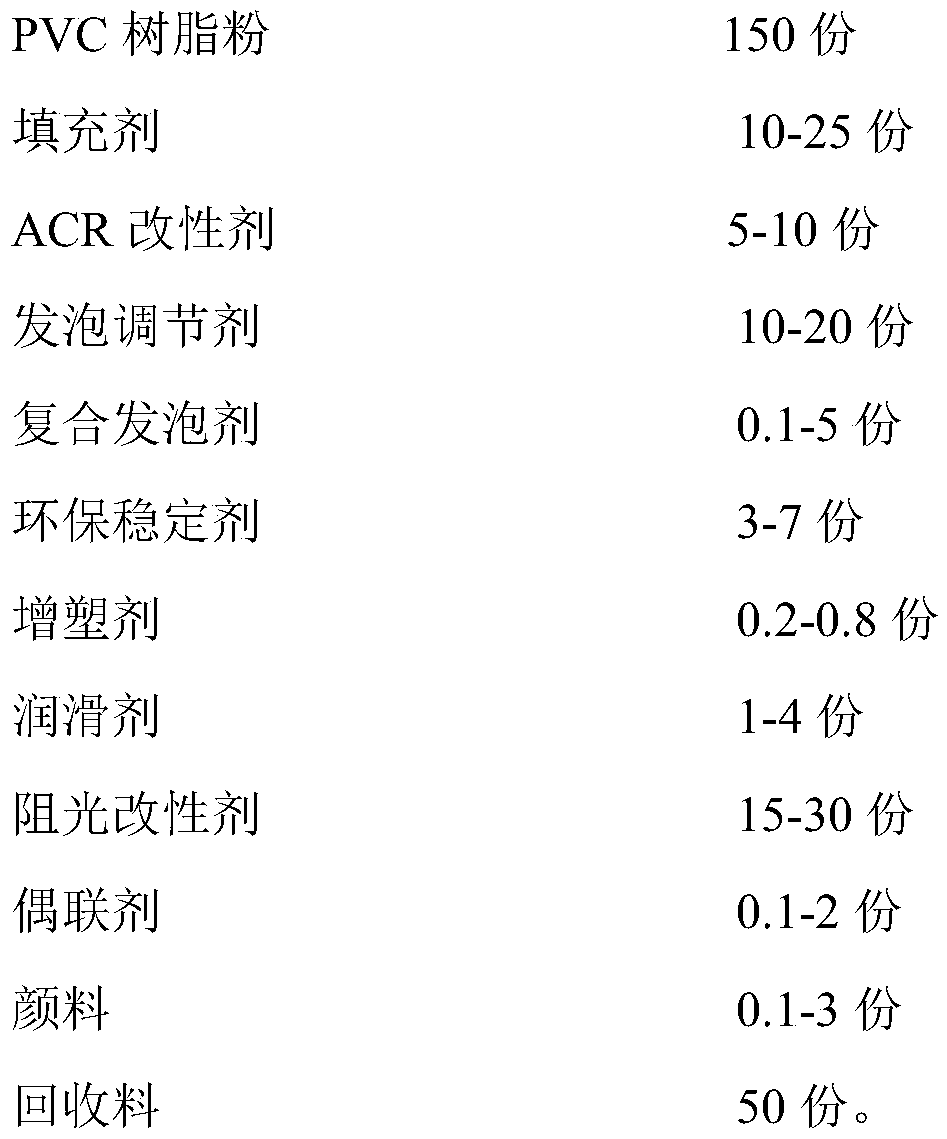

[0048] A highly weather-resistant polyvinyl chloride light-blocking foam board of the present invention is made of the following raw materials in parts by weight:

[0049]

[0050] The difference between the preparation method and Example 1 is that the specific process parameters of the twin-screw extruder in step (4) are: the speed of the main engine is 17rpm / min, the current of the main engine is 110A, and the temperature of the screw barrel is 165°C, 165°C, and 170°C respectively. , 175°C, confluence core temperature 160°C, mold lip oil temperature 175°C.

Embodiment 3

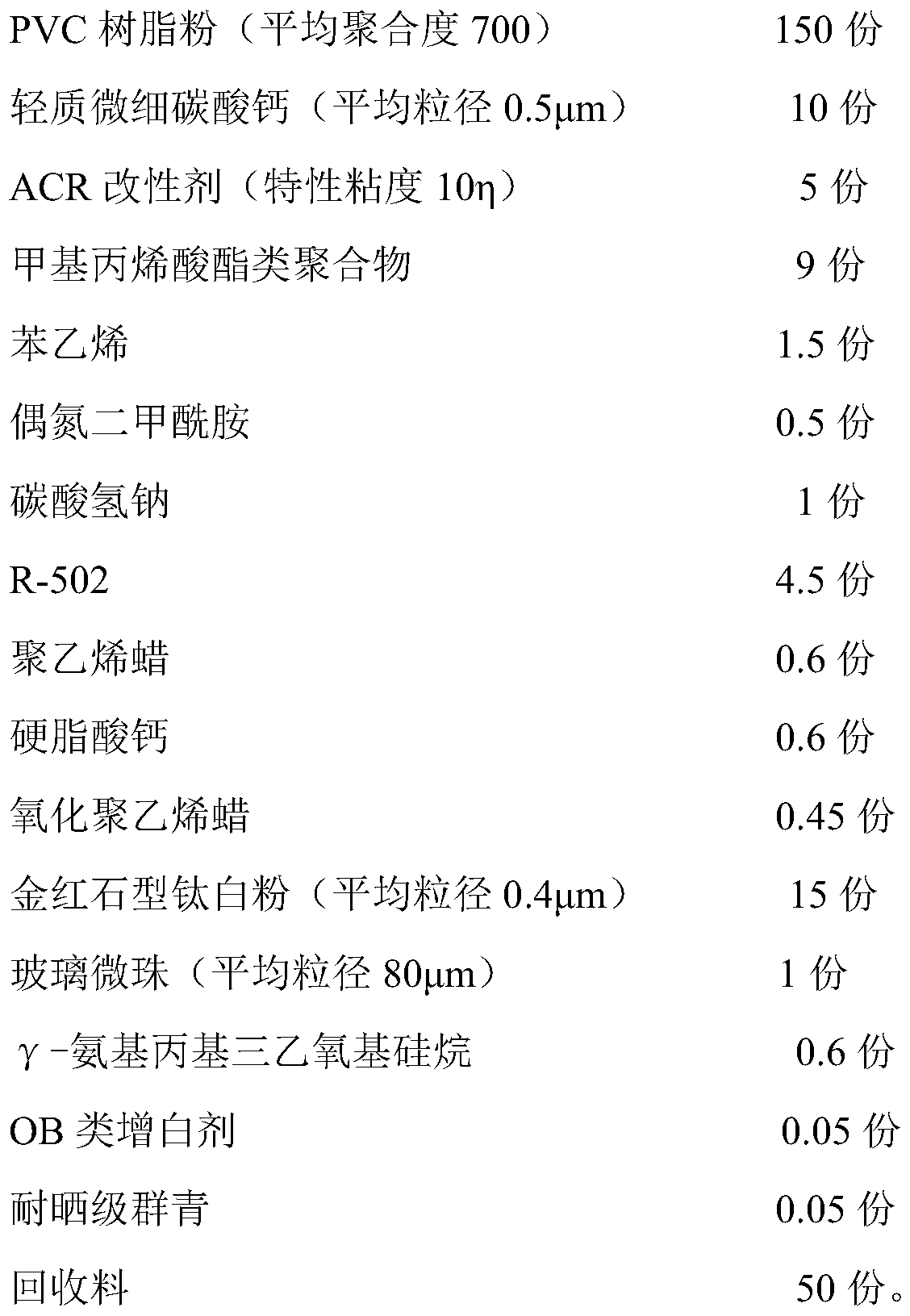

[0052] A highly weather-resistant polyvinyl chloride light-blocking foam board of the present invention is made of the following raw materials in parts by weight:

[0053]

[0054]

[0055] The difference between the preparation method and Example 1 is that the specific process parameters of the twin-screw extruder in step (4) are: the speed of the main engine is 13rpm / min, the current of the main engine is 100A, and the temperature of the screw barrel is 165°C, 165°C, and 170°C respectively. , 175°C, confluence core temperature 160°C, mold lip oil temperature 165°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com