Carbonized oak wine barrel and fabrication process thereof

A production process and oak technology, which is applied in the field of carbonized oak wine barrels and its production process, can solve the problems of large moisture differences, low oak utilization rate, and different barrel sizes, and achieve pure taste and uniform carbonization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

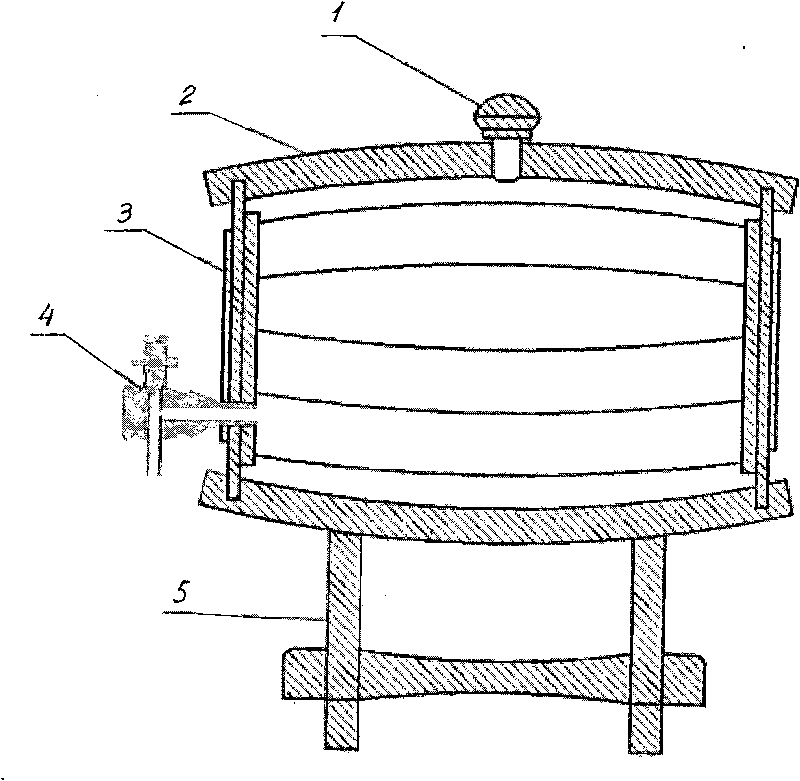

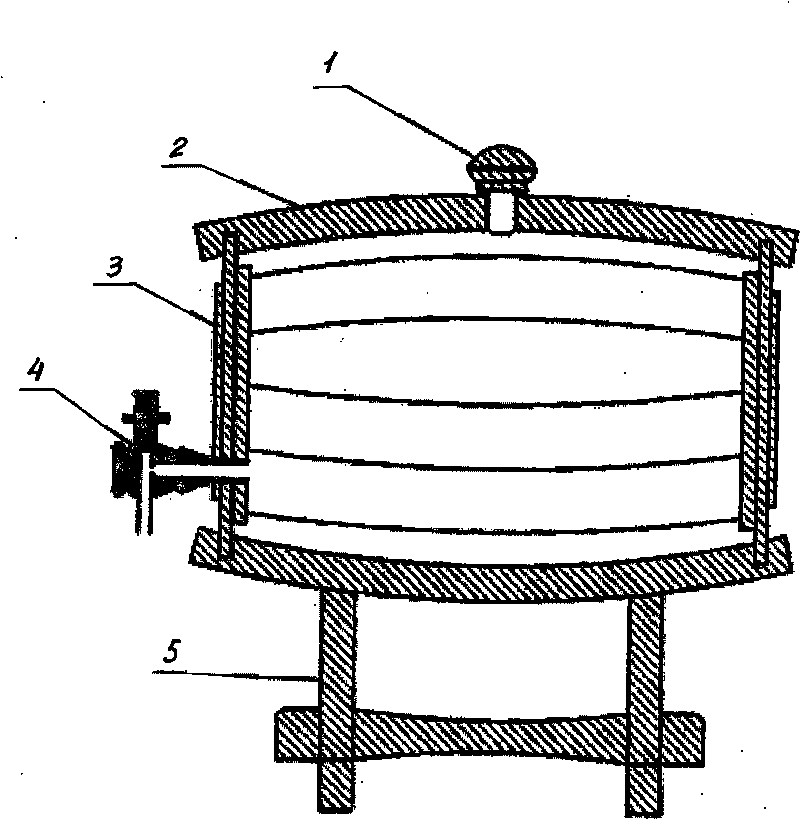

[0016] Example 1: Combination figure 1 , The present invention is a carbonized oak wine barrel, which is composed of a barrel frame (5), a barrel wall (2), a barrel plug (3), a wine filling stopper (1) and a wine outlet valve (5). (5) Connect the barrel wall (2), the barrel wall (2) is connected to the barrel plug (3), the wine filling plug (1) is located above the barrel wall (2), and the wine outlet valve (5) is set on the barrel plug (3) ) Downside.

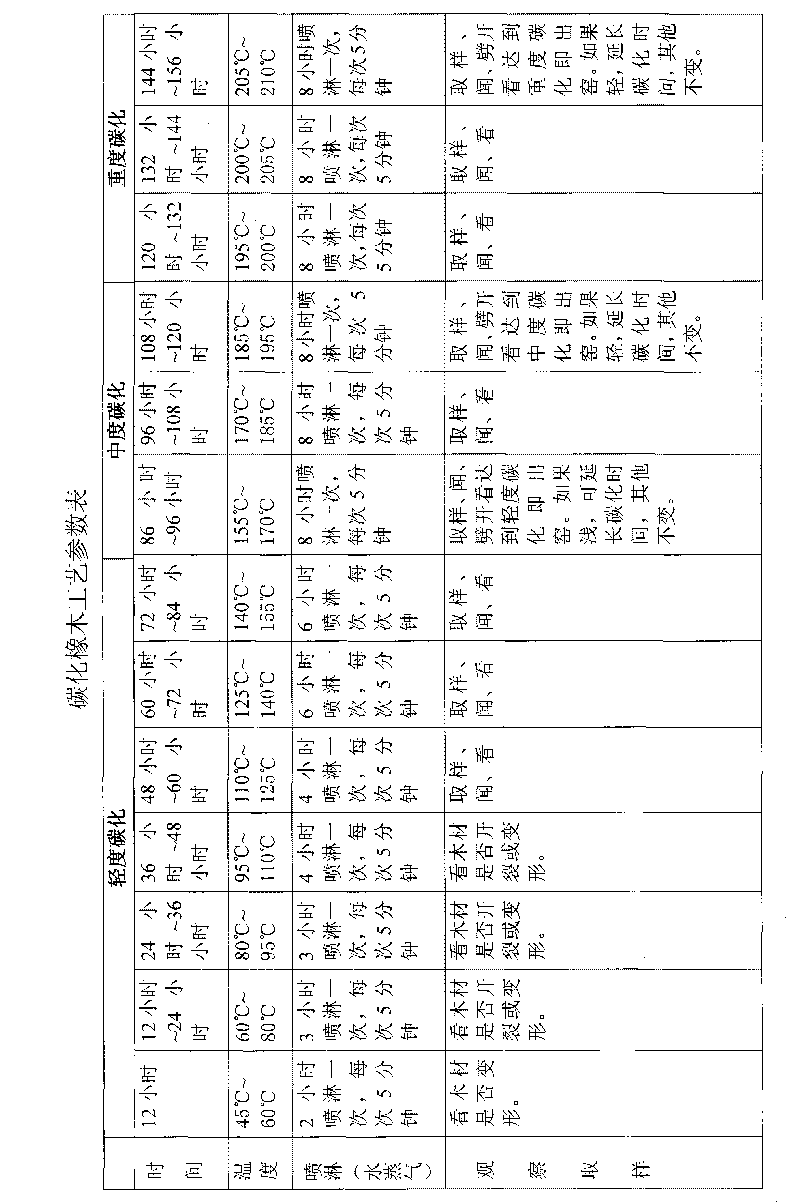

[0017] The manufacturing process of oak wine barrels of the present invention includes the following steps:

[0018] Step 1: Choose high-quality oak, remove the core material and surface material of the wood by diameter cutting, and leave the intermediate material to be processed into boards of different specifications;

[0019] Step 2: Dry the processed boards naturally in the open air, and when the wood reaches about 20% moisture, put it into the drying kiln for initial drying. The initial drying is generally after 18 days when t...

Embodiment 2

[0025] Example 2: Combination figure 1 The carbonized oak wine barrel and its production process of the present invention adopt infrared electric heating overall carbonization technology to make the oak carbonization degree uniform from the inside to the outside, ensure the pure and stable taste of wine storage, and the carbonized oak tube has been closed to inhibit wine penetrate. The carbonized oak wine barrel of the present invention can be stored for a long time before or after the wine is stored without deformation or cracking, which ensures the exquisite craftsmanship of the oak wine barrel when it leaves the factory and has more collection value. The invention solves the problem of converting the original partial and surface carbonization of the oak wine barrel into full carbonization (from the inside to the outside), and comprehensive deep carbonization, so that the wood never rots and the utilization rate is 100%. The invention makes the moisture content of the oak wi...

Embodiment 3

[0026] Example 3: Combination figure 1 The carbonized oak wine barrel of the present invention is a barrel shaped like a drum that can be used for filling, storing (improving the quality of wine), and holding wine. It is made of pure natural oak. Oak contains tannins, total phenols, dry leaching, eugenol, methyl caprolactone, and galactan, which can enrich the taste of wine, improve the quality of wine, and add carbonized The oak removes the odor and enriches the aroma of wine. It is the best irreplaceable container for wine storage for hundreds of years. It consists of a barrel body, two barrel plugs, barrel collars, barrel racks, barrel plugs and wooden valves. Pull up the wine stopper and put the wine into the barrel, and turn the wooden valve to the open position to put the wine. Wine storage capacity is 0.5L~225L. The core of the invention is the barrel body, and the barrel plugs are all made of carbonized oak. Carbonized oak wine barrels have a pure taste for wine stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com