Collagen fiber stuffing product and processing method thereof

A collagen fiber and product technology, which is applied in the field of fiber filler products, can solve the problems of inability to prepare and have no implementability, and achieve the effects of high static stability, environmental protection, and high wind resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

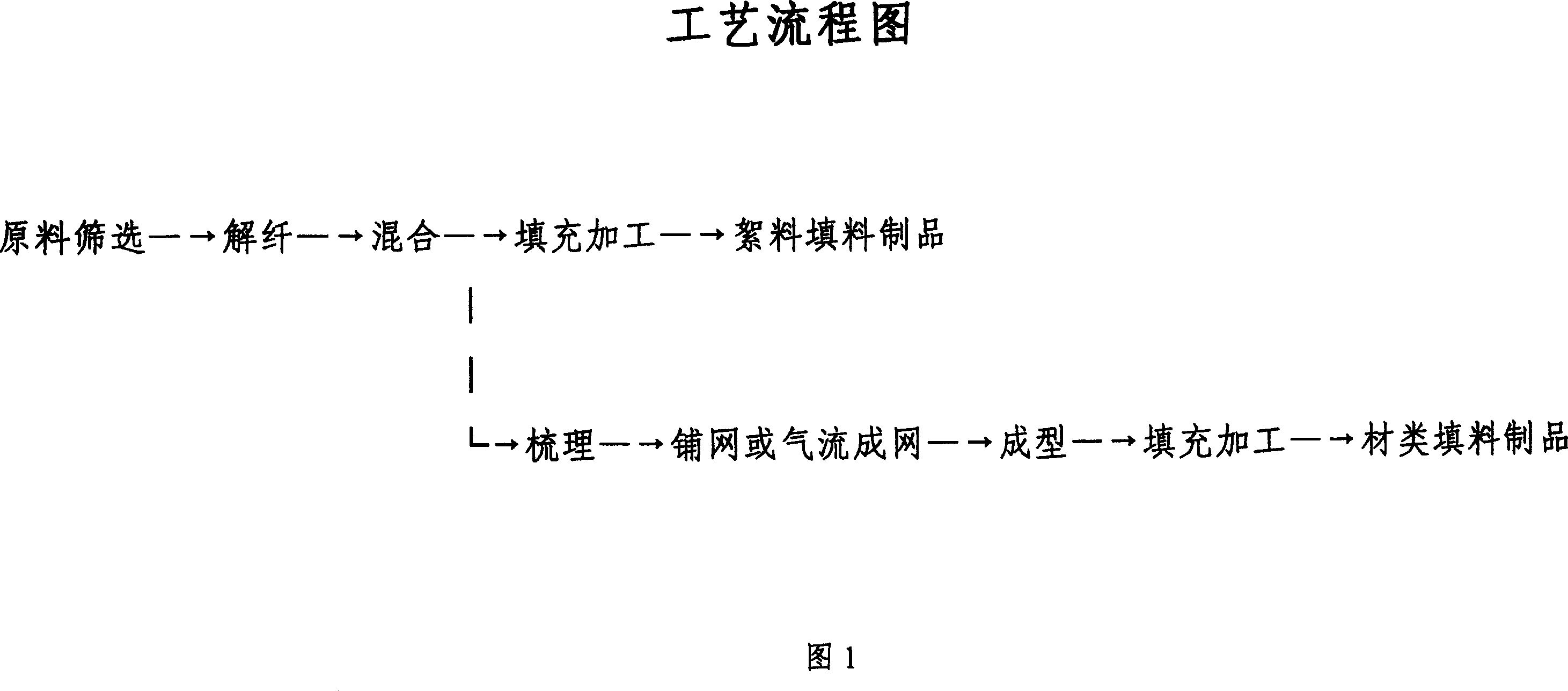

[0035] Process flow: raw material screening - defibrillation - mixing - flocculation filler - filling processing

[0036] Process description

[0037] 1. Raw material screening: select at least one of all animal leathers such as tanned cattle, sheep, horses, pigs, dogs, deer, rabbits, crocodiles, snakes and their leftovers and waste leather products.

[0038]2. Defibering: A reciprocating liquid opener is used for defibration. The liquid opener may be equipped with at least one beater for opening equipment and / or a carding device for a carding machine in the container. The liquid used in the liquid opener is water, according to the different raw materials of leather, 0.2-2% detergent, 1-10% oil and its products, 0.2-1.5% penetrating agent and 0.03-0.5% alkali can be added according to the weight of water. At least one method is to fully immerse the liquid in the raw material, so that the interfibrous interstitial matter between the collagen fibers becomes a lubricant again un...

Embodiment 2

[0042] Process flow: raw material screening - defibrillation - mixing - carding - laying net - forming - material filler - filling processing

[0043] Process description

[0044] 1, 2, 3 steps are identical with embodiment 1

[0045] 4. Comb. The mixed fibers are combed into a web by a carding machine.

[0046] 5. Laying net: use the existing technology of net laying machine or air-laid machine, and carry out net laying according to different thickness requirements.

[0047] 6. Forming: the existing non-woven process is processed by mechanical reinforcement method or chemical bonding method or thermal bonding method.

[0048] 7. Filling processing. Fill the above-mentioned material fillers between various fabrics and linings by cutting to make stuffing products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com