Lithium/polyparrole secondary button cell and its preparation method

A button battery, polypyrrole technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as difficulty in peeling positive electrode materials and electrodes, unsuitable for large-scale industrial production, etc., and achieve easy industrial production and high discharge capacity. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

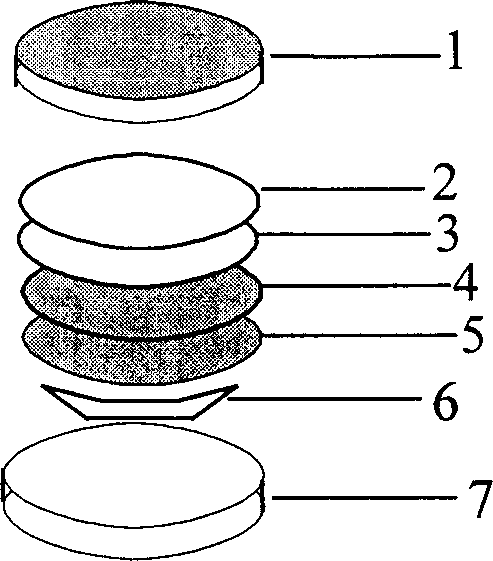

[0034] The preparation process of lithium / polypyrrole secondary button cell is as follows:

[0035] · Preparation of positive electrode active material:

[0036] The positive active material is polypyrrole / silicon dioxide nanocomposite. The material adopts the material provided in the 01136948.5 patent application.

[0037] · Preparation of positive electrode sheet 4:

[0038] Mix 1 gram of polypyrrole / silicon dioxide nanocomposite material obtained by the above method with 0.05 gram of conductive carbon black with a particle size of 33nm, 0.1 gram of adhesive polyvinylidene fluoride and 10ml of N-methylpyrrolidone (NMP), and make it easy to coat The coated slurry is coated on the collector (aluminum foil with a thickness of 0.015mm), put in a vacuum oven at 50°C and dried for 1 hour, take it out, punch it into a disc, put it in a vacuum oven at 50°C, and bake for 24 Take it out in 1 hour; then, cut it, pressurize 10MPa to shape it, so that the thickness of the positive ele...

Embodiment 2

[0044] After the prepared slurry is coated on the collector, put it in a 50°C vacuum oven to dry for 1.5 hours, take it out, punch it into a disc, put it in a 50°C vacuum oven, bake it for 24 hours and take it out; Carry out cutting, pressurize 20MPa and set the shape, make the thickness of the positive electrode sheet be 0.15mm, weigh, and finally store in a vacuum for future use. Others are with embodiment 1.

Embodiment 3

[0046] After coating the prepared slurry on the collector, put it in a vacuum oven at 50°C to dry for 2 hours, take it out, punch it into a disc, put it in a vacuum oven at 50°C, bake it for 24 hours and take it out; then, Carry out cutting, pressurize 30MPa finalize shape, make the thickness of positive electrode sheet be 0.1mm, finally store in vacuum, standby. Others are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com