Corrugated tray bridge adopting toothed multi-pole T-type joint projection welding

A multi-pole, corrugated technology, applied in the direction of electrical components, etc., can solve the problems that hinder the production and technological progress of high-strength topology thin-plate cable trays, and achieve the effects of no deformation, reduced production costs, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

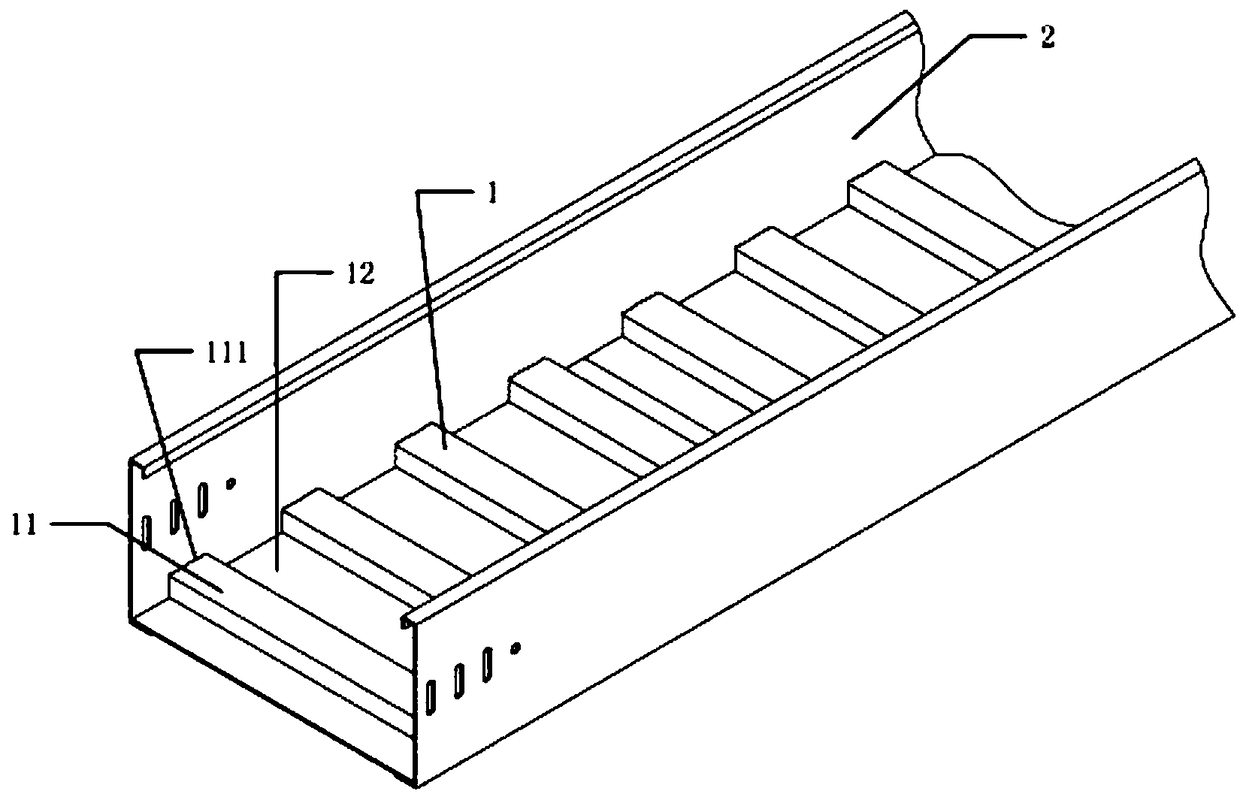

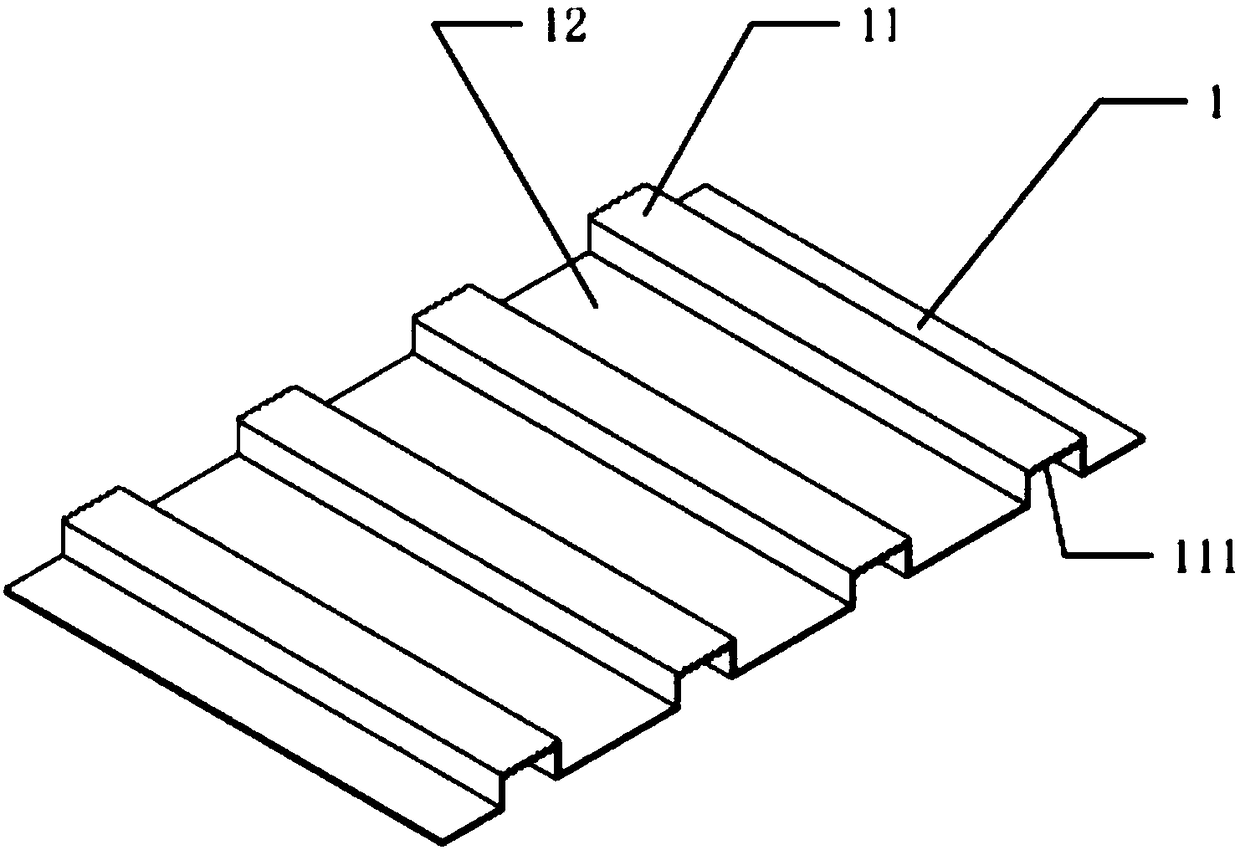

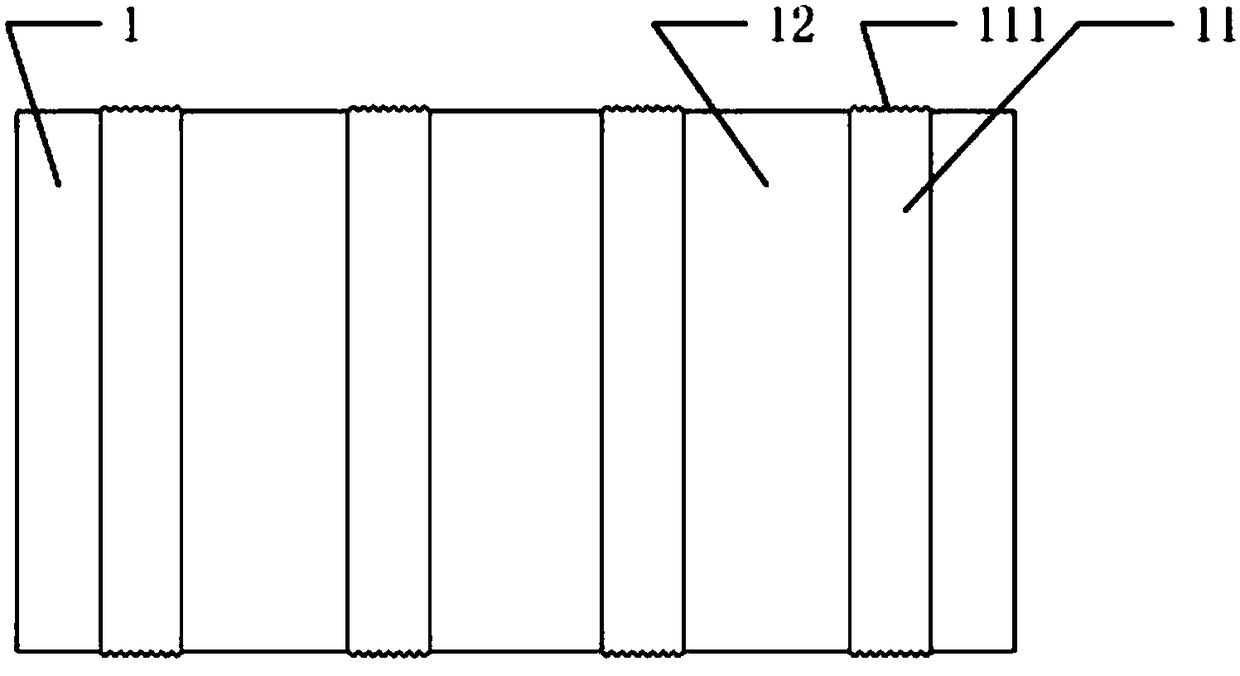

[0020] A corrugated pallet bridge adopting tooth-shaped multi-pole T-shaped connection projection welding of the present invention includes a bottom plate 1, bottom plate protrusions 11, bottom plate protrusion end face tooth shapes 111, bottom plate grooves 12, and side plates 2; the bottom plate protrusions 11 The bottom plate 1 is continuously arranged at intervals from the bottom plate groove 12 to form a corrugated shape, and a plurality of convex points are respectively provided on the two sides of the bottom plate protrusion 11 to form a tooth shape 111 on the end surface of the bottom plate protrusion. The bottom plate protrusions on both sides of the bottom plate 1 The end tooth profile 111 is welded to the side plate 2 of the bridge to form the corrugated pallet bridge. On both sides of the corrugated bottom plate 1 corresponding to the parts to be welded, a plurality of bumps are provided to form tooth profiles 111 on the raised end surface of the bottom plate.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com