Preparation method of emulsified hotpot seasoning

A technology for hot pot base material and slag, which is applied to the field of preparation of emulsified hot pot base material, can solve the problems that the effective components of the hot pot base material cannot be fully utilized, the flavor of the base material is unstable, and is not easy to quantitatively weigh, and the like. The effect of low production cost and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

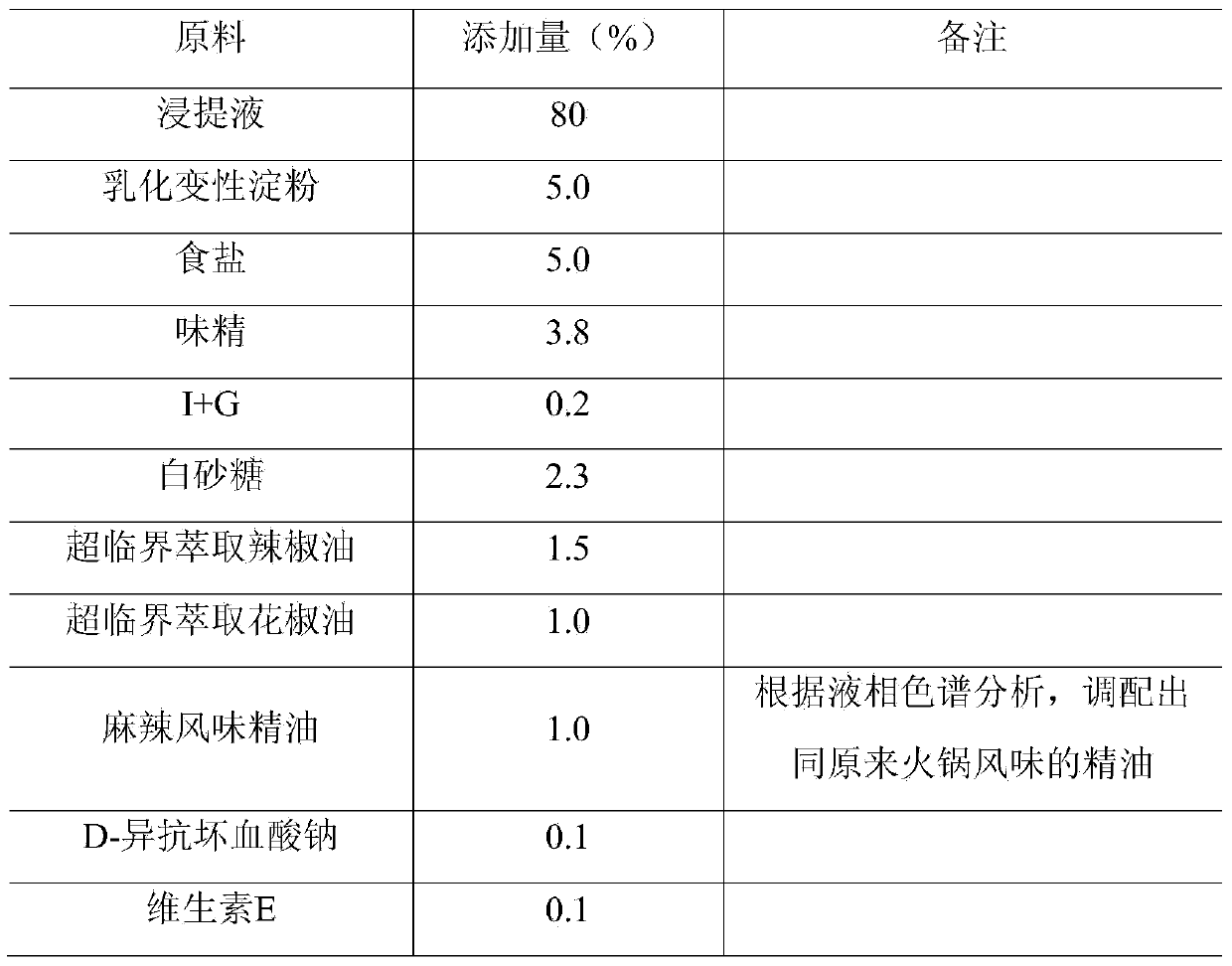

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following examples.

[0023] A kind of preparation method of emulsified chafing dish bottom material involved in the present embodiment, the steps are as follows:

[0024] 1. Raw material separation

[0025] The raw material for producing the emulsified hot pot bottom material is the normally fried hot pot bottom material. The red oil in the original hot pot bottom material can be separated by a 40-80 mesh centrifugal filter. The separated red oil is directly packaged. For the bottom material without red oil, such as sauerkraut bottom material, it is directly crushed, and the hot pot red oil is separated from the slag for use. Using a centrifugal filter, the filtration speed of the product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com