Patents

Literature

61results about How to "Dry shrinkage is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and insulated wallboard

ActiveCN102249641ASolve insulation problemsSolve fire resistanceSolid waste managementCement mortarStearate

A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover, and an insulated wallboard solve technical problem in a prior art that self-leveling cement mortar with weak waterproofness causes weak insulation effect of an insulated wallboard. A self-leveling cement mortar dry powder for insulated composite wallboard waterproof cover is employed as a technique. Ingredients of the self-leveling cement mortar dry powder comprise a compound impervious component; and the impervious component is prepared by mixing a redispersible high-molecular polymer and one of an organosilicon waterproof agent and a stearate, or a mixture of the two, and accounts for 0.6-4.3wt% of the self-leveling cement mortar dry powder. A special impervious ingredient is added to enhance compactness, microdilatancy and low dry shrinkage property of the cement based self-leveling mortar, so as to substantially increase waterproof function and endurance of the cement based self-leveling mortar. Therefore, a problem that a cladded super-light foaming cement sheet material loses insulation function due to water penetration and problems of flame resistance and endurance are solved fundamentally.

Owner:TANGSHAN POLAR BEAR BUILDING MATERIAL

High-flexibility and low-shrinkage fiber reinforced cement-based composite material

The invention belongs to the technical field of building materials, and in particular relates to a high-flexibility and low-shrinkage fiber reinforced cement-based composite material. The composite material is prepared by mixing cement, coal ash, silicon powder, gypsum, an expanding agent, a water reducing agent, a shrinkage reducing agent, a defoaming agent, a thickening agent, fine sand, fibers and water, wherein the total mass percentage of the cement, the coal ash, the silicon powder, the gypsum, the expanding agent, the water reducing agent, the shrinkage reducing agent, the defoaming agent, the thickening agent, the fine sand and the fibers is 77-85 percent, and the mass percentage of the water is 15-23 percent. The fiber reinforced cement-based composite material has the performance characteristics of low shrinkage, high flexibility, small crack width, quickness in condensation and early strength and is high in compressive strength and good in synergism with other materials.

Owner:TSINGHUA UNIV

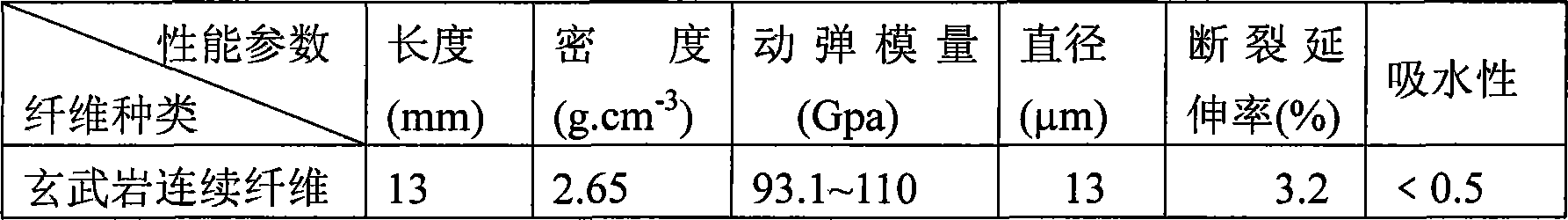

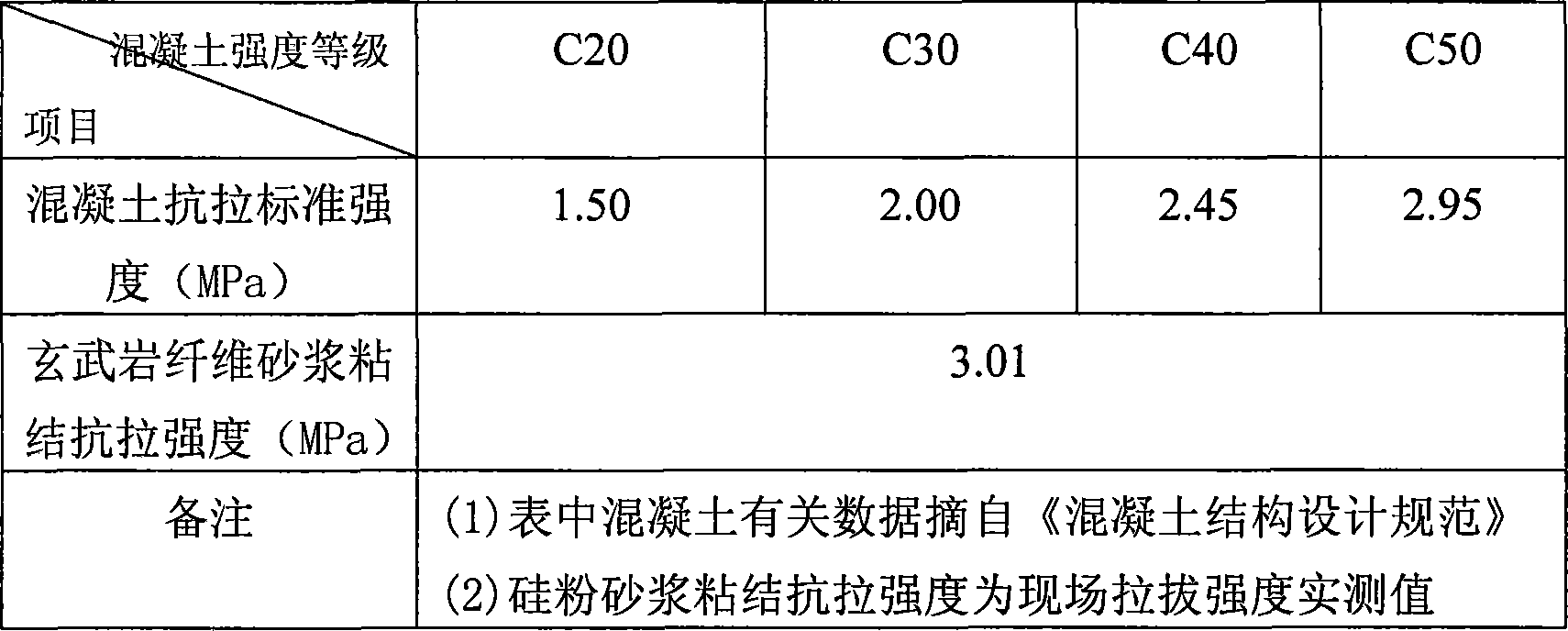

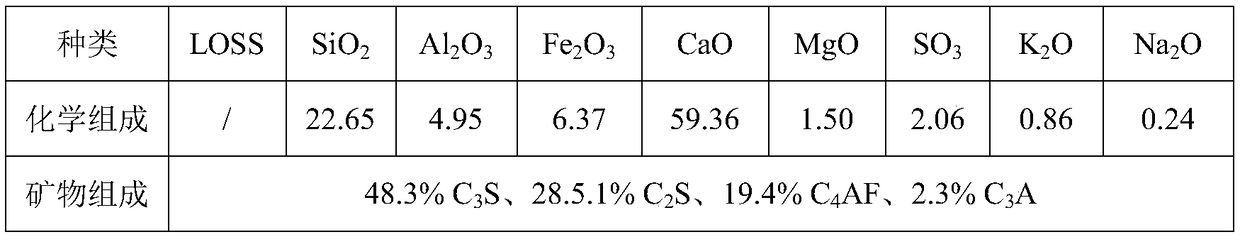

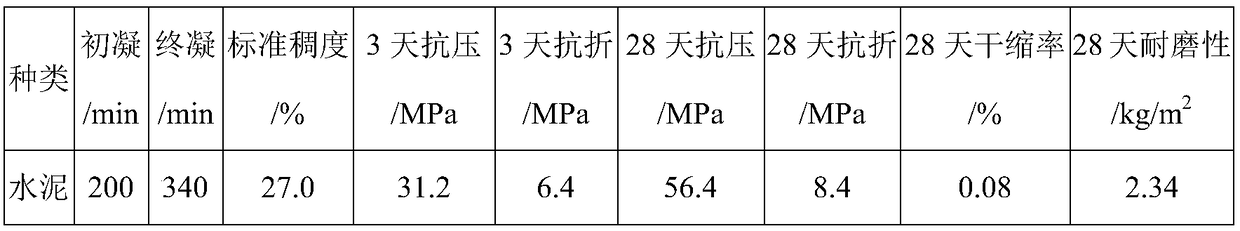

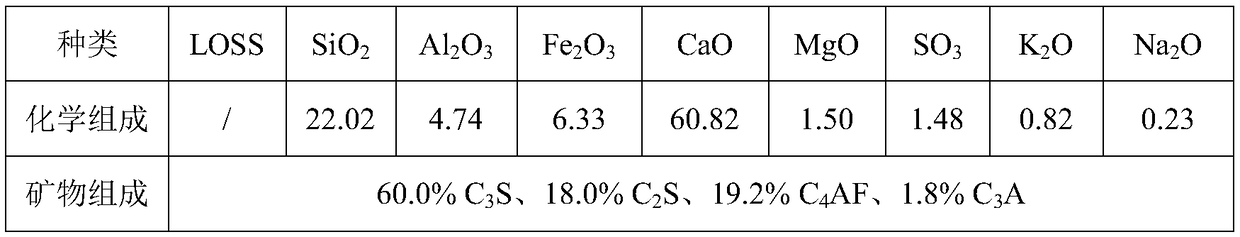

Method for rehabilitating concrete surface injury using high-strength abrasion-proof basalt fibre mortar

InactiveCN101235673AHigh tensile strengthHigh modulus of elasticityBuilding repairsHydraulic engineering apparatusAnti freezingHydraulic structure

The invention discloses a process for repairing the surface wounds of concrete with basalt fiber plaster which is high strength and abrasion resistance. The repairing steps comprise firstly conducting chiseling, cleaning and curing moisture holding for the repair surface, and then brushing binding agent on the repair surface, then brushing basalt fiber plaster after slightly drying, and finally conducting the curing. The invention primarily proposes a process for repairing the large area wound such as surface concrete aging, carbonizing and peeling and cracking and the like on the hydraulic structure such as locks, dams and bridges and the like through preparing basalt fiber plaster which is high strength and abrasion resistance with chopped basalt fiber. The experiment shows that the surface concrete of hydraulic structure which is repaired has excellent mechanic property, impact abrasion resistance and excellent durability such as permeability resistance and anti-freezing, and favorable binding property, can meet the technical requirements of high speed sand inclusion current abrasion and corrosion resistance and ship attack and the like. And the repairing process has simple technology, low cost and excellent effect.

Owner:HOHAI UNIV

Preparation method of activated adsorbent and application of prepared activated adsorbent

ActiveCN104587954AImprove adsorption capacityLight weightOther chemical processesWaste water treatment from metallurgical processSorbentStrong acids

The invention relates to the technical field of activated adsorbents and application thereof and in particular relates to a preparation method of an activated adsorbent and application of the prepared activated adsorbent. The preparation method of the activated adsorbent comprises the following steps: 1) carrying out hydrothermal reaction; and 2) carrying out activation treatment. The preparation method of the activated adsorbent has the advantages that diatomite and coal ash are mainly adopted as basic materials, and roasting is carried out, so that the specific area is greatly increased, and the adsorption property is greatly improved; a surfactant is added, so that the adsorption property is further improved; a heavy metal adsorption principle adopts ion exchange, heavy metal can be recycled, the adsorbent can be regenerated, and the activated adsorbent can be widely applied to severe environments such as deeply polluted and strong acid and strong alkali waste water or can be applied to remediation of heavy metal polluted soil; and compared with the prior art, the activated adsorbent has the advantages that the capability of adsorbing heavy metals in electroplating wastewater is greatly improved, the investment is low, the cost is low, copper, chromium and nickel can be recycled, and the adsorbent can be regenerated, so that a huge economic benefit is produced, and a soil remediation effect is also significant.

Owner:INNER MONGOLIA PURUIFEN ENVIRONMENTAL SCI ANDTECH

Road delayed-coagulation cement and preparation method thereof

InactiveCN108726904AReduce consumptionReduce calcination temperature and liquid phase viscosityCement productionResource utilizationEconomic benefits

The invention relates to road delayed-coagulation cement and a preparation method thereof. The road delayed-coagulation cement comprises special cement clinker, limestone waste, modified steel slag powder and phosphorus gypsum. According to the road delayed-coagulation cement, a cement raw material is prepared from carbon-containing shale, the phosphorus gypsum serves as mineralizing agents of clinker calcination, steel slag powder is prepared in a crushing, iron removing and grinding manner, the steel slag powder and the limestone waste serve as cement admixtures, and the phosphorus gypsum serves as a cement delayed coagulant. By the aid of the technical scheme, the prepared road delayed-coagulation cement has the advantages that coagulation time is suitable, early strength is high, laterstrength is rapidly increased, breaking strength is high, abrasion resistance is good, dry shrinkage performance is low and the like. Efficient resource utilization of solid waste such as the carbon-containing shale, the limestone waste, steel slag and the phosphorus gypsum is achieved, and the road delayed-coagulation cement has important economic benefits and social benefits.

Owner:GEZHOUBA SONGZI CEMENT

Semi-flexible pavement injection grout

InactiveCN101693611AImprove road performanceExtended service lifeIn situ pavingsRoad surfaceUltimate tensile strength

A semi-flexible pavement injection grout is characterized in that the semi-flexible pavement injection grout comprises the following raw materials by mass percentage: 54.0064-65.6958 percent of common silicate cement, 33.1-37.3 percent of water, 0.001-0.662 percent of water reducing agents, 0-7.944 percent of plumping agents and 0-0.8028 percent of air entraining agents. By employing the semi-flexible pavement injection grout for construction, the grout can be easily poured into the clearances of asphalt mixtures and well combined with the asphalt mixtures. The semi-flexible pavement injection grout of the invention has small dress shrinkage and strong intensity, which can improve the road performance of semi-flexible pavement and prolong the life time of the semi-flexible pavement.

Owner:CHANGAN UNIV

Basalt fiber composite reinforcement concrete and preparation method thereof

The invention discloses basalt fiber composite reinforcement concrete and a preparation method thereof to mainly solve the problems of low strength, easy aging and poor compounding with concrete in the existing concrete. The basalt fiber composite reinforcement concrete comprises basalt fiber composite reinforcement and concrete, wherein the basalt fiber composite reinforcement is a fiber reinforcement material formed by surface treatment of basalt fibers, impregnation of composite resin and solidification; and the concrete comprises the following components: basalt short fiber, fly ash, clay,mountain gravel, quartz gravel medium sand, a water reducing agent, a zirconate coupling agent, and silicate cement. Through the above scheme, the basalt fiber composite reinforcement concrete provided by the invention achieves the purposes of good compounding between the basalt fiber composite reinforcement and concrete, and high strength, light weight and difficult aging of the basalt fiber composite reinforcement, and has very high practical and popularization values.

Owner:成都天府轨谷科技有限公司

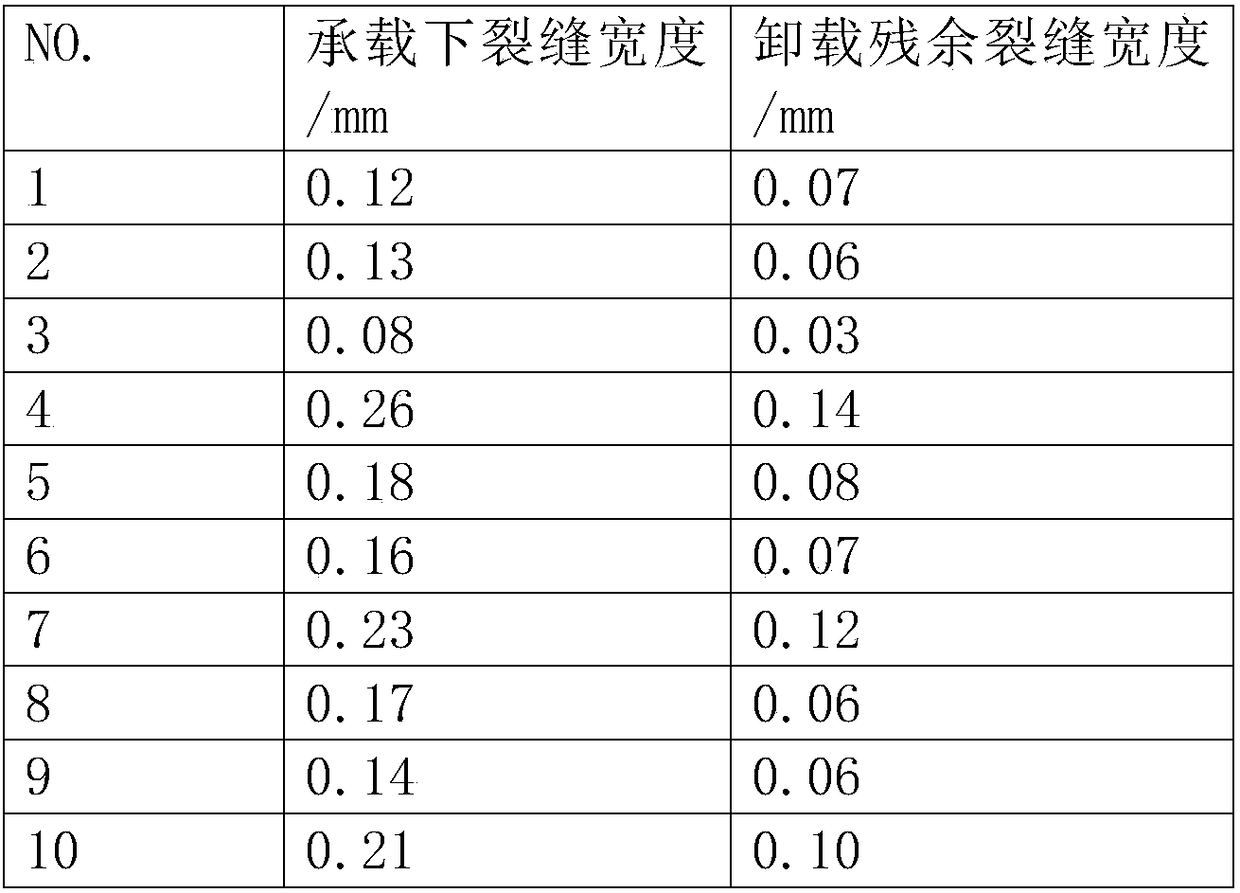

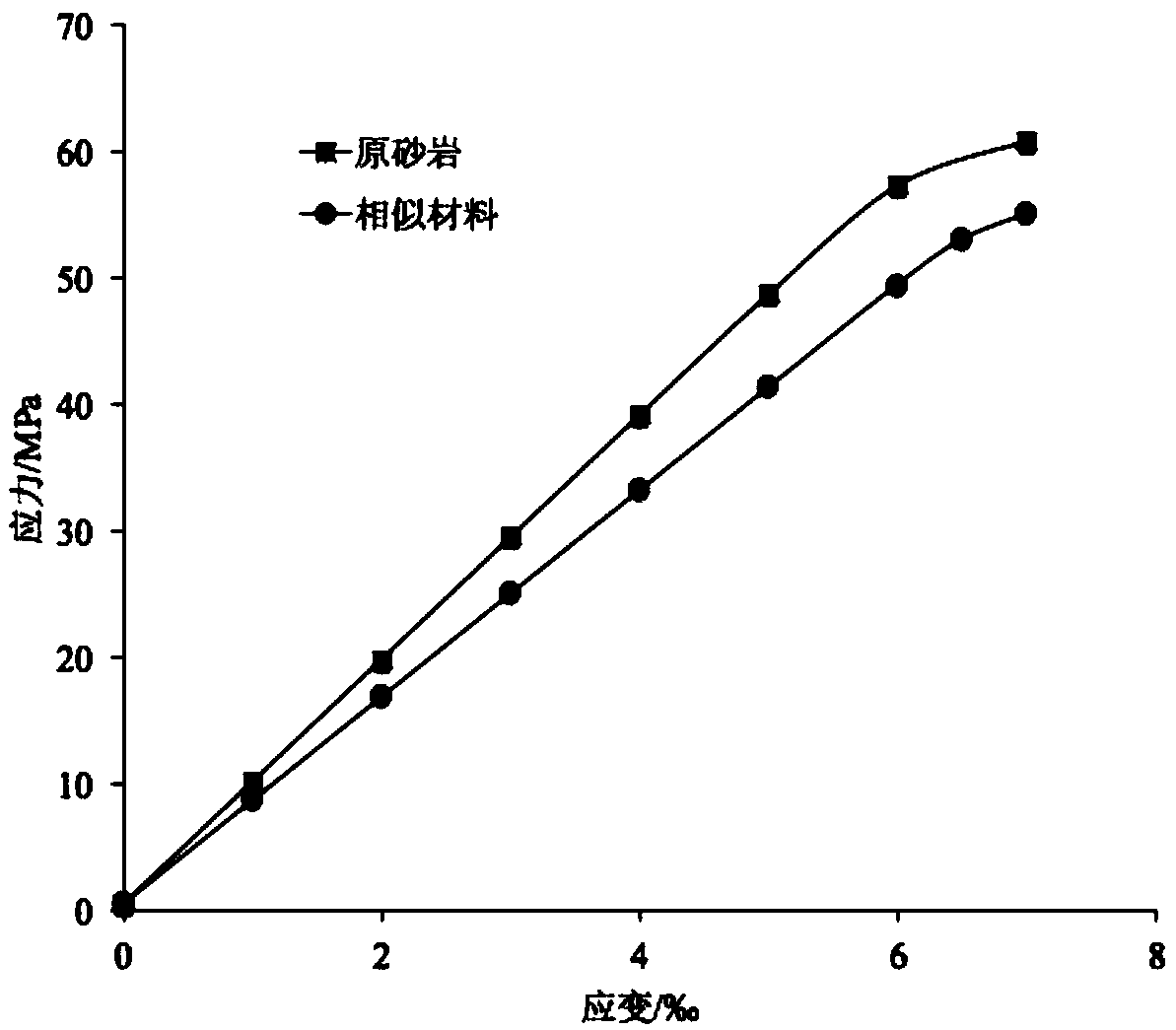

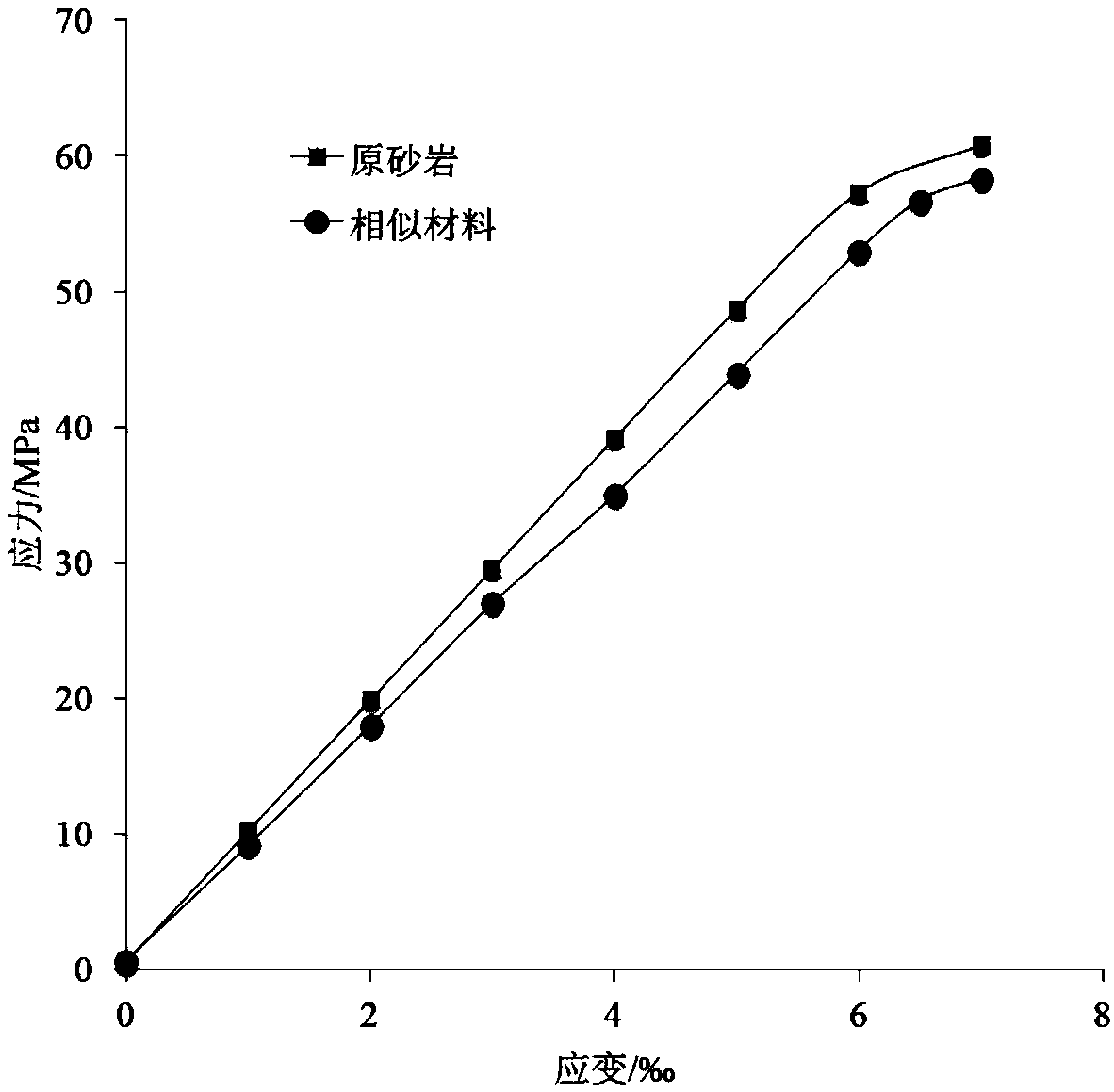

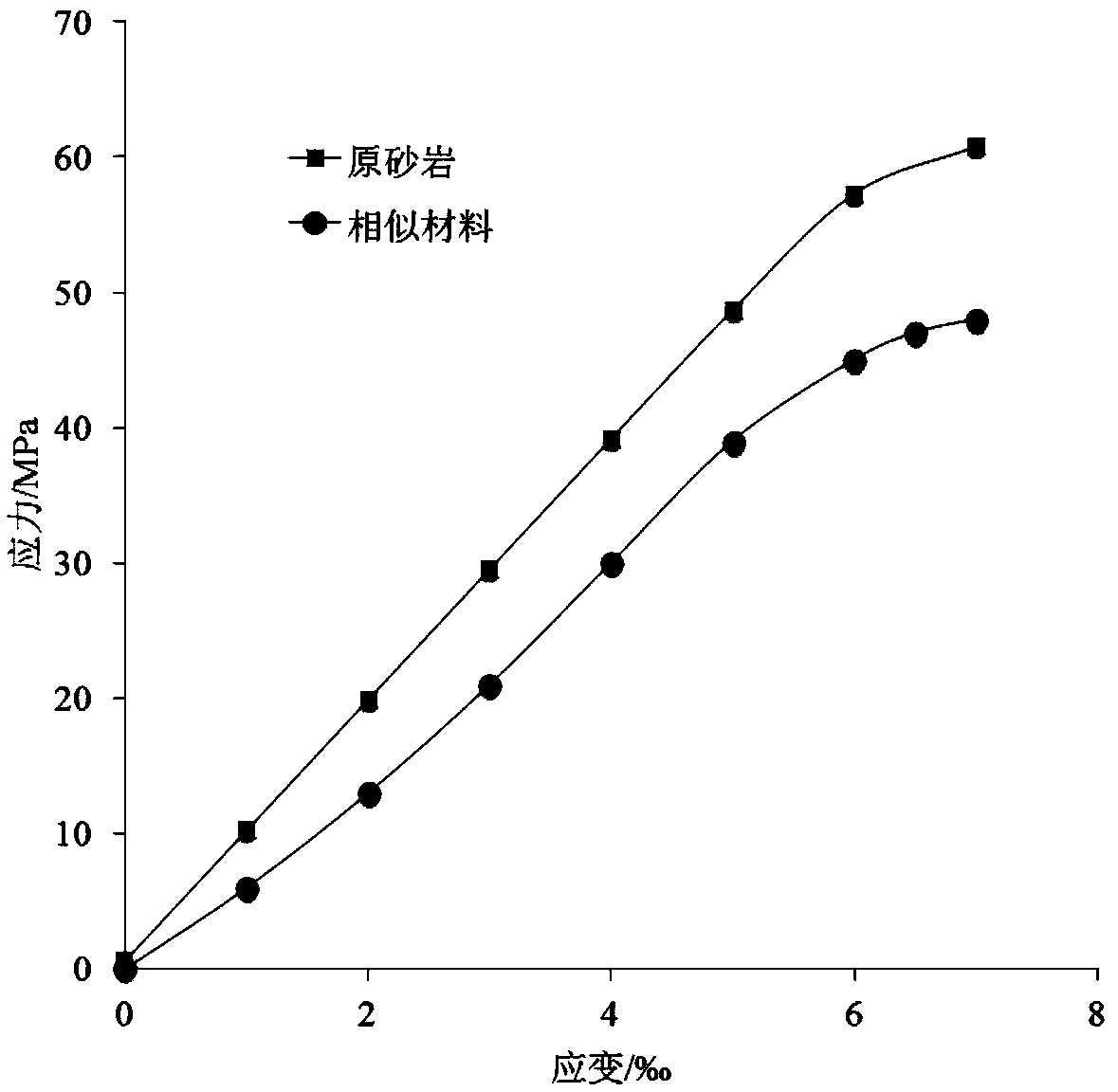

Sandstone similar material and preparation method thereof

InactiveCN109020364AImprove brittlenessHigh strengthSolid waste managementPreparing sample for investigationMechanical propertyWater reducer

The invention provides a sandstone high-strength high-brittleness similar material and a preparation method thereof. Raw materials comprise quartz sand, silicon powder, cement, distilled water and a water reducer. based on physical and mechanical properties and microscopic features of protolith, a method of regulating material properties by using aggregate is adopted, quartz sand is selected to improve brittleness of the material, and silicon powder is selected to raise strength of the material. Thereby, brittleness and strength of the sandstone similar material are achieved, and main physicaland mechanics parameters (density, elastic modulus, cohesion, internal friction angle, uniaxial compressive strength, tensile strength and Poisson's ratio, etc.) of the similar material and protolithmeet the similarity theory. Features of sandstone in rock slope of Xinjiang Tianshan highway are successively simulated. The types of required materials are less, and the cost is low. The manufactureefficiency is high. The material of the invention has wide practicality.

Owner:HUBEI ENG UNIV

Silicon dioxide aerogel mortar and preparation method thereof

The invention provides a silicon dioxide aerogel mortar and a preparation method thereof, belongs to the technical field of mortar preparation, and mainly relates to mortar and a preparation method thereof, which aim at solving the problem of failure to meet current actual requirements of mortar property in the prior art. The silicon dioxide aerogel mortar is prepared from the following components in parts by weight: 100 parts of cement, 300 parts of sand, 0.08 to 0.5 part of defoaming agent, 10 to 20 parts of silicon dioxide aerogel microsphere, 25 to 40 parts of ethyl acrylate emulsion, 0.02 to 0.1 part of polymer powder, and 5 to 7 parts of water. The silicon dioxide aerogel mortar has the advantages that the sticking property of whole cement mortar is improved, the tension strength, rapture strength and sticking durability are greatly improved, the dry shrinkage is decreased, the cracking is reduced, and the anti-freezing property and anti-seepage property are improved.

Owner:XINHUASHENG ENERGY SAVING TECH CO LTD

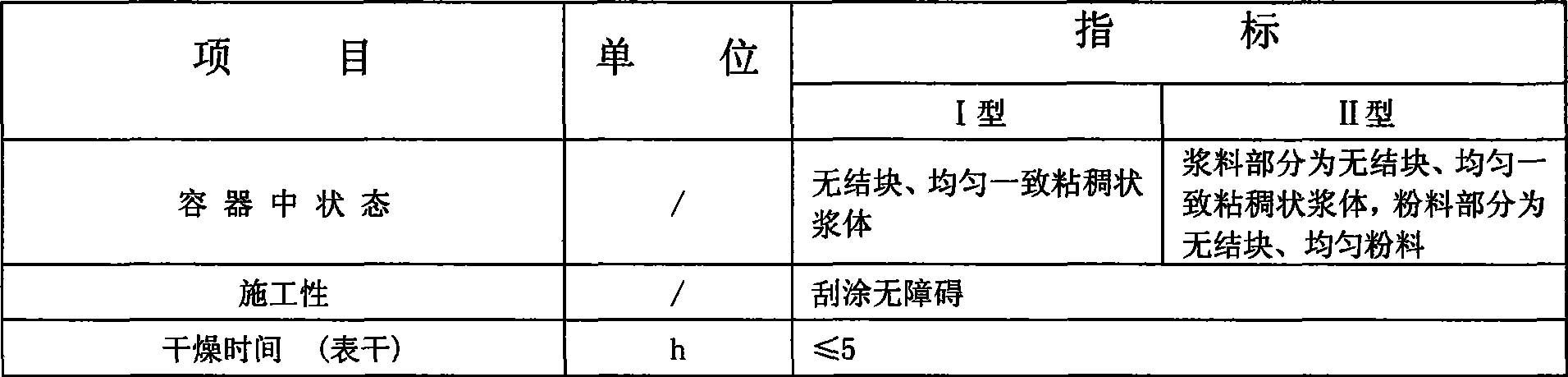

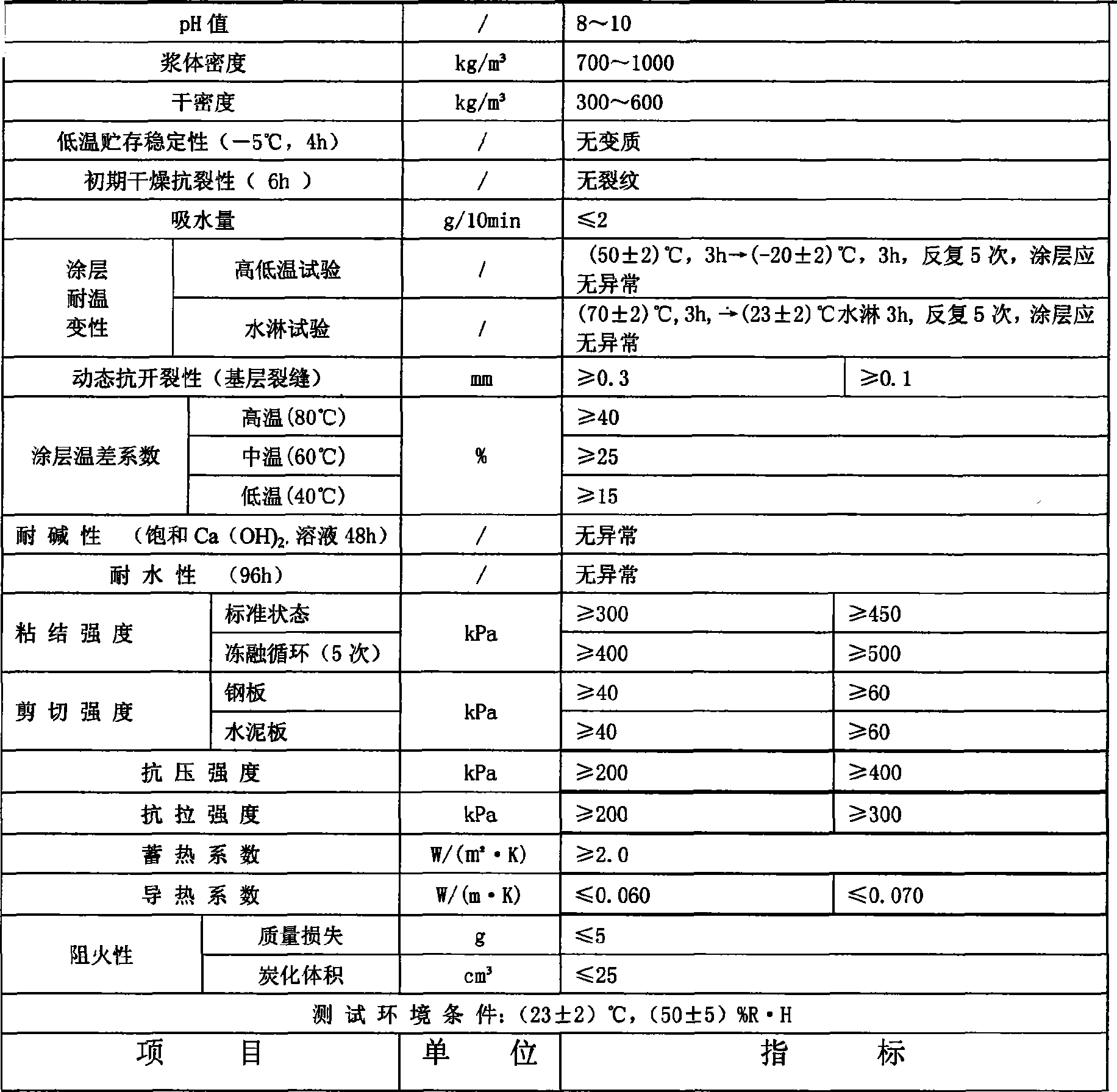

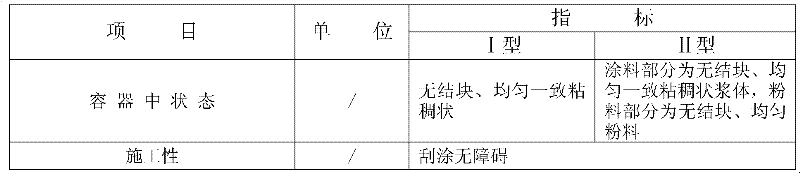

Microhollow super-fibre heat insulation coatings for building insulation and method of use thereof

InactiveCN101381546ACreate pollutionHealth hazardFireproof paintsCovering/liningsNoise removalThermal coefficient

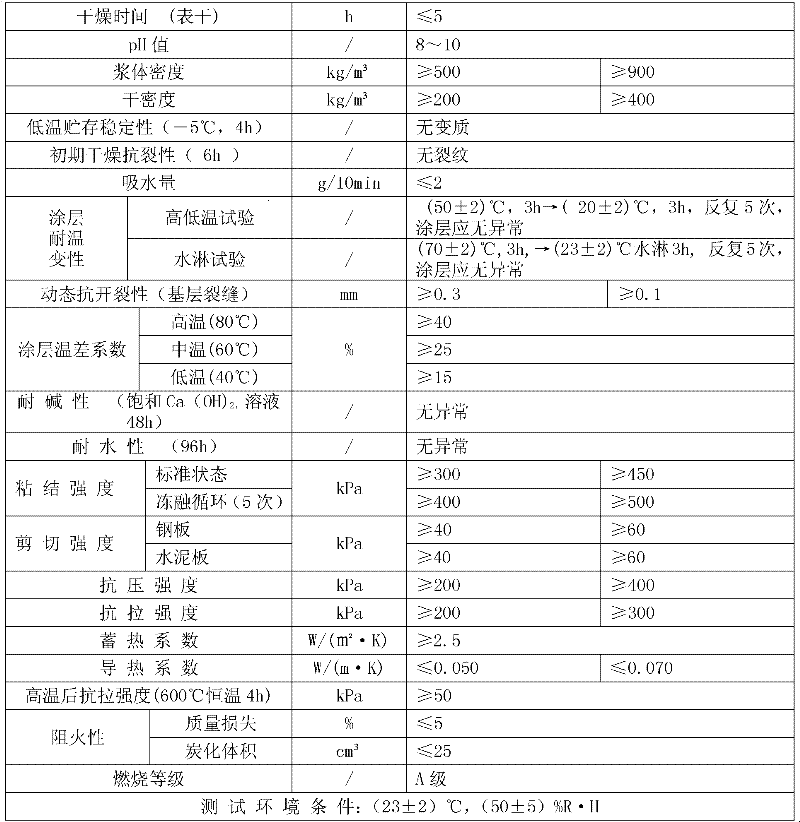

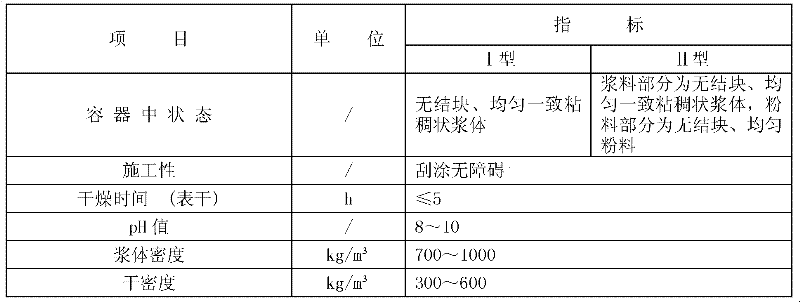

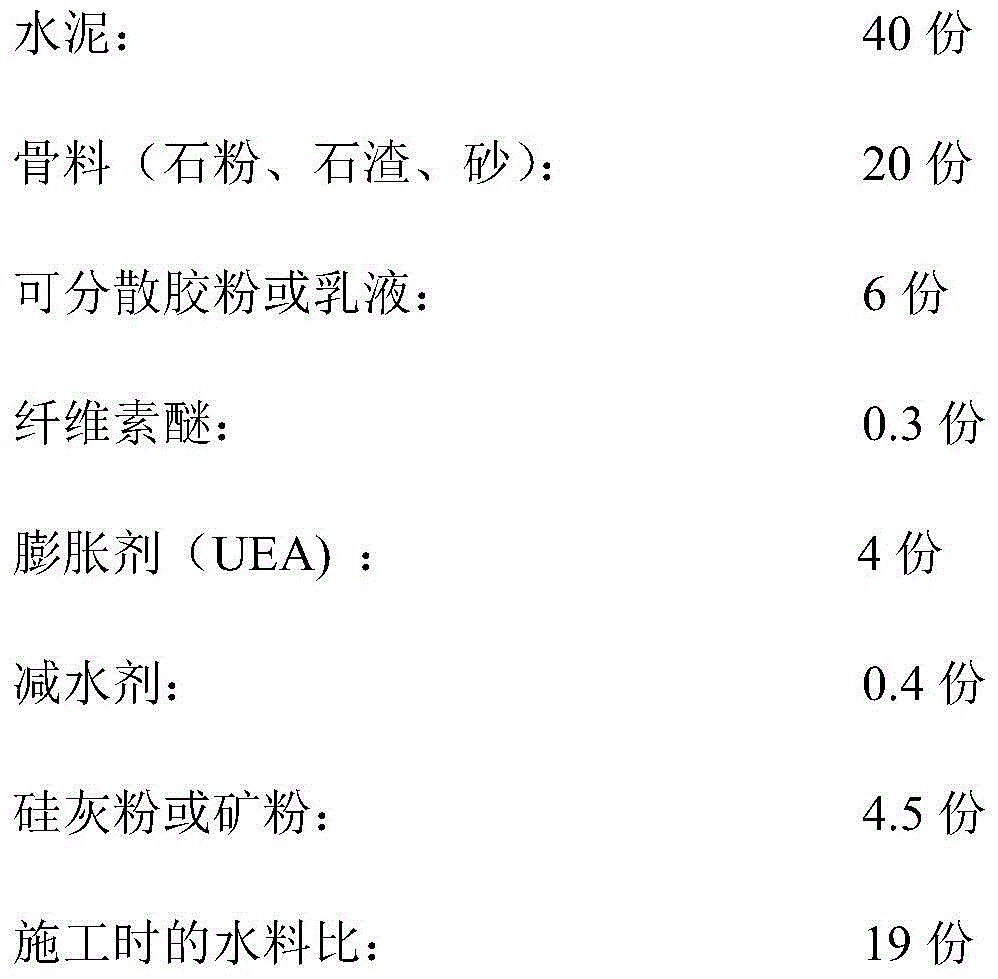

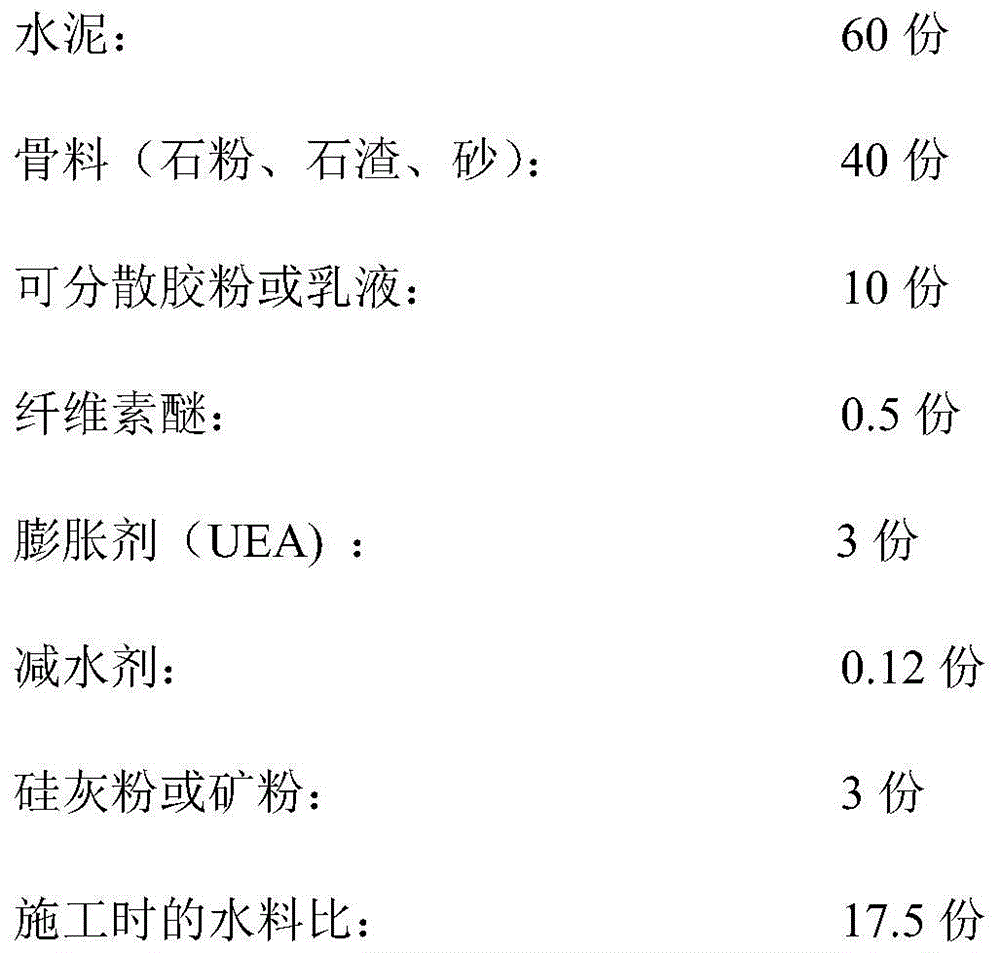

The invention provides a micro hollow fiber thermal insulating coating for buildings and an application method thereof. The micro hollow fiber thermal insulating coating for buildings is divided into a I-type single-component micro hollow fiber thermal insulating coating for buildings and a II-type double-component micro hollow fiber thermal insulating coating for buildings, and is used as an exterior wall thermal insulating coating or used to pipes and other various places needing coating the thermal insulating coating. The coating is added with super hollow fibers and aramid fibers with high-temperature resistance, acid and alkali resistance and light weight, so that the coating has the advantages of low thermal coefficient and heat storage coefficient, obvious heat retaining effect, nontoxic formula, environmental protection, excellent fire resistance, super-strong chemical stability, high cohesional strength, noise removal, high cost performance, long service life, wide application, simple and easy construction, good effect, labor and physical resource conservation, and obvious economic and environment-friendly benefits.

Owner:FUJIAN OUNUO PAINT TECH

Foamed concrete material and its application

InactiveCN1824623ALow costQuality improvementSolid waste managementCeramicwareFoam concreteFoaming agent

The present invention relates to a foam concrete material and its application. Its main ingredients are inorganic gelation material, filling material and concrete foaming agent. The described inorganic gelation material is cement and the filling material is stone powder or mineral powder, and the weight ratio of all the ingredients is: cement: filling material: foaming agent: water=30-60:30-60:0.5-2:20-50.

Owner:王亦德

High-performance microscopic microfiber building heat insulation and heat preservation slurry and using method thereof

ActiveCN102531465AReduce volumeLow thermal conductivityClimate change adaptationHeat proofingSlurrySilicon dioxide

The invention provides high-performance microscopic microfiber building heat insulation and heat preservation slurry with high tensile strength, compressive strength, heat insulation performance and tear resistance, and a using method thereof. The slurry comprises the following components of crylic synthetic resin, fluorinated silicone synthetic resin, a water retention thickening agent solution,a sepiolite fiber, a vermiculite fiber, a mullite fiber, powdered silicon dioxide, pearlife, a rock wool fiber, hollow ceramic microballs, a defoaming agent, a mildewproof bacteriacide and water; andfurthermore, white portland cement, a reinforcing agent and water which is 20 to 30 weight percent of a component A can be added.

Owner:FUJIAN OUNUOCHUANGNENG NEW MATERIAL TECH CO LTD

Foamed ceramic decorative plate and preparation method thereof

The invention provides a foamed ceramic decorative plate and a preparation method thereof.The surface of foamed ceramic is coated with decorative mortar to obtain an integral preformed part.After use of the foamed ceramic decorative plate, blade coating of walls or spraying of the decorative mortar is avoided, and accordingly convenience in operation is realized while engineering construction efficiency can be effectively improved.In addition, the service life of the foamed ceramic decorative plate is far longer than that of an organic coating or a plastic composite sheet, and the manufacturing cost of the foamed ceramic decorative plate is much lower than that of a stone composite board.

Owner:GUANGZHOU GOOMASTONE DECORATIVE MATERIAL CO LTD

Light compound thermal-insulation mortar

The invention discloses light compound thermal-insulation mortar. The light compound thermal-insulation mortar comprises the following components in parts by weight: 35-40 parts of cement, 8-12 parts of converter slag granules, 12-18 parts of a reinforced material, 16-22 parts of compound thermal-insulation aggregate, 0.25-0.35 part of resin type redispersible powder, 0.6-0.9 part of cold water type polyvinyl alcohol, 0.1-0.2 part of hydroxypropyl methyl cellulose, 0.01-0.03 part of air entraining agent, 0.06-0.1 part of water glass, 0.005-0.01 part of inorganic retarder, 8-13 parts of polyphenyl granules, 30-50 parts of glass beads and 0.2-0.5 part of concrete water-proofing agent. The light compound thermal-insulation mortar has the advantages that the cement is saved; meanwhile, the thermal-insulation aggregate is added, so that the mortar has a light effect; meanwhile, an thermal-insulation effect is enhanced; after the construction is finished, the mortar is unlikely to crack and fall and can effectively resist water and fire.

Owner:陈昊

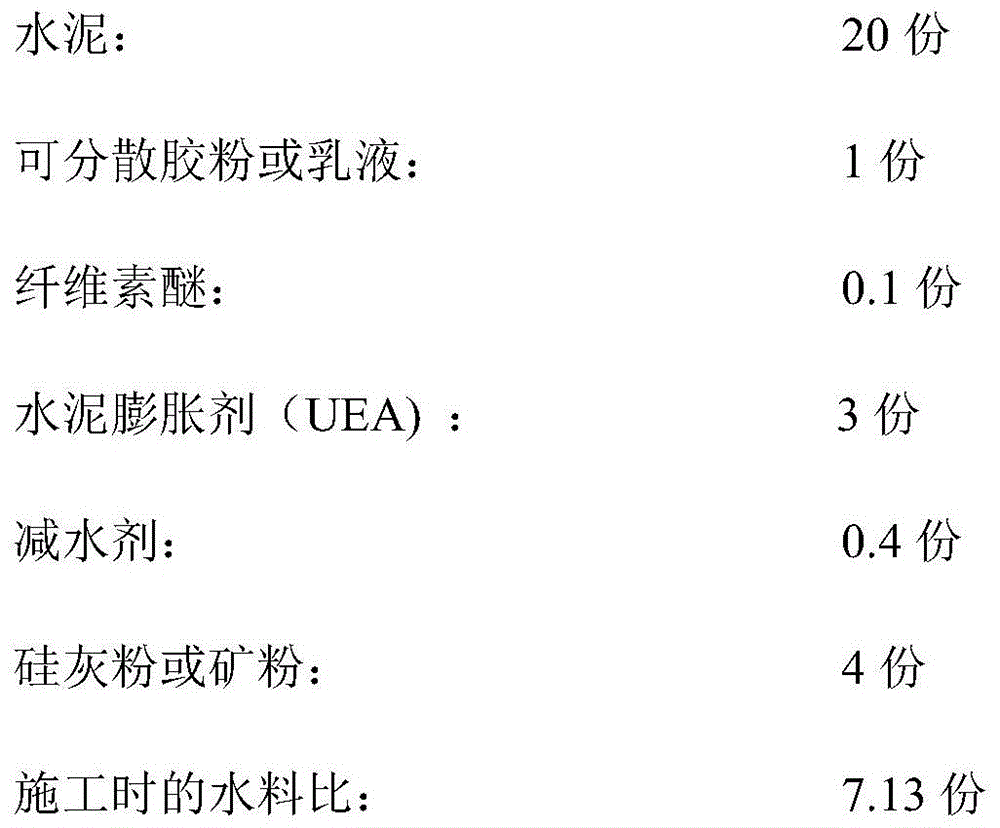

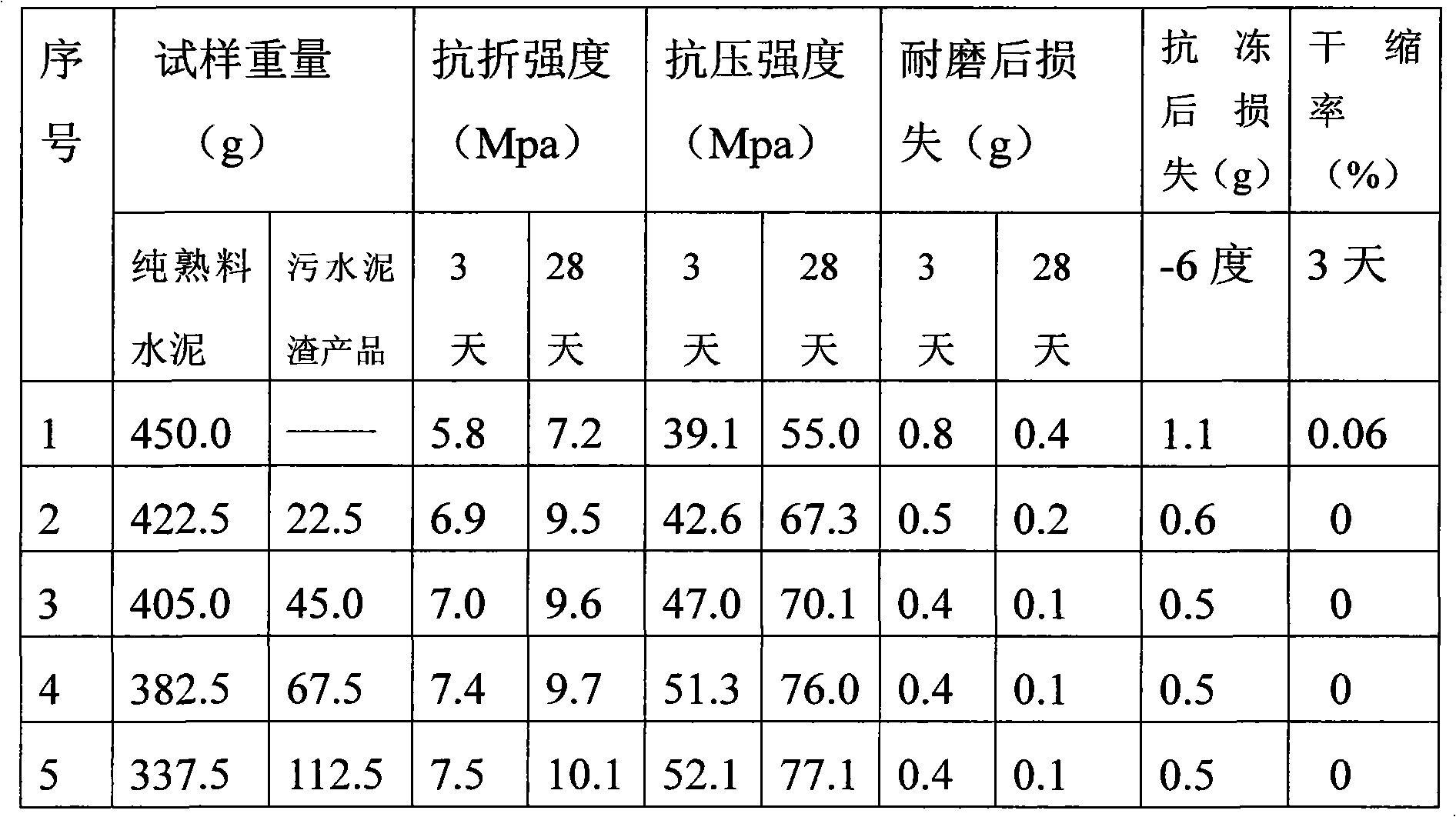

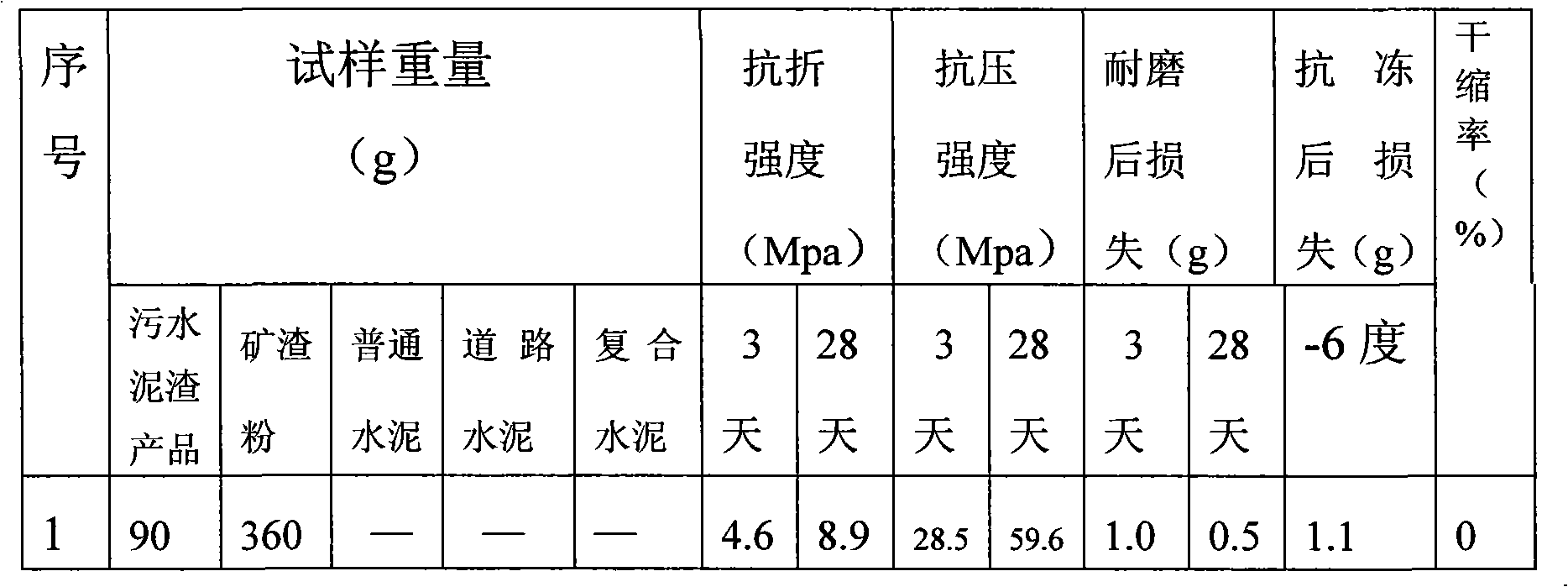

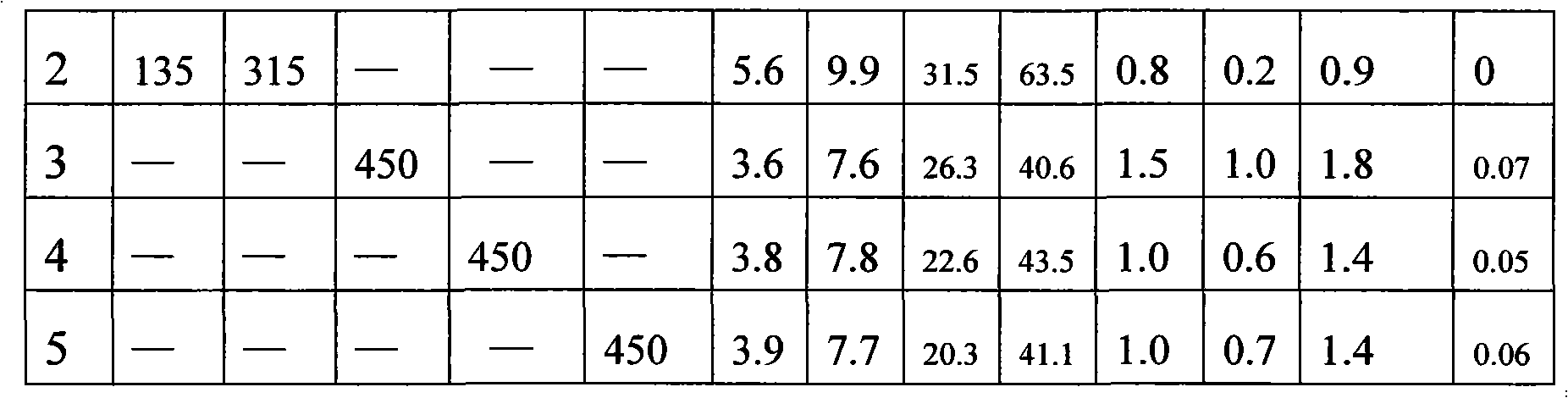

Sewage water body refuse type cement and method of preparing the same

InactiveCN101343149AGood dispersionImprove high dispersionSolid waste managementCement productionFrostAluminium salts

The invention relates to waste water sludge type cement, which is mainly mixed by cement and a product of waste water sludge. The product of waste water sludge is prepared by the method that waste water sludge, and acetylene gas slag or lime sludge, or waste water sludge, acetylene gas slag or lime sludge, bauxite slag, phosphogypsum or desulfurization gypsum, mineral slag and fly ash are in certain proportion with proper water to be added into a mixing and molding machine so as to be processed into nodules, after the nodules are naturally air dried into raw meal nodules, the raw meal nodules are dried and roasted, and the product of waste water sludge is prepared. Then the product of waste water sludge and cement clinker are mixed together in certain proportion to be ground into powder, that is, the waste water sludge type cement; or the product of waste water sludge is ground into powder, then the powder is mixed together with cement, and the waste water sludge type cement is formed. The product of waste water sludge can be mixed with pure clinker cement, and can be also mixed with other commercial cement. The method can process the waste water sludge, which is discharged from the waste water processing factories and is difficult to be processed, into high quality cement that has advantages of large demand, less investment, high wear-resisting strength, good frost resistance performance, small dry shrinkage performance, being favorable for environmental protection and reducing cost.

Owner:江苏金大地建材科学研究院有限公司

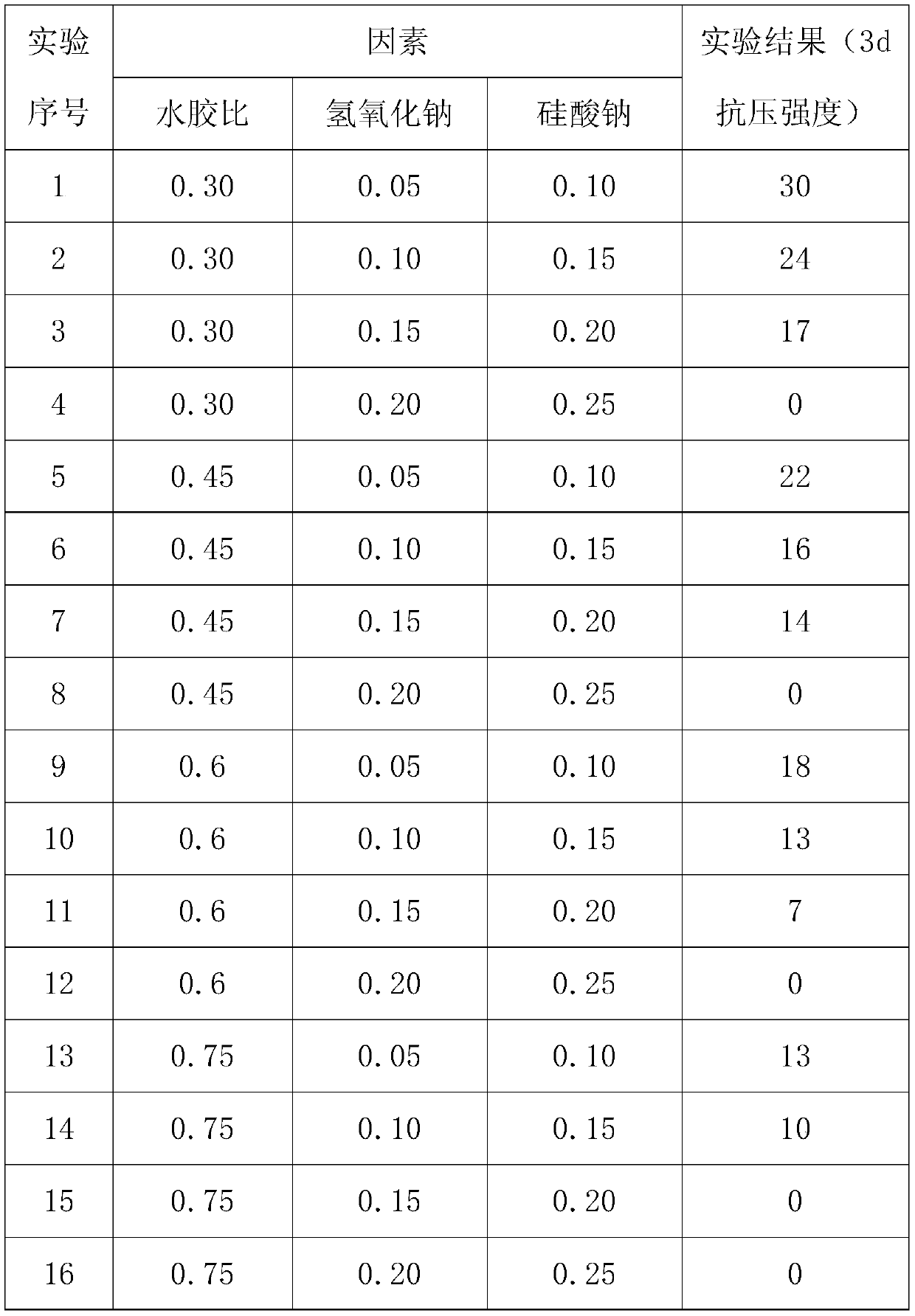

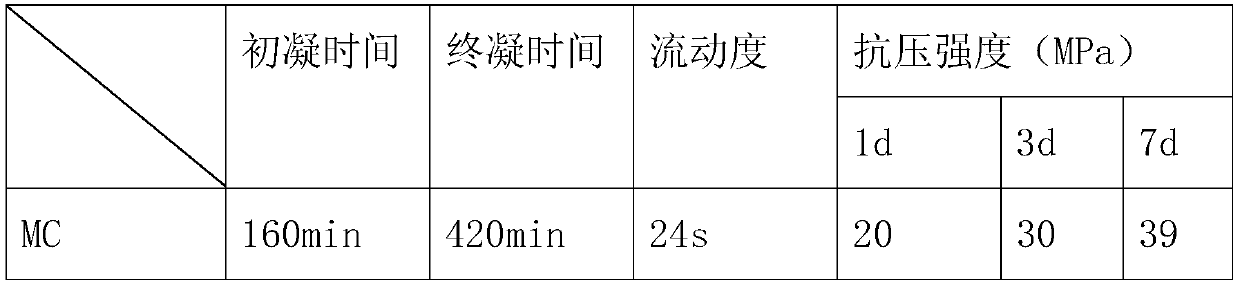

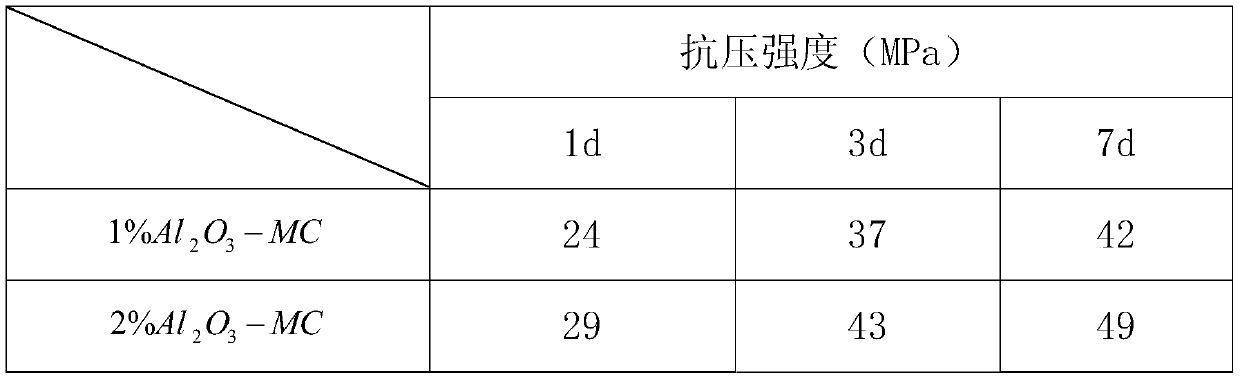

Nanometer Al2O3-Ca<2+>-based metakaolin geopolymer road repairing material

InactiveCN109809751AImprove heat resistanceGood freezing resistanceCement productionGeopolymerSodium silicate

The invention discloses a nanometer Al2O3-Ca<2+>-based metakaolin geopolymer road repairing material. A formula comprises nanometer Al2O3, Ca(OH)2, calcined kaolin, sodium silicate, sodium hydroxide and distilled water according to a mass ratio of 0.02 to 0.1 to 1 to 0.1 to 0.05 to 0.3. A metakaolin geopolymer has good interfacial bond property and excellent durability and heat resistance, can beused for well repairing cracks and pit slots on a road, and can improve the service life of the road repairing material. Tests show that by adding the Ca(OH)2 into the metakaolin geopolymer, the setting time of the road repairing material can be shortened, and by adding the Al2O3, the compressive strength of the road repairing material can be obviously increased. The 1d compressive strength of theroad repairing material can reach 31 MPa; the initial and final setting time of the road repairing material is respectively 60 min and 295 min; the mechanical property is excellent; and the road repairing material can replace cement as a new green building material to a certain extent, and has a good application prospect.

Owner:NORTHEAST FORESTRY UNIVERSITY

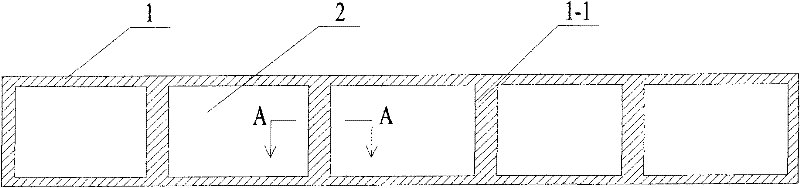

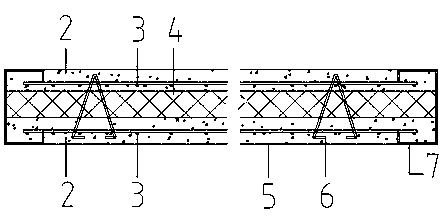

Assembly type steel rib reinforcing cell concrete composite floor slab and production method thereof

InactiveCN109465957AAvoid destructionIncreased durabilityFloorsCeramic shaping apparatusFiberglass meshFloor slab

The invention discloses an assembly type steel rib reinforcing cell concrete composite floor slab and a production method thereof. The assembly type steel rib reinforcing cell concrete composite floorslab is characterized in that a zinc-plated lightgage steel joist framework is arranged between heat-preserving polystyrene boards, steel bar meshes are welded into the lightgage steel joist framework so that a reinforced steel framework can be formed, a steel bar triangle frame and the steel bar meshes are fixedly connected, the reinforced steel framework and the heat-preserving polystyrene boards are connected into one by pouring light micropore concrete, and the micropore concrete double-layer sandwich structure is formed; fiberglass mesh is arranged between light micropore concrete slurryand the lightgage steel joist framework; and lifting lugs are arranged in the concrete to serve as lifting parts of the floor slab. The floor slab has the same life as the building main body structure, integrates the functions of bearing, heat preserving, sound insulating and seepage preventing, and has the characteristics that prefabrication production in a factory is achieved, assembly type installing is adopted, secondary stacking layers do not need to be manufactured, the construction speed is high, durability is good, and the cost is low. The technical problems that a current prefabricated reinforcement concrete stacking floor slab is high in cost, large in weight and poor in heat preserving performance, steel bars are tied on site, and construction is tedious are solved.

Owner:NORTHWEST UNIVERSITY FOR NATIONALITIES +2

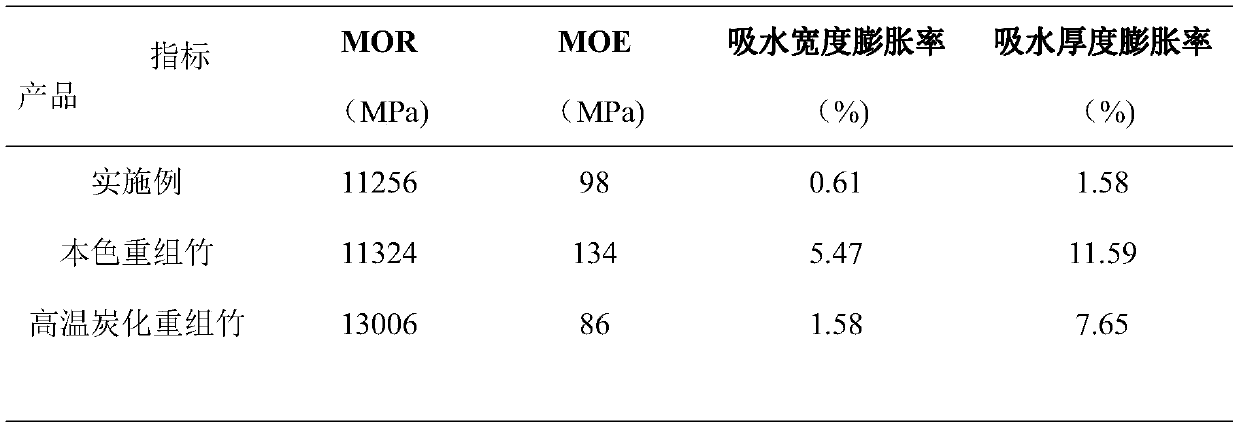

Anti-cracking reconsolidated bamboo manufacturing method

PendingCN111002408ADry shrinkage is smallImprove stabilityPressure wood treatmentWood treatment detailsPlasticizerCeramic materials

The invention discloses an anti-cracking reconsolidated bamboo manufacturing method, which mainly comprises the steps of bamboo chip preparation, specifically, longitudinally splitting bamboo, and removing inner joints to form bamboo chips; ultrahigh-pressure treatment, specifically, conducting ultrahigh-pressure treatment on the bamboo chips by using a plasticizer as a pressure transmission medium, wherein the ultrahigh pressure is 200-400Mpa; softening treatment, specifically, placing the bamboo chips in a weak alkaline solution for softening treatment; rolling and splitting, specifically, rolling and flattening the bamboo chips in the radial direction, splitting the bamboo chips in the thickness direction, and then defibering and splitting the bamboo chips to form sheet-shaped bamboo bundles; gum dipping treatment, specifically, drying the sheet-shaped bamboo bundles, and then placing the sheet-shaped bamboo bundles in a vacuum high-pressure environment to be soaked in resin gum for10-30s; drying and balancing: specifically, drying the sheet-shaped bamboo bundles, and then placing the sheet-shaped bamboo bundles in a balancing kiln for moisture content balancing, wherein the balancing time is 7-15 days; and hot-pressing curing, specifically, preparing the sheet-shaped bamboo bundles into reconsolidated bamboo plates, stacking and heavily pressing the reconsolidated bamboo plates, aging for 7-10 days at the room temperature, and then conducting subsequent processing. The reconsolidated bamboo plates manufactured through the method can be effectively prevented from cracking, and the material cost is low.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Foamed concrete material and its application

The present invention relates to a foam concrete material and its application. Its main ingredients are inorganic gelation material, filling material and concrete foaming agent. The described inorganic gelation material is magnesium oxide and magnesium chloride solution, and the filling material is stone powder or mineral powder, and the weight ratio of all the ingredients is: magnesium oxide: magnesium chloride solution: filling material: foaming agent=20-50:24-50:24-50:1-2.

Owner:王亦德

Composite thermal-insulation mortar for outer walls

InactiveCN103896519ADry shrinkage is smallAvoid stratificationThermal insulationHydroxypropylmethyl cellulose

The invention discloses a composite thermal-insulation mortar for outer walls, which is prepared from the following components in percentage by weight: 60-80 parts of cement, 0.25-0.35 part of resin-type redispersible latex powder, 0.6-0.9 part of cold-water polyvinyl alcohol, 0.1-0.2 part of hydroxypropyl methylcellulose ether, 0.01-0.03 part of air entraining agent, 0.06-0.1 part of water glass, 0.005-0.01 part of inorganic retarder, 8-13 parts of polyphenyl granule, 30-50 parts of vitrified microbead and 0.2-0.5 part of concrete waterproofing agent. The mortar has the advantages of favorable thermal-insulation effect and low tendency to bulging or shedding after construction, and can effectively resist water and fire.

Owner:陈昊

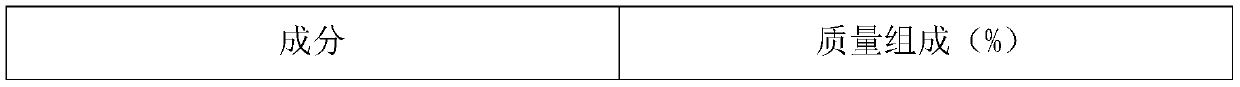

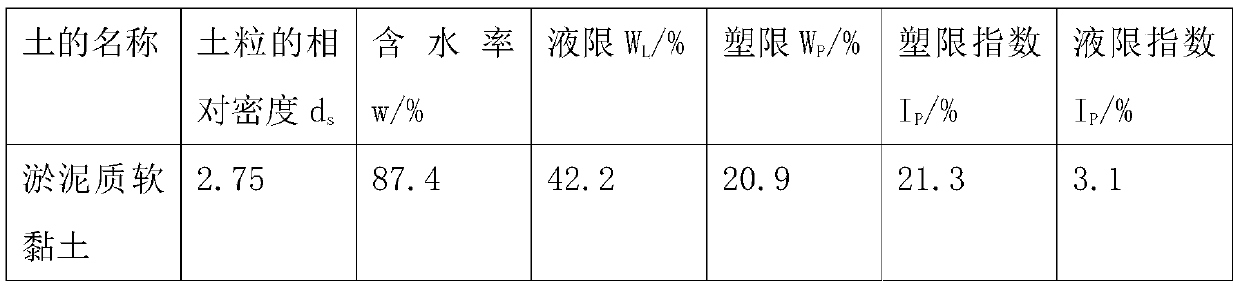

Soft soil foundation curing agent prepared from industrial waste residues

The invention relates to the field of soft soil foundation hardening, in particular to a soft soil foundation curing agent prepared from industrial waste residues. The advantage that industrial residues are cheap is sufficiently used, and both the problem in treating industrial wastes and the problem in treating soft foundations of sludge soft clay can be solved; in addition, the curing agent provided by the invention is good in early strength, good in application and good in water stability and is capable of remarkably alleviating the problems that sludge soft clay in littoral regions is highin water content and low in shearing resistance.

Owner:TANGSHAN IND VOCATIONAL TECHN COLLEGE

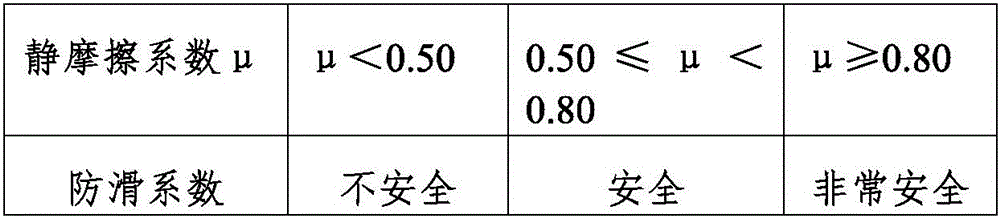

Novel anti-slipping floor tiles and preparation method of novel anti-slipping floor tiles

InactiveCN106747295ANot easy to damageProduct quality is stableCeramic materials productionClaywaresCoal ganguePerlite

The invention relates to the technical field of building materials and in particular relates to novel anti-slipping floor tiles and a preparation method of the novel anti-slipping floor tiles. The novel anti-slipping floor tiles are prepared from the following raw materials in parts by weight: 20 to 30 parts of granite, 12 to 18 parts of marble, 25 to 35 parts of clay, 20 to 40 parts of cement, 10 to 20 parts of coal gangue, 8 to 12 parts of expanded perlite, 12 to 18 parts of expanded bentonite, 6 to 9 parts of a water reducing agent, 8 to 14 parts of a thickener, 18 to 22 parts of an anti-slipping agent and a number of water. The floor tiles provided by the invention are firm and durable, have no toxin or harms, are natural and environmentally friendly, and also have an anti-cracking effect; the floor tiles are not easy to damage, the product quality is stable and the production cost is greatly reduced; under the condition of guaranteeing great demanding on the floor tiles by a building industry, the prepared floor tiles have a relatively high anti-slipping property and the anti-slipping property is greatly improved; the safety of working places and public places is guaranteed and the occurrence rate of slipping accidents is reduced.

Owner:GUIZHOU XINGGUI HENGYUAN NOVEL BUILDING MATERIAL CO LTD

Cement grinding aid and preparation method therefor

The present invention discloses a cement grinding aid. The grinding aid comprises the following compositions components in parts by weightmass: 60-65 parts of alkali slag, 10-15 parts of straw ash, 15-20 parts of steel slag and 5-10 parts of calcium lignosulphonate, and the compositions components contain the following substances in based on the total mass percentage of the cement grinding aid by mass percentage: 30-41% of calcium oxide, 28-35% of silicon dioxidesilica, 8-16% of aluminum oxidealundum, 6-12% of sulfur trioxide and 5-8% of carbamideurea. The preparation method comprises the ofllowng steps: fFirstly, uniformly mixing and stirring the alkali slag, the straw ash, the steel slag and the calcium lignosulphonate are mixed and uniformly agitated; secondly, the mixture is preparing the mixture ed into spherical particles; lastlyand finally, stacking and curing the spherical particles are subjected to stacking, solidification and removing free water and partial part of water of crystallization removal, as a result to obtain, the a cement grinding aid is obtainedproduct. The cement grinding aid disclosed by the present invention is low in production cost, and good in product performance.

Owner:淮安市水泥厂有限公司

Preparation method of high-strength self-compacting concrete

The invention provides a preparation method of high-strength self-compacting concrete. The preparation method comprises the following steps: (1), weighing the following raw materials, by weight: 290-320 parts of cement, 70-85 parts of fly ash, 65-75 parts of silica fume, 650-750 parts of quartz sand, 700-800 parts of gravels, 25-35 parts of glass beads, 12-15 parts of a nano titanium dioxide / basalt stone powder composite material, 1.5-2 parts of redispersible polymer rubber powder, 1-1.2 parts of an epoxy silane coupling agent and 10-15 parts of an additive; and (2), uniformly mixing glass beads, redispersible polymer rubber powder and an epoxy silane coupling agent to obtain a pre-mixture; pouring cement, fly ash, silica fume and the nano titanium dioxide / basalt stone powder composite material into a stirrer, uniformly performing stirring, adding the pre-mixture, water and quartz sand, performing stirring for 120-150 seconds, then adding crushed stone and the additive, continuously performing stirring for 120-150 seconds, and uniformly performing stirring, so as to obtain the self-compacting concrete. The concrete prepared in the invention has the advantages of high strength, goodworking performances and excellent durability.

Owner:江苏昆腾新材料科技有限公司

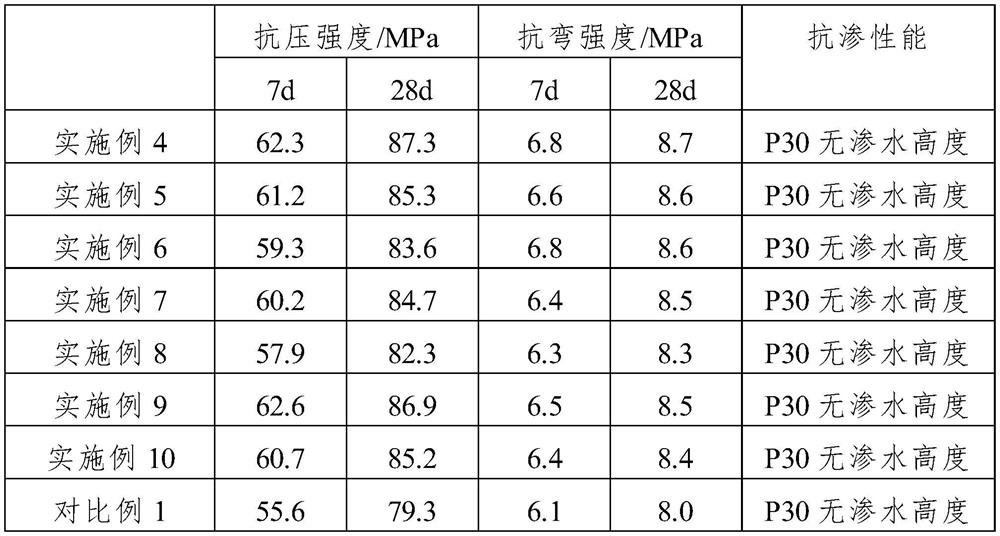

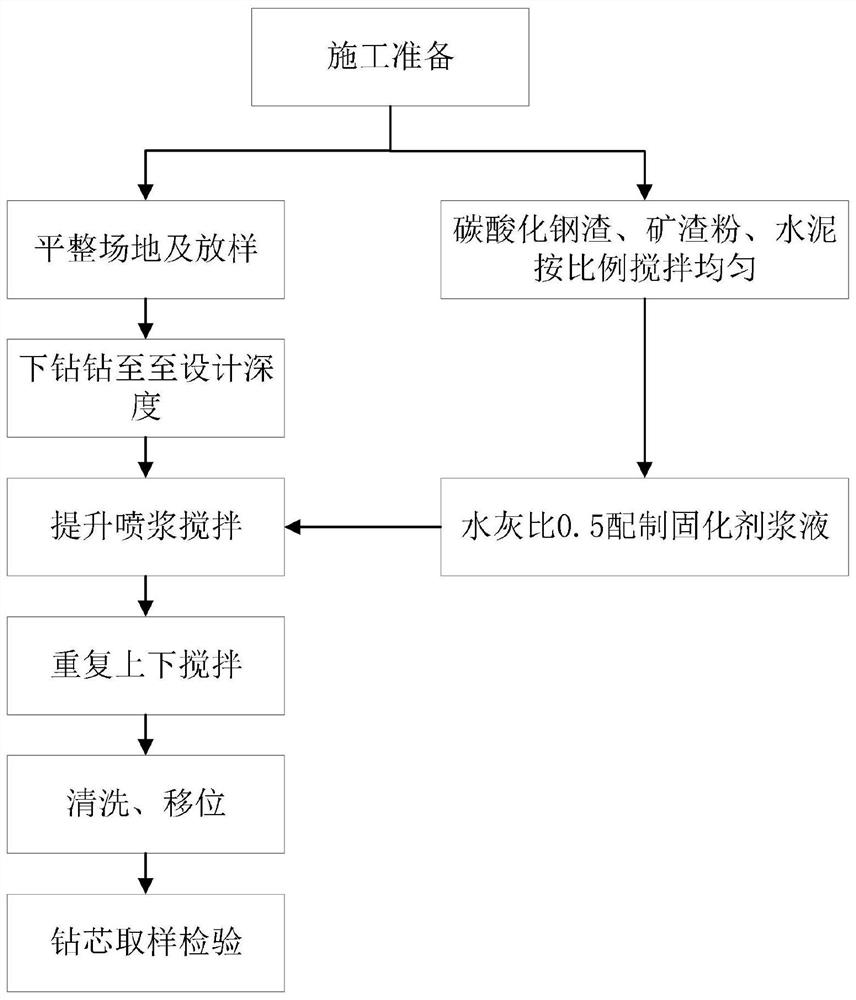

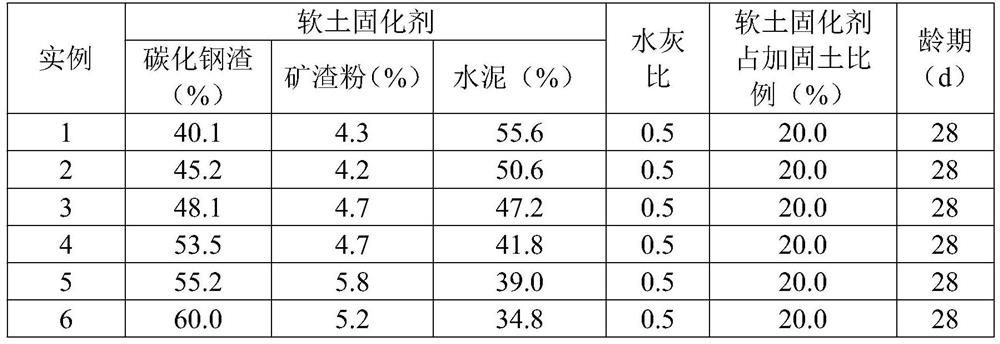

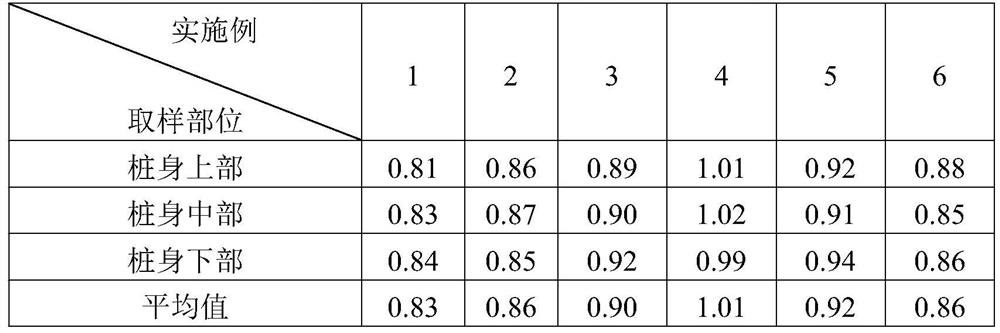

Soft soil foundation curing agent and construction method for curing soft soil foundation

InactiveCN112919834ASolve the problem of low utilization rate of solid wasteReduce reinforcement costsCement productionBulkheads/pilesSoil scienceSlag

The invention discloses a soft soil foundation curing agent and a construction method for curing a soft soil foundation. The curing agent comprises the following raw materials in percentage by mass: 40.1%-60.0% of carbonated steel slag, 4.2%-5.8% of slag powder and 34.2%-54.1% of cement. When the sum of the mass of the soft soil, the mass of the water and the mass of the soft soil curing agent is 100%, the doping ratio of the soft soil curing agent is 12.0-20.0%. The preparation method comprises the following steps: (1) preparation of soft soil foundation curing agent slurry: weighing carbonated steel slag, slag powder and cement according to a ratio, putting into a sample preparation barrel, fully mixing, adding water according to a water-cement ratio of 0.45-0.55, and stirring to prepare the soft soil foundation curing agent slurry. The carbonated steel slag and the slag powder are used for replacing a cement curing agent, the soft soil curing agent for fixing the soft soil foundation is prepared, the soft soil foundation is cured, and the strength of a cured pile body meets the design requirement. The problem of utilization of metallurgical industry solid waste is solved, and the problem of treatment of soft soil foundations in urban development and construction is also solved.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Novel imitation antique city wall pointing mortar and pointing method thereof

The invention relates to novel imitation antique city wall pointing mortar and a pointing method of the novel imitation antique city wall pointing mortar. The pointing mortar comprises the following components in parts by weight: 60 parts of fly ash, 40 parts of cement, and 180 parts of sand, wherein the fly ash is an original-state dry discharged fly ash, the cement is No.32.5 slag portland cement, and the sand is fine-to-medium sand. The pointing mortar disclosed by the invention has the advantages of small fly ash / cement dry shrinkage, good workability, low hydration heat, high late intensity, good sulfate corrosion resistance, and the like. In the aspect of environmental protection, waste fly ash of power plants can be effectively used, and the cement can be saved, thereby achieving the effect of energy conservation and environmental protection. The cost is reduced, the benefit is improved, and the economic benefit of enterprises is increased.

Owner:MCC TIANGONG GROUP

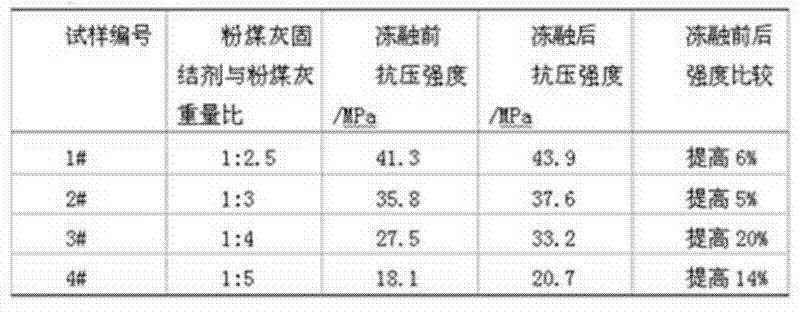

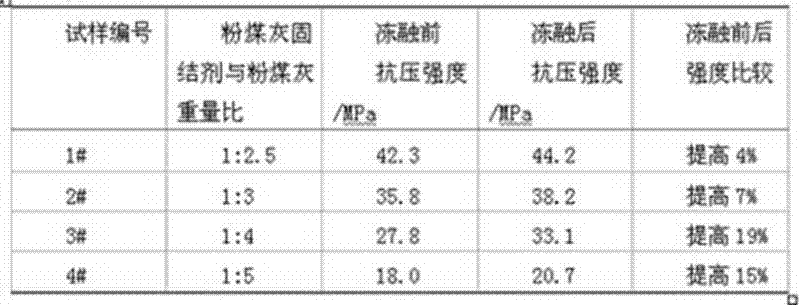

Coal ash solidifying agent for coal ash building materials

The invention discloses a coal ash solidifying agent for coal ash building materials, wherein the coal ash solidifying agent comprises clinker, granulated blast-furnace slag, gypsum, lime and crystal nucleus elements, and is prepared by each raw material above in parts by weight. The coal ash solidifying agent provided by the invention can enable the adulteration quantity of coal ash in the coal ash building materials to be increased, and the reasonable utilization of coal ash is promoted; and by utilizing the coal ash solidifying agent provided by the invention, the freezing-proof capability of the coal ash building materials can be strengthened, and the prepared coal ash building materials have small dry contractibility rate and good freezing-resistant performance.

Owner:北京清渠环保科技有限公司

Water-absorbent deodorizing household mat prepared from coal ash and production process of water-absorbent deodorizing household mat

InactiveCN108147745AHigh carbon contentStrong water absorptionCeramicwareFloor carpetsFiberEcological environment

The invention relates to a water-absorbent deodorizing household mat prepared from coal ash and a production process of the water-absorbent deodorizing household mat. The household mat is prepared from, by weight, 18%-22% of diatomite, 42%-48% of coal ash, 10%-15% of calcium hydroxide, 8%-12% of Portland cement, 8%-10% of wood pulp fibers and 3%-5% of quartz powder. The production process includeswood pulp fiber paste preparation, cementing agent preparation, flowing forming, demoulding, steaming, drying, sanding and polishing and carving and cutting. By use of the coal ash which is industrial waste, saving of natural resources such as raw ores is benefited, and ecological environment pollution caused by wastes can be abated beneficially. In addition, the water-absorbent deodorizing household mat is high in water absorption performance and air purification and deodorization performance, quick in moisture release and resistant to mildewing and fire and intrinsically has advantages of light weight and high strength.

Owner:JIANGXI YUANYANG WEILI IND CO LTD

Wood modifying agent and production method thereof

InactiveCN106625946ADry shrinkage is smallIncreased air-dry densityWood treatment detailsWood impregnation detailsPhosphoric acidUrea

The invention provides a wood modifying agent and a production method thereof. The wood modifying agent comprises the following components in parts by weight: 20-60 parts of phosphoric acid, 10-30 parts of urea, 2-10 parts of hexamine, 0.1-0.3 part of catalyst, and 2-10 parts of butane tetracarboxylic acid. The produced wood modifying agent can prominently improve the wood strength and density, reduces the wood wet expansion performance and dry shrinkage performance, and meanwhile, is excellent in environmental protection and lower in cost.

Owner:NANJING BOJUN NEW MATERIAL CO LTD +1

Yellow phosphorus slag pavior brick and production method thereof

InactiveCN107098654AAddressing Uncontrolled EmissionsSolve the pollution of the environmentSolid waste managementBrickSlag

The invention provides a yellow phosphorus slag pavior brick and a production method thereof, which relate to the technical field of a pavior brick production method technology. The pavior brick comprises the following raw materials in parts by weight: 15-20 parts of cement, 30-35 parts of sand, 15-20 parts of pebble, 20-25 parts of yellow phosphorus slag powder, 10-15 parts of granular yellow phosphorus slag, 0.5-1 part of raw pulverized limestone, 0.2-0.5 parts of a water reducer, 0.5-2.5 parts of a delayed coagulant, and 4-6 parts of water. The production method comprises the following steps: 1) mixing sand, pebble, the yellow phosphorus slag powder, the granular yellow phosphorus slag and the raw pulverized limestone and stirring the materials to obtain a mixture; 2) adding the cement, the water reducer and the delayed coagulant in the mixture, adding water for stirring to obtain a mixed slurry, performing compacting moulding on the mixed slurry by a building block forming machine to obtain the molded building block; and 3) performing maintenance on the molded building block for 29-30 days at the temperature of 25-27 DEG C and humidity of 92-95%. The method solves the problems of non-utilization of waste, low compressive strength, low flexural intensity and low abrasion resistance of the current pavior brick.

Owner:合肥慧林建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com