Foamed ceramic decorative plate and preparation method thereof

A technology of foamed ceramics and decorative boards, applied in the field of decorative materials, can solve the problems of poor adhesion, short service life, and high cost of stone materials, and achieve improved matrix strength and compactness, low cost, and good compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 Preparation of Uniform Color Foamed Ceramic Decorative Board

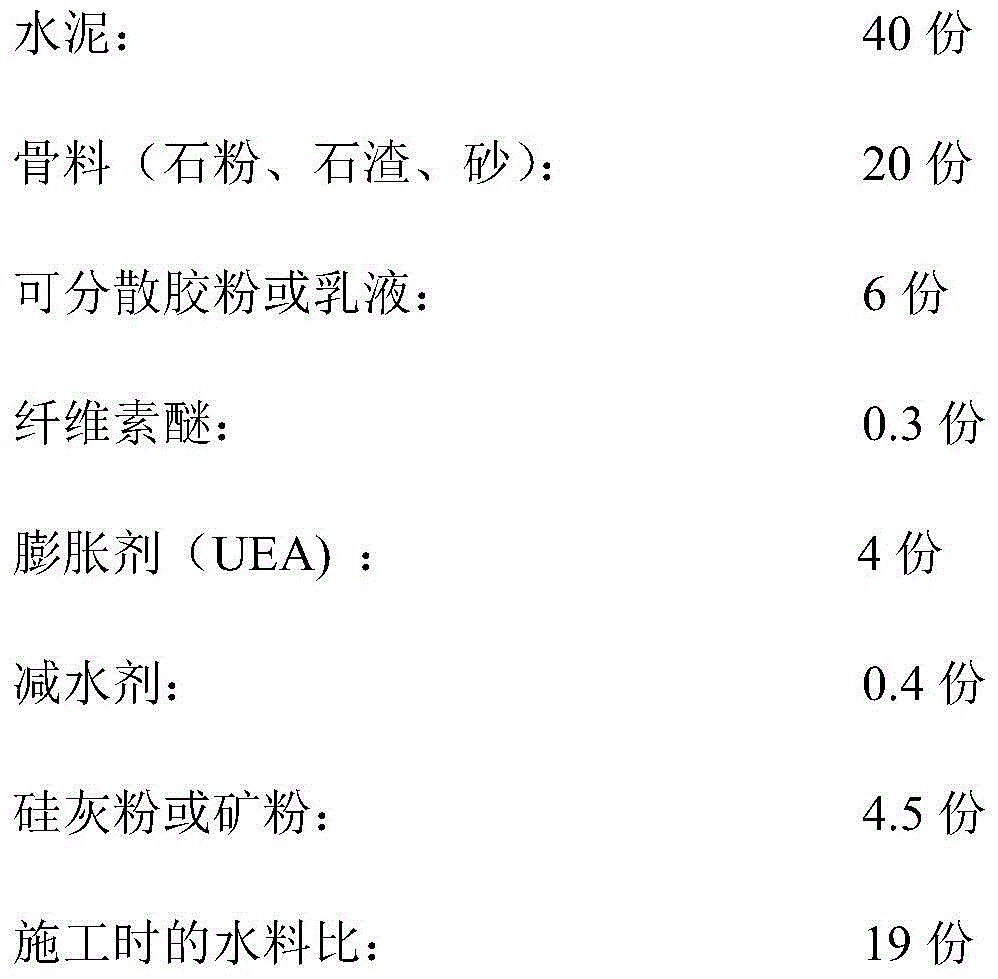

[0023] (1) First prepare decorative mortar according to the mass ratio of the following raw materials, add corresponding pigments as needed, and stir evenly to form a single-color viscous paste;

[0024]

[0025] (2) Use a gray knife or spray gun to scrape or spray the decorative mortar paste on the surface of the foamed ceramics to ensure that the surface of the foamed ceramics is completely and evenly covered without scraping or spraying to cause the bottom to appear, forming a sandstone or relief texture. For coatings, when fineness and flatness are required, reduce the discharge volume of the nozzle of the spray gun and increase the air discharge volume to fully disperse and atomize the material to make the surface layer more uniform and fine;

[0026] (3) After curing and curing to form a certain strength, the foamed ceramic decorative board can be trimmed and cut into a rough surface. If n...

Embodiment 2

[0027] Example 2 Preparation of a textured foamed ceramic decorative board

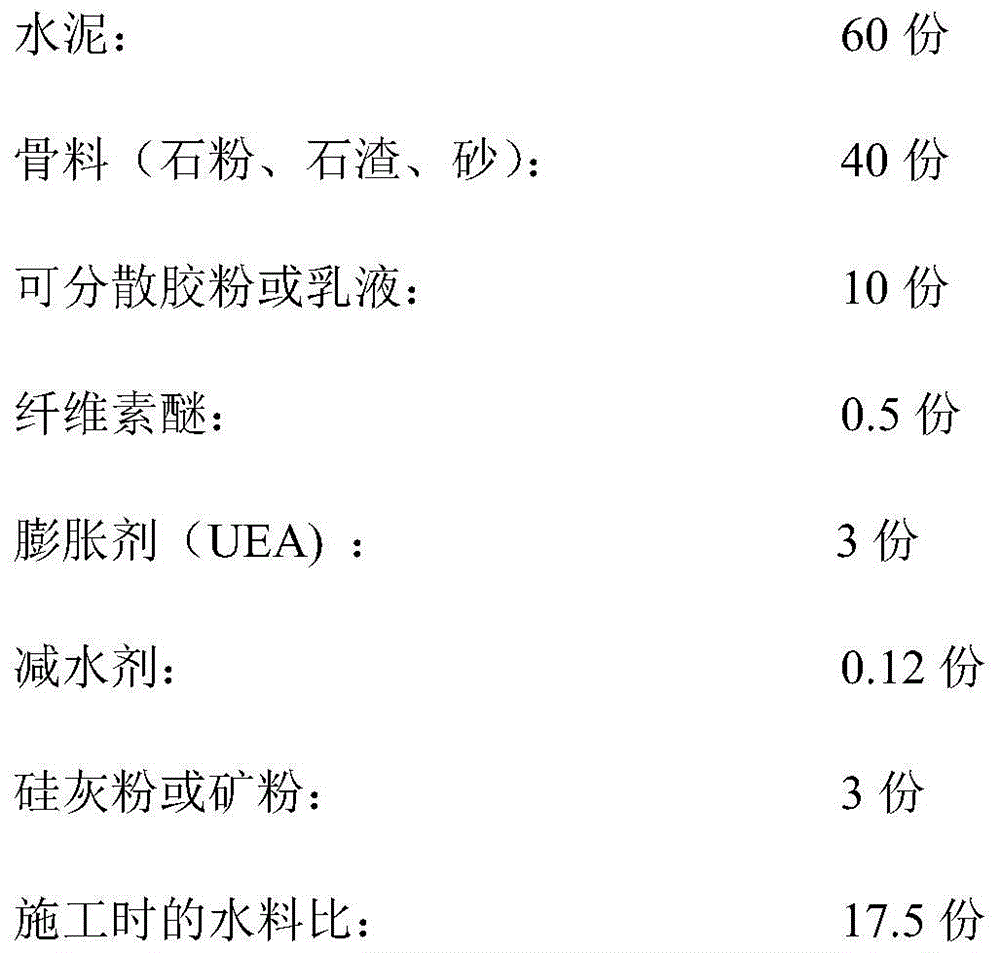

[0028] (1) Prepare decorative mortar according to the mass ratio of the following raw materials, add various pigments as required, and stir to make viscous pastes of various colors;

[0029]

[0030] (2) According to the color and texture pattern of natural sandstone, various color pastes are scraped or sprayed on the surface of the foamed ceramics to form a stone surface with the same color changes and layers as natural sandstone. In order to enhance the texture In this embodiment, color paste is applied to the base surface to enhance the degree of simulation;

[0031] (3) After being cured and cured, a textured foamed ceramic decorative board will be formed.

Embodiment 3

[0032] Embodiment 3 prepares the foamed ceramic decorative plate of fair-faced concrete color

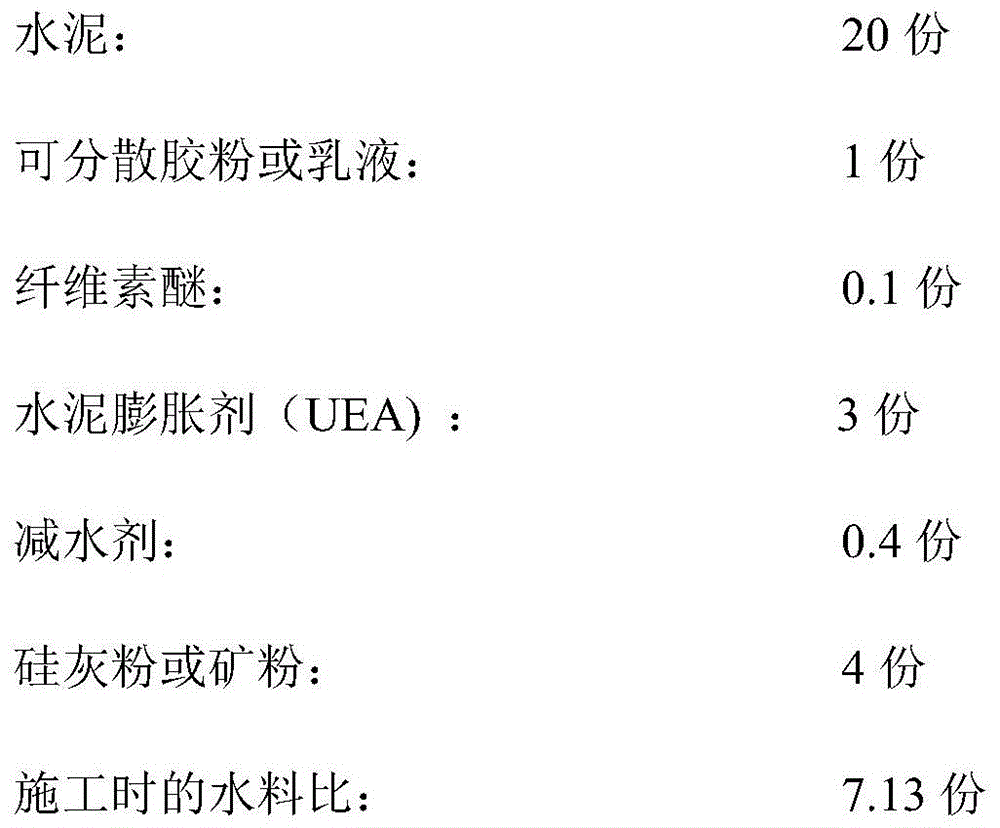

[0033] (1) First prepare the decorative mortar with clear-faced concrete color according to the following raw material mass ratio, and stir to make a viscous paste;

[0034]

[0035] (2) First scrape the surface of the foamed ceramics with an aqueous solution of an interface agent (acrylic emulsion, styrene-butadiene emulsion, or construction glue) to increase the bonding force between the mortar and the foamed ceramics, and then stir well with step (1) The cement decorative mortar is scraped or sprayed, and the follow-up operation method is the same as embodiment 1;

[0036] (3) Because the clear-water concrete finishing mortar is relatively fine (without coarse aggregate), it will form a clear-water concrete surface with a uniform and smooth surface after curing, and then cut and trim it into a light-weight clear-water concrete-colored foamed ceramic decorative board.

[0037]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com