Patents

Literature

42results about How to "Same material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

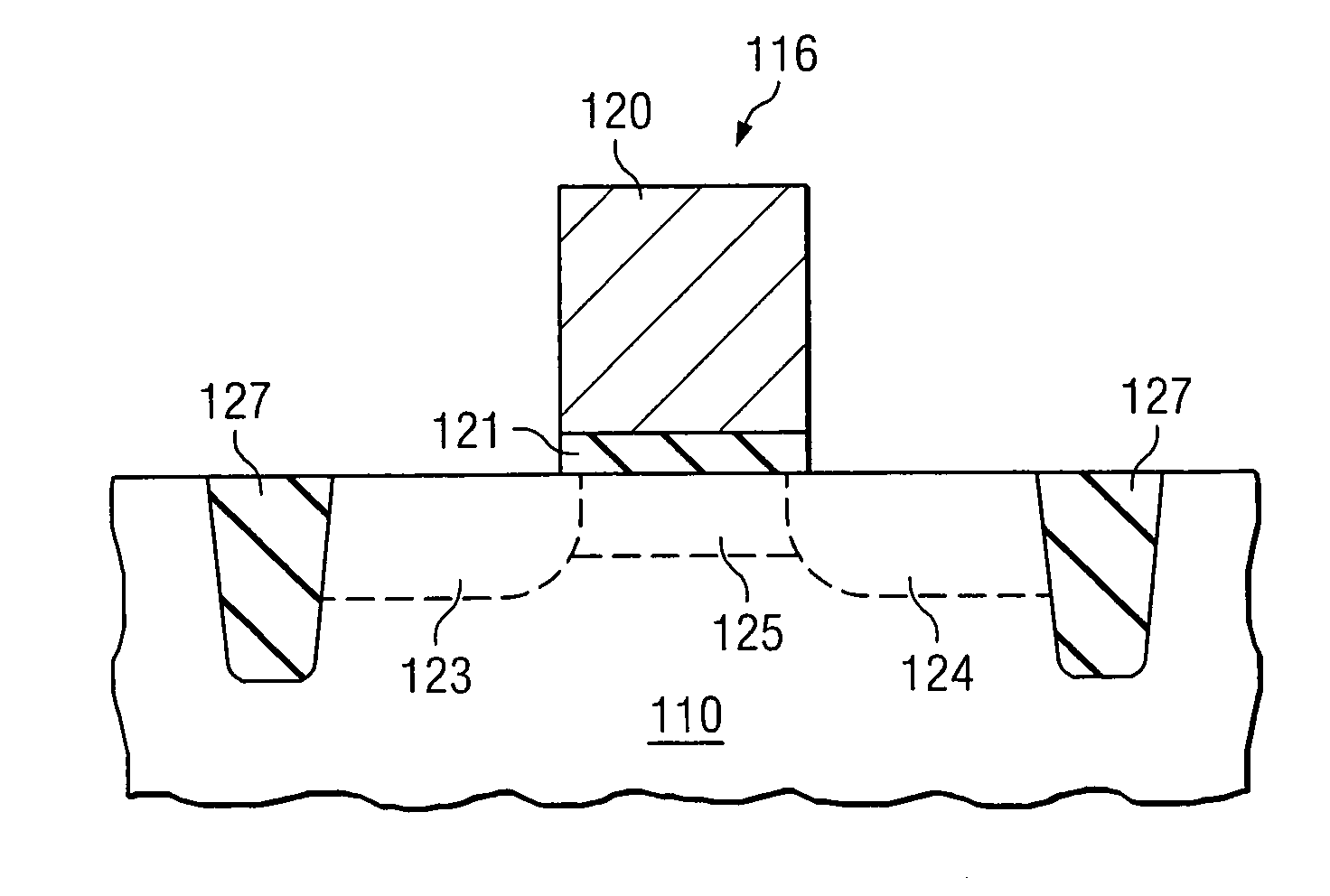

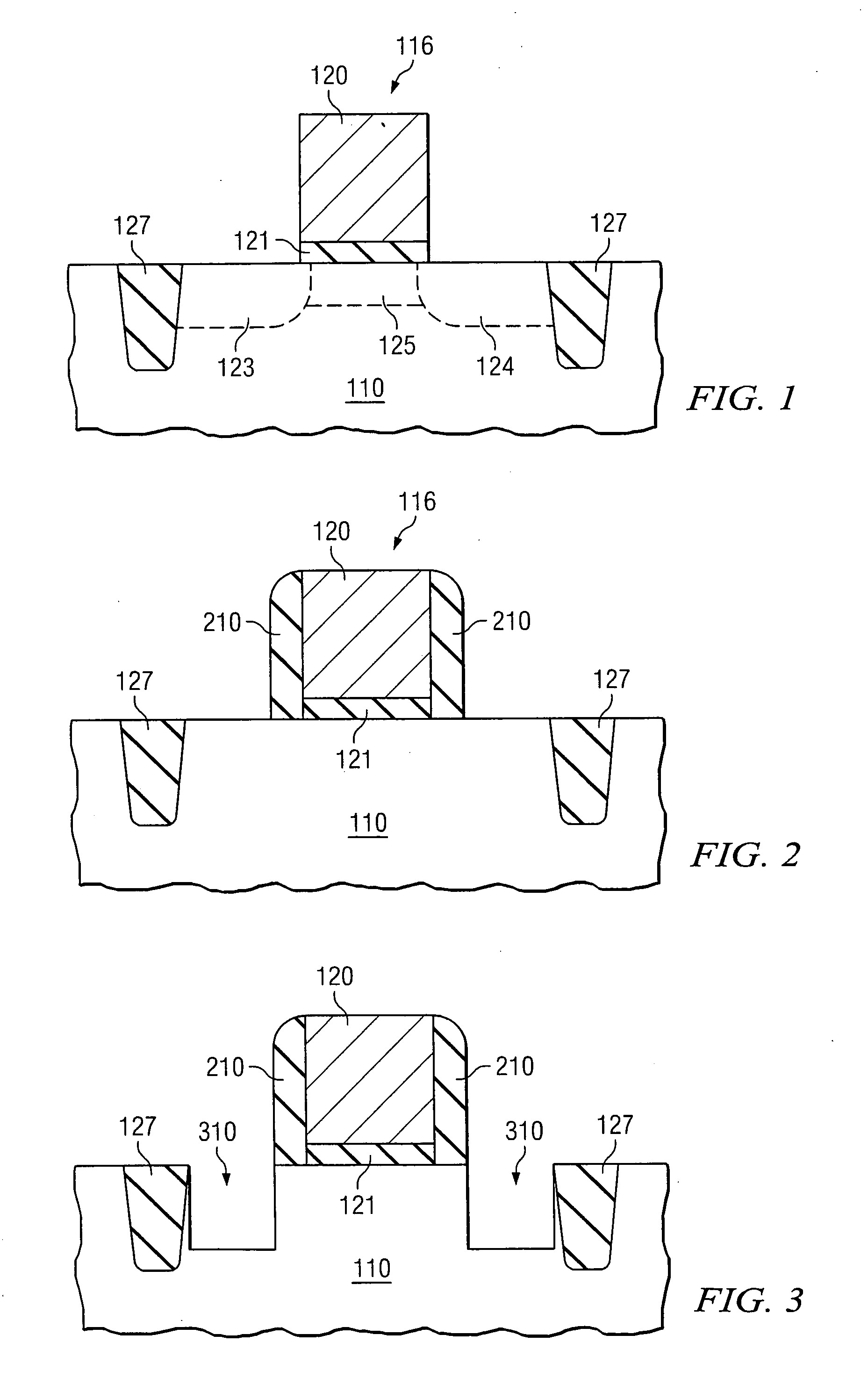

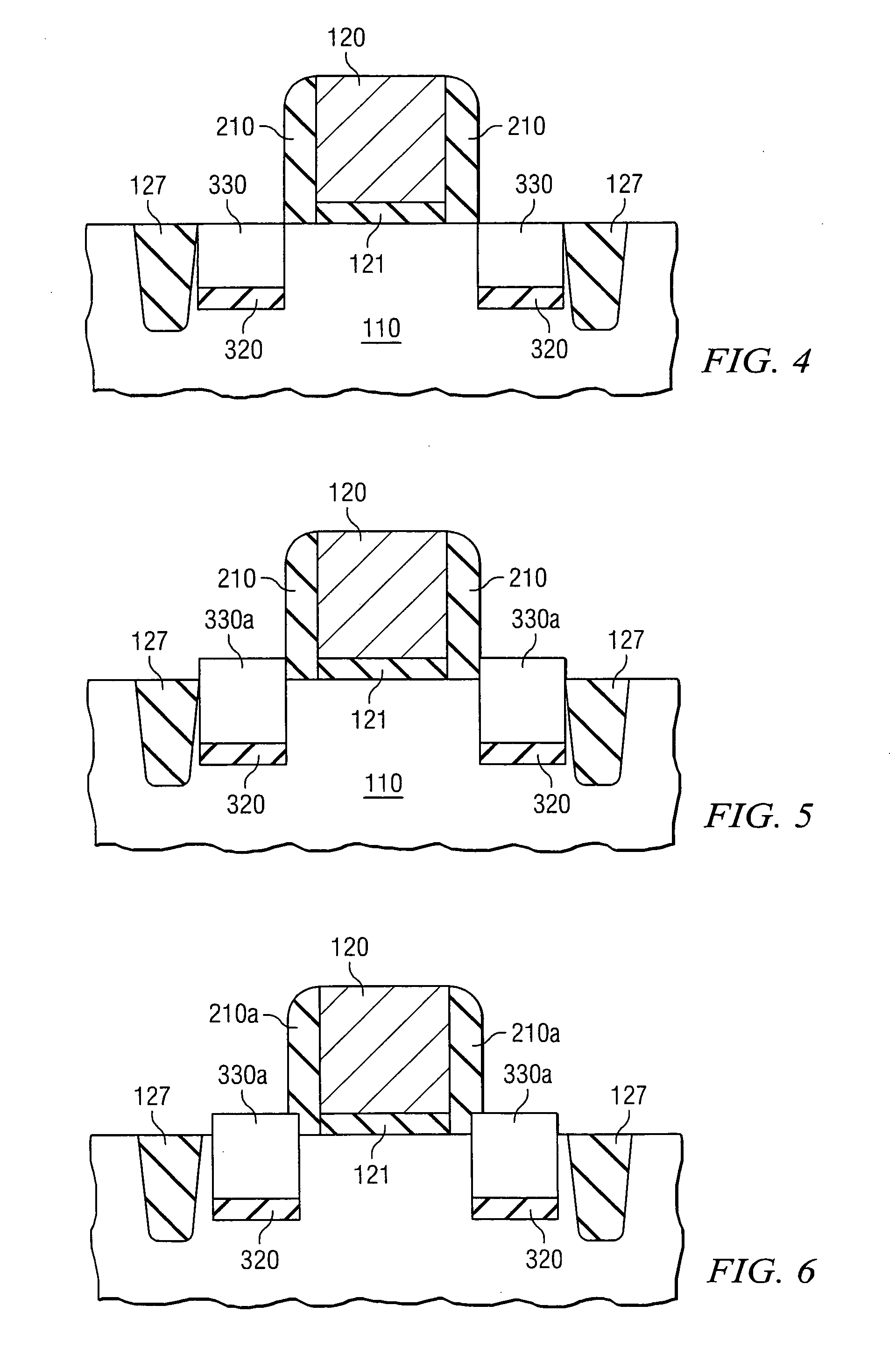

Embedded SiGe stressor with tensile strain for NMOS current enhancement

ActiveUS20070057287A1Improve device performanceSame materialSemiconductor/solid-state device manufacturingSemiconductor devicesTensile strainEngineering

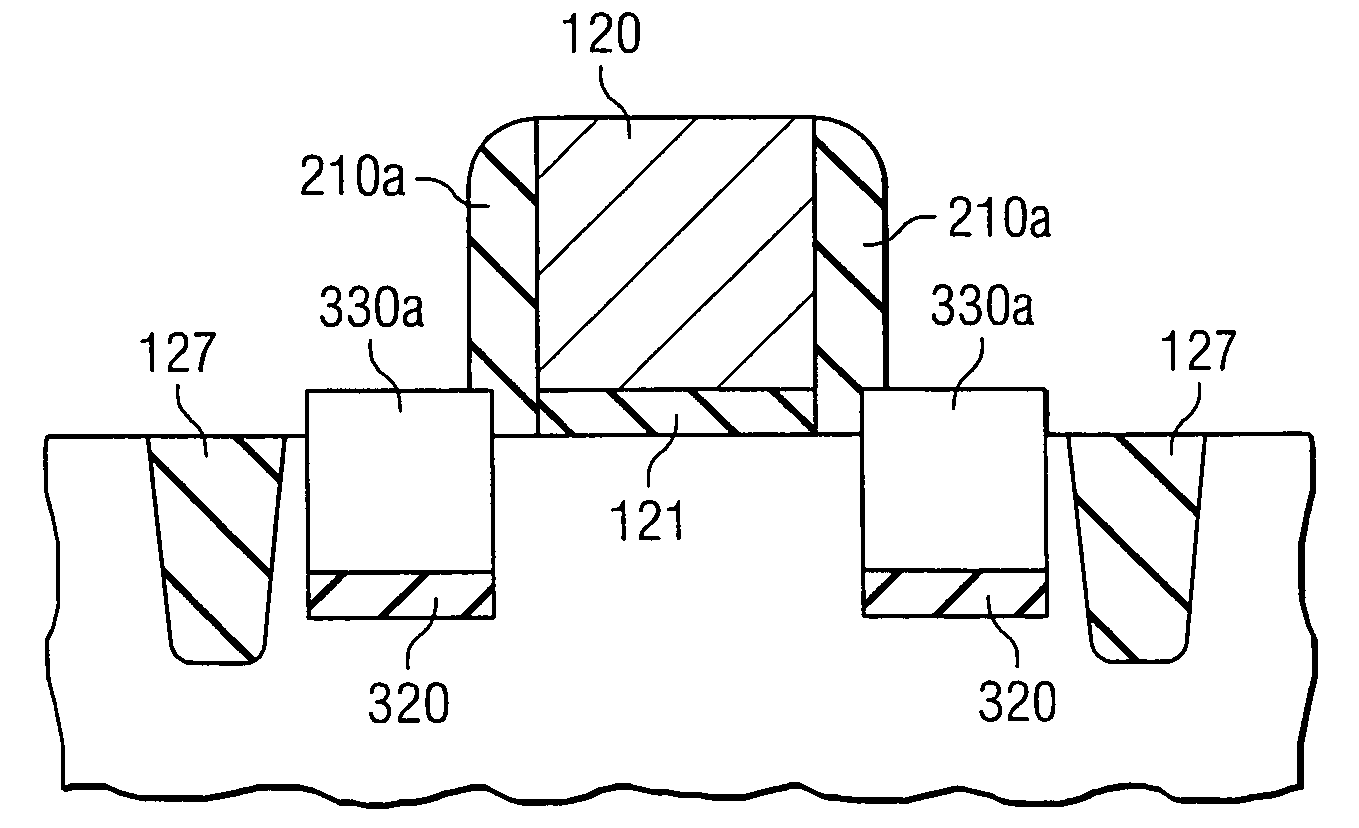

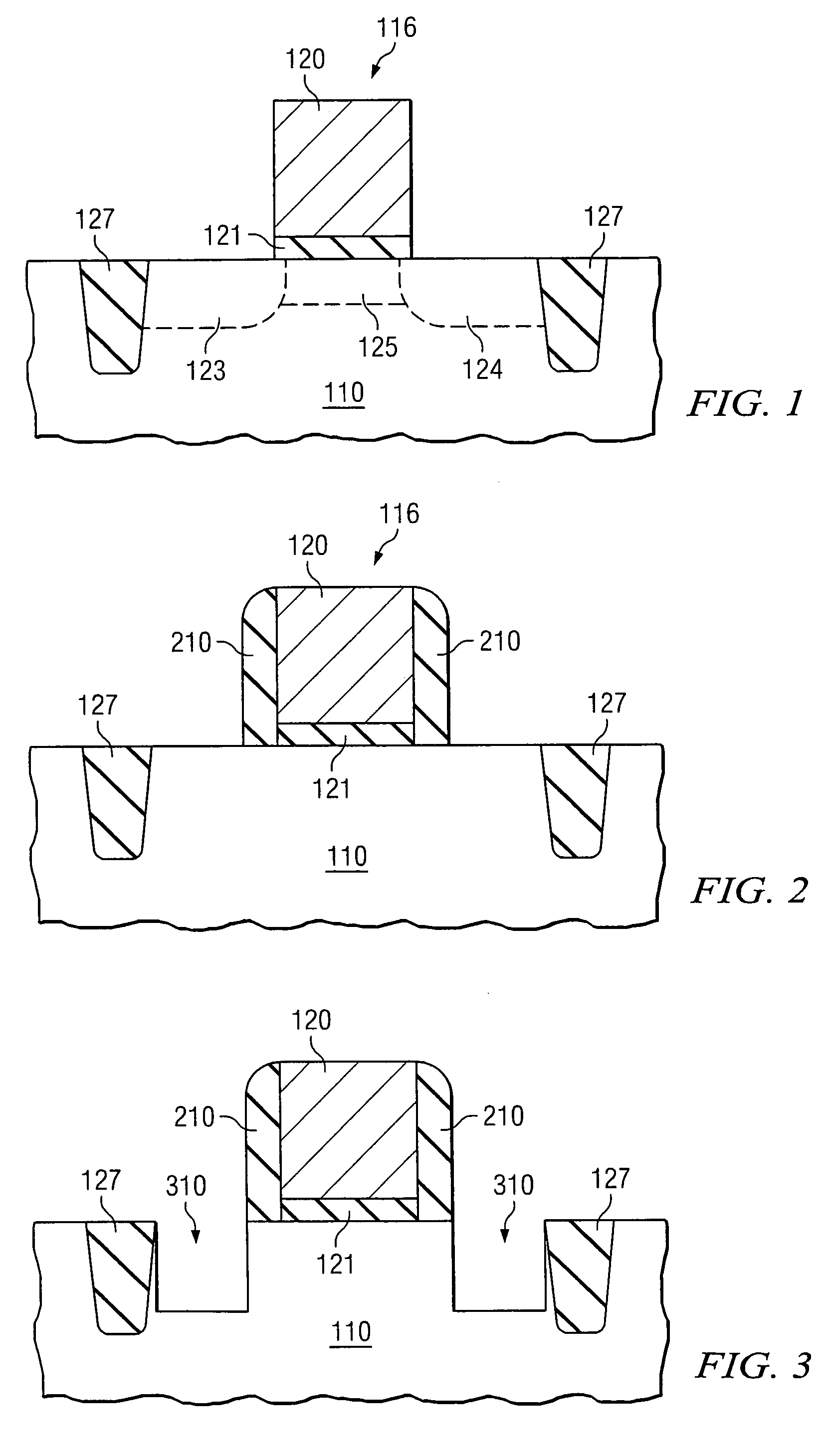

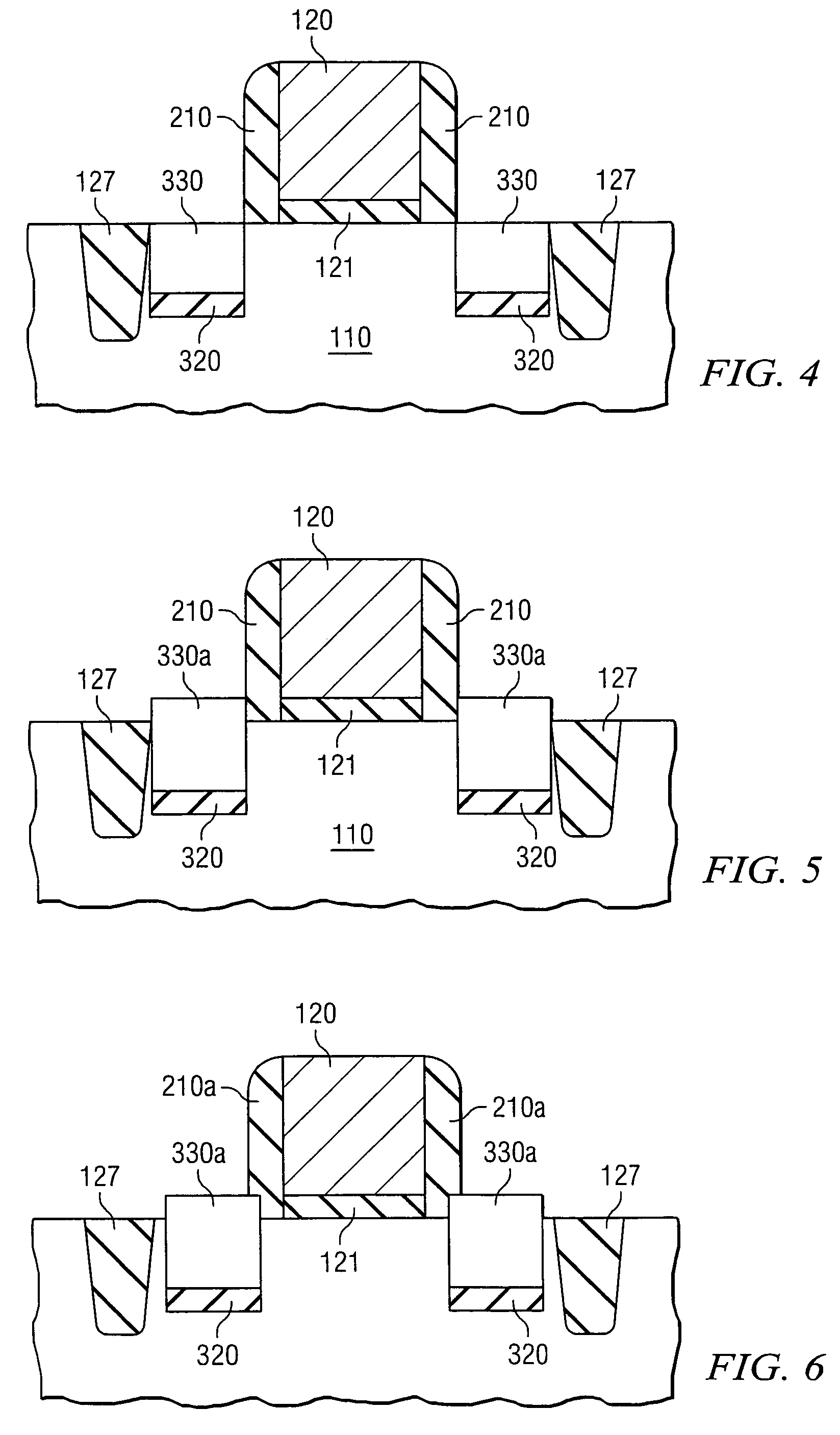

MOS devices having localized stressors are provided. Embodiments of the invention comprise a gate electrode formed over a substrate and source / drain regions formed on either side of the gate electrode. The source / drain regions include an embedded stressor and a capping layer on the embedded stressor. Preferably, the embedded stressor has a lattice spacing greater than the substrate lattice spacing. In a preferred embodiment, the substrate is silicon and the embedded stressor is silicon germanium. A method of manufacturing is also provided, wherein strained PMOS and NMOS transistors may be formed simultaneously.

Owner:TAIWAN SEMICON MFG CO LTD

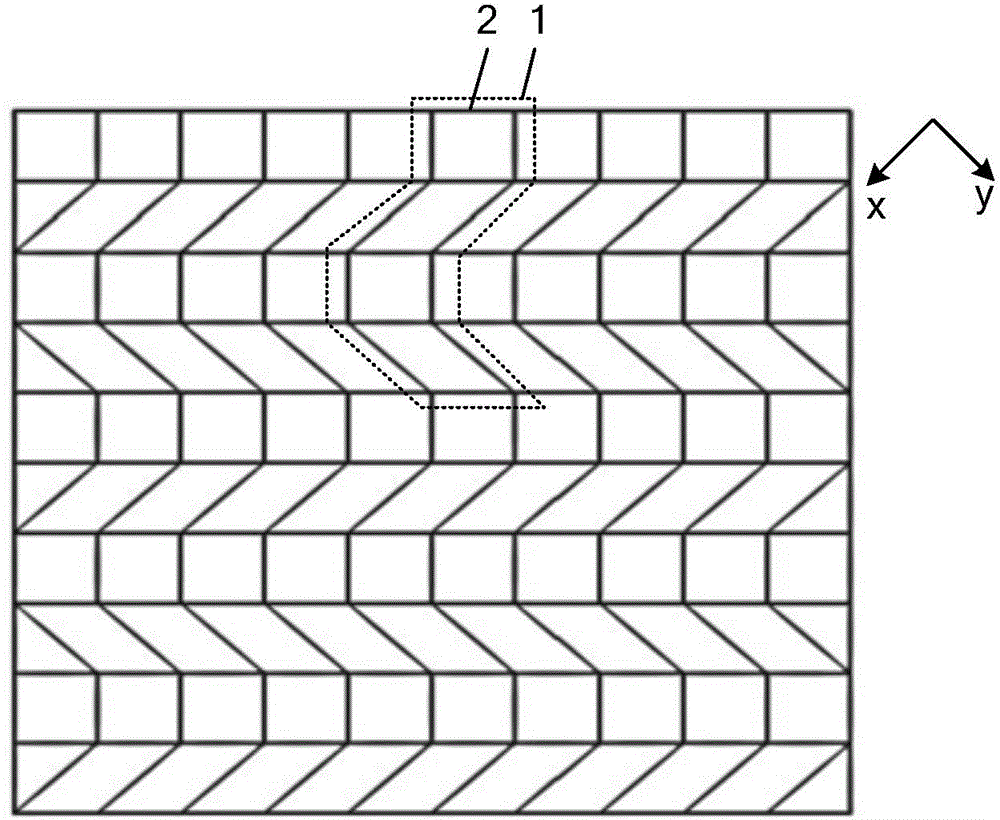

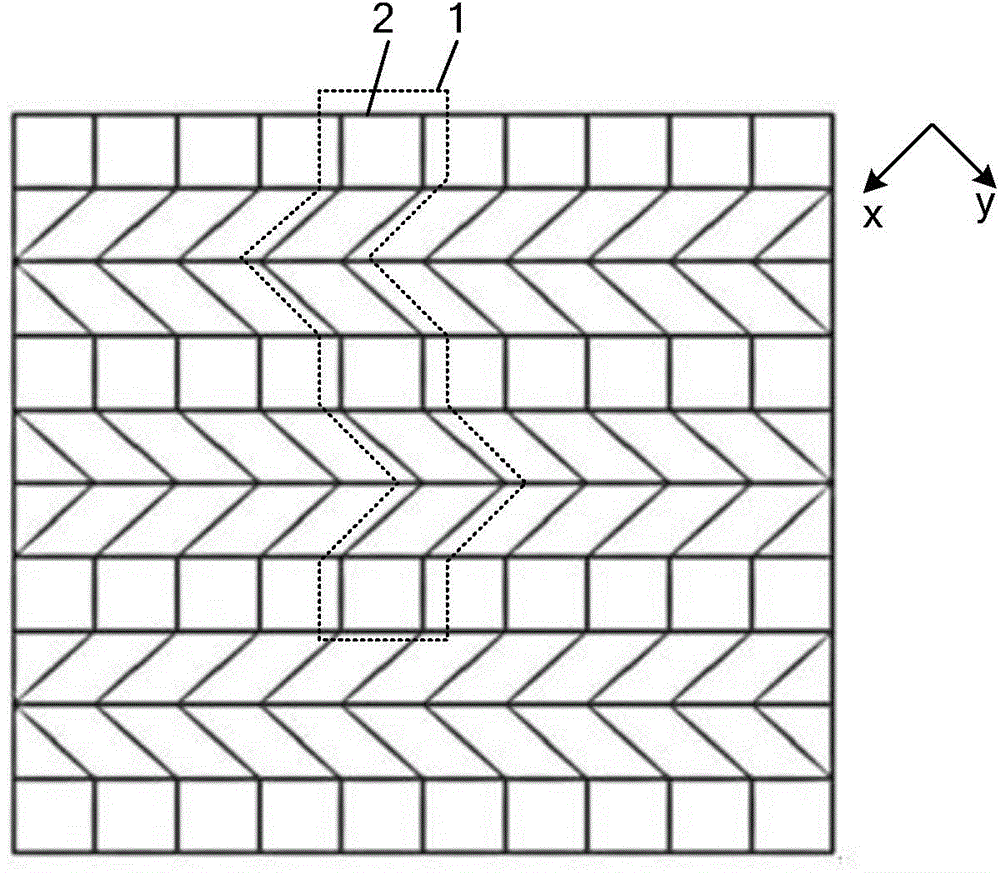

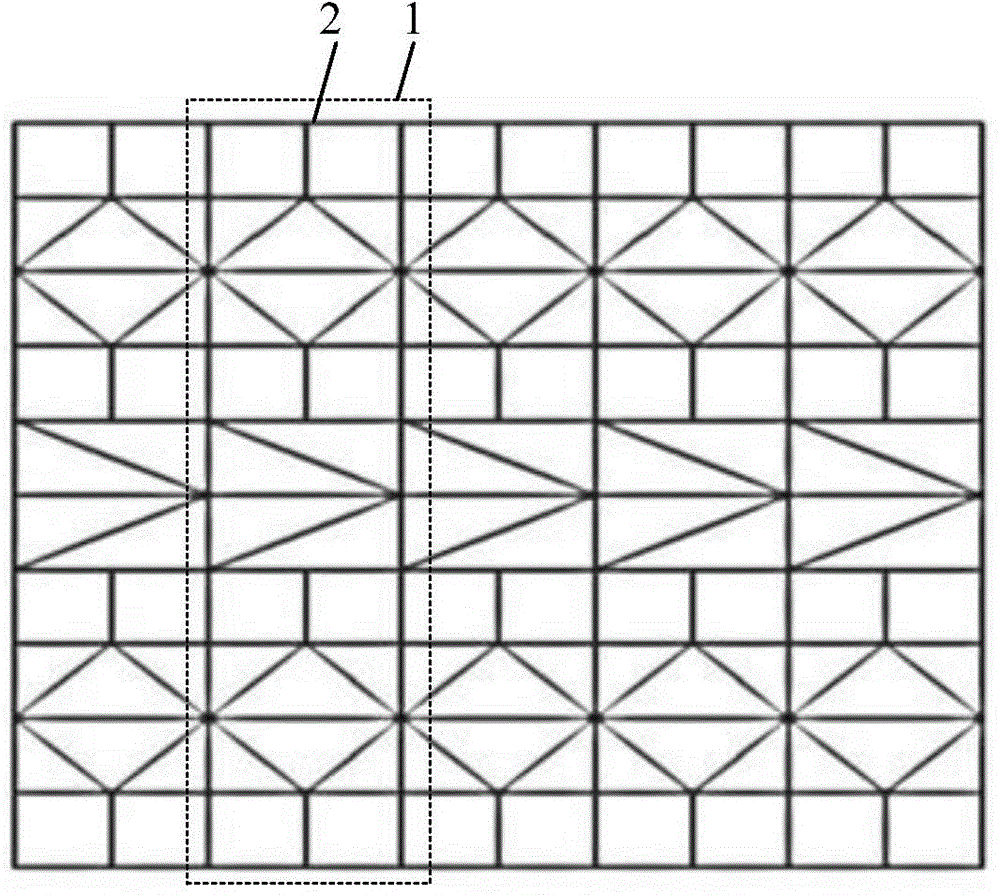

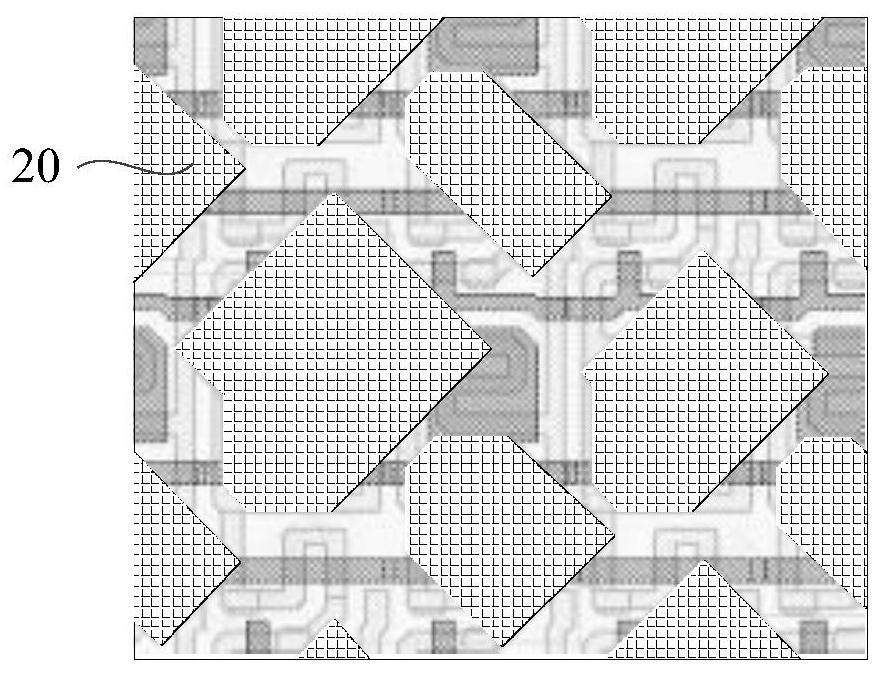

Metal grid, touch screen and display device

ActiveCN104375710ASame materialImprove line overlapInput/output processes for data processingDisplay deviceEngineering

The embodiment of the invention discloses a metal grid, a touch screen and a display device, and relates to the technical field of display. The Moire fringe phenomenon can be improved when the width of metal lines is large. The metal grid comprises a plurality of repeating units. The metal lines in the repeating units define at least two different patterns. The patterns defined by the metal lines in the repeating units are arranged irregularly.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

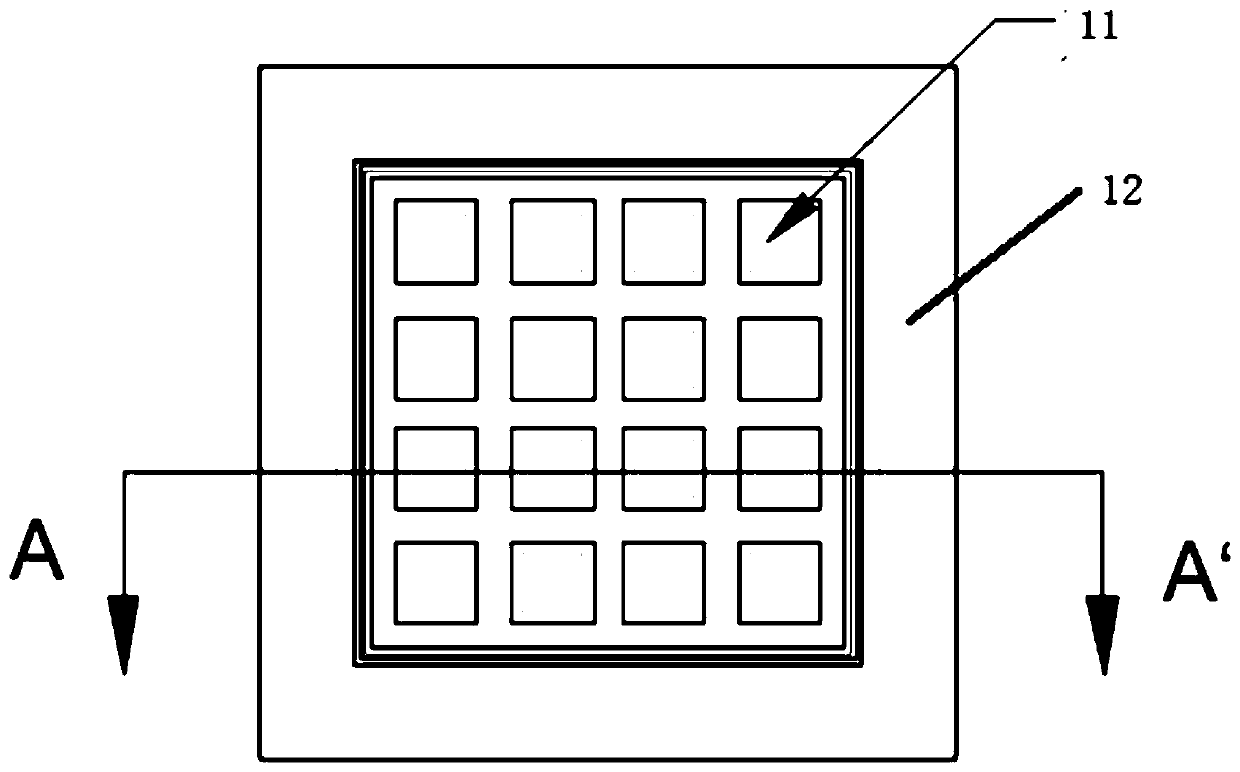

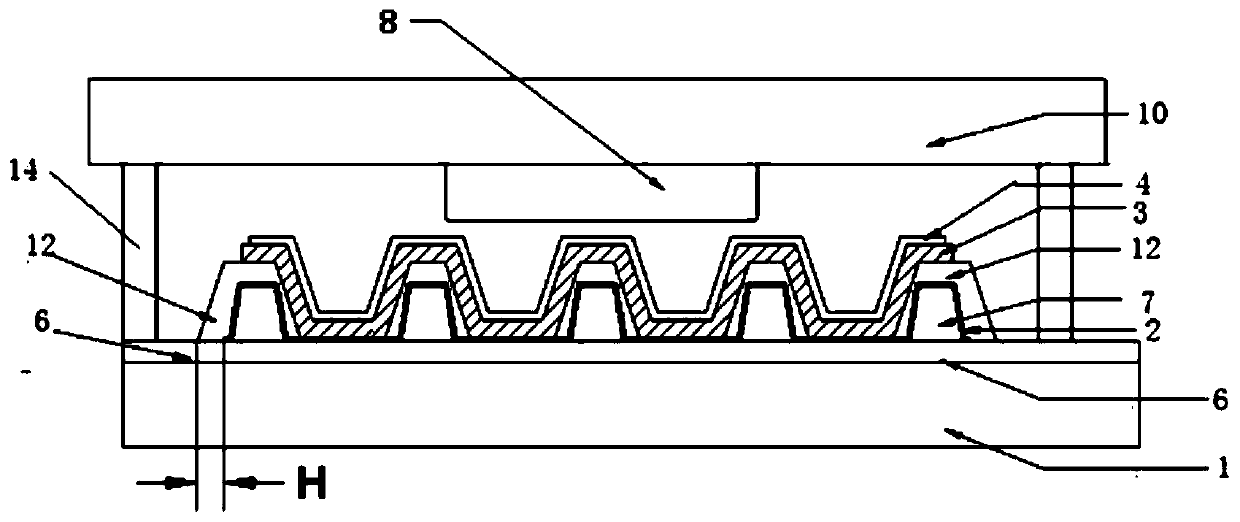

High-stability OLED device and preparation method thereof

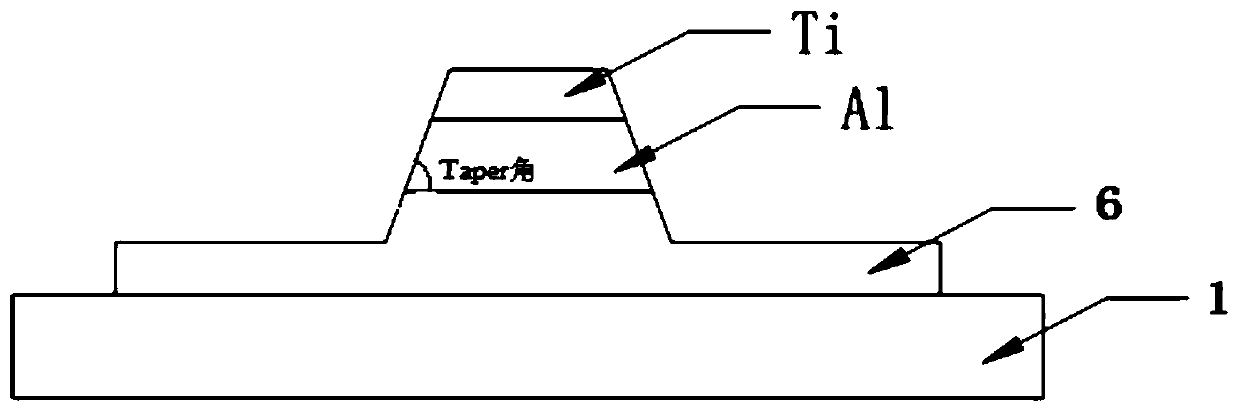

InactiveCN109888116APrevent side erosionSolve the phenomenon of "undercut"Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringAuxiliary electrode

The invention provides a high-stability OLED device and a preparation method thereof. The high-stability OLED device comprises a substrate and a packaging cover plate 10, wherein the substrate is divided into a pixel region and a packaging region; the substrate and the packaging cover plate are connected through a sealing medium; a first electrode layer, an organic light-emitting layer and a second electrode layer are overlapped on the pixel region on the substrate; and a buffer layer is arranged between the first electrode layer and the substrate. Through the arrangement of the buffer layer,the lateral erosion phenomenon caused by dry etching of the auxiliary electrode layer is solved, and meanwhile, metal ions of the glass substrate are blocked from permeating into the first electrode layer, and electrochemical corrosion is avoided; by adding the auxiliary electrode, the brightness uniformity of a screen body is improved; a pixel defining layer is simultaneously arranged on the first electrode layer and the auxiliary electrode layer and is in direct contact with the buffer layer, so that a very good surrounding structure is formed for an effective pixel region and / or pixels of the OLED, volatile gas outgas is prevented from being released into the pixels to cause pixel shrinkage, and the reliability of the screen body of the OLED is improved.

Owner:GUAN YEOLIGHT TECH CO LTD

Embedded SiGe stressor with tensile strain for NMOS current enhancement

ActiveUS7612389B2Improve device performanceSame materialSemiconductor/solid-state device manufacturingSemiconductor devicesTensile strainEngineering

MOS devices having localized stressors are provided. Embodiments of the invention comprise a gate electrode formed over a substrate and source / drain regions formed on either side of the gate electrode. The source / drain regions include an embedded stressor and a capping layer on the embedded stressor. Preferably, the embedded stressor has a lattice spacing greater than the substrate lattice spacing. In a preferred embodiment, the substrate is silicon and the embedded stressor is silicon germanium. A method of manufacturing is also provided, wherein strained PMOS and NMOS transistors may be formed simultaneously.

Owner:TAIWAN SEMICON MFG CO LTD

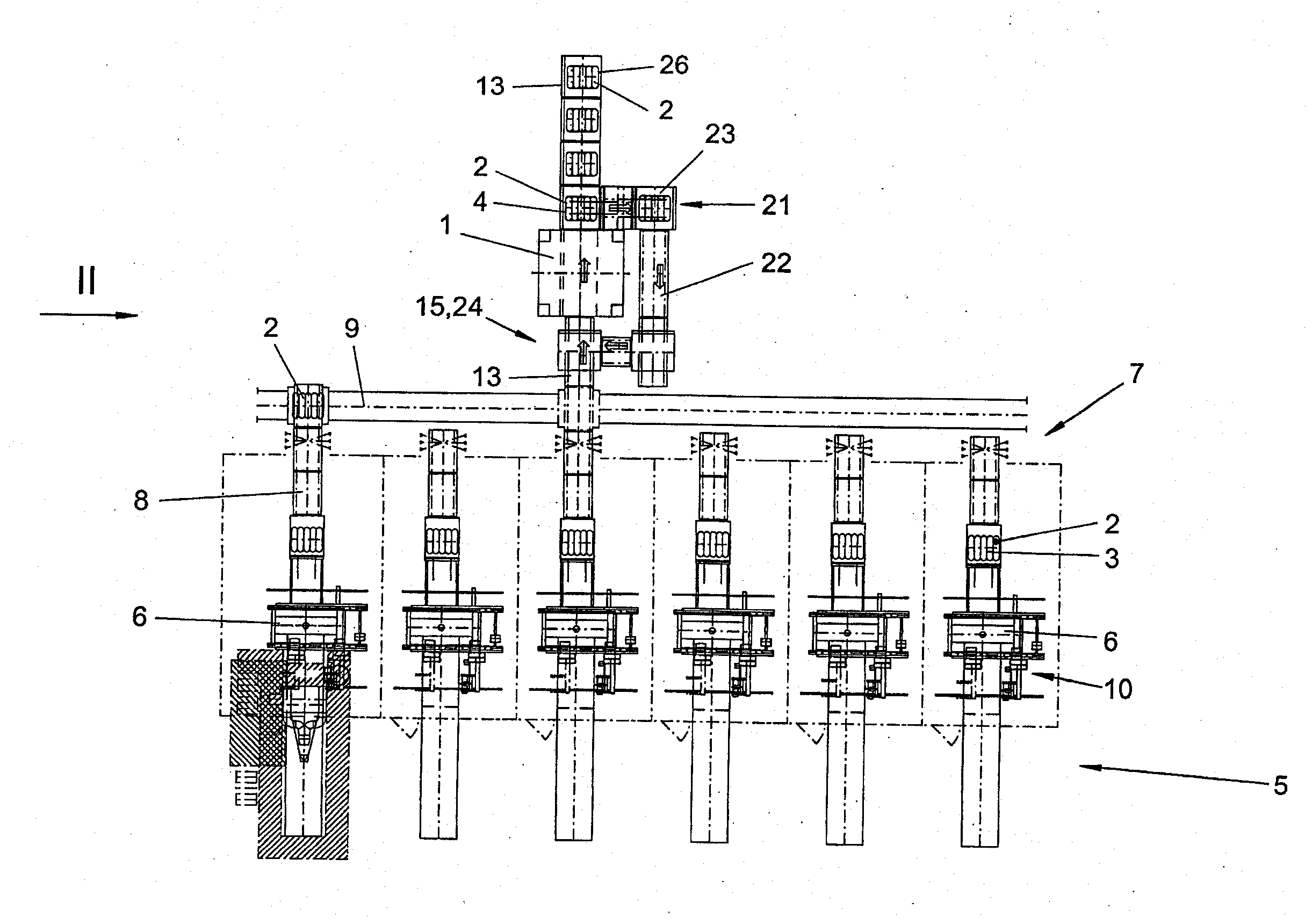

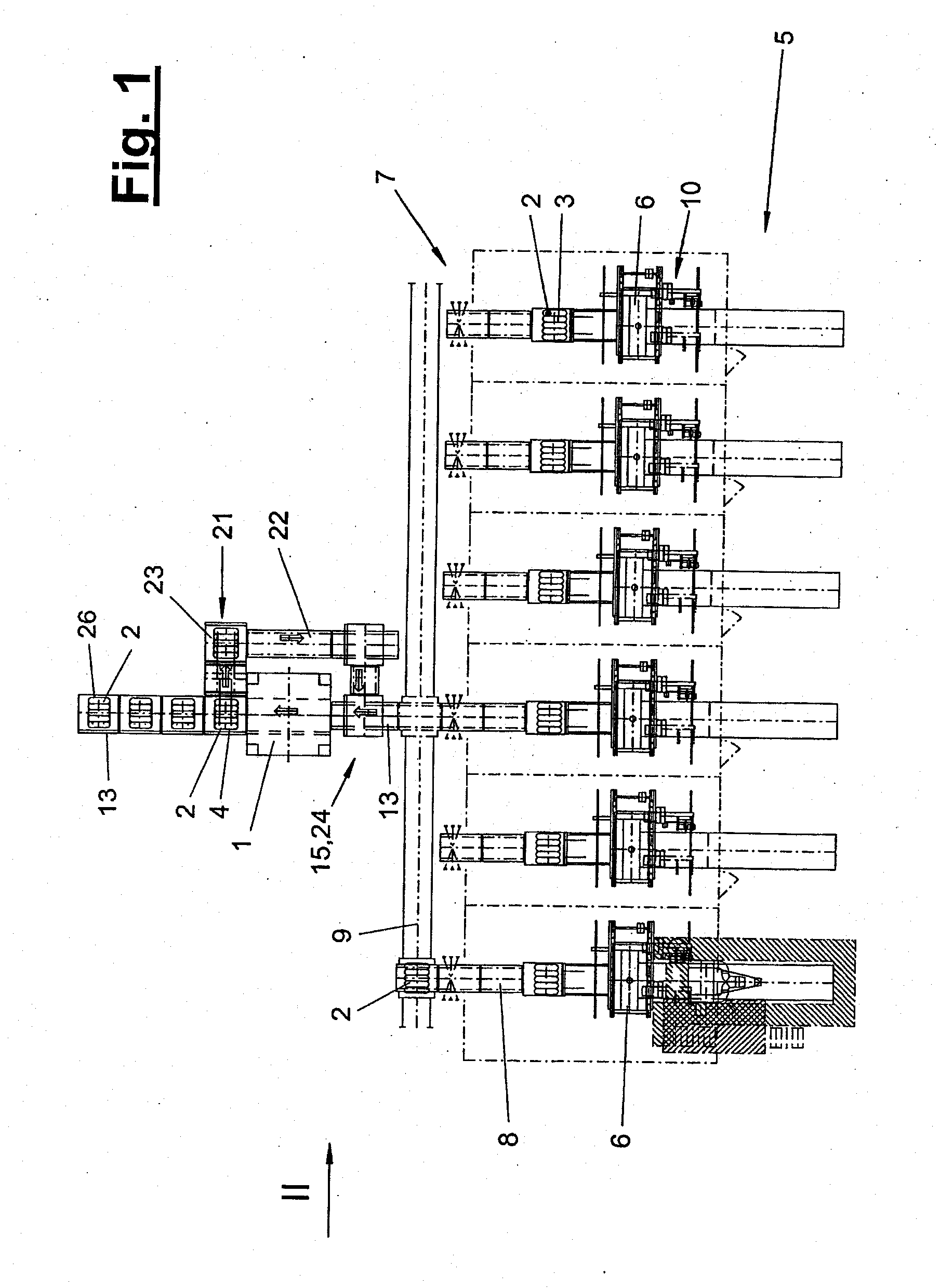

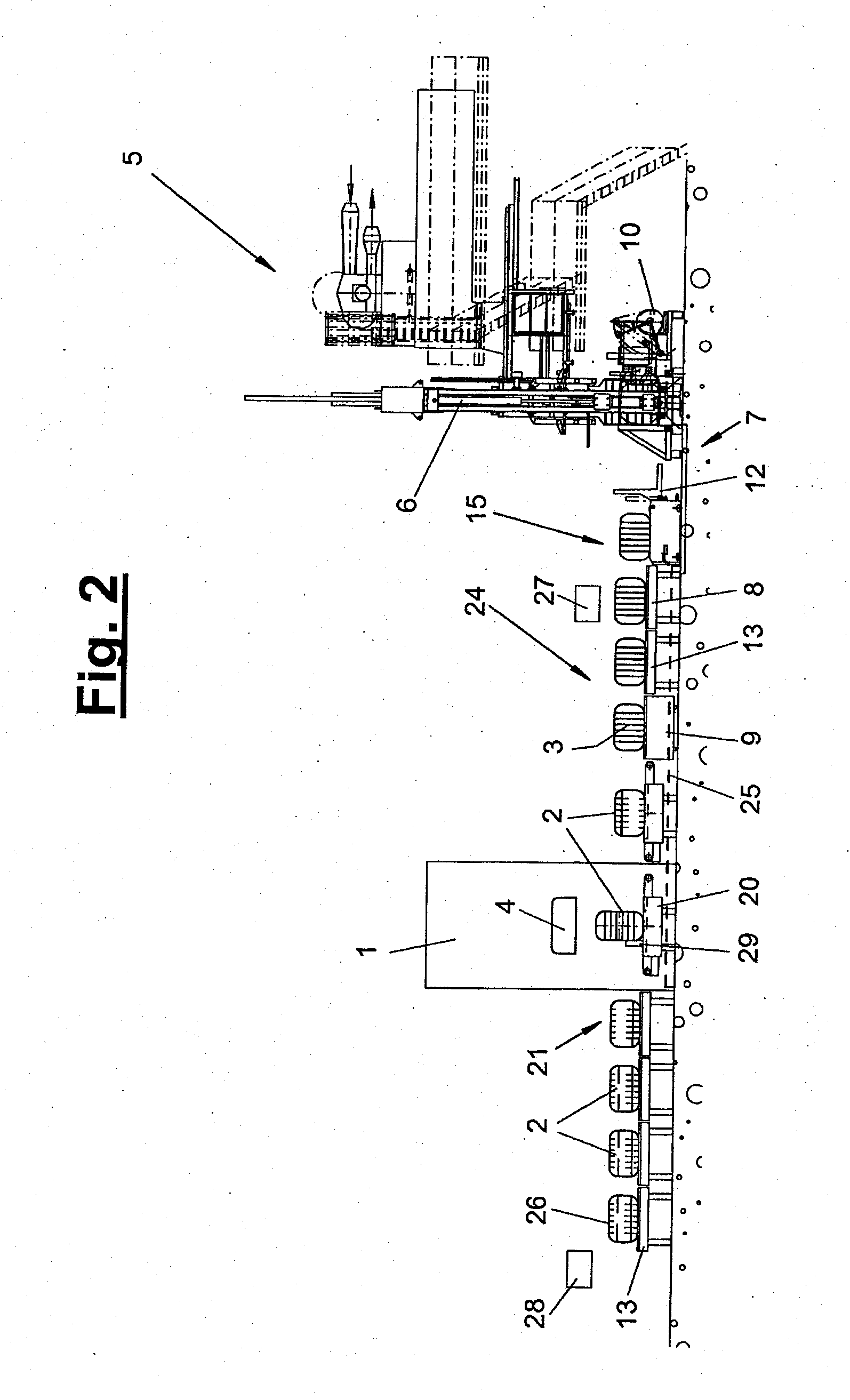

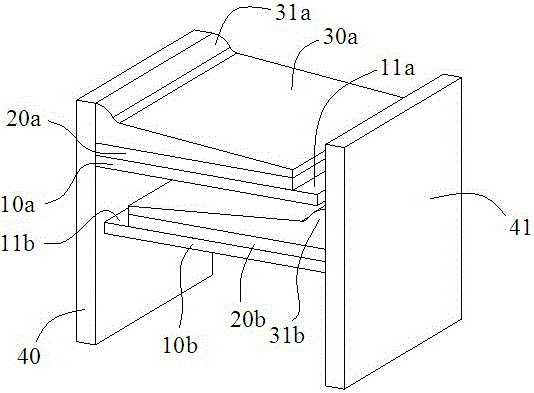

Packaging device and packaging process

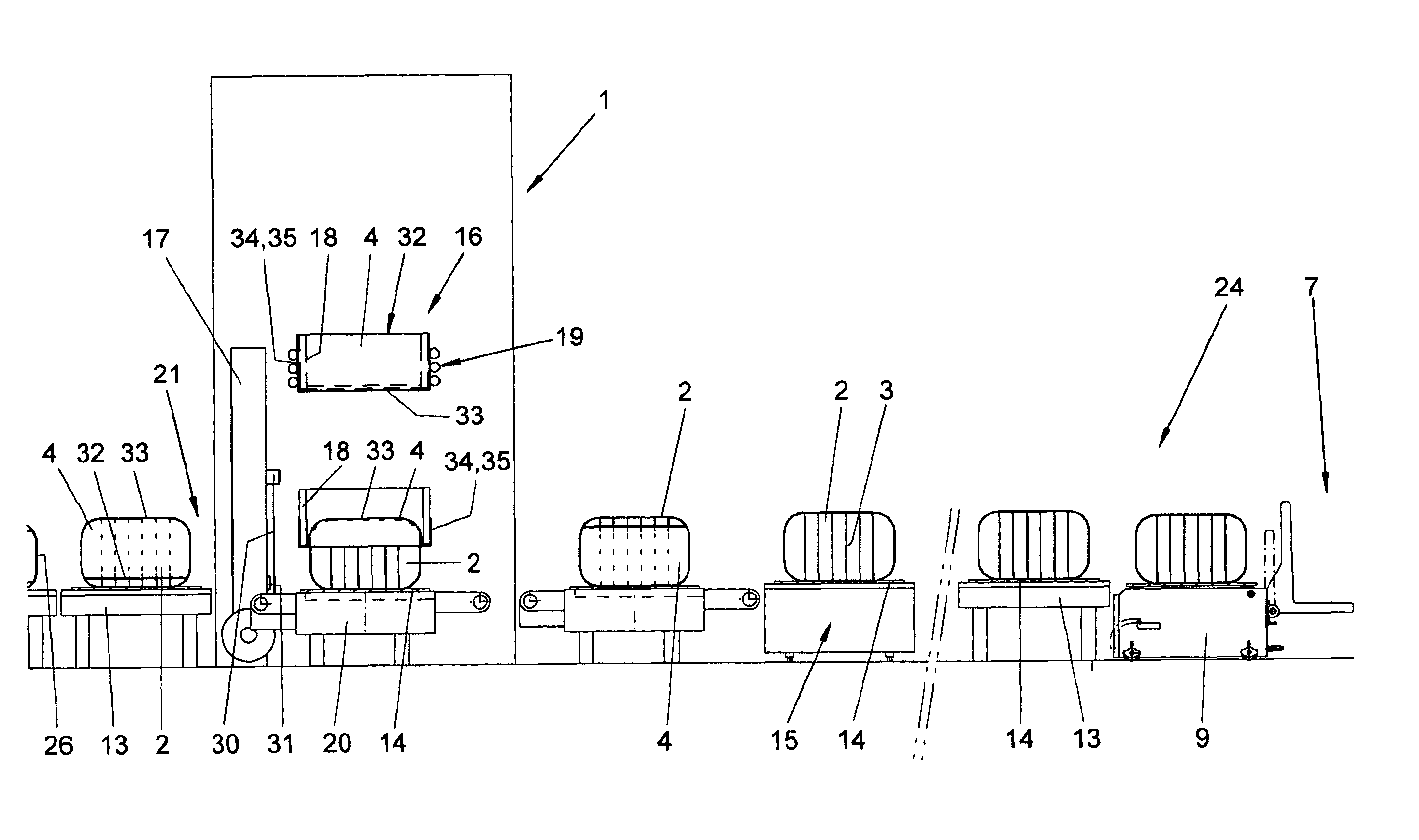

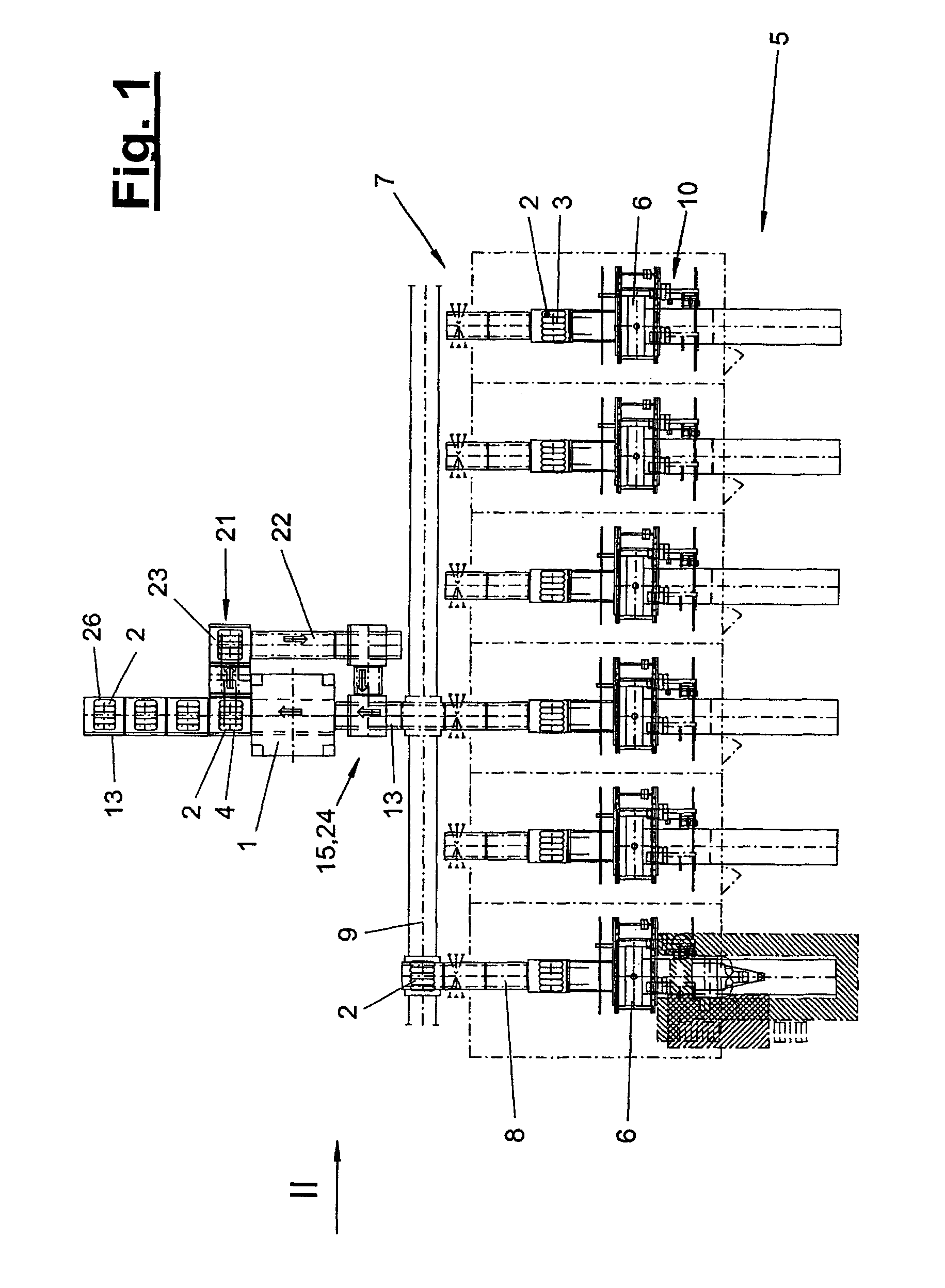

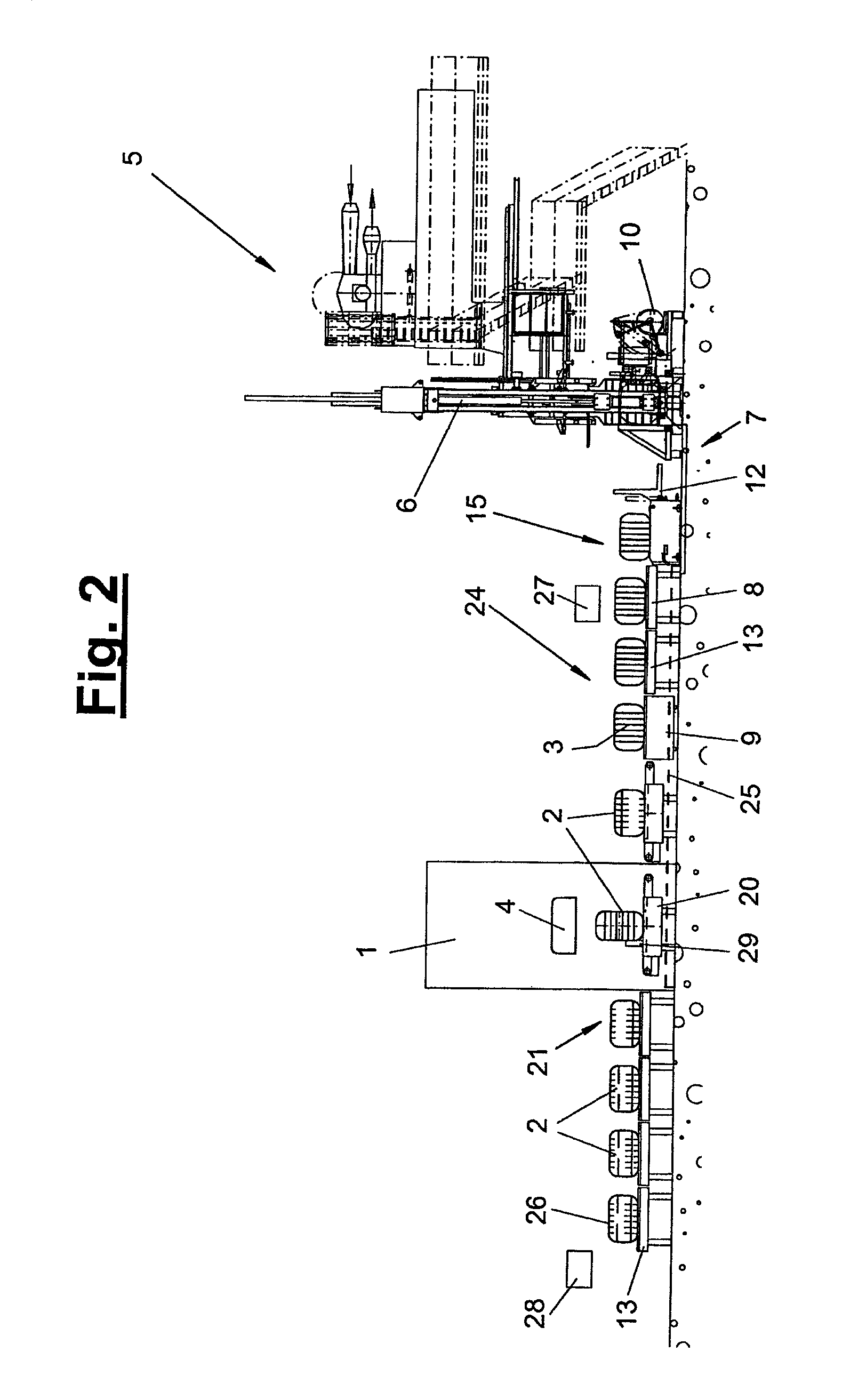

ActiveUS20110011036A1Improved packaging techniqueHighly compactWrappers shrinkageWrapping material feeding apparatusShrink wrapBiomedical engineering

Owner:HI TECH TEXTILE HLDG

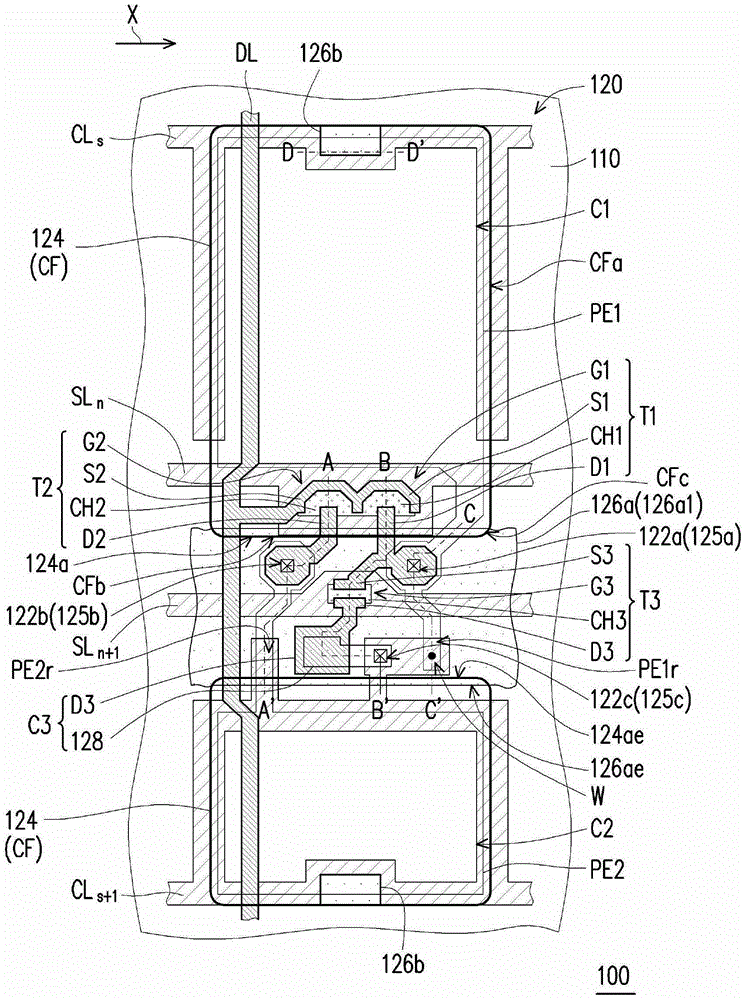

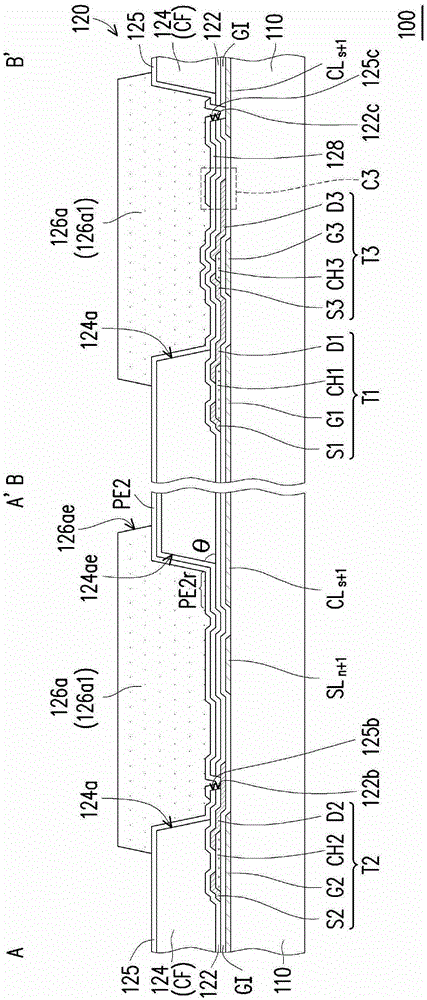

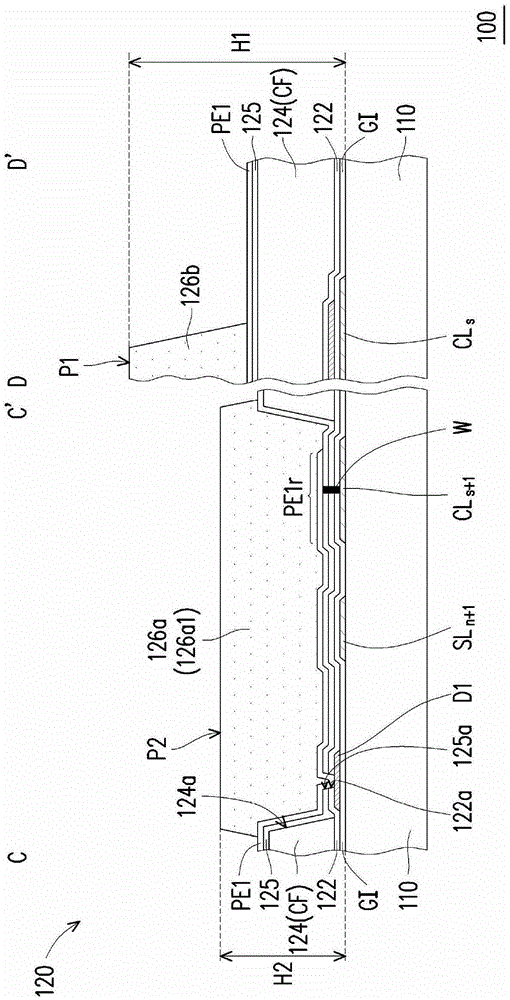

Pixel structure and display panel

ActiveCN105301854AIncrease opening ratioLayout flexibilityNon-linear opticsInsulation layerEngineering

A pixel structure comprises a data line, a first scanning line, a sharing line, a first active element, a second active element, an insulation layer coating the first active element and the second active element, a colorful filtering pattern arranged on the insulation layer, a first pixel electrode and a second pixel electrode arranged on the colorful filtering pattern and a protection pattern. The colorful filtering pattern has a groove. The first pixel electrode fills in the groove so as to electrically connect with the first active element. The first pixel electrode has one portion located in the groove and configured to overlap with the sharing line. The second pixel electrode fills in the groove so as to electrically connect with the second active element. The second pixel electrode has one portion located in the groove and configured to overlap with the sharing line. The protection pattern fills in the groove so as to cover partial first pixel electrode and second pixel electrode. The protection pattern is insulation transparent material.

Owner:AU OPTRONICS CORP

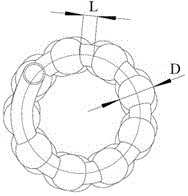

Foamed ceramic decorative plate and preparation method thereof

The invention provides a foamed ceramic decorative plate and a preparation method thereof.The surface of foamed ceramic is coated with decorative mortar to obtain an integral preformed part.After use of the foamed ceramic decorative plate, blade coating of walls or spraying of the decorative mortar is avoided, and accordingly convenience in operation is realized while engineering construction efficiency can be effectively improved.In addition, the service life of the foamed ceramic decorative plate is far longer than that of an organic coating or a plastic composite sheet, and the manufacturing cost of the foamed ceramic decorative plate is much lower than that of a stone composite board.

Owner:GUANGZHOU GOOMASTONE DECORATIVE MATERIAL CO LTD

Production process of 3D glass back cover plate of mobile phone

InactiveCN109608932AImprove gripSave on polishing costsPolishing machinesClimate change adaptationScreen printingHeat resistance

The invention discloses a production process of a 3D glass back cover plate of a mobile phone, comprising the steps of: cutting a 3D glass raw material by using a glass substrate cutting machine to obtain a base material; performing CNC processing on the base material, then putting the processed base material into a graphite mold, and then conducting shaping with hot pressing and bending in a hotpressing bending machine, and conducting cooling to obtain a slab; polishing the slab, and then conducting tempering to obtain a tempered slab; and conducting LOGO screen printing and spraying ink onthe tempered slab, and conducting drying, so as to obtain the 3D glass back cover plate of the mobile phone. The production process of the 3D glass back cover plate of the mobile phone provided by theinvention has a simple process and a low defect rate, the obtained back cover plate has a high strength, and good wear resistance and heat resistance.

Owner:安徽金龙浩光电科技有限公司

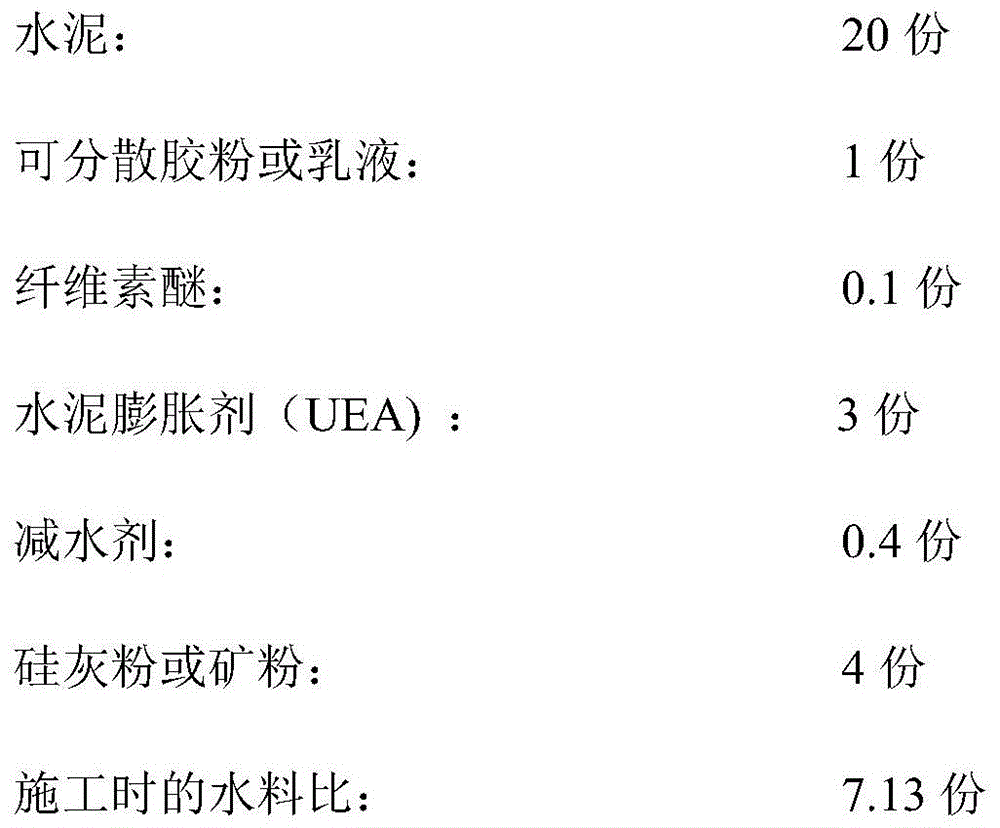

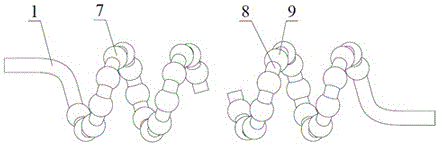

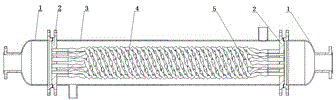

Novel spiral winding pipe heat exchanger

InactiveCN105115320AEnhance the destructive effectSame materialStationary tubular conduit assembliesTubular elementsPlate heat exchangerEngineering

The invention provides a novel spiral winding pipe heat exchanger. The novel spiral winding pipe heat exchanger consists of such parts as a pipe box, a pipe plate, a shell, a heat exchange pipe and a core cylinder, wherein the heat exchange pipe is a novel spiral winding pipe; the novel heat exchange pipe comprises two parts of an inlet section and a winding section; the inlet section is a polishing pipe; the winding section is formed by alternately connecting a spiral winding polishing pipe section with an arc section; other parts of the heat exchanger are still structural types in a general spiral winding pipe heat exchanger; the polishing pipe section and the arc section in the winding section of the heat exchange pipe are smoothly transited, and are the same in material and wall thickness; and a ratio of a diameter D of the arc section to a length L of the straight pipe section is greater than 2(D / L greater than 2). The novel spiral winding pipe heat exchanger is high in turbulent degree, high in heat exchange coefficient, not easy to scale and compact in structure when a working medium flows in the pipe for heat exchange, and is better in development prospect and high in actual application value.

Owner:ZHENGZHOU UNIV

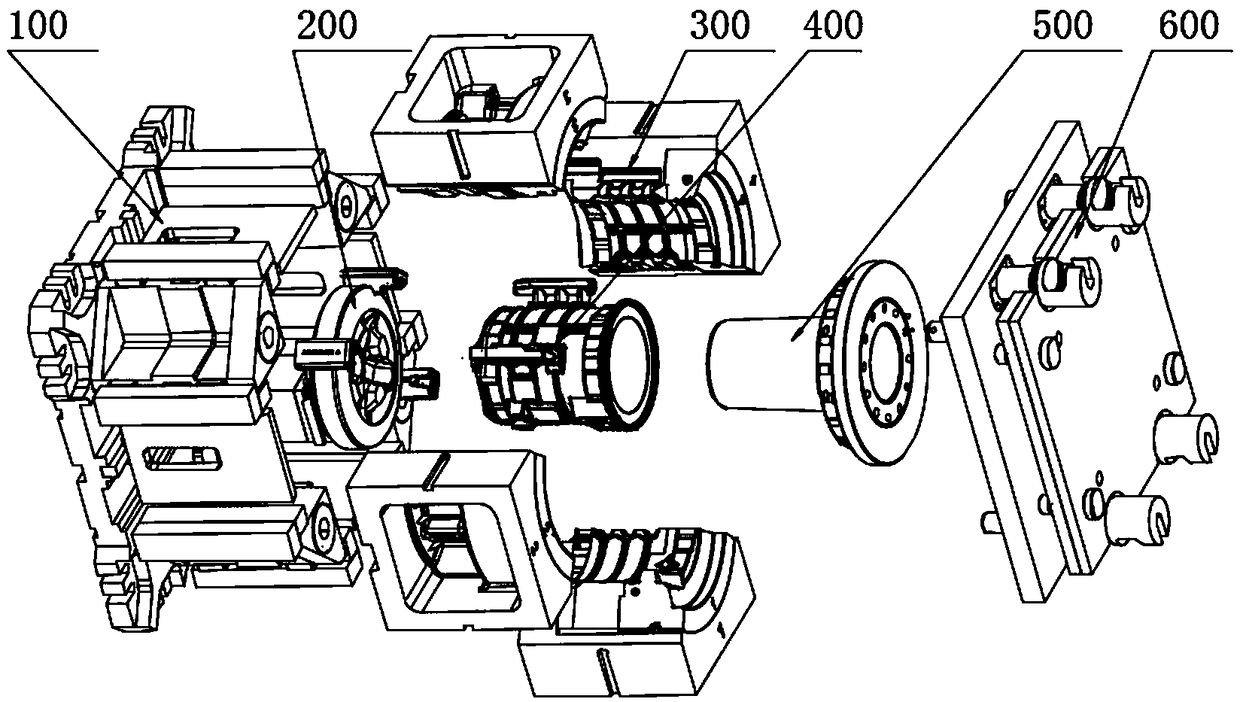

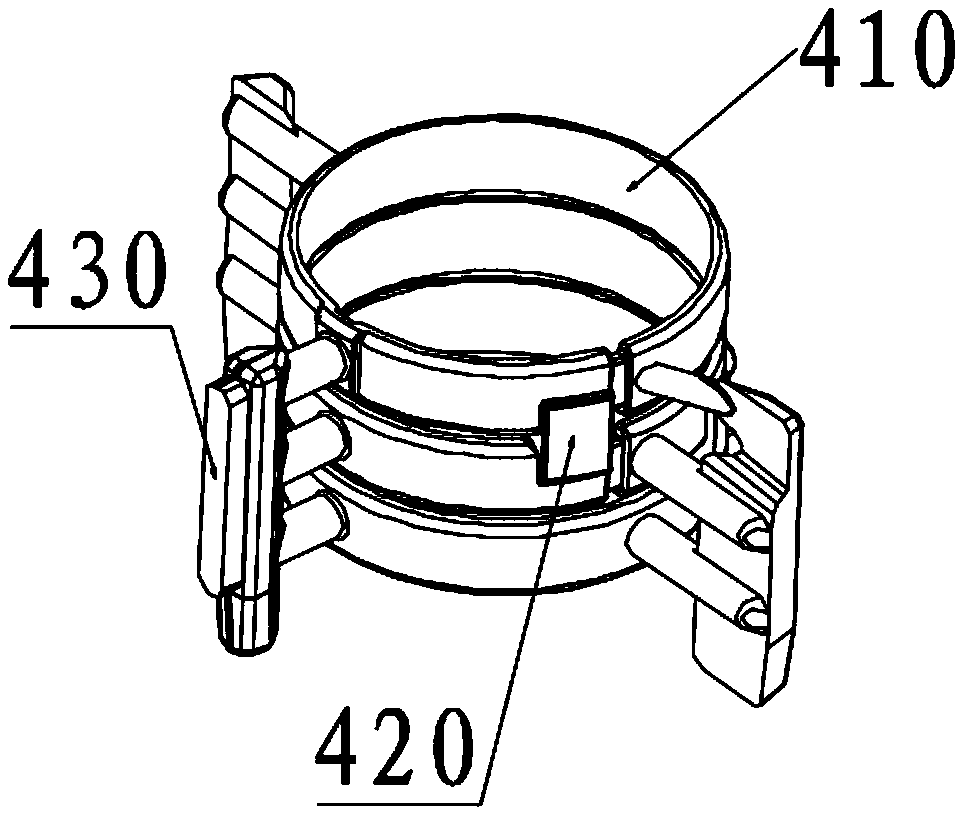

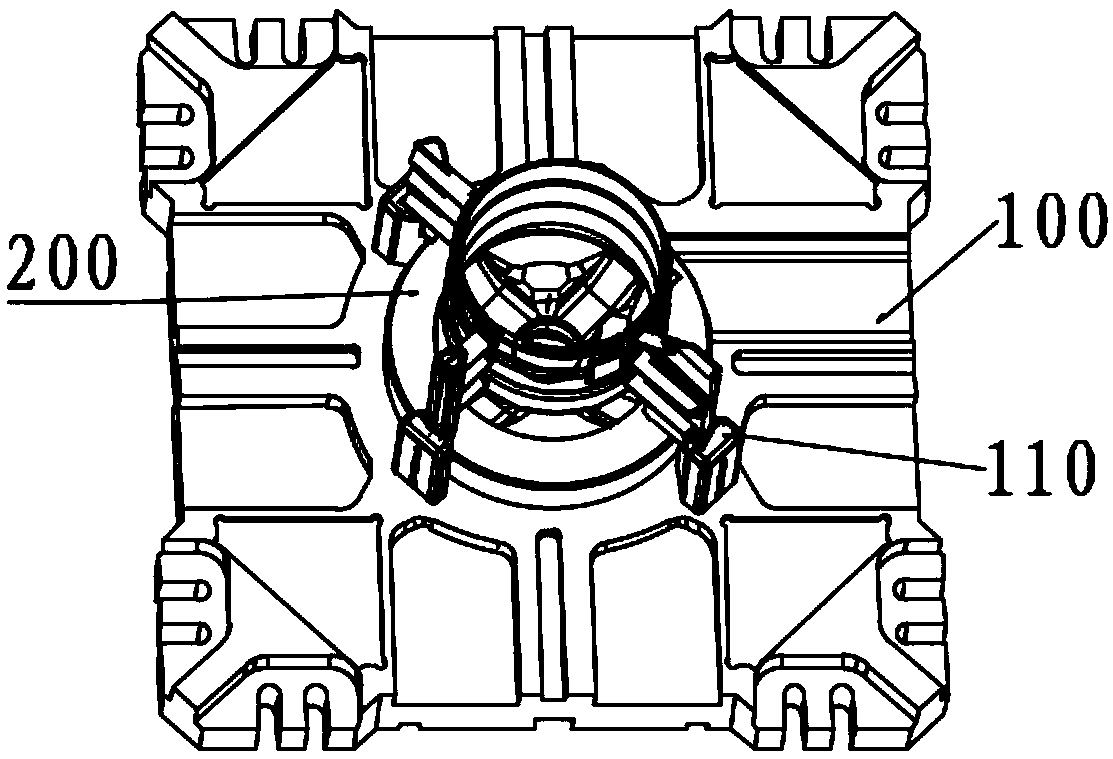

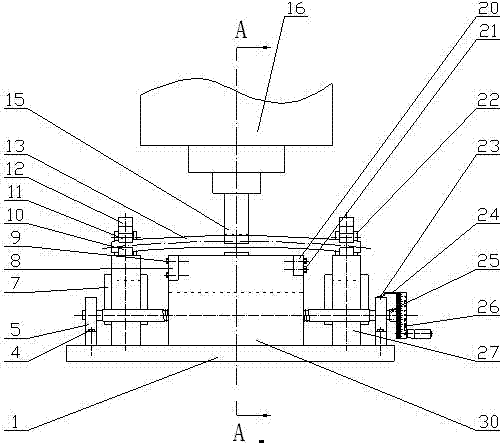

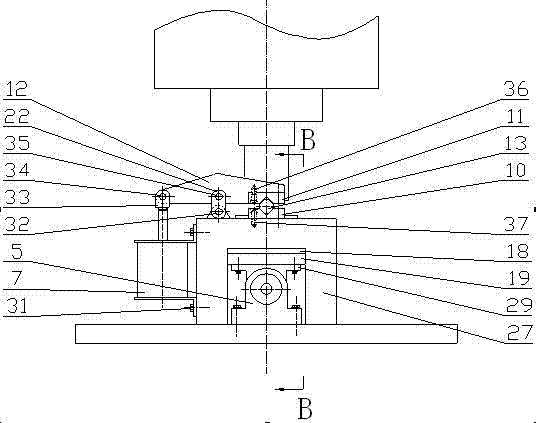

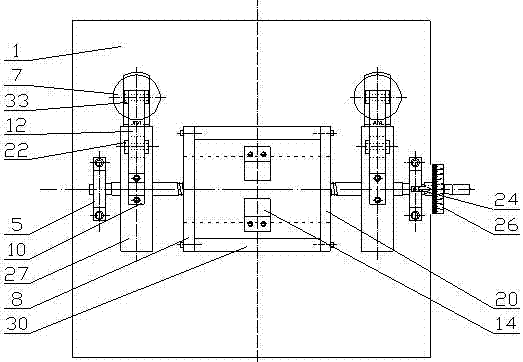

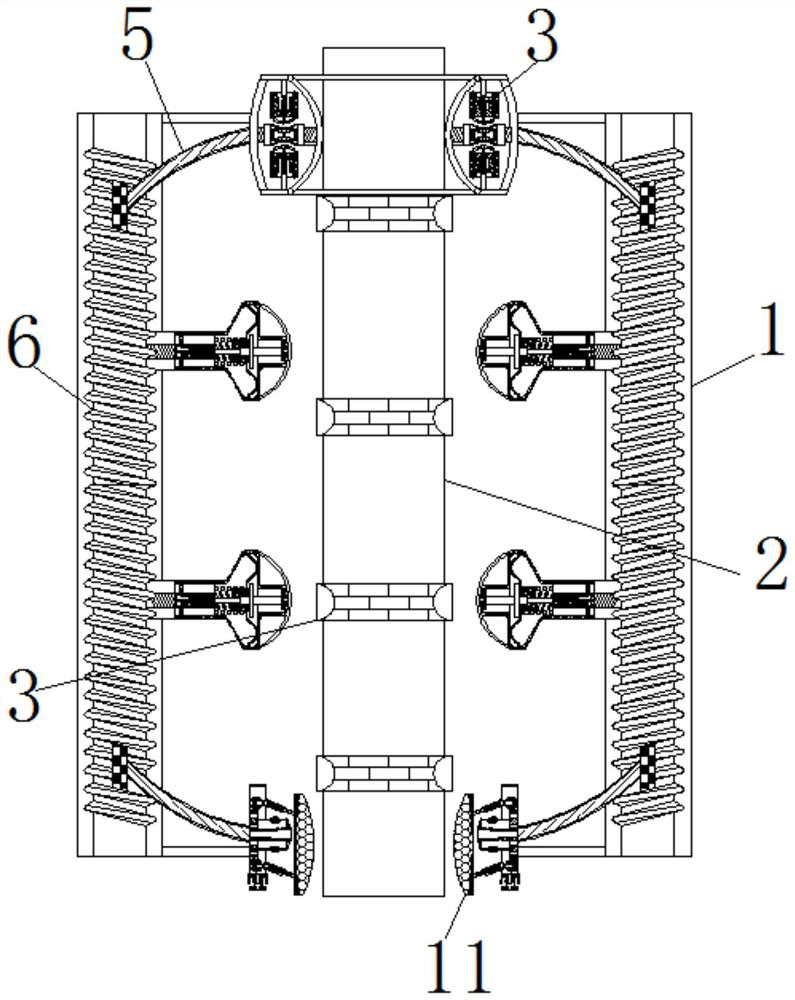

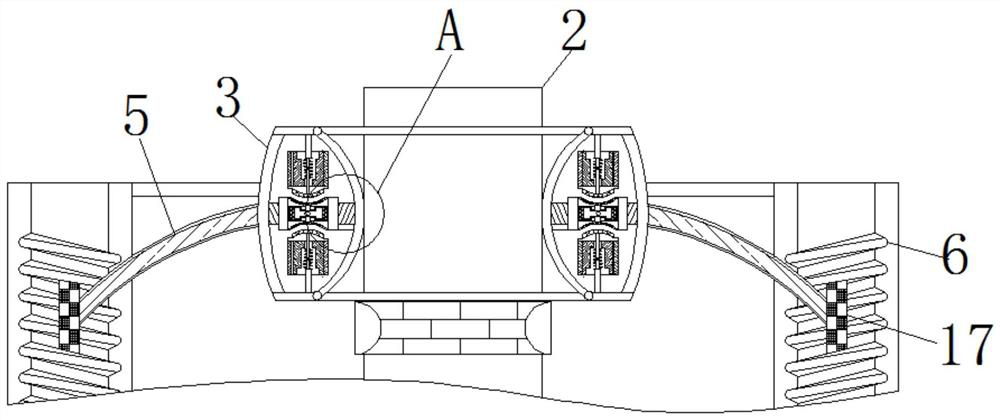

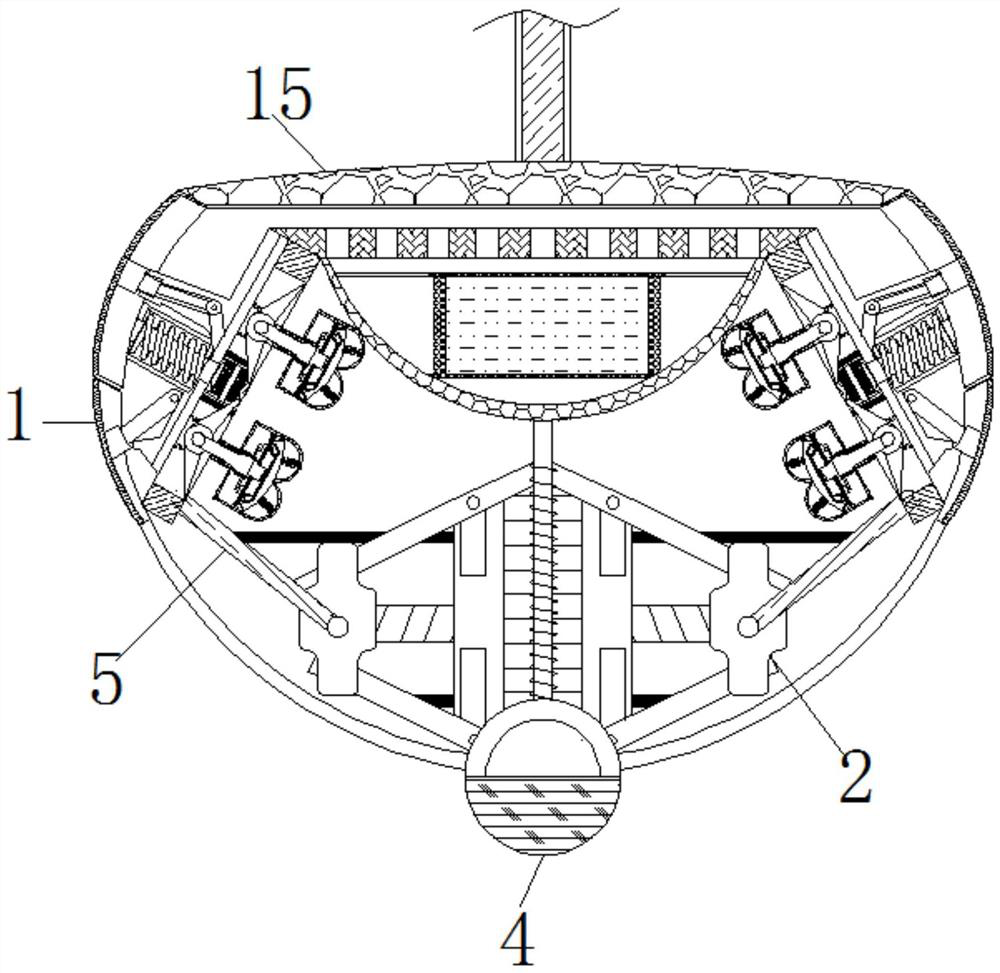

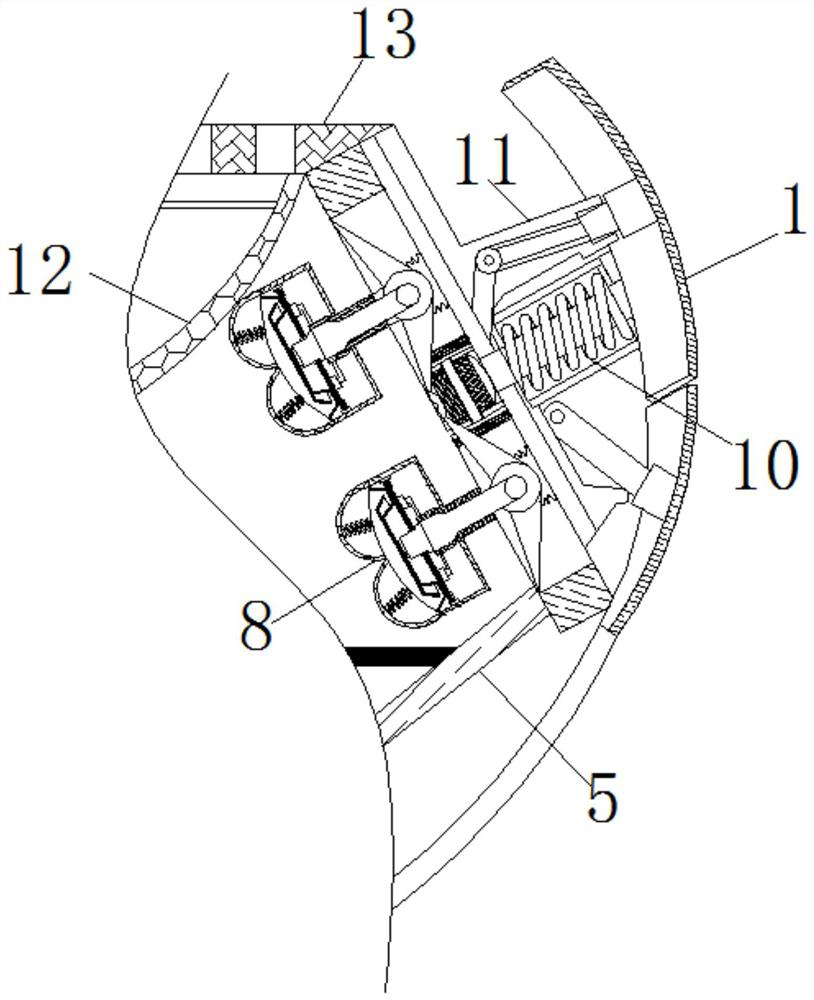

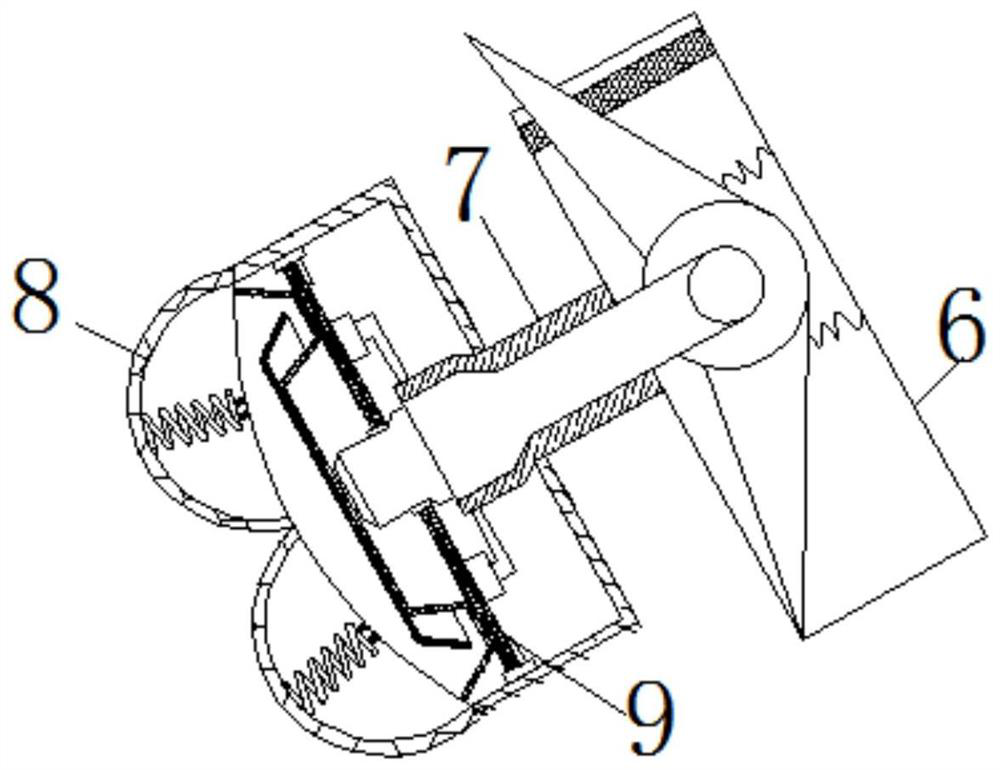

Die used for preparing motor peripheral shell of new energy automobile and equipment

The invention provides a die used for preparing a motor peripheral shell of a new energy automobile and equipment, and relates to the technical field of motor peripheral shell casting. The die used for preparing the motor peripheral shell of the new energy automobile comprises a bottom die installing plate, a bottom die, side dies, a sand core, an upper die and an upper die installing plate; the bottom die is fixed to the bottom die installing plate, the multiple side dies are connected to the bottom die installing plate in a sliding manner and surround the peripheral side of the bottom die, and the sand core is fixed above the bottom die; the sand core comprises a plurality of annular parts and connecting parts, the multiple annular parts are arranged at intervals, and the connecting parts are located between any two adjacent annular parts for connecting the two adjacent annular parts; the upper die is cylindrical, one end of the upper die is fixed to the upper die installing plate, and the other end of the upper die is located in a hollow zone of the sand core; and a gap is reserved between the inner surface of each side die and the outer edge face of the sand core, and a gap isreserved between the inner surface of the sand core and the outer surface of the upper die.

Owner:KUNSHAN ZHONGYITE MACHINERY IND

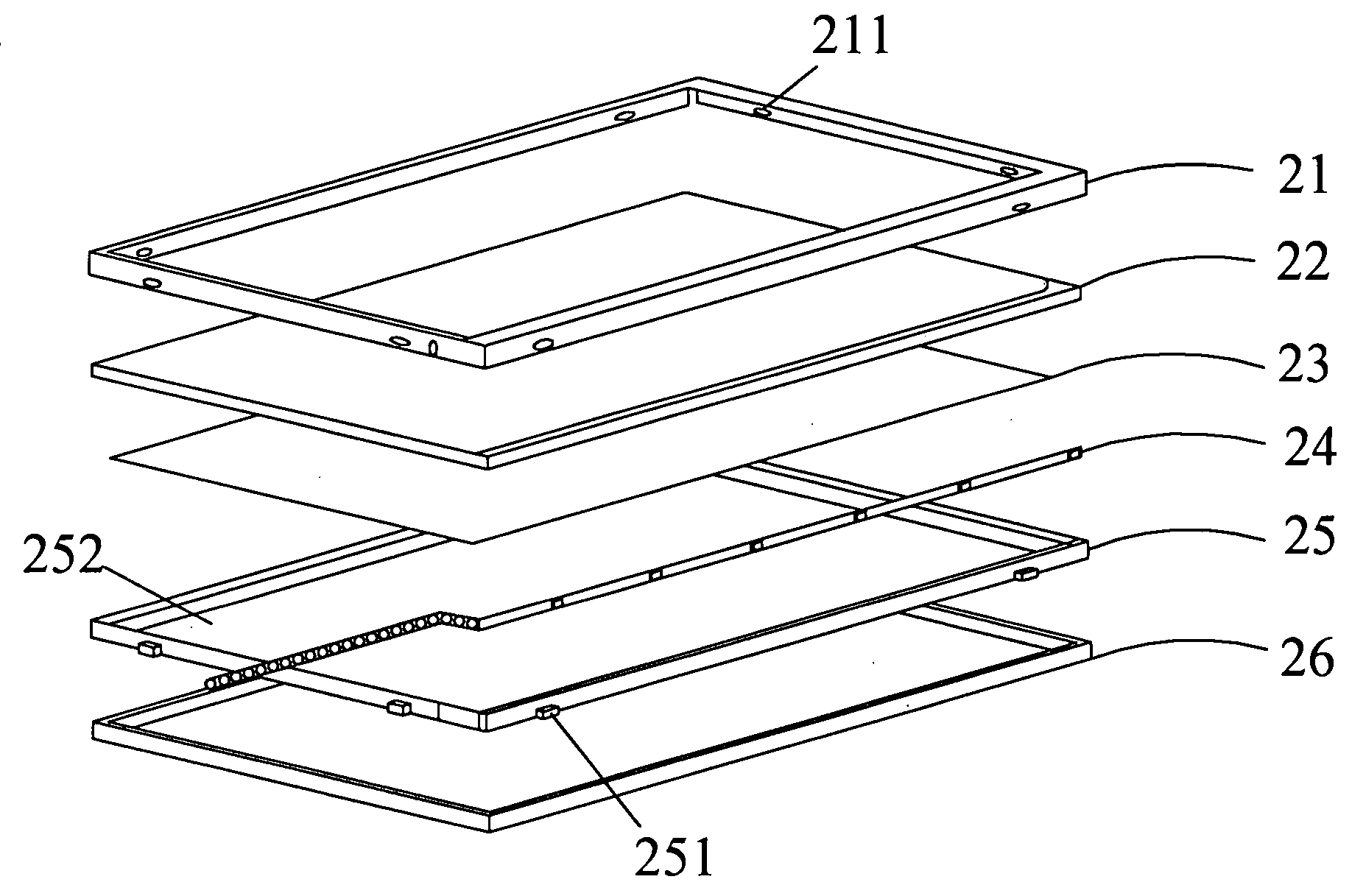

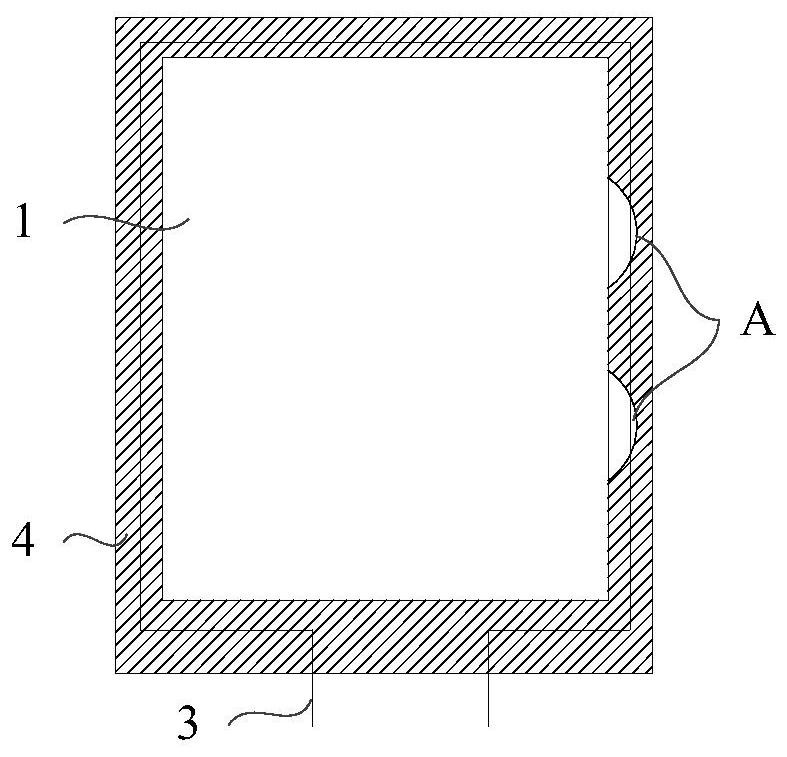

Display device with composite backlight module

ActiveUS20100165230A1Reduce in quantityThe production process is simpleIlluminated signsNon-linear opticsExit surfaceElectrical battery

The present invention discloses a display device comprising a bezel, a cell, at least one film, a light bar and a composite backlight module. The composite backlight module comprises a plurality of connecting structures coupled with the bezel for fixing and protecting the cell, a containing space for containing the cell and the film, and a light guide portion for guiding light emitted by the light bar to a light exit surface of the composite backlight module. The composite backlight module is made of a same material by injection molding.

Owner:HANNSTAR DISPLAY CORPORATION

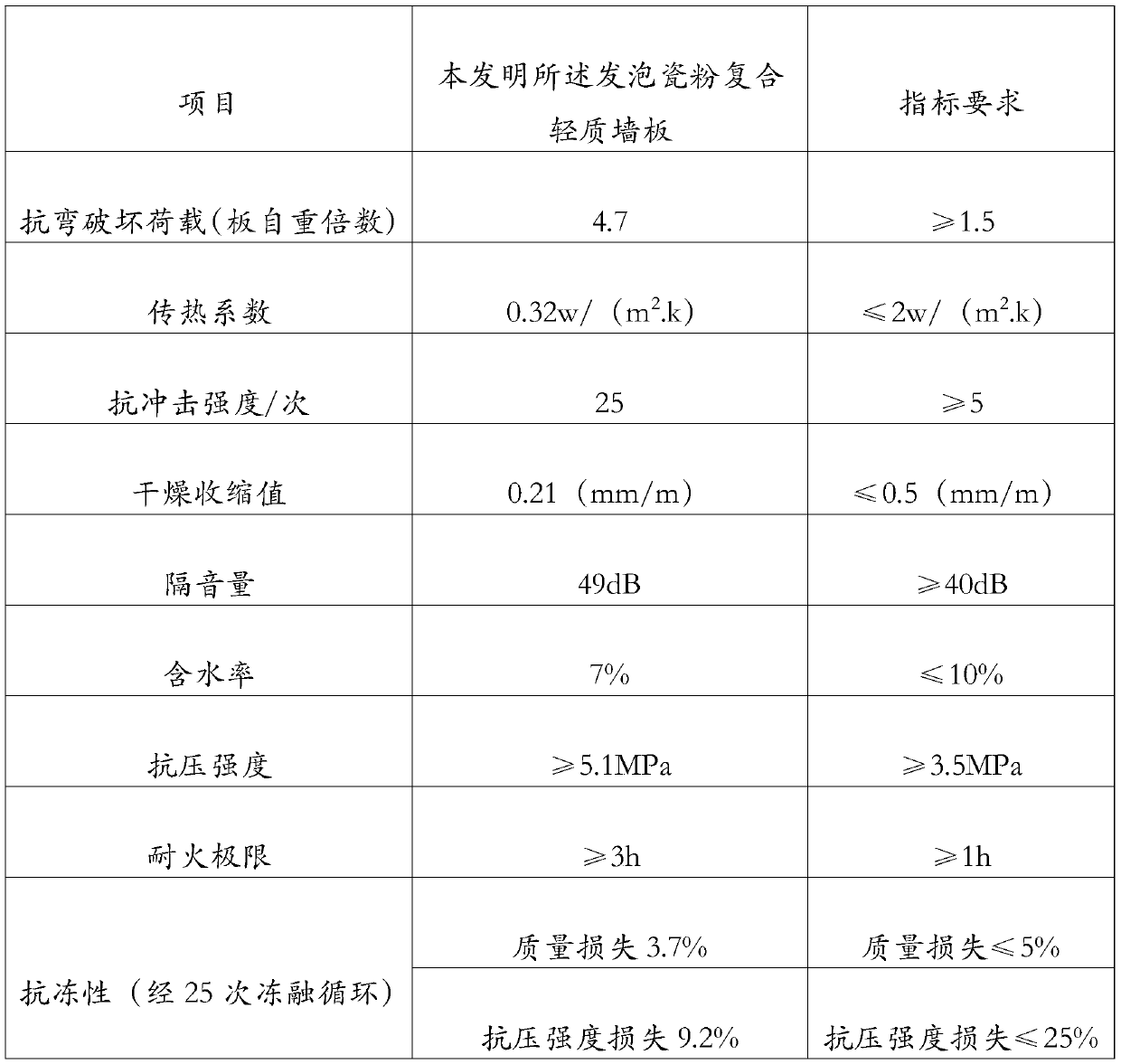

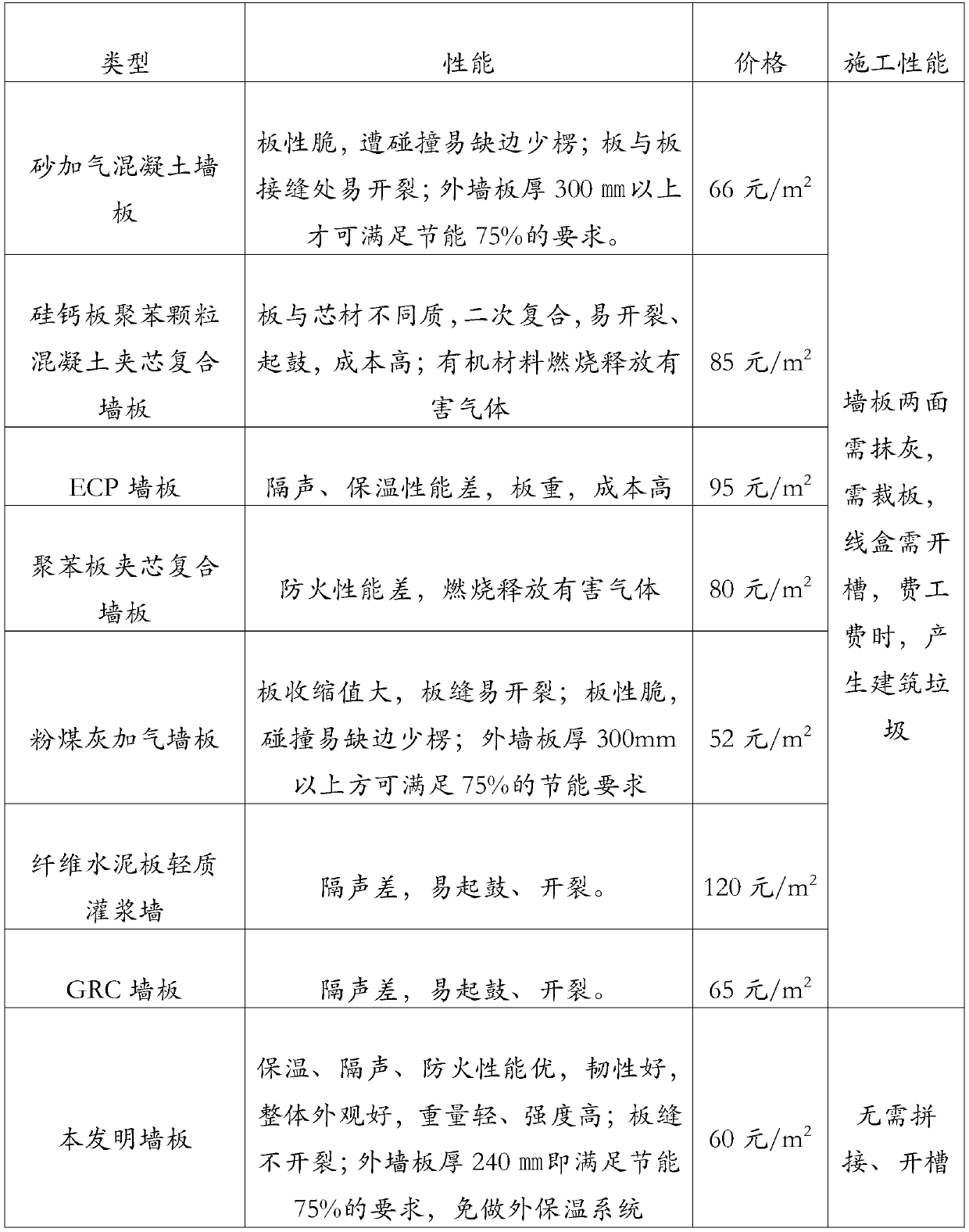

Foam porcelain powder composite light wallboard and production process thereof

InactiveCN110256106AShorten maintenance timeHigh strengthCeramicwareIndustrial wasteAging resistance

The invention discloses a foamed porcelain powder composite light wallboard and a production process thereof. The foamed porcelain powder composite light wallboard comprises the following raw materials: cement, porcelain powder, alkali-resistant glass fiber, a foaming agent and external additives. The foamed porcelain powder composite light wallboard has the beneficial effects that the foamed porcelain powder composite light wallboard adopts industrial waste residues as raw materials, has low cost and good benefit, realizes comprehensive utilization of resources, is beneficial to ecological civilization construction, and conforms to national industrial policies. The bottom layer and the top layer of the foamed porcelain powder composite light wallboard adopt a mixture reinforced by the alkali-resistant glass fiber to serve as a protective layer, a middle layer adopts a foamed mixture as a core material, and the foamed porcelain powder composite light wallboard has the advantages of the same material, one-step molding, strong bonding force, high whole board strength, good toughness, superior compression resistance, sound insulation and aging resistance, one-step molding in the production process, and no plastering on both sides of the wallboard in the use process, thus saving the cost and improving the working efficiency.

Owner:山东铭城环保新材料科技有限公司

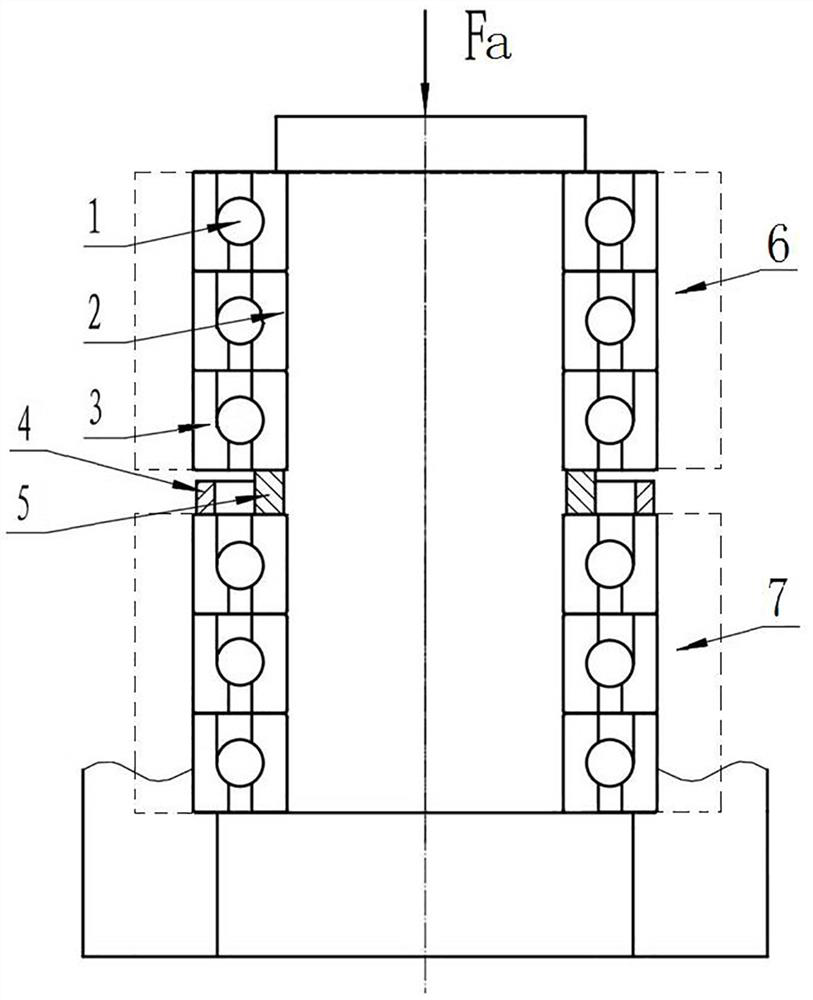

Workpiece straightening machine

PendingCN107537887AOperational quality is stable and reliableImprove work efficiencyRocker armEngineering

The invention discloses a workpiece straightening machine. The workpiece straightening machine is used for straightening bending and deformation of slender shafts, and comprises a universal oil press,a straightening special pressing head, a straightening special fixture and a pressing head travel limiting device. The straightening special pressing head is fixedly connected to the outer end of a piston rod of the oil press. The straightening special fixture comprises a fixture support, a rocker arm, an upper positioning block, a lower positioning block, a connecting rod, an air cylinder and apneumatic control device. According to the workpiece straightening machine, a needed hand wheel rotation angle can be looked up from a "workpiece tortuosity-anti-bending deformation-hand wheel rotation angle" form which is concluded from previous straightening practices according to the measured bending deformation of a to-be-straightened workpiece, the hand wheel is adjusted manually to the corresponding rotation angle, the oil press is started to press downwards, and then the straightening work can be completed. The operation process is manually digitalized, the working efficiency and the straightening precision are improved, and the rejection rate is decreased and the experience requirement for an operator is lowered.

Owner:XUZHOU NORMAL UNIVERSITY

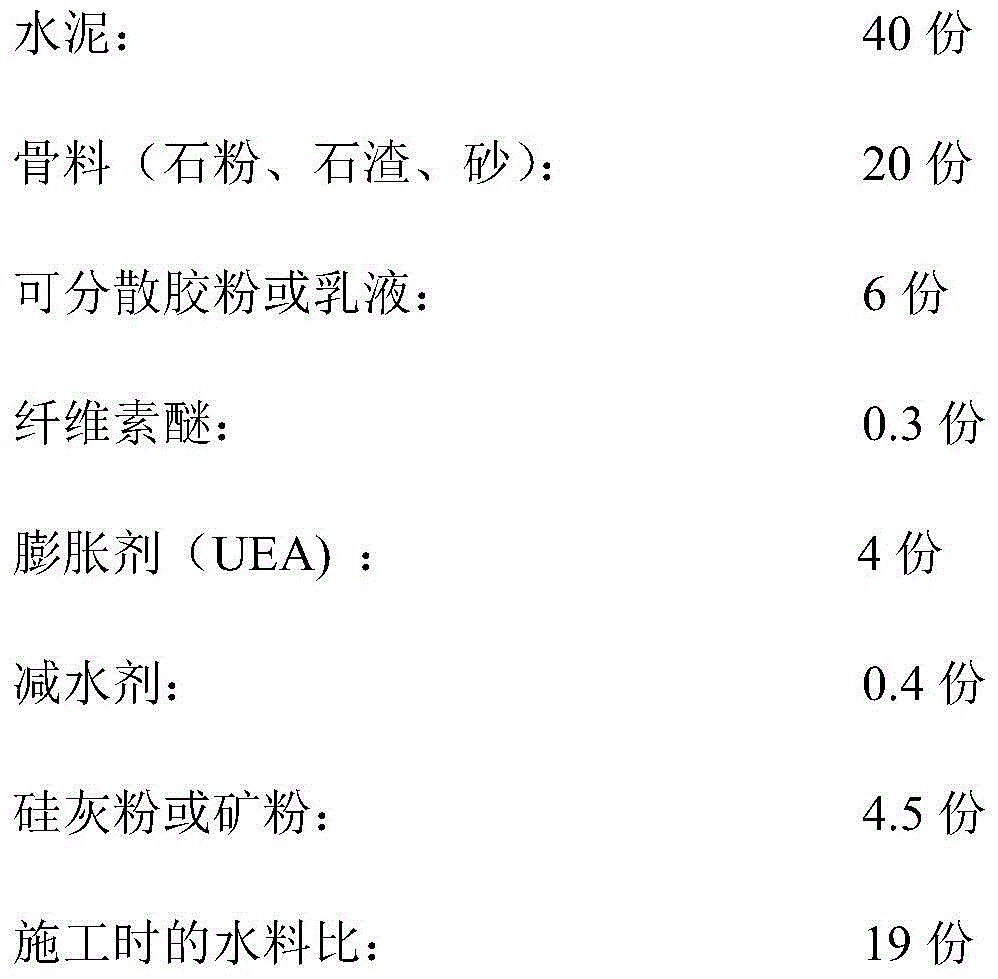

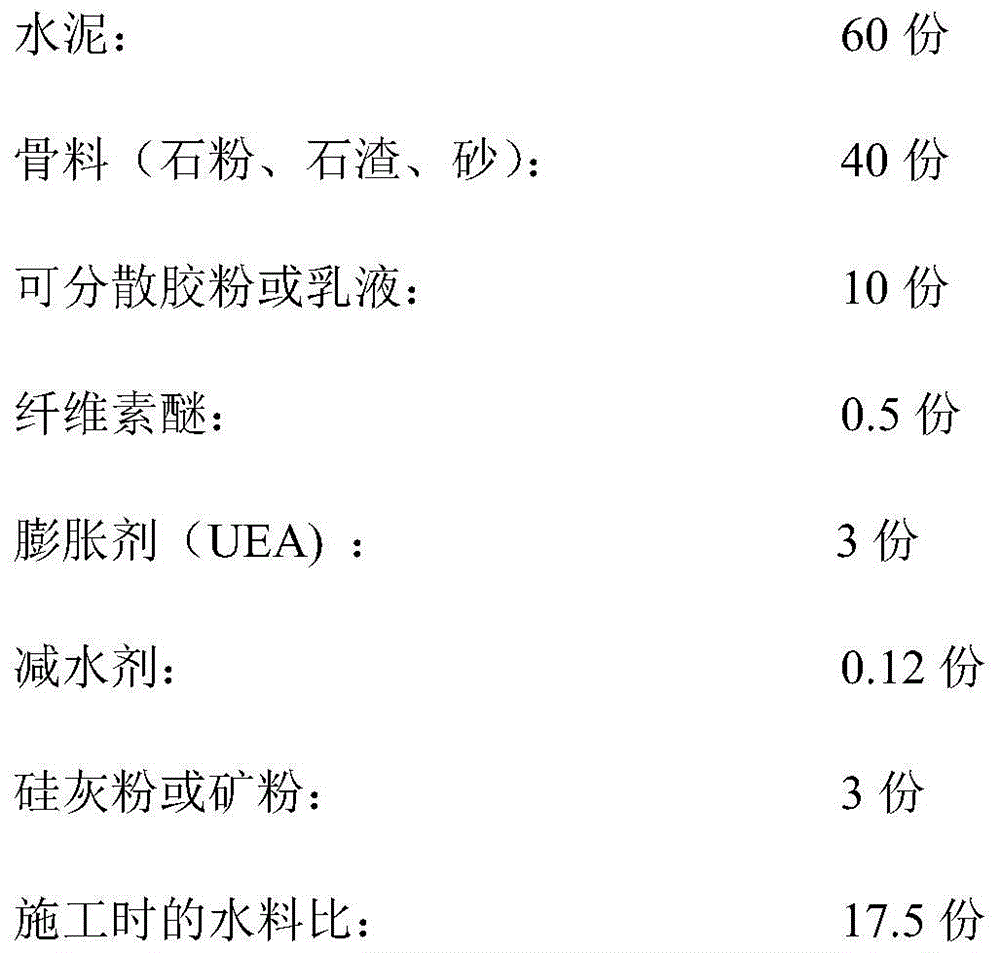

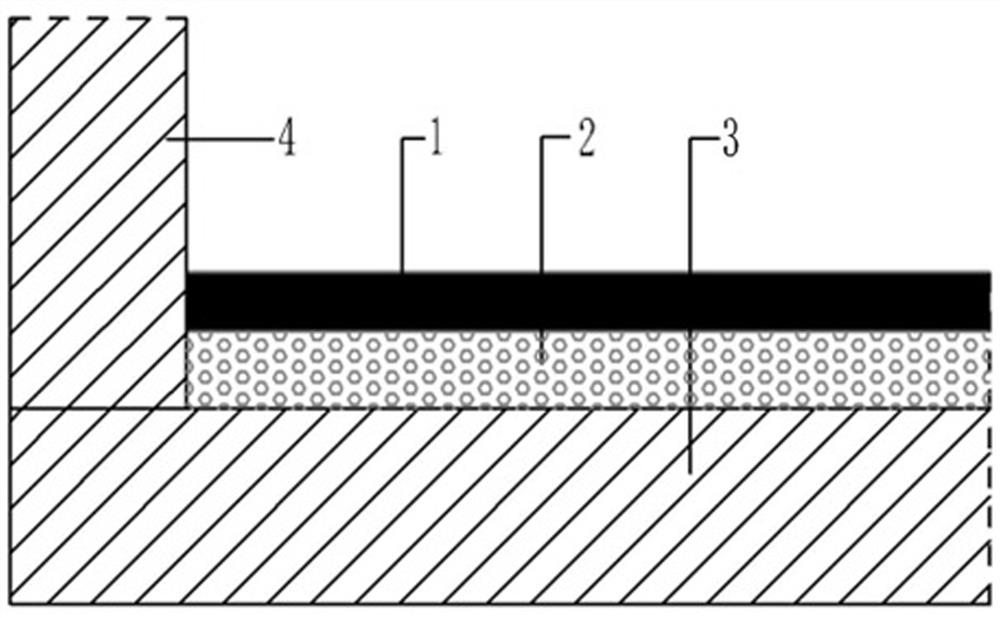

Gypsum-based composite thermal insulation terrace and construction method thereof

InactiveCN113187197AAvoid hollowing between layersQuality improvementCovering/liningsFlooring insulationsThermal insulationEngineering

The invention provides a gypsum-based composite thermal insulation terrace and a construction method thereof. The terrace is composed of a gypsum-based self-leveling mortar protection leveling layer and a gypsum-based double-foaming slurry thermal insulation filling layer from top to bottom, the thickness of the gypsum-based self-leveling mortar protection leveling layer is 20-50 mm, the thickness of the gypsum-based double-foaming slurry thermal insulation filling layer is 20-50 mm. The gypsum-based double-foaming slurry thermal insulation filling layer and the gypsum-based self-leveling mortar protection leveling layer are both made of gypsum-based materials, not only have the advantages of being low in shrinkage rate, coordinating in shrinkage, stable in bonding, flat, resistant to cracking and the like, but also can adopt a mechanical pumping cast-in-place process for the two-layer structure, can be hardened within five hours for continuous construction, the quality, the efficiency and the cost of the thermal insulation terrace can be obviously improved.

Owner:浙江金铠建筑科技有限公司

Packaging device and packaging process

ActiveUS8549820B2Highly compactHighly compressedWrappers shrinkageWrapping material feeding apparatusShrink wrapBiomedical engineering

Owner:HI TECH TEXTILE HLDG

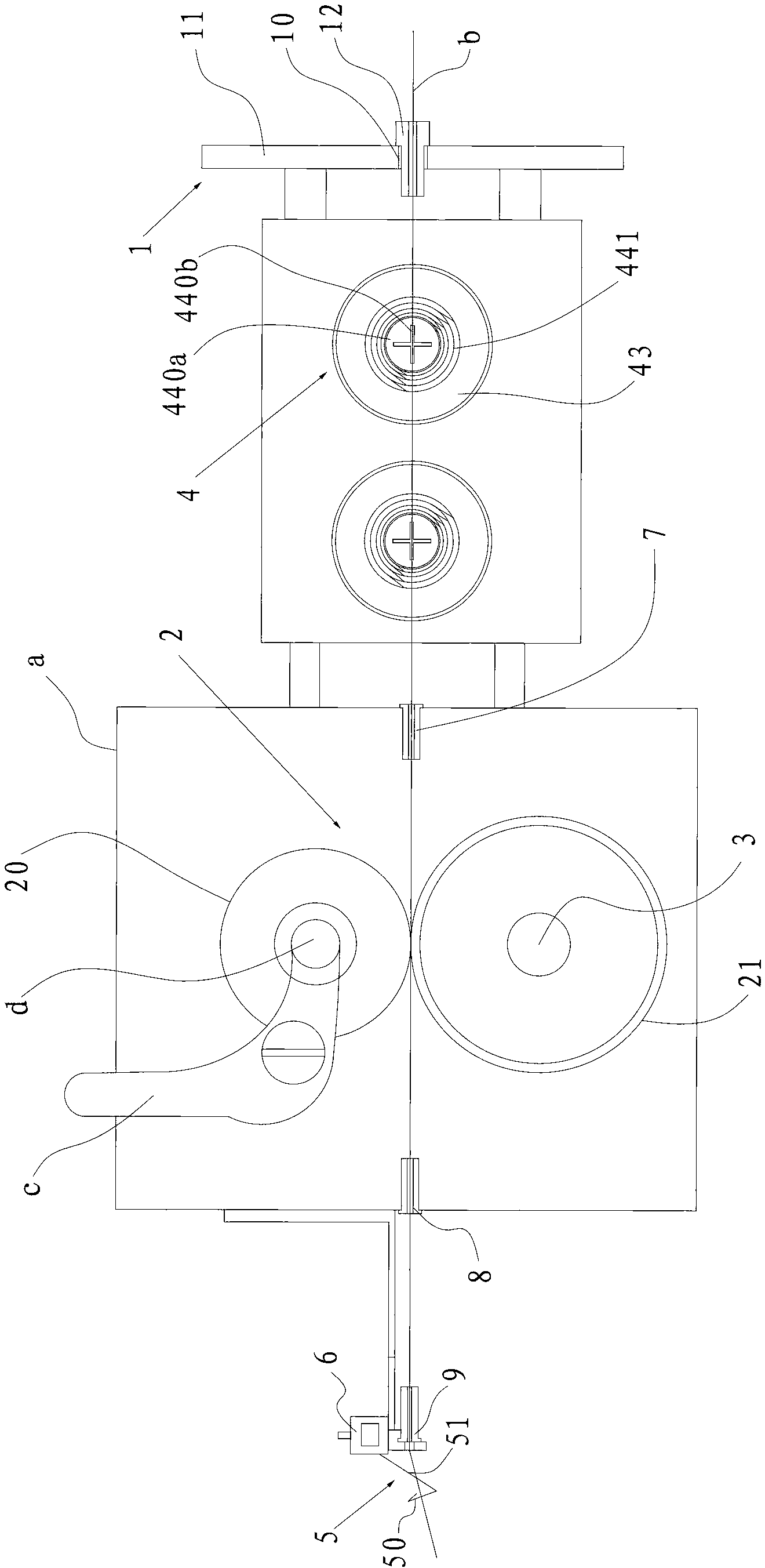

Conveying device for yarns

The invention relates to a conveying device for yarns. The conveying device comprises a yarn winder, a roller pair and a driving mechanism, the roller pair comprises an upper roller and a lower roller, the lower roller is fixedly arranged on a driving shaft of the driving mechanism, the upper roller can rotate around the axis of itself, and the upper roller is arranged on the lower roller in a pressing mode. The conveying device for yarns is characterized in that the conveying device further comprises a plurality of tension clamps arranged between the roller pair and the yarn winder, a yarn guiding hook and a yarn breakage sensor, wherein the yarn guiding hook and the yarn breakage sensor are arranged on a yarn outlet of the roller pair, the tension clamps are used for adjusting tightness degree of the yarns, the yarn guiding hook comprises a yarn hook and a hook handle, one end portion of the yarn breakage sensor is communicated with the driving mechanism, a contact is arranged at the other end portion of the yarn breakage sensor, and when the yarns pass by the yarn hook, a hook handle is not contacted with a contact, and when the yarns do not pass by the yarn hook, the hook handle is contacted with the contact. According to the conveying device for yarns, tightness degree of the yarns is adjusted by the tension clamps, and meanwhile after the yarns are broken, the driving mechanism stops working, an operator easily finds the yarn breakage, so that production efficiency of a textile device is improved.

Owner:江苏舒跑科技有限公司

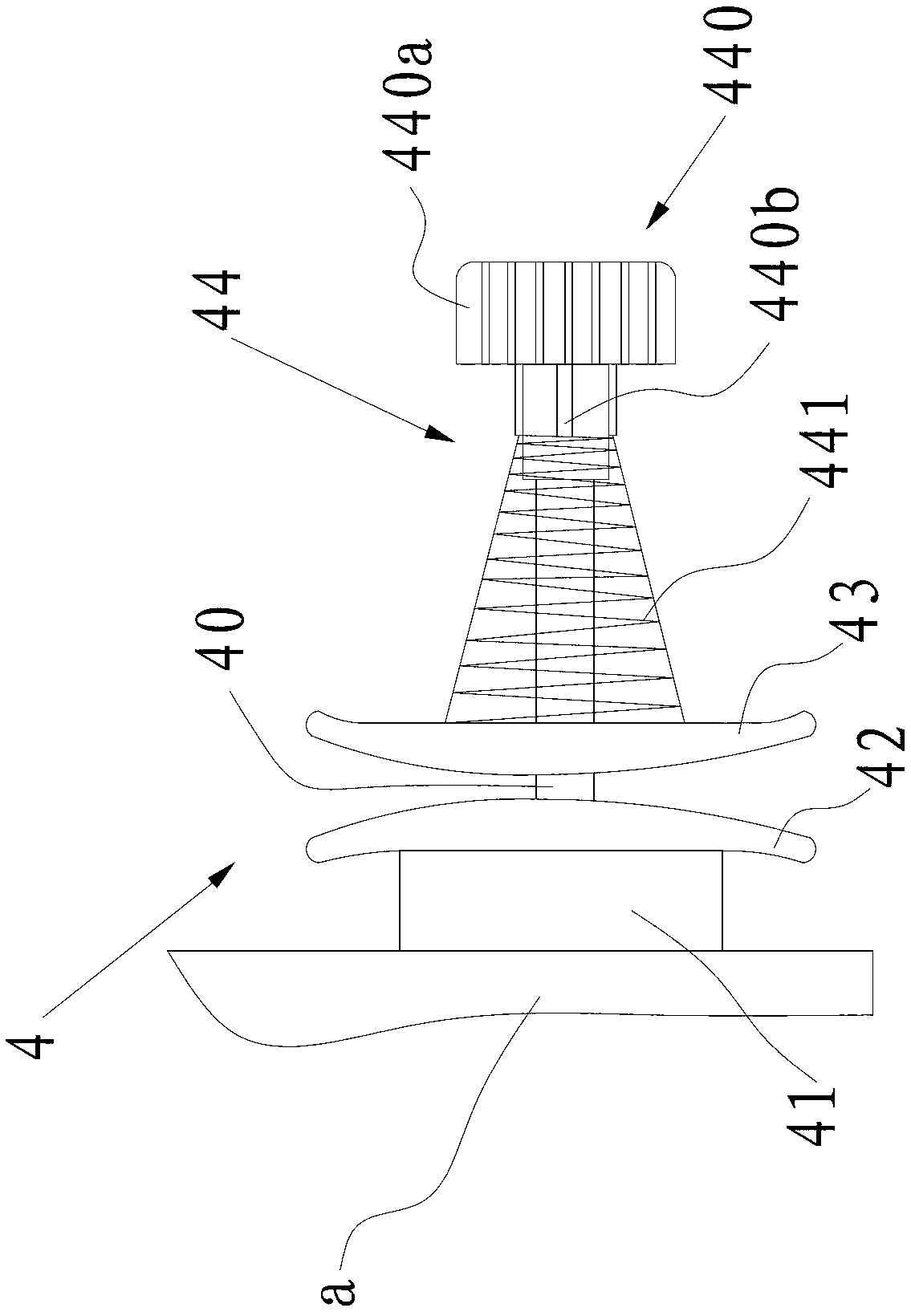

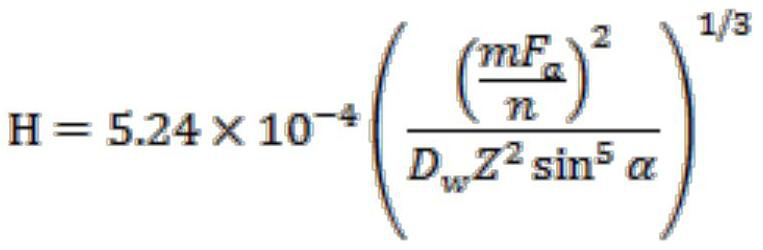

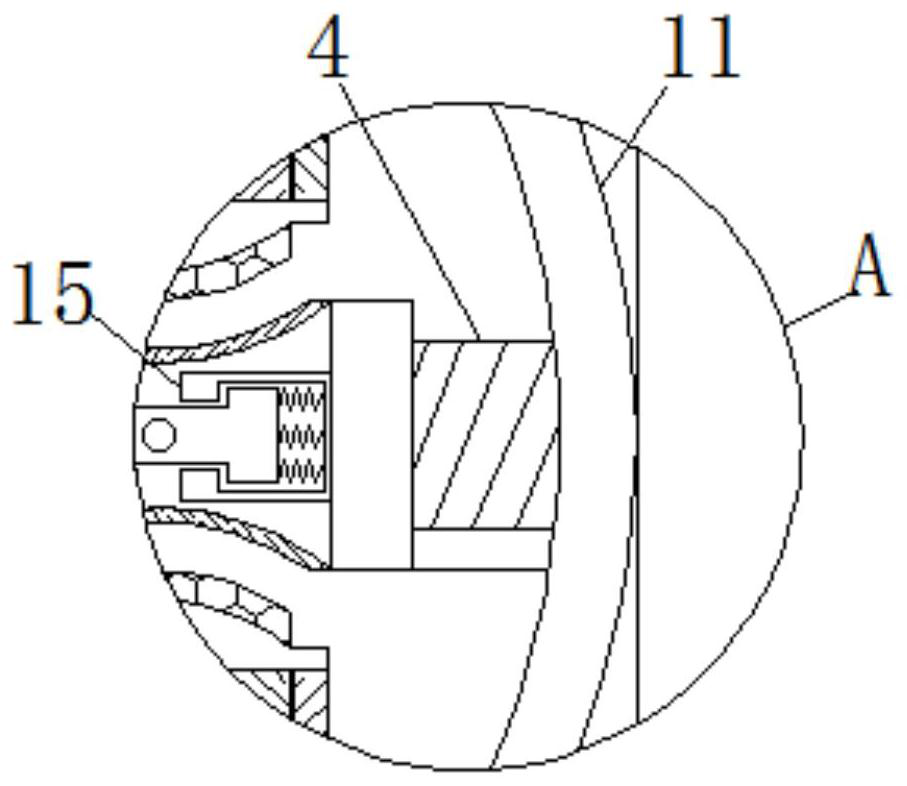

Thrust bearing pack assembled in series

ActiveCN113294431AImprove the uniformity of forceExtended service lifeBearing assemblyBall bearingsClassical mechanicsThrust bearing

The invention relates to a thrust bearing pack assembled in series. The thrust bearing pack assembled in series comprises at least four strings of thrust bearings arranged in series and space ring assemblies, wherein each space ring assembly is arranged between every two strings of adjacent thrust bearings so as to divide the thrust bearings into at least two sub-bearing packs, and the number of the thrust bearings of each sub-bearing pack is smaller than or equal to three; each space ring assembly comprises an outer space ring and an inner space ring, the outer space ring corresponds to a bearing outer ring of each thrust bearing, and the inner space ring corresponds to a bearing inner ring of each thrust bearing; when the bearing inner ring of each thrust bearing needs to bear external axial force, the height of each outer space ring is smaller than that of each inner space ring; and when the bearing outer ring of each thrust bearing needs to bear external axial force, the height of each outer space ring is larger than that of each inner space ring. By means of the design, all the thrust bearings participating in assembly bear the axial force together, so that the external axial force is distributed on all the thrust bearings, the stress uniformity of all the thrust bearings is improved, and the service life of the thrust bearings is effectively prolonged.

Owner:LUOYANG BEARING RES INST CO LTD

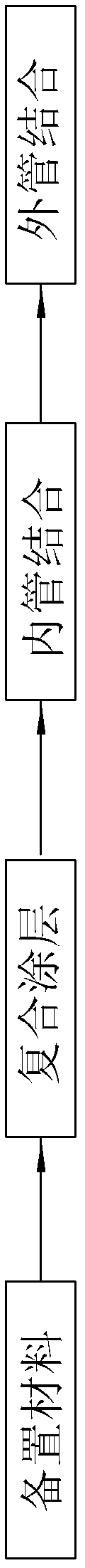

Preparation method of multi-wall layer weather-resistant plant fiber reinforced air pipe

ActiveCN111421852AStrong surface damage resistanceHelps keep warmNon-macromolecular adhesive additivesLignocellulosic adhesivesInsulation layerPlant fibre

The invention provides a preparation method of a multi-wall layer weather-resistant plant fiber reinforced air pipe. The preparation method comprises the following steps of mixing and emulsifying modified plant fibers and phenolic foam materials in different proportions to obtain surface layer and core layer fiber foam materials, and performing paving in a laminated manner to obtain a plant fiberreinforced foam heat-insulation layer; sequentially paving an outer isolation layer, the plant fiber reinforced foam heat-insulation layer, a damp-proof layer and a sealing layer, spraying a couplingagent among the layers during paving, brushing vinyl resin, then paving the next layer by using a fiber-based plasticizing adhesive, and finally obtaining the multi-wall layer weather-resistant plantfiber reinforced air pipe; additionally arranging a mute buffer layer between the outer isolation layer and the plant fiber reinforced foam heat-insulation layer to increase the mute performance; or additionally arranging a phase change layer between the plant fiber reinforced foam heat-insulation layer and the moisture-proof layer to improve the energy-saving performance. The multi-wall layer weather-resistant plant fiber reinforced air pipe prepared by the invention has the advantages of good heat insulation performance, light weight, good flame-retardant performance and good anti-breaking performance.

Owner:INT CENT FOR BAMBOO & RATTAN

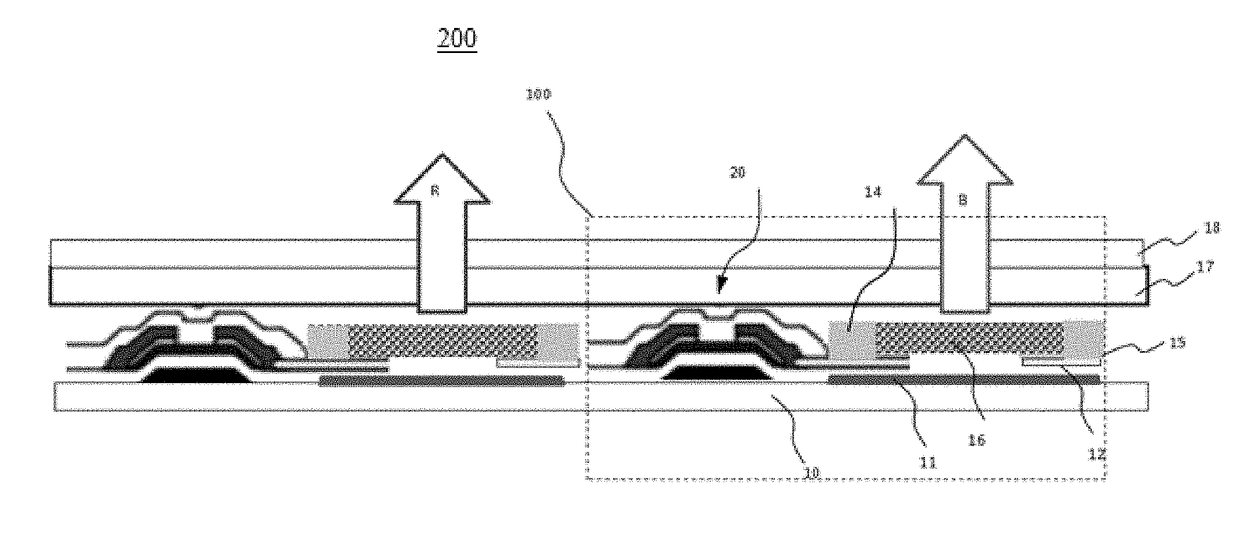

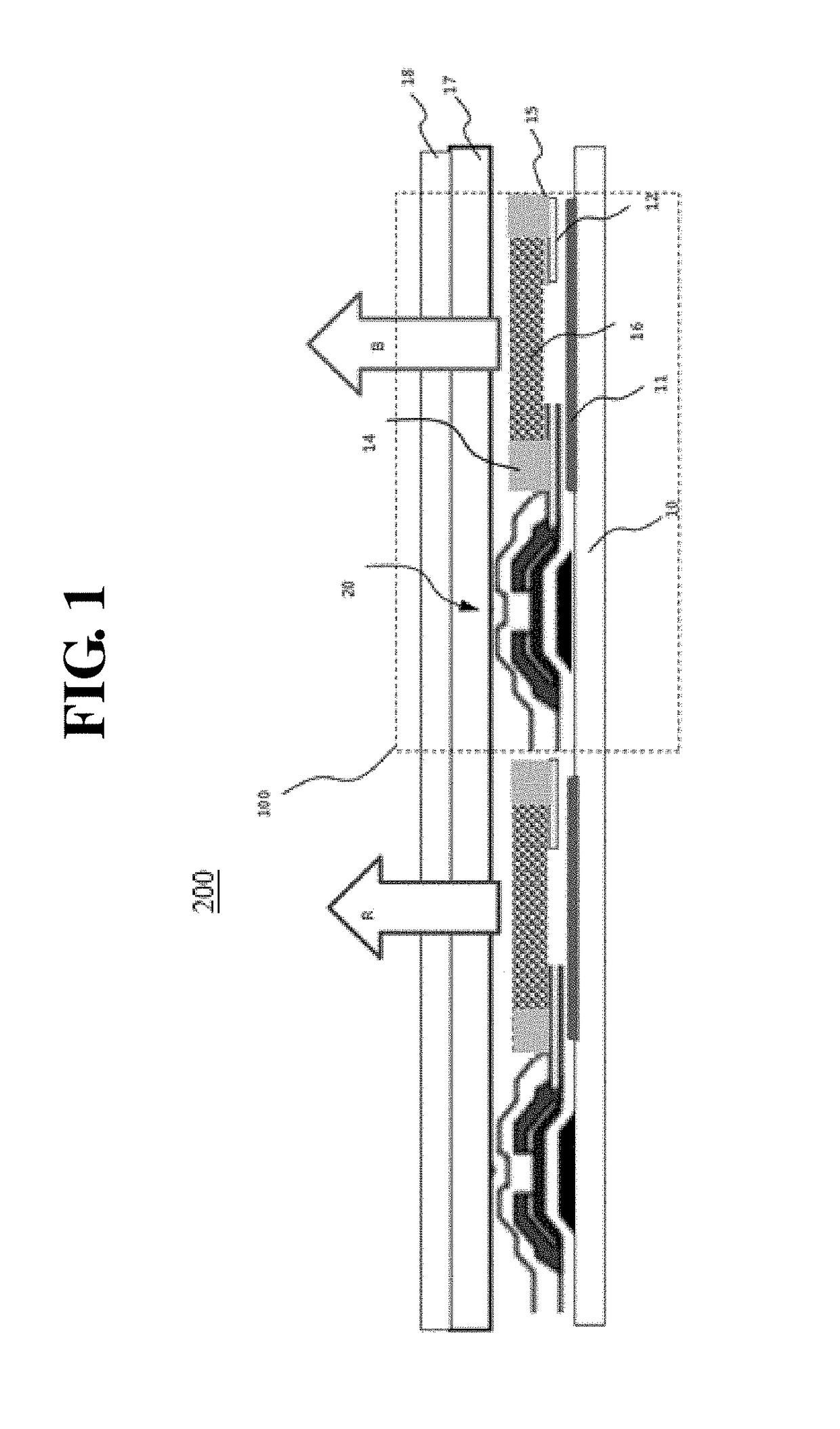

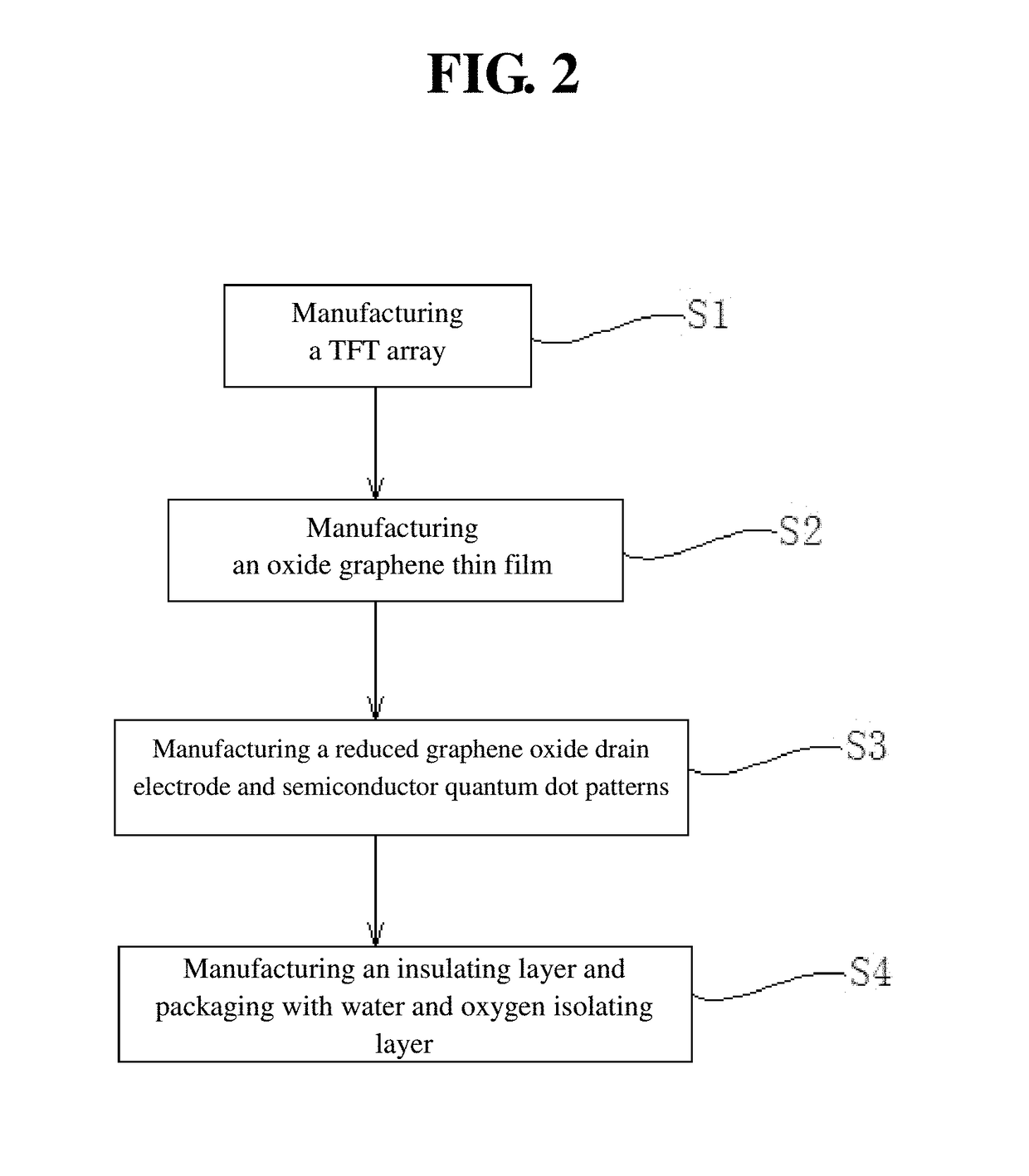

Graphene light emitting display and method of manufacturing the same

InactiveUS20180294377A1Increase the areaIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceOptoelectronics

A graphene light emitting display and a method of manufacturing the same are disclosed. The method comprises: manufacturing a graphene oxide (GO) thin film on a surface of a substrate with a thin film transistor formed thereon; providing a photomask corresponding to the GO thin film to form a source electrode, a drain electrode and a graphene quantum dot layer of a graphene light emitting transistor; and wherein the photomask includes: a complete transparent part corresponding to the region in which the source electrode and the drain electrode are located; a light blocking part corresponding to the region in which the thin film transistor is located; and a semitransparent part corresponding to the region in which the graphene quantum dot layer is located; wherein an insulating layer and a water and oxygen isolating layer are formed sequentially on a surface of the substrate with the graphene light emitting transistor formed thereon.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Display panel, preparation method of display panel and display device

ActiveCN112151585AAvoid uneven brightnessIncrease contrastSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceBright line

The invention provides a display panel, a preparation method of the display panel and a display device. The display panel comprises a display area and a non-display area arranged on the periphery of the display area, an array substrate is arranged in the display area, a plurality of pixel areas are arranged on the array substrate in an array mode, and pixel limiting areas are formed between the adjacent pixel areas. Shading pieces are arranged in the pixel limiting areas. A shading part is arranged at the adjacent position of the display area and the non-display area, and at least part of theshading part extends into the non-display area. The problem that bright lines appear in the non-display area on the periphery of the display area can be avoided, meanwhile, reflective light is prevented from being generated in the display area, the stability of the characteristics of the thin film transistor in the display area is guaranteed, the contrast ratio and the black position level of thedisplay panel are improved, and the display effect of the display panel is optimized.

Owner:KUNSHAN GO VISIONOX OPTO ELECTRONICS CO LTD

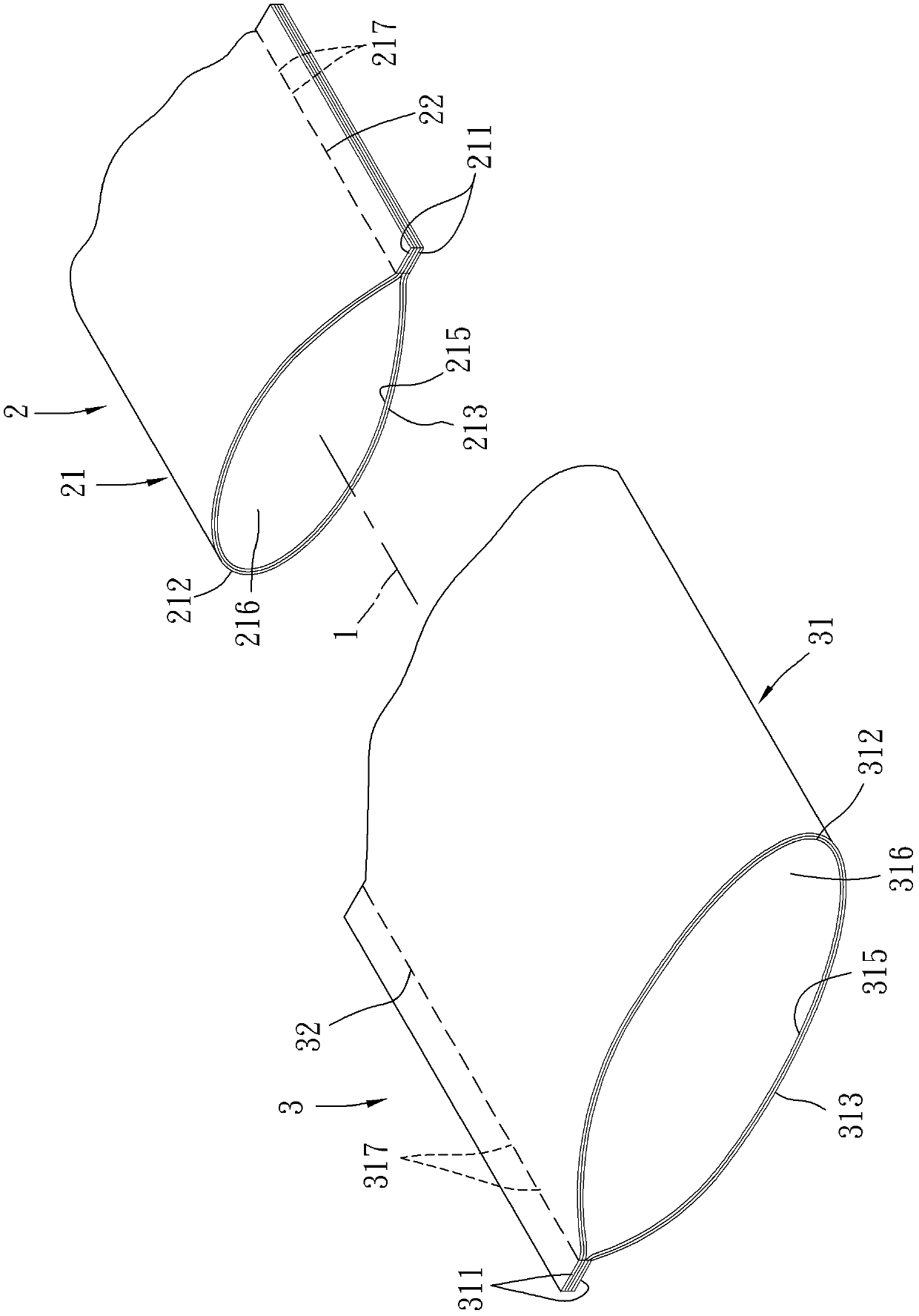

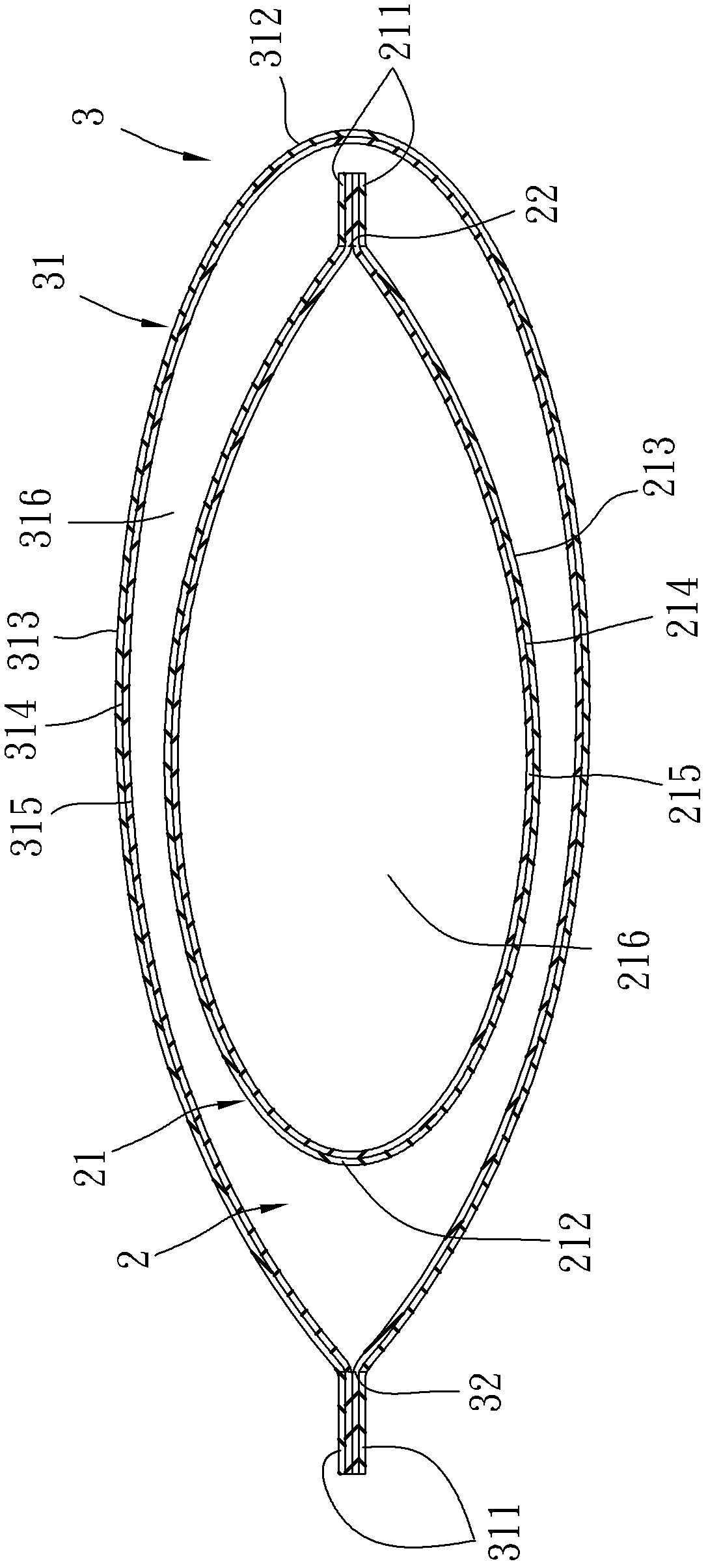

Water seepage pipe and manufacturing method thereof

InactiveCN103286018AReduce sizeDoes not take up spaceLayered productsSpray nozzlesEngineeringMechanical engineering

A water seepage pipe comprises an inner pipe unit and an outer pipe unit, and the inner pipe unit is sleeved with the outer pipe unit. A manufacturing method of the water seepage pipe comprises the steps as follows: an inner peripheral surface of an inner soft cloth layer is coated with an inner waterproof layer, so that an inner pipe body is formed; an inner peripheral surface of an outer soft cloth layer is coated with an outer waterproof layer, so that an outer pipe body is formed; two side edges of the inner pipe body are stitched and connected by the aid of an inner connection line; two side edges of the outer pipe body are stitched and connected by the aid of an outer connection line; and finally, the inner pipe unit is sleeved with the outer pipe unit, and the inner connection line and the outer connection line are located on two opposite sides. When the water seepage pipe is not used, the water seepage pipe can be flattened and collected, so that the size is reduced, less space is relatively occupied, and the water seepage pipe can be stored easily.

Owner:李淑女 +1

Method of manually forging iron pan

The invention discloses a method of manually forging an iron pan. In the method, a pure iron sheet serves as a material, a pan shape is formed through three times of hot forging, a metallographic structure is changed, and material toughness is improved; then, the iron pan is evenly forged and hammering marks are overlapped through three times of cold forging, and finally 'starry sky' hammering marks are formed; then, handle coiling is performed to form a unique support with comfortable hand feel; and finally, the iron pan is enameled for health and rust prevention. By means of a manual forgingmode, physical non-stickiness of the iron pan is realized, and a simple sheet is turned into a pan more suitable for frying, stir-frying, cooking and deep-frying.

Owner:SHANDONG HUAMIN STEEL BALL

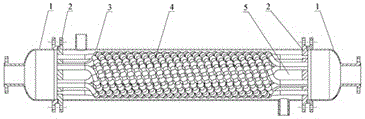

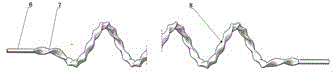

Novel spiral-twisted-wrapped-tube heat exchanger

InactiveCN105605949ACompact structureIncreased turbulenceHeat exhanger conduitsHeat exchanger casingsShell and tube heat exchangerPlate heat exchanger

The invention provides a novel spiral-twisted-wrapped-tube heat exchanger which is mainly composed of a tube box, a tube plate, a shell, a heat exchange tube, a core cylinder and other parts, wherein the heat exchange tube is a novel spiral twisted wrapped tube. The novel spiral twisted wrapped tube comprises an inlet section and a wrapped twisted section, wherein the inlet section is the combination of a flat tube pressed from a circular tube and a twisted tube twisted from a flat tube; the wrapped twisted section is formed by twisting and wrapping a flat tube pressed from a circular tube; and the other parts of the heat exchanger are still the structural styles in a common spiral-wrapped-tube heat exchanger. The inlet section and twisted wrapped section in the heat exchange tube have a smooth transition, are made from the same material and have the same wall thickness. According to the novel spiral-twisted-wrapped-tube heat exchanger, the working medium has the advantages of high turbulence degree, high heat transfer coefficient and compact structure when performing flow and heat exchange in the tube. The novel spiral-twisted-wrapped-tube heat exchanger has favorable universality with the parts of the common shell-and-tube heat exchanger, and thus, has wide practical application value.

Owner:ZHENGZHOU UNIV

A method for preparing multi-wall weather-resistant plant fiber reinforced air duct

ActiveCN111421852BStrong surface damage resistanceHelps keep warmNon-macromolecular adhesive additivesLignocellulosic adhesivesInsulation layerPlant fibre

Owner:INT CENT FOR BAMBOO & RATTAN

Rotary paint spraying equipment for bamboo and wood product processing

InactiveCN112705393APaint AccelerationFlexible stroke adaptationEdge grinding machinesGrinding carriagesPulp and paper industryMaterials science

The invention relates to the technical field of bamboo and wood manufacturing, and discloses rotary paint spraying equipment for bamboo and wood product processing. The rotary paint spraying equipment for bamboo and wood product processing comprises shells, bamboo and wood are movably connected in the shell, polishing plates are movably connected to the surface of the bamboo and wood, meshing plates are movably connected in the polishing plates, and screw rods are movably connected to the surfaces of the meshing plates; rotating shafts are movably connected to one ends, away from the meshing plates, of the screw rods, material spraying plates are movably connected to the surfaces of the rotating shafts and located below the screw rods, pressure storage pipes are movably connected to the interiors of the material spraying plates, material storage boxes are fixedly connected to the interiors of the material spraying plates and located on the surfaces of the pressure storage pipes, and flow guide pipes are fixedly connected to the ends, away from the pressure storage pipes, of the material storage boxes. According to the rotary paint spraying equipment for bamboo and wood product processing, paint in the material storage boxes is sprayed out from the flow guide pipes and is sprayed on the surface of the bamboo and wood sliding downwards, due to the fact that the number of the material spraying plates is four, purified water can be thrown out while the paint is thrown out, and swing working gaps of the material spraying plates and the purified water make up, so that the effect that polishing and paint spraying can be achieved without transferring through the appearance of the bamboo and wood is achieved.

Owner:云和县新彩滚漆有限公司

High-self-healing sheet resistance thin film capacitor

InactiveCN105702455ASame materialSame performanceThin/thick film capacitorFixed capacitor electrodesThin film electrodeSelf-healing

The invention relates to a self-healing high-resistance film capacitor, which belongs to the technical field of capacitors. The film electrode in the capacitor is cut from a metallized film, and the metallized film includes a base film, and the base film is uniformly A layer of Al is vapor-deposited, and a layer of Zn with a cross-section in the shape of "Ω" is vapor-deposited on the Al layer, and blank areas are formed after the two sides of the metallized film exceed the Al layer and the Zn layer. This technical solution uses a metallized film to be cut into two thin film electrodes to ensure that the material and performance of the two thin film electrodes are basically the same, the product has higher stability in use, and the beneficial effect is remarkable.

Owner:TONGLING XINZHOU ELECTRONICS TECH

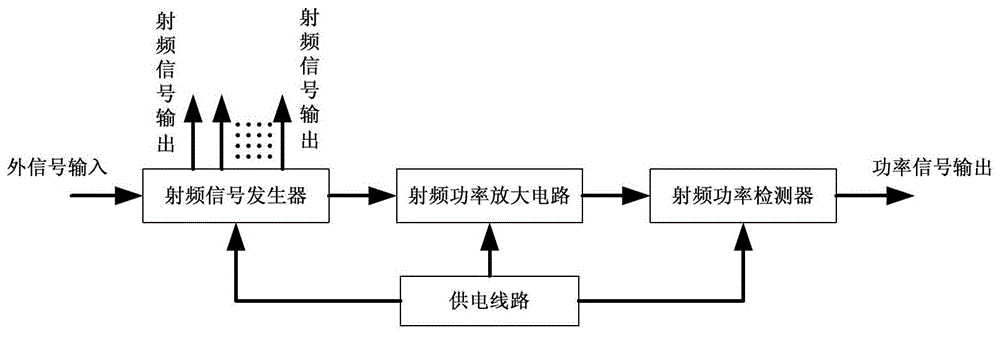

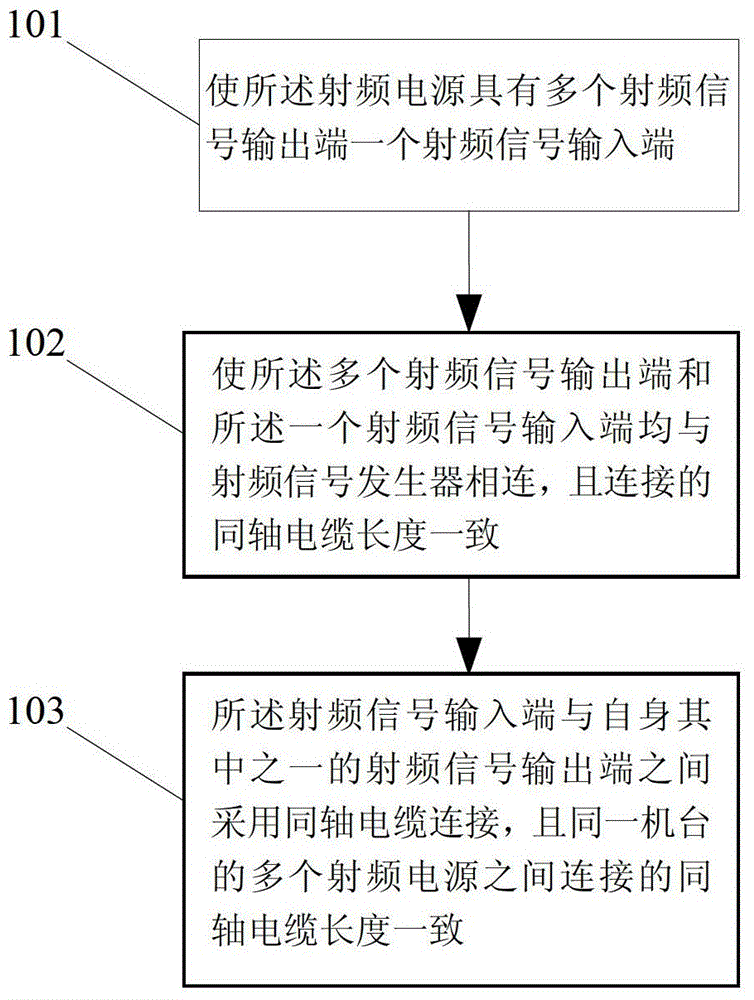

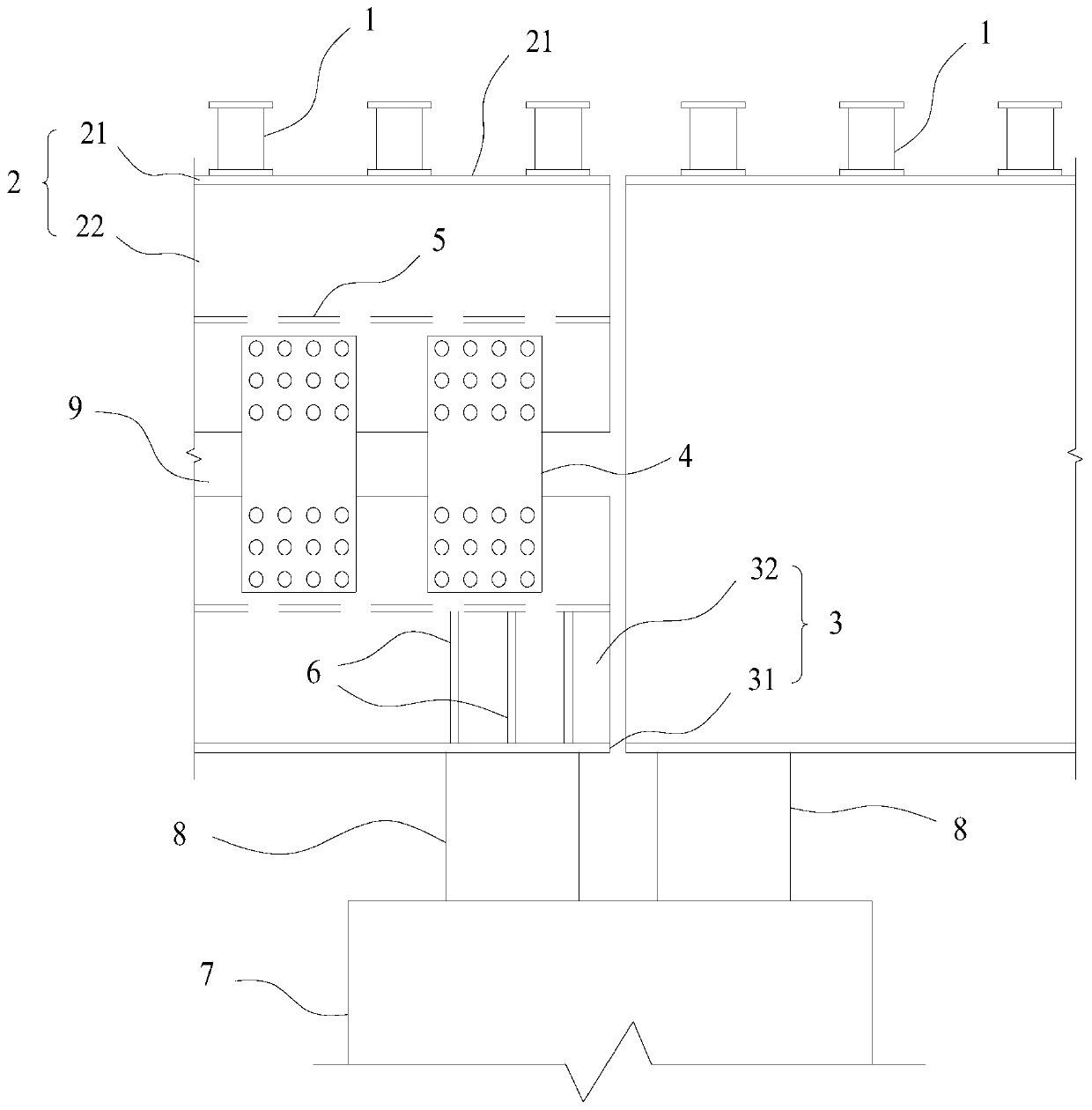

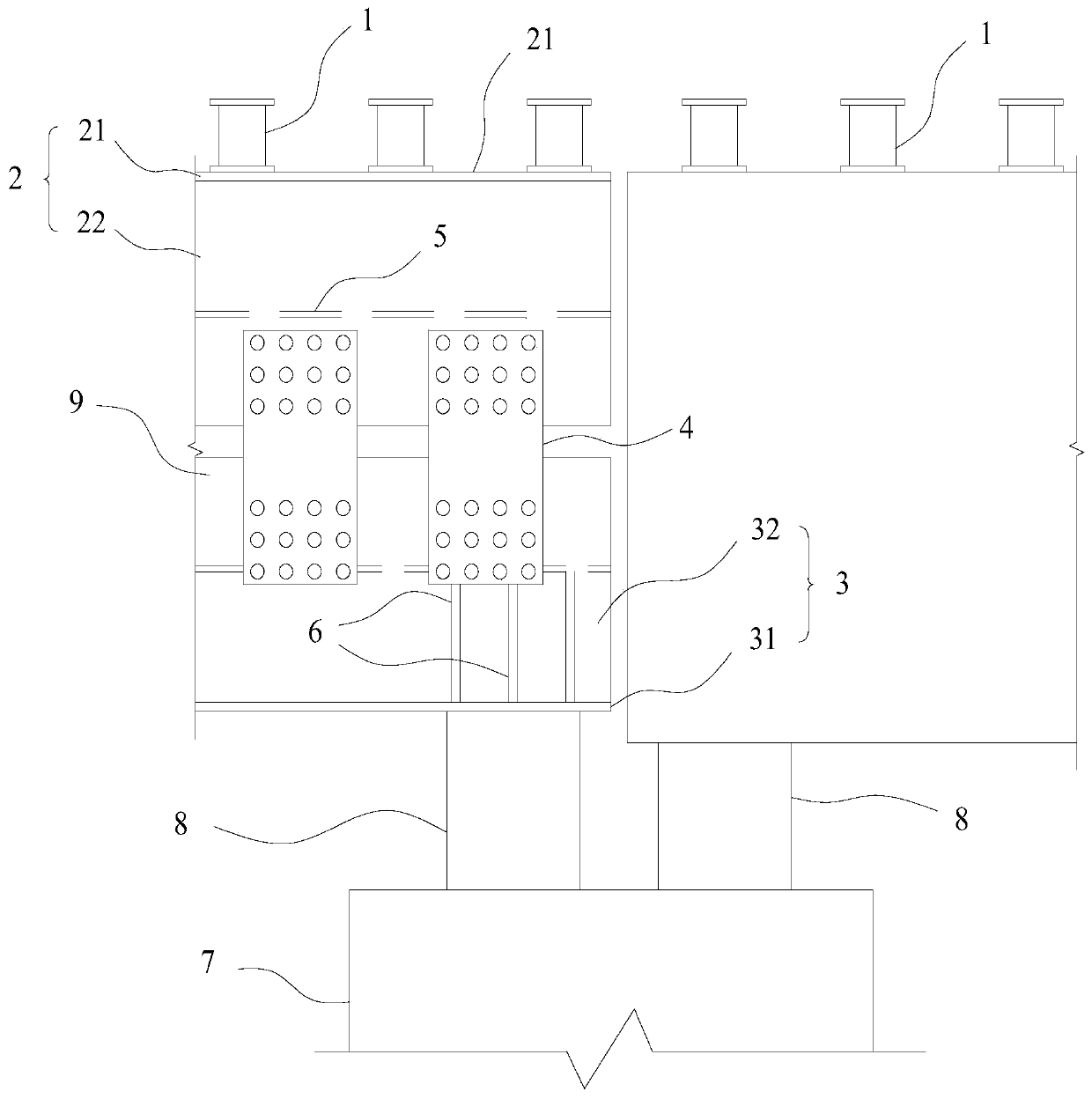

A Phase Synchronization Method of External Input Signal of RF Power Supply

ActiveCN103856214BEliminate signal phase differenceAvoid crosstalkPulse automatic controlElectric discharge tubesCoaxial cablePhase difference

Disclosed is a method for phase synchronization of externally inputted signals of a radiofrequency power supply, comprising: making the radio frequency power supply to be provided with multiple radiofrequency signal output ends and one radiofrequency signal input end; making the multiple radiofrequency signal output ends and the one radiofrequency signal input end to be all connected with a radiofrequency signal generator, where connecting coaxial cables are of a same length; the radiofrequency signal input end connects to one of the radiofrequency signal output ends of self by using a coaxial cable, while connecting coaxial cables between multiple radiofrequency power supplies of a same machine are of a same length. For a path that is passed through by a radiofrequency signal used by the radiofrequency power supplies, the present invention provides the coaxial cables of a same length for transmission of the radiofrequency signal, therefore, signal phase differences between the radiofrequency power supplies of a same machine are eliminated, phase synchronization is maintained, crosstalk is prevented, and process stability is increased. The present invention requires only that the coaxial cables connecting to the external are of a same length and material to implement phase synchronization, thus is not only of reduced costs, but also convenient and expeditious.

Owner:SOI MICRO CO LTD

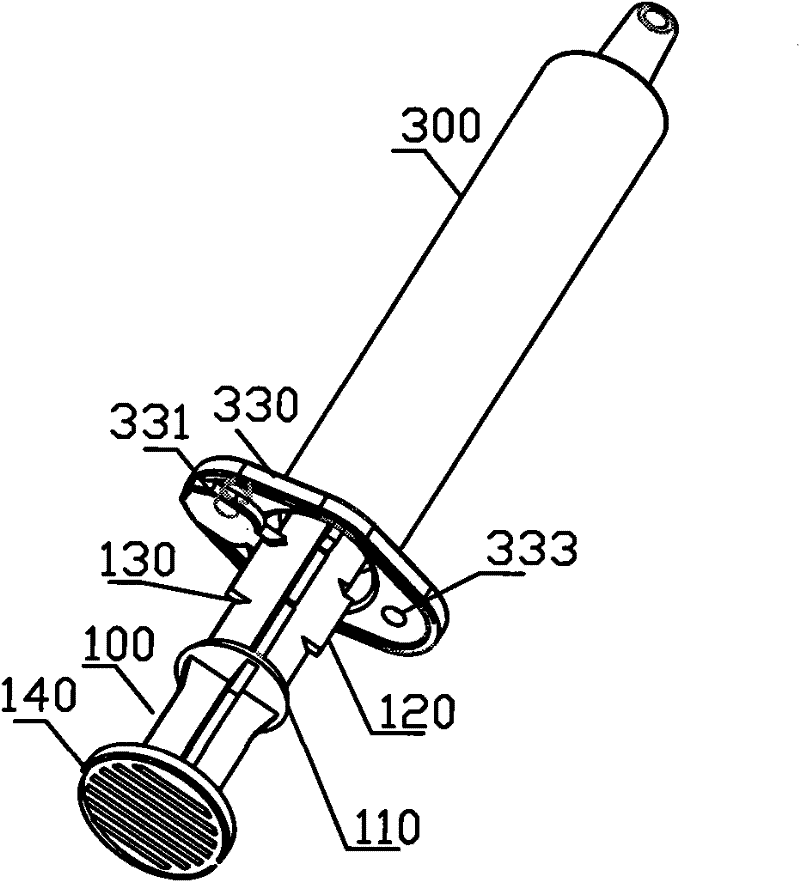

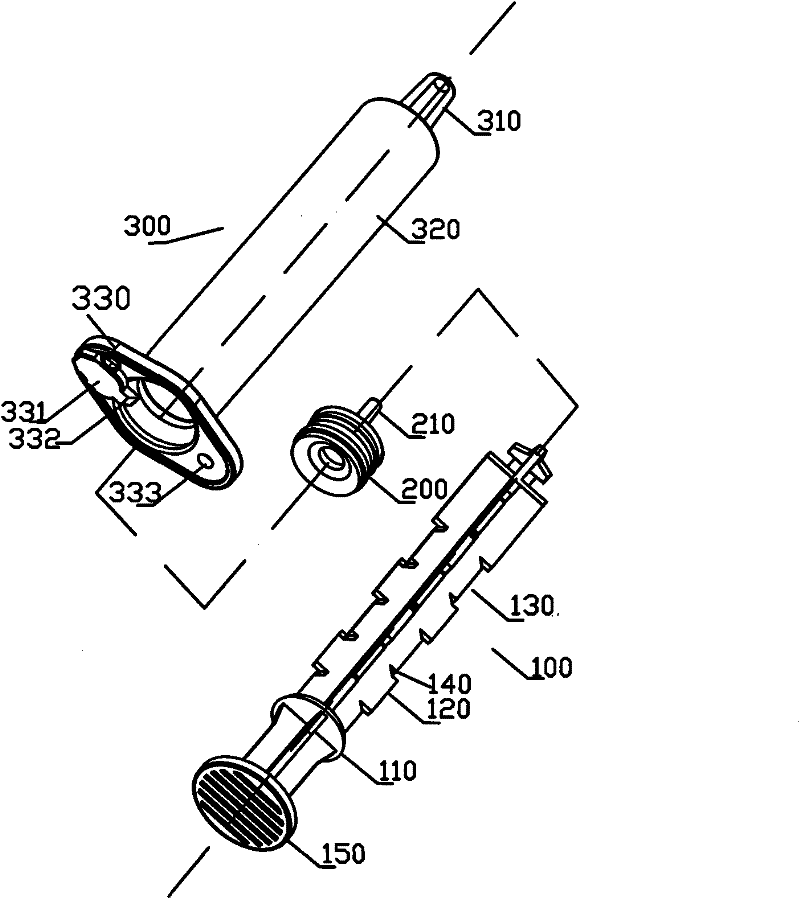

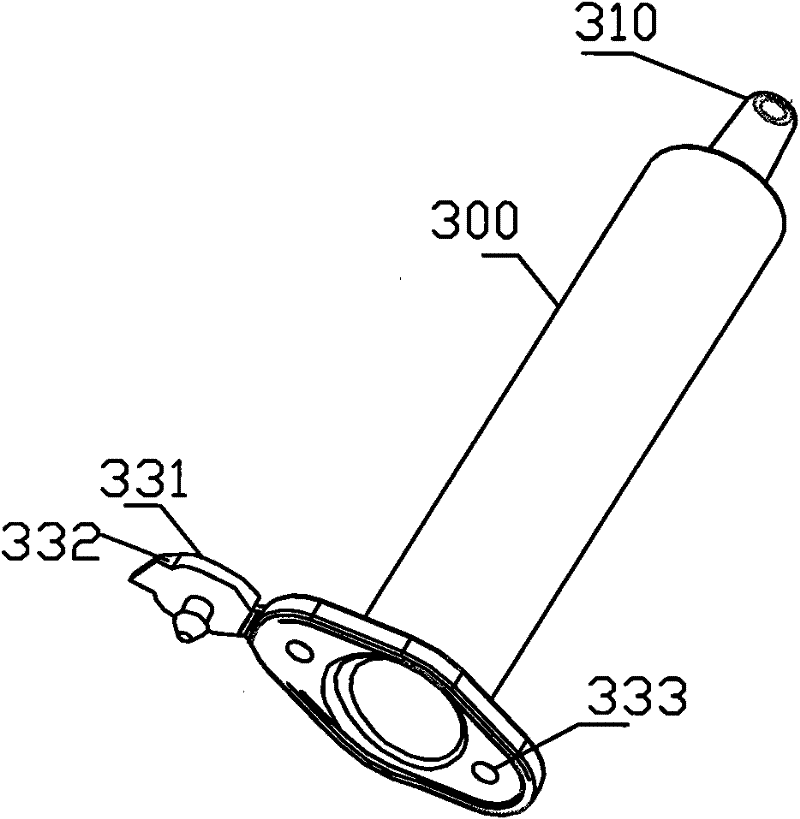

Insulin syringe

ActiveCN101979108BGood for popular useSame materialInfusion syringesIntravenous devicesEngineeringInsulin syringe

The invention discloses an insulin syringe, which comprises a core rod, a piston and an outer tube, wherein the outer tube comprises a conical head, a tube body and a turned edge, the front end of the conical head is connected with an injection needle base, the rear end of the conical head is connected with the tube body, and the front end of the piston is provided with a core column matched withthe conical head. The rear end of the tube body is provided with the turned edge for hand holding, and the core rod is provided with a groove; the turned edge is provided with a limit sheet which canbe embedded into the groove to lock a push rod, and the limit sheet is in embedded connection with the turned edge; and the rear part of the core rod is provided with an annular sheet. The limit sheet is provided with a bolt for blocking the groove. The core rod is a cross core rod, side walls are mutually vertical, side arms are provided with rolled leaves arranged in axial symmetry, the rolled leaves comprise upper rolled leaves and lower rolled leaves which are alternately arranged along the axial direction, and grooves are formed between the upper rolled leaves and the lower rolled leaves. The insulin syringe has the advantages of simple structure, safety, reliability and low cost.

Owner:シャンハイジュミンバイオテックサイエンスカンパニーリミテッド

A method for testing the optimal stiffness limit of magnetic levitation track beams

The invention provides a test method for the optimal stiffness limit of a magnetic levitation track beam. With breaking of the traditional concept, the verification stiffness is transformed into the measurement stiffness; and follow-up design work is realized conveniently. Optimal stiffness limits of different models at different running speeds are determined effectively. The test precision is high during the measuring process; level-by-level multi-times stiffness adjustment is carried out conveniently; the adjustment is precise; and the adjustment gradient is flexible and variable. The methodis also suitable for the verification link with high precision and full verification. One same hollow box body can be applied to multiple tests repeatedly, so that wasting is reduced, energy-saving and environment-friendly effects are realized, and the test cost is lowered. Under the condition of multi-span hollow box body existence, different stiffness values are adjusted for different hollow box bodies simultaneously and multiple groups of data can be obtained by one test, so that the test efficiency is increased effectively, the work difficulty of the field test is reduced, and the test cycle is shortened. And thus the construction cost and operating cost of the magnetic levitation railway are lowered. The test method has the great significance in the promotion and development of the magnetic levitation railway in China.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Auxiliary environment-friendly equipment for conveniently manufacturing non-setting adhesive screen printing plate

InactiveCN112644145AImprove cleanlinessMeet the developing conditionsForme preparationScreen printingEngineering

The invention relates to the technical field of non-setting adhesive manufacturing, and discloses auxiliary environment-friendly equipment for conveniently manufacturing a non-setting adhesive screen printing plate. The auxiliary environment-friendly equipment comprises a shell, wherein an extension frame is movably connected to the interior of the shell, a compression spring is movably connected to the interior of the extension frame, a wiping ball is fixedly connected to the bottom of the extension frame, movable rods are movably connected to the left side and the right side of the extension frame correspondingly, deflection plates are movably connected to the ends, away from the extension frame, of the movable rods, supporting rods are movably connected to the surfaces of the deflection plates, light-transmitting covers are fixedly connected to the ends, away from the deflection plates, of the supporting rods, light sources are fixedly connected in the light-transmitting covers, and spring rods are movably connected to the sides, away from the supporting rods, of the deflection plates. When the extension frame is extruded, a certain force is applied to the surfaces of the deflection plates through the movable rods, the deflection plates contract by extruded folding rods, and the wavelength of light generated by deflection of light emitted by the light sources is changed, so that the effect of self-adjusting the wavelength of the light according to the working time while the surface smoothness of the screen printing plate is ensured is achieved.

Owner:林青仕

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com