Gypsum-based composite thermal insulation terrace and construction method thereof

A construction method, gypsum-based technology, applied in the direction of construction, building structure, floor, etc., can solve the problems of low construction efficiency, poor flatness, etc., and achieve the effect of improved quality, same material properties, and complementary functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

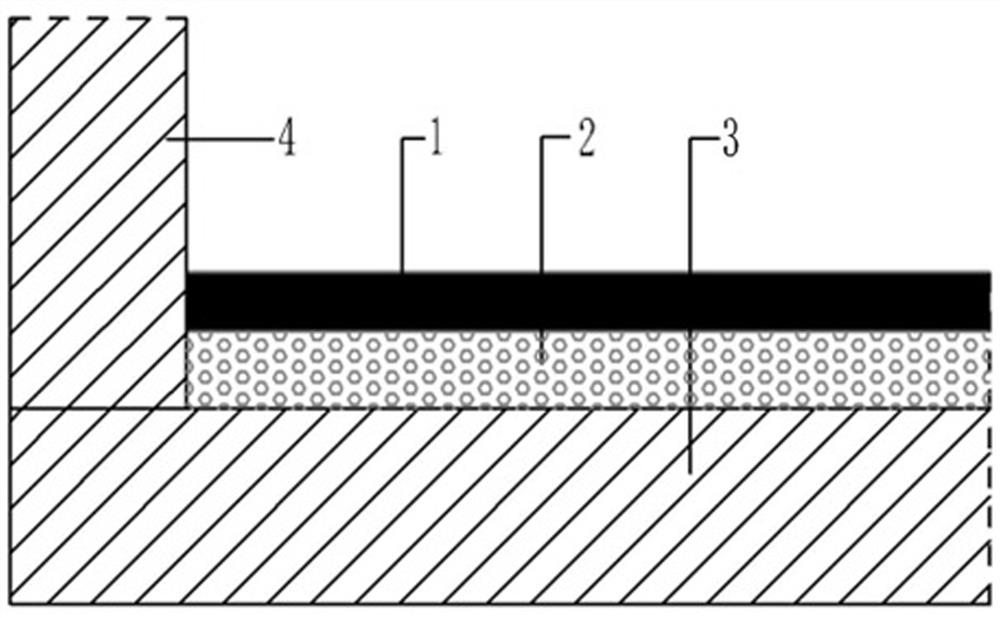

[0039] The gypsum-based composite thermal insulation floor of this embodiment is composed of a gypsum-based self-leveling mortar protection leveling layer 1 and a gypsum-based double-foaming slurry insulation filling layer 2 from top to bottom, and the gypsum-based self-leveling mortar protection leveling layer 1 The thickness is 20mm, and the thickness of the gypsum-based double foamed slurry insulation layer 2 is 20mm.

[0040] The above-mentioned gypsum-based self-leveling mortar is based on 1000kg of building gypsum. The necessary additive ratio is: 110kg of cement, 5kg of gypsum water reducer, 2.5kg of gypsum defoamer, 2kg of gypsum retarder, and 350kg of mixing water.

[0041] The above-mentioned gypsum-based double-foaming slurry is 1m 3 The mixing ratio is: 200kg of building gypsum, 0.1kg of gypsum retarder, 1.5kg of gypsum foaming agent, and a cumulative volume of polystyrene foam particles of 0.7m 3 , 150kg of mixing water.

[0042] The construction method of the gyp...

Embodiment 2

[0049] The gypsum-based composite thermal insulation floor of this embodiment is composed of a gypsum-based self-leveling mortar protection leveling layer 1 and a gypsum-based double-foaming slurry insulation filling layer 2 from top to bottom, and the gypsum-based self-leveling mortar protection leveling layer 1 The thickness is 30mm, and the thickness of the gypsum-based double-foamed slurry insulation filling layer 2 is 30mm.

[0050] The above-mentioned gypsum-based self-leveling mortar is based on 1000kg of building gypsum, and the necessary additive ratio is: 90kg of cement, 4kg of gypsum water reducer, 2kg of gypsum defoamer, 1.5kg of gypsum retarder, and 450kg of mixing water.

[0051] The above-mentioned gypsum-based self-leveling mortar can also be optionally mixed with 600kg of fine sand and 80kg of fly ash.

[0052] The above-mentioned gypsum-based double-foaming slurry is 1m 3 The mixing ratio is: 300kg of building gypsum, 0.3kg of gypsum retarder, 1kg of gypsum ...

Embodiment 3

[0056] The gypsum-based composite thermal insulation floor of this embodiment is composed of a gypsum-based self-leveling mortar protection leveling layer 1 and a gypsum-based double-foaming slurry insulation filling layer 2 from top to bottom, and the gypsum-based self-leveling mortar protection leveling layer 1 The thickness is 40mm, and the thickness of the gypsum-based double-foamed slurry insulation filling layer 2 is 40mm.

[0057] The above-mentioned gypsum-based self-leveling mortar is based on 1000kg of building gypsum, and the necessary additive ratio is: 60kg of cement, 2kg of gypsum water reducer, 1kg of gypsum defoamer, 1kg of gypsum retarder, and 600kg of mixing water.

[0058] The above-mentioned gypsum-based self-leveling mortar can also be optionally mixed with 1000kg of fine sand and 70kg of micro-silica fume.

[0059] The above-mentioned gypsum-based double-foaming slurry is 1m 3 The mixing ratio is: 350kg of building gypsum, 0.7kg of gypsum retarder, 2kg o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com