Pixel structure and display panel

A pixel structure and display panel technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of difficult laser, difficult design of display panel, difficult repair of pixel structure, etc., and achieve the effect of high aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

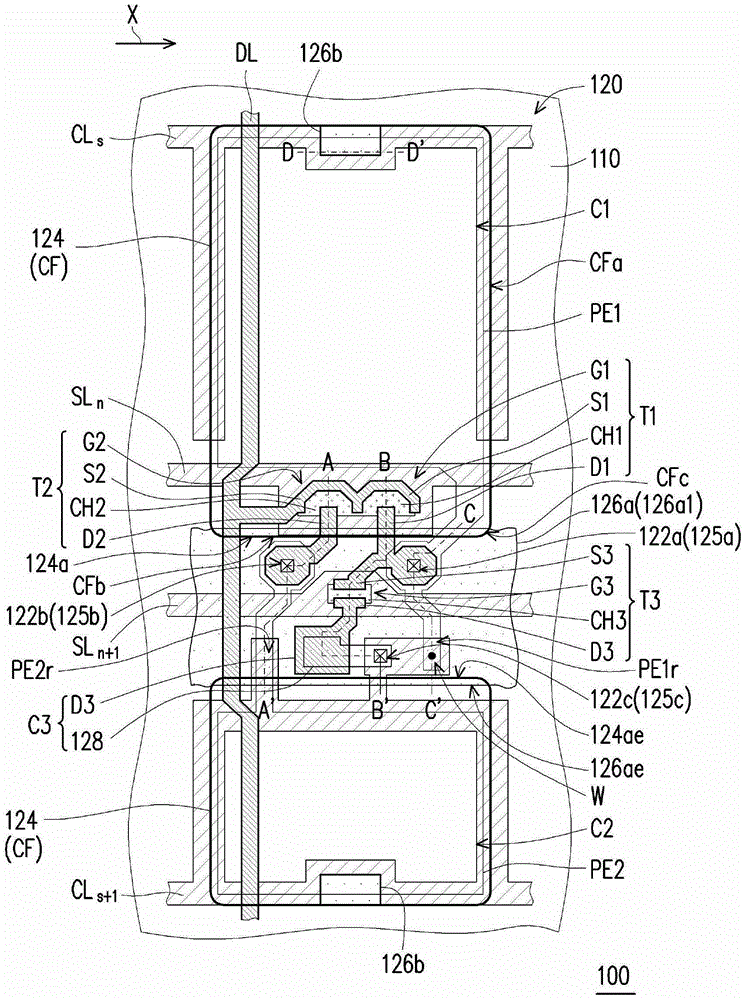

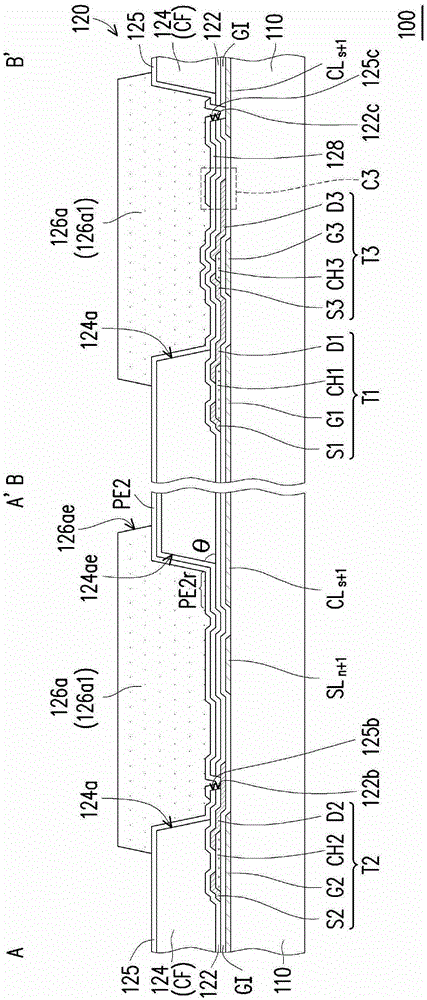

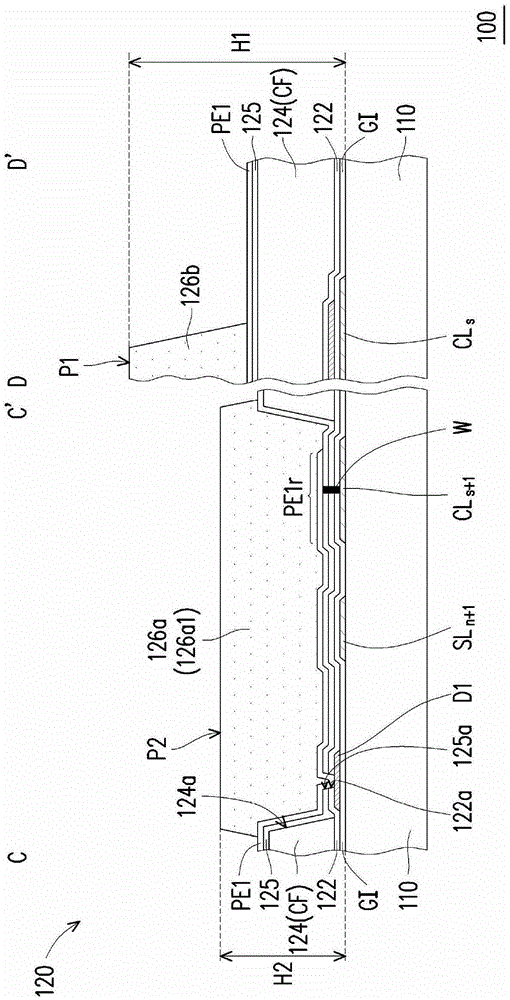

[0085] figure 1 It is a schematic top view of a pixel array substrate according to an embodiment of the present invention. Please refer to figure 1 The pixel array substrate 100 includes a first substrate 110 and a pixel structure 120 disposed on the first substrate 110 . In this embodiment, the first substrate 110 is, for example, a transparent substrate, and the material of the transparent substrate may be glass, quartz, organic polymer or other applicable materials. However, the present invention is not limited thereto. In other embodiments, the first substrate 110 may also be an opaque / reflective substrate, and the material of the opaque / reflective substrate may be conductive material, wafer, ceramic or other applicable materials. Material. It should be noted that although figure 1 Only one pixel structure 120 is shown as a representative, but those skilled in the art figure 1 The pixel structure 120 and the following description can be based on actual needs, and a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com