Foam porcelain powder composite light wallboard and production process thereof

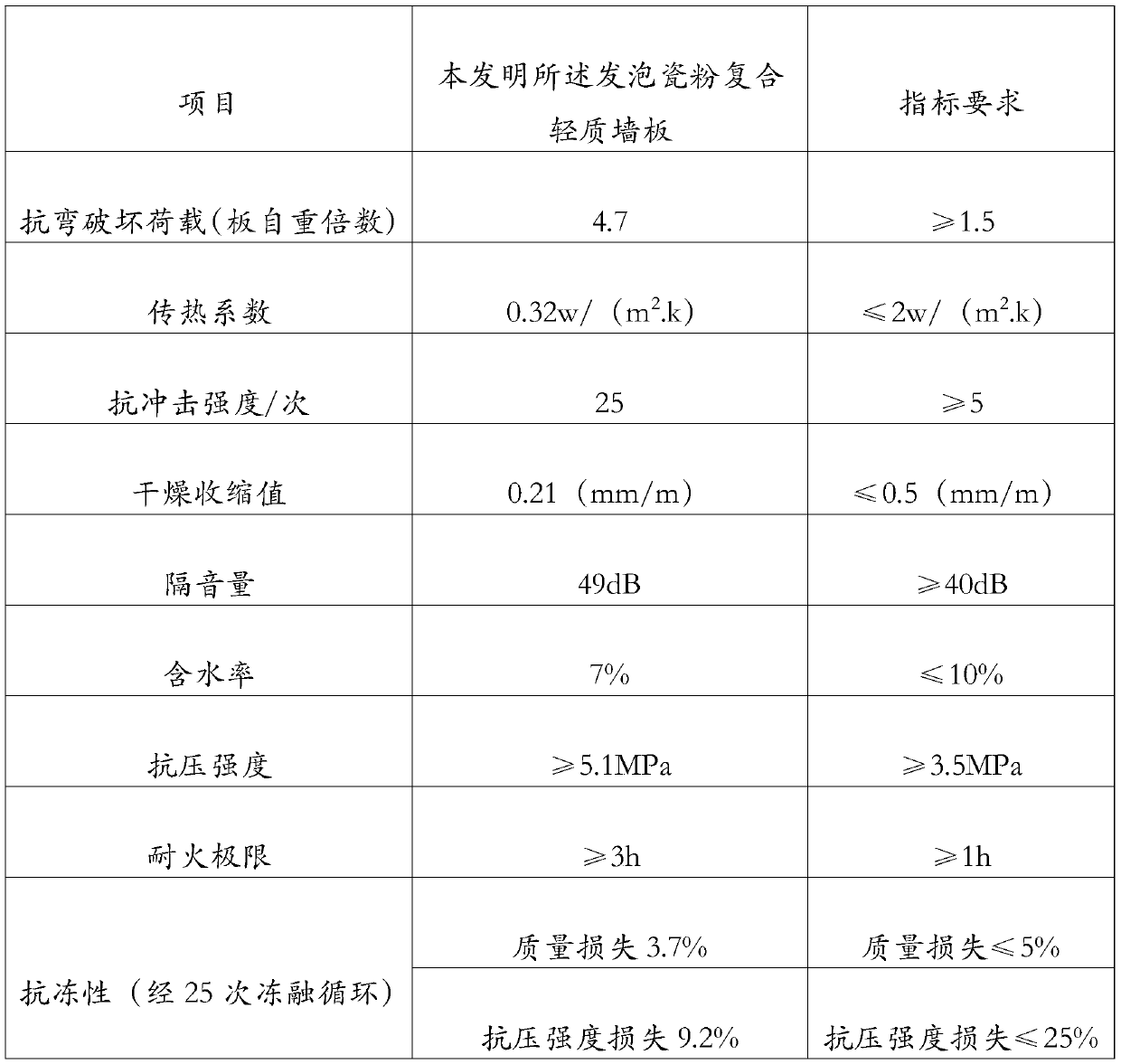

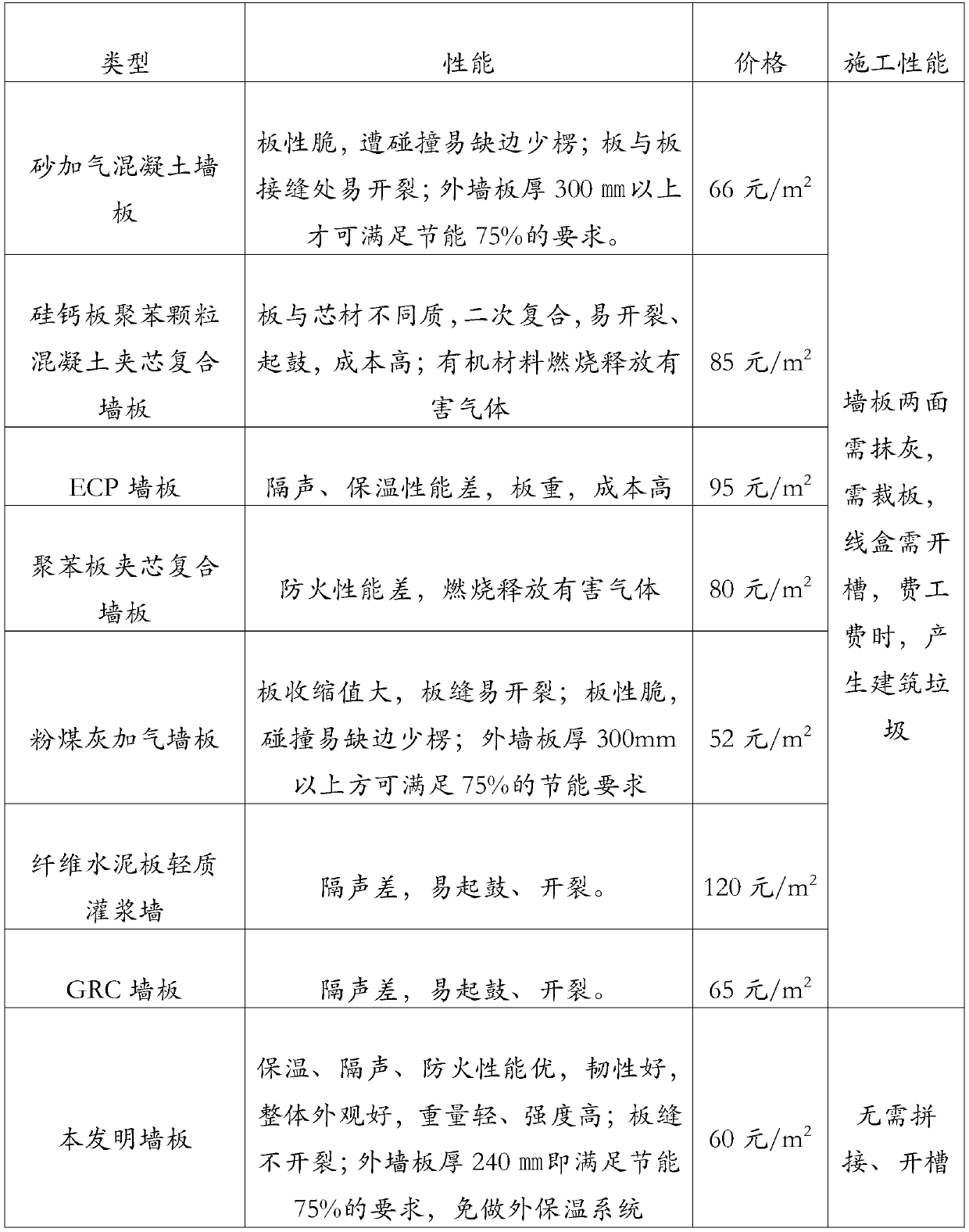

A light-weight wallboard and production process technology, applied in the field of architectural light-weight wallboard, can solve the problems of fire safety performance disclosure, poor heat insulation performance, unfavorable building energy saving, etc., to shorten maintenance time, enhance strength, and effectively Conducive to the effect of ecological civilization construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A foamed porcelain powder composite lightweight wallboard comprises the following raw materials in parts by weight: 100kg of cement, 80kg of porcelain powder, 50kg of alkali-resistant glass fiber, 0.6kg of foaming agent, and 3kg of external additives.

[0030] The production process of the foamed porcelain powder composite lightweight wallboard comprises the following steps:

[0031] (1) mixing and stirring each raw material to obtain a mixture; mixing and stirring each raw material evenly and foaming through a foaming machine to obtain a foamed mixture;

[0032] (2) distributing and molding the mixture to obtain the bottom layer, heat-treating the bottom layer, then distributing the foaming mixture on the surface of the bottom layer to obtain a middle layer, carrying out heating and shaping treatment on the middle layer, and then distributing the mixture on the surface of the middle layer to obtain a top layer , heat treatment on the top layer to obtain prefabricated w...

Embodiment 2

[0035] A foamed porcelain powder composite lightweight wallboard, comprising the following raw materials in parts by weight: 110kg of cement, 100kg of porcelain powder, 55kg of alkali-resistant glass fiber, 0.7kg of foamed concrete foaming agent, and 3kg of external additives;

[0036] The external additive is composed of the following raw materials in parts by weight: 8 kg of diethylene glycol, 15 kg of starch syrup, 12 kg of glycerol, 6 kg of triethanolamine, 18 kg of anhydrous sodium sulfite, and 25 kg of water.

[0037] The production process of the foamed porcelain powder composite lightweight wallboard comprises the following steps:

[0038] (1) mixing and stirring each raw material to obtain a mixture; mixing and stirring each raw material evenly and foaming through a foaming machine to obtain a foamed mixture;

[0039] (2) Distributing and molding the mixture to obtain a bottom layer with a thickness of 0.8 cm. The bottom layer is heat-treated for 1 min at a temperatur...

Embodiment 3

[0042] A foamed porcelain powder composite lightweight wallboard, comprising the following raw materials in parts by weight: 120kg of cement, 115kg of porcelain powder, 60kg of alkali-resistant glass fiber, 0.8kg of foamed concrete foaming agent, and 3.5kg of external additives;

[0043] The external additive is composed of the following raw materials in parts by weight: 9 kg of diethylene glycol, 16 kg of starch syrup, 13 kg of glycerol, 7 kg of triethanolamine, 20 kg of anhydrous sodium sulfite, and 28 kg of water.

[0044] The production process of the foamed porcelain powder composite lightweight wallboard comprises the following steps:

[0045] (1) mixing and stirring each raw material to obtain a mixture; mixing and stirring each raw material evenly and foaming through a foaming machine to obtain a foamed mixture;

[0046](2) Distributing and molding the mixed material to obtain a bottom layer with a thickness of 0.9 cm, heating the bottom layer for 1.2 minutes at a temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com