High-self-healing sheet resistance thin film capacitor

A technology of film capacitors and high square resistance, applied in the field of capacitors, can solve problems such as poor self-healing, low current-carrying capacity, electrode film breakdown, etc., and achieve significant beneficial effects and high stability in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

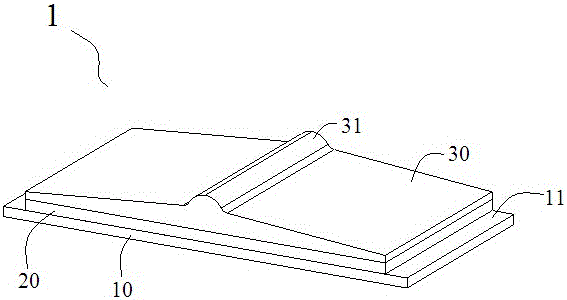

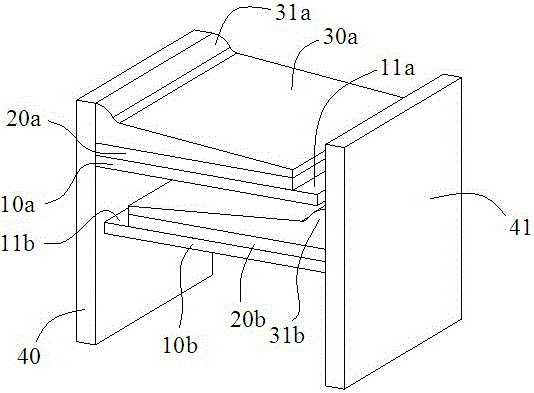

[0013] like figure 1 As shown, the present invention provides a kind of self-healing high square resistance film capacitor, the film electrode in the described capacitor is cut and formed by a metallized film 1, and described metallized film 1 comprises base film 10, and described base film A layer of Al layer 20 is uniformly vapor-deposited on 10, and a layer of Zn layer 30 with a cross-sectional shape of "Ω" is vapor-deposited on the Al layer 20. The two sides of the metallized film 1 exceed the Al layer 20 and the Zn layer 30 to form Blank area 11. This technical solution uses a metallized film 1 to cut into two thin film electrodes to ensure that the materials and performance of the two thin film electrodes are basically the same, and the product has higher stability in use.

[0014] Further, the middle part of the Zn layer 30 is provided with a thickening area 31, and the effect of the thickening area 31 has two aspects, one is to facilitate reference when the metallized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com