Water seepage pipe and manufacturing method thereof

A manufacturing method and technology of seepage pipes, applied in the direction of spraying devices, spraying devices, layered products, etc., can solve the problems of easy blocking of water flow, occupying storage space, inconvenient use, etc., and achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0036] For convenience of description, in the following embodiments, similar components are denoted by the same reference numerals.

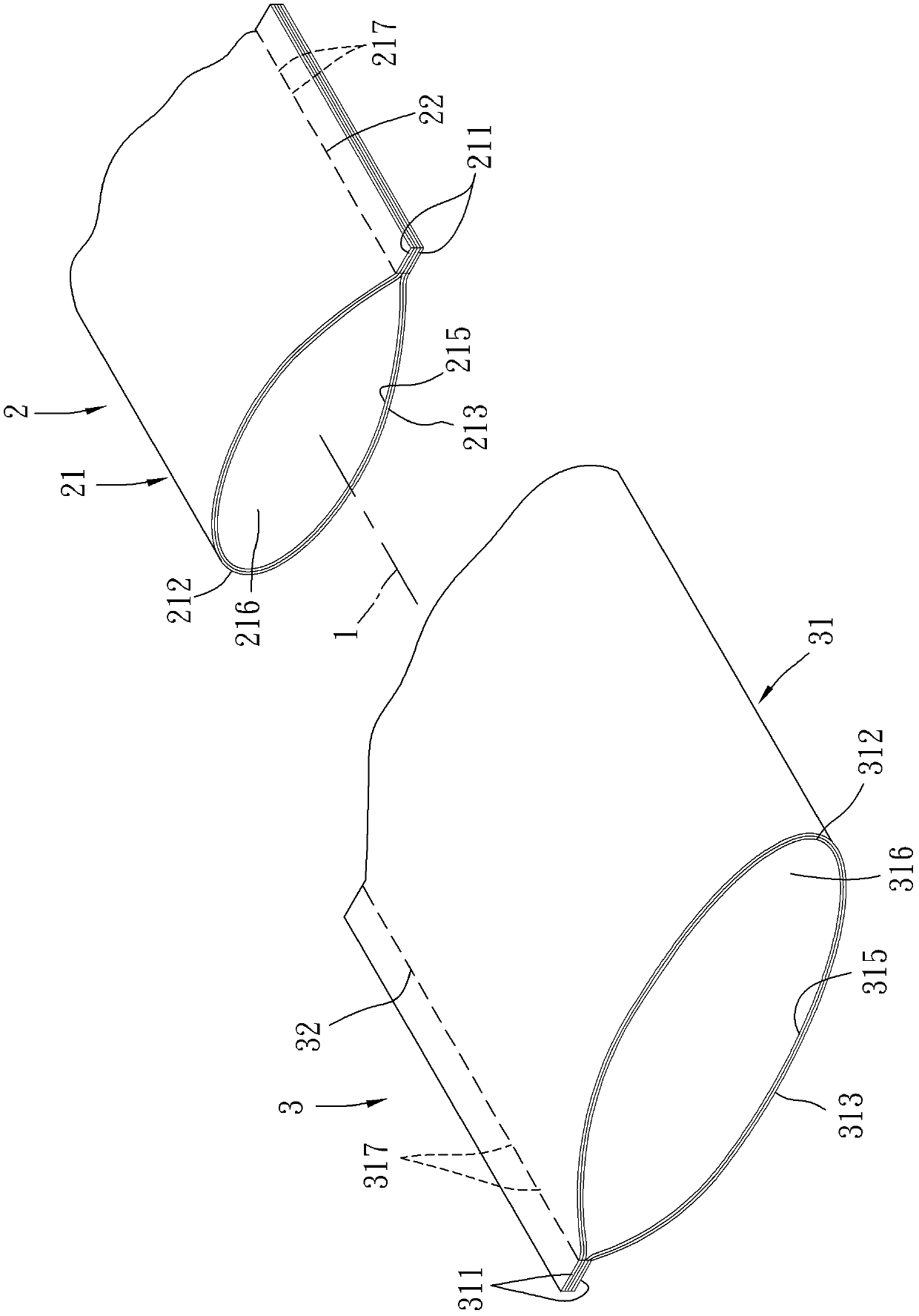

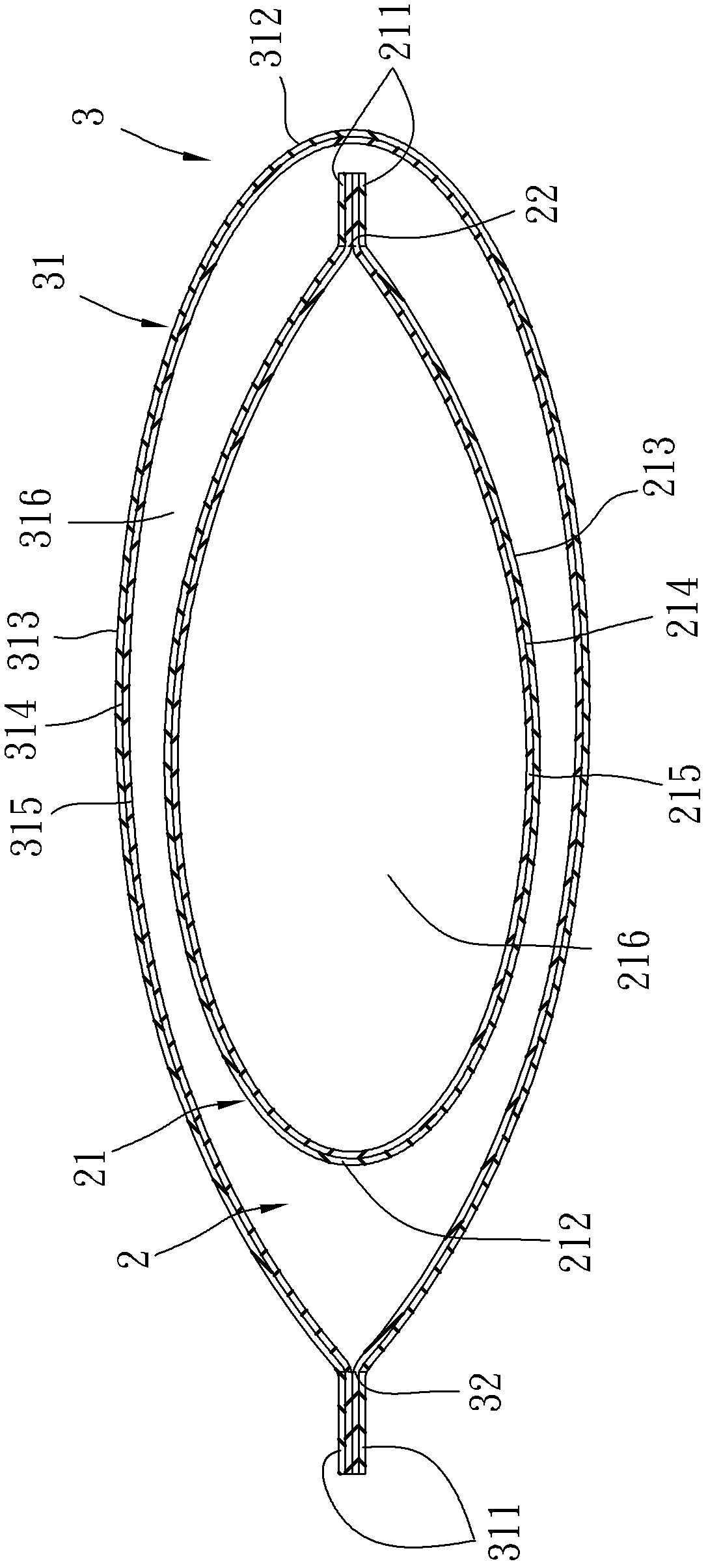

[0037] refer to figure 1 and figure 2 , the first preferred embodiment of the water seepage pipe of the present invention is used to be arranged on the soil surface or in the soil near the root of at least one plant not shown in the figure, and the water seepage pipe includes a long direction along a center line 1 An extended inner tube unit 2, and an outer tube unit 3 surrounding and sleeved on the periphery of the inner tube unit 2.

[0038] The inner tube unit 2 includes an inner tube body 21 with a slightly U-shaped section and a closed opening. The inner tube body 21 has two inner side portions 211 respectively located at the opening and parallel to the centerline 1 up and down. and an inner connecting portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com