Conveying device for yarns

A conveying device and yarn technology, which is applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of high cost of production equipment, affecting the working efficiency of textile equipment, and the complexity of textile equipment, etc., to achieve improvement The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

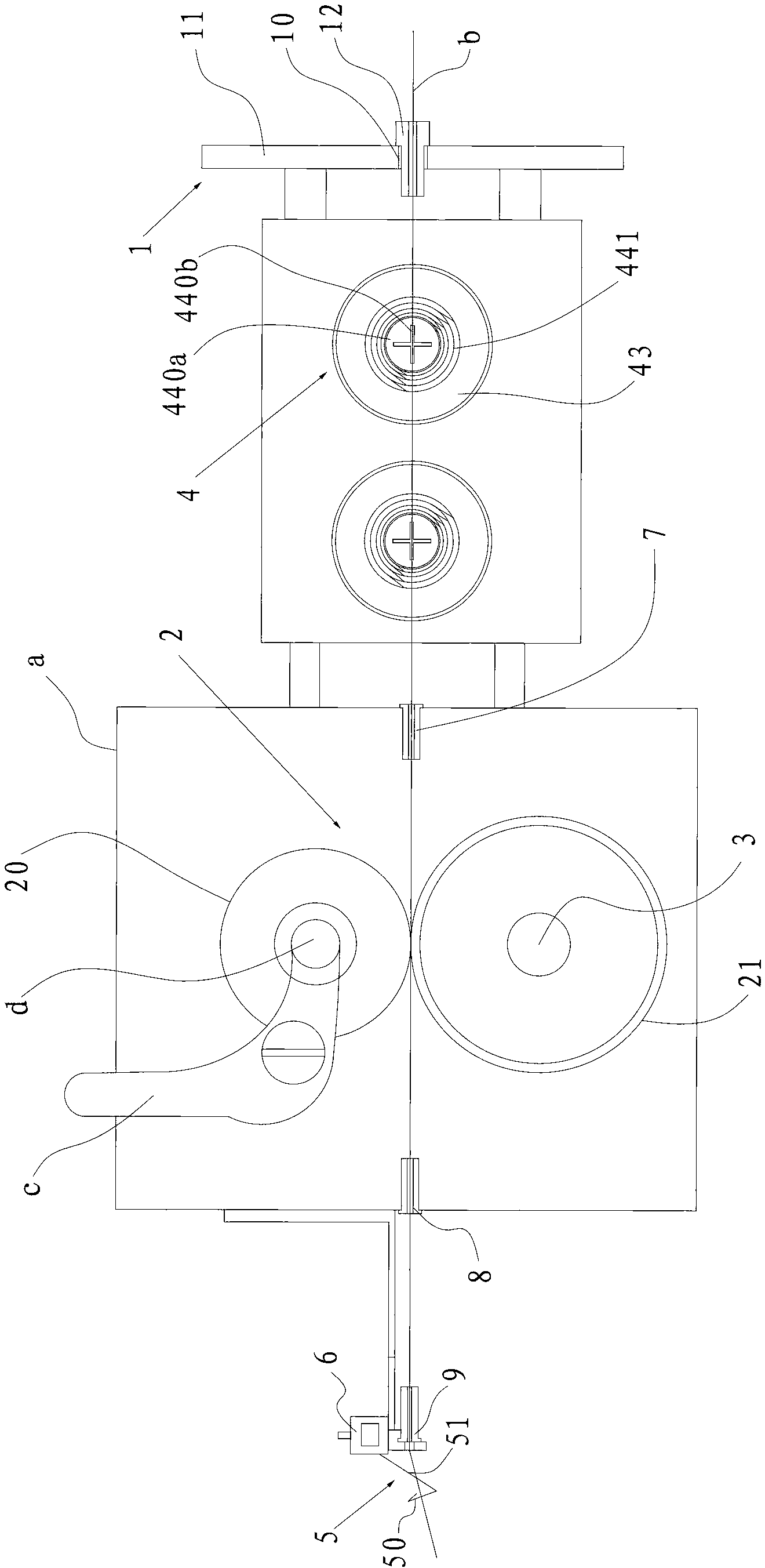

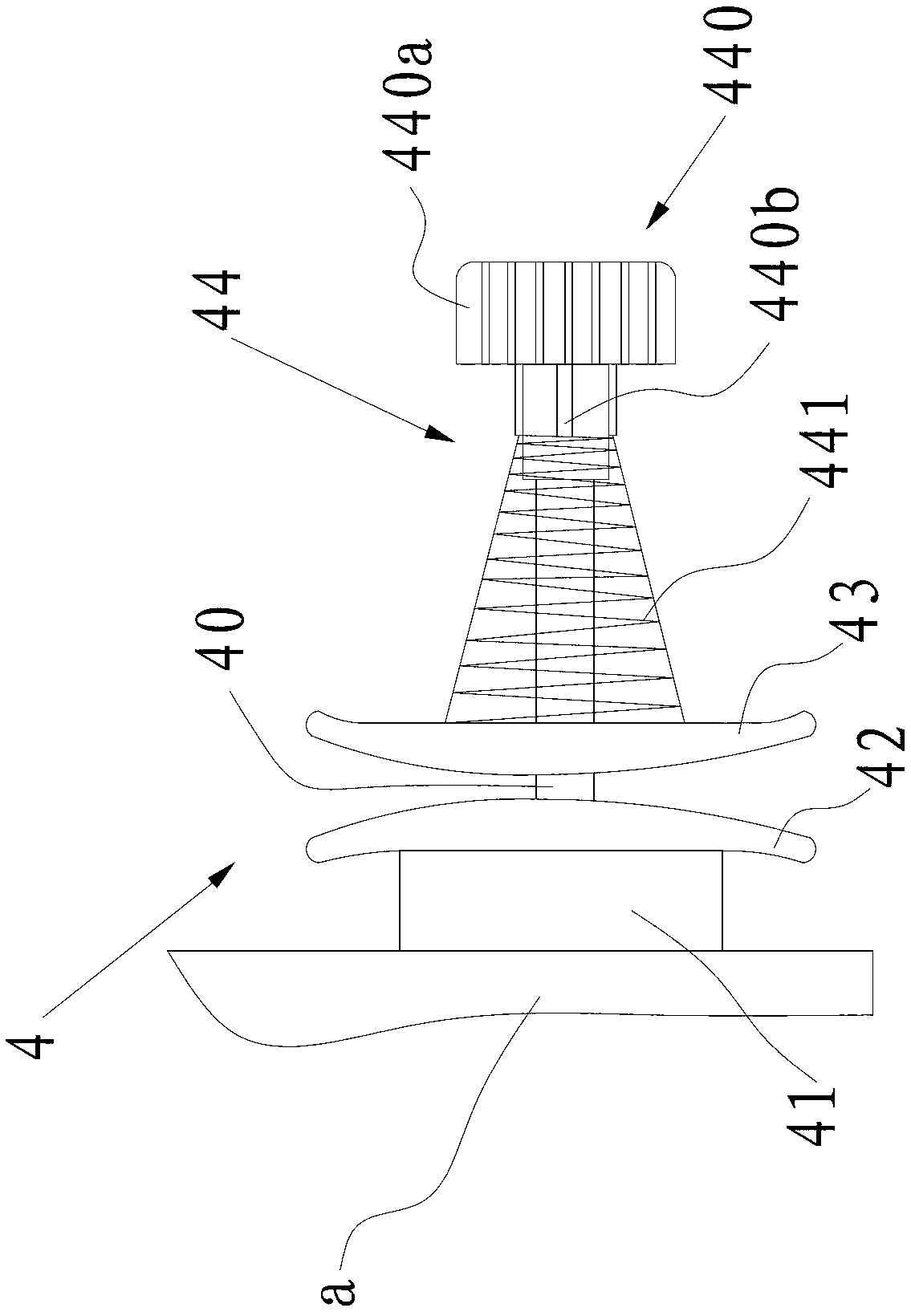

[0018] Such as figure 1 with figure 2 As shown, the yarn delivery device of this embodiment includes a thread passer 1 and a roller pair 2 fixed on the frame a, a driving mechanism for driving the roller pair 2 to rotate relatively, and a roller pair 2 and the thread passer A plurality of tension clamps 4 between 1, a wire hook 5 and a wire breakage sensor 6 arranged at the outlet of the roller pair 2, wherein the roller pair 2 includes an upper roller 20 and a lower roller 21, and the lower roller 21 is fixedly arranged on the drive mechanism On the driving shaft 3, the upper roller 20 can rotate around its own axis, the upper roller 20 is pressed on the lower roller 21, the tension clamp 4 is used to adjust the tightness of the yarn b, the wire hook 5 includes a wire hook 50 and a hook handle 51, One end of the thread breakage sensor 6 is in communication with the driving mechanism, and a contact point is arranged in the other end. When the yarn b passes through the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com