Novel spiral winding pipe heat exchanger

A spiral wound tube and spiral winding technology, applied in the field of heat exchange tubes, can solve the problems of long operation cycle, affecting equipment efficiency, affecting heat exchange effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

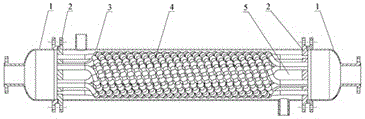

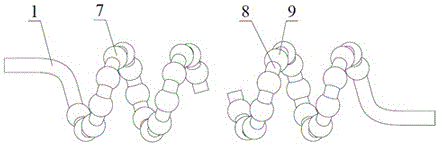

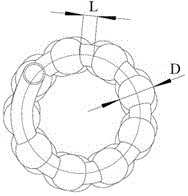

[0010] The purpose of the present invention is achieved in this way: the wave-node wound tube heat exchanger is mainly composed of a shell, a core body and its connecting pipe, etc., wherein the shell is mainly composed of a cylinder [3], a pipe box [1], etc.; the core body It is mainly composed of core tube [5], heat exchange tube [4], gasket, tube clamp and so on. The core tube [5] is to support the heat exchange tube [4], the first layer of heat exchange tubes is wound around the core tube, and the first layer of heat exchange tubes is covered with pads of appropriate thickness (for positioning the radial interval); then Wrap the second layer of heat exchange tubes along the opposite direction of the gasket and the first layer of heat exchange tubes; follow these steps in sequence; figure 2 As shown, the heat exchange tube provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com