Patents

Literature

31results about How to "Shorten the time of anaerobic fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for improving sludge anaerobic fermentation and acid production

InactiveCN101768609AAchieve reductionImprove efficiencyFermentationSolid phasesVolatile organic compound

The invention discloses a method for improving sludge anaerobic fermentation and acid production, belonging to the environmental protection technical field. The method is taken as follows: the residual sludge of municipal sewage plants are used as the raw material, wall breaking action is applied to the microorganisms in the sludge by control of the operating parameters of ultrasonic in order to ensure most of the organic substances in the cells of the microorganisms to be dissolved, lye is added to the sludge to regulate the pH value of the sludge, and the sludge is transformed furthest from the solid phase to the liquid phase and made to produce volatile organic matter under the action of the lye and the microorganisms. The invention further improves the quantity of the organic acid produced from the sludge on the basis of sludge innoxiousness and resource utilization.

Owner:TONGJI UNIV

Method for improving methanogenesis of residual sludge by heat and alkali combined pretreatment

ActiveCN103172242AIncrease productionIncrease the rate of hydrolysisWaste based fuelBiological sludge treatmentMethanogenesisSludge

The invention belongs to the technical field of environmental protection and relates to a method for improving the methanogenesis of residual sludge by heat and alkali combined pretreatment. According to the method, after the residual sludge is thermally pretreated, the dissolving in water of organic matters such as protein and polysaccharide in the residual sludge can be improved significantly so that abundant water-soluble organic matrixes can be provided for the fermentation of the sludge and the generation of acids; and in addition, after the residual sludge is pretreated under the initial alkaline condition, the dissolving and the dehydrating of the sludge can be promoted further and short chain fatty acids can be produced continuously. Therefore, the residual sludge dehydrating efficiency and the acid generating efficiency can be improved greatly by the combination of thermal pretreatment and the initial alkaline condition so that the yield of methane can be increased to the maximum extent.

Owner:TONGJI UNIV

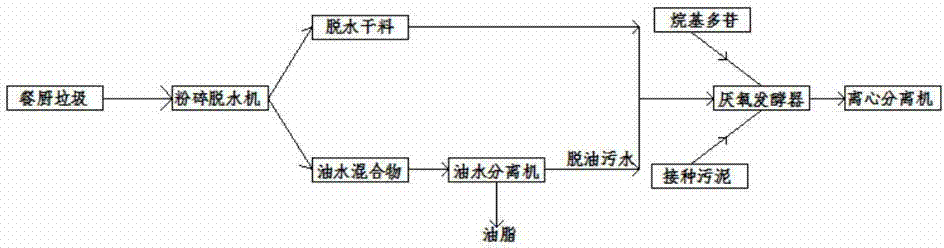

Method for producing short-chain volatile fatty acids by utilizing kitchen wastes and short-chain volatile fatty acids

InactiveCN104498541AIncrease productionGood denitrification and phosphorus removalFermentationBiotechnologyVolatile fatty acids

The invention discloses a method for producing short-chain volatile fatty acids by utilizing kitchen wastes and the short-chain volatile fatty acids. The method specifically comprises the following steps: uniformly mixing and stirring the kitchen wastes serving as a fermentation substrate and sludge serving as an inoculum, thereby obtaining a fermentation matrix; and adding alkyl polyglucosides into the fermentation matrix, and performing anaerobic fermentation under a stirring condition. The reduction, recycling and innocent treatment of the kitchen wastes are realized, and the method has the advantages of low operating cost, high profit, high yield of the short-chain volatile fatty acids and the like.

Owner:HUNAN UNIV

Short-chain volatile fatty acid and preparation method thereof

The invention discloses a short-chain volatile fatty acid and a preparation method thereof. The preparation method for the short-chain volatile fatty acid comprises the following steps of employing sludge as a fermentation substrate; adding sodium nitrite into the fermentation substrate, performing pretreatment in an acid environment, and performing anaerobic fermentation under an alkaline condition to obtain the short-chain volatile fatty acid. According to the short-chain volatile fatty acid and the preparation method thereof, the sludge of a sewage treatment plant is taken as a raw material, and is jointly treated by virtue of free nitrite pretreatment and alkaline anaerobic fermentation, and the concentration of free nitrite in the system, the pretreatment time, the fermentation pH value and the action of microorganisms in the sludge are controlled to maximally convert undissolved sludge organic matters in the sludge into the short-chain volatile fatty acid, so that the yield of the volatile fatty acid produced from the sludge is further increased on the basis of resourcefully utilizing the sludge and reducing environmental pollution caused by the sludge, and the reaction time is shortened; the short-chain volatile fatty acid and the preparation method thereof have the advantages of high product yield, simple preparation method, energy conservation, consumption reduction, low running cost and the like.

Owner:HUNAN UNIV

Method for promoting organic acid yield from sludge

InactiveCN101085997AAchieve reductionAchieve stabilizationFermentationBiological sludge treatmentOrganic acidMicroorganism

The invention belongs to envrionmental protection technique field, in detail relates to a method for increasing organic aicd output through adding anion surface active agent and controlling basic pH value. It takes primary sludge, excess sludge or mixture of them in wastewater treatment plant, converses organic matter in insoluble sludge to organic acid maximumly by adding anion surface active agent, controlling basic pH and employing bacteria function in said sludge. The ratio between consumption amount of anion surface active agent and sludge dry amount is 0.01: 1- 0.1- 1, the pH is controlled between 8 to 12 for bacteria action, the retention time of sludge in reactor is from 5 hours to 30 days. The invention increases organic acid output when makes full use of sludge and reduces environmental pollution.

Owner:TONGJI UNIV

Method for promoting sludge to produce organic acid utilizing surface active agent

ActiveCN1814764AAchieve reductionAchieve stabilizationSludge treatmentMicroorganism based processesOrganic acidSludge

This invention relates to a method for promoting sludge to producing organic acid with a surface active agent, which takes the elementary deposition mud, residural sludge or their mixtures of a pollutant water process plant as the raw material to turn the undissolved sludge organics in the mud to organic acid acted by microbials in the mud, the ratio of the volume of the surface active agent and the dry sludge is 0.01: 1-0.3 : 1 and sludge stays for 5 hours ¿C 30 days in the reactor, which reduces volume of sludge and pollution to the environment and uses it as the resource.

Owner:TONGJI UNIV

Method for improving short-chain fatty acid produced by excess sludge through hot alkali combined pretreatment

The invention belongs to the technical field of environmental protection, and relates to a method for improving short-chain fatty acid produced by excess sludge through hot alkali combined pretreatment. According to the method, the excess sludge in a sewage treatment plant serves as raw material, through hot pretreatment, controlling of initial alkaline power of hydrogen (PH) value conditions and the functions of microorganism is conducted, not only are non-aqueous resolvable organic matters in the sludge promoted to be dissolved and are the non-aqueous resolvable organic matters hydrolyzed to be converted to resolvable organic matters, but also the resolvable organic matters such as protein and polysaccharide are fully converted into the short-chain fatty acid, and pollution of the sludge to the environment is reduced. The temperature of the hot pretreatment is 60-120 DEG C, the time of the hot pretreatment is 15-60min, the initial PH value range of the functions of the microorganism is 8-12, the standing time of the sludge in a reactor is 1-12 days, and the temperature is 30-40 DEG C.

Owner:TONGJI UNIV

Method used for increasing sludge anaerobic fermentation production of volatile short-chain fatty acids

The invention discloses a method used for increasing sludge anaerobic fermentation production of volatile short-chain fatty acids, and belongs to the technical field of sludge resource recycling, andmore specifically relates to a calcium peroxide (CaO2) combined free ammonia (FA) method used for increasing sludge anaerobic fermentation production of volatile short-chain fatty acids. The method comprises following steps: sludge obtained through removing supernatant of municipal sewage plant residual sludge after natural static precipitation is taken as a fermentation base material, the fermentation base material is uniformly mixed with calcium peroxide (CaO2) and ammonium chloride (NH4Cl), at a certain temperature, pH is adjusted to convert ammonia nitrogen into free ammonia (FA), pre-treatment reaction is carried out for 72h, and at stirring conditions, anaerobic fermentation is carried out continuously, wherein under the calcium peroxide (CaO2) combined free ammonia (FA) pre-treatment effect, hydrolysis rate is increased obviously, acidifying phase is promoted, methanogen activity is inhibited at the same time, and large amount accumulation of volatile short-chain fatty acids canbe realized. The method is capable of increasing the amount of volatile short-chain fatty acids obviously; the produced volatile short-chain fatty acids can be applied in sewage processing; sewage nitrogen and phosphorus removal effect is improved; sludge quantitative reduction, harmlessness treatment, and resource recycling are realized.

Owner:HUNAN UNIV

Method utilizing sludge anaerobic fermentation to produce fatty acid

InactiveCN104099380AImprove dissolution efficiencyImprove hydrolysis efficiencyFermentationSludgeFatty acid

The invention provides a method utilizing sludge anaerobic fermentation to produce fatty acid. The method comprises the following steps: taking sludge obtained from sewage treatment as a raw material; removing the supernatant after natural settlement to obtain a sludge sample, mixing the sludge sample and alkyl glycoside serving as a surfactant, and fermenting the mixture in the anaerobic environment to produce the fatty acid. The method can prevent the sludge sample from producing methane and improve the organic acid production capability of the sludge sample; the obtained organic acid can be continually applied in the sewage treatment process to improve the effect in removing nitrogen and phosphorus from sewage, so that reduction, harmlessness and recycling of sludge treatment can be realized.

Owner:TONGJI UNIV

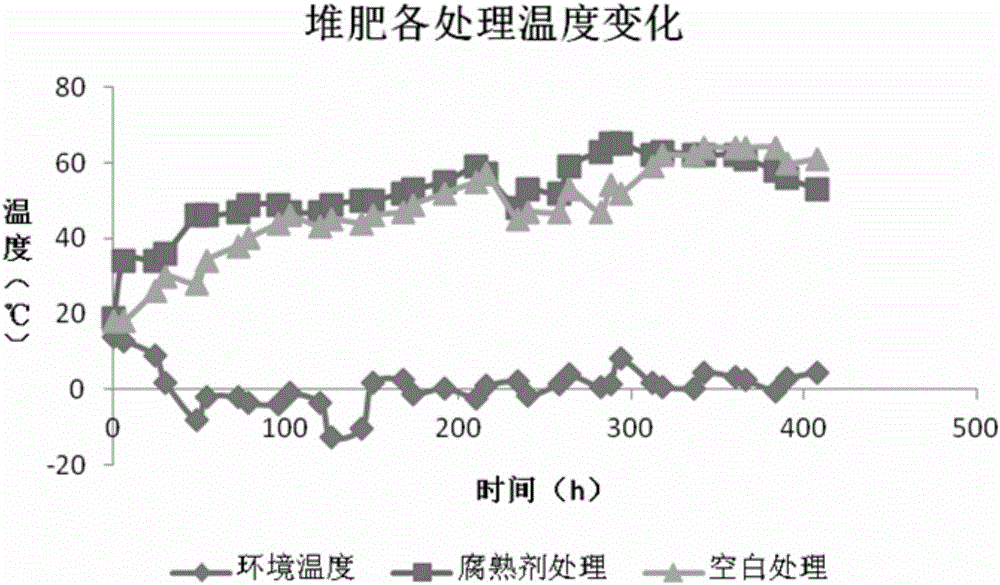

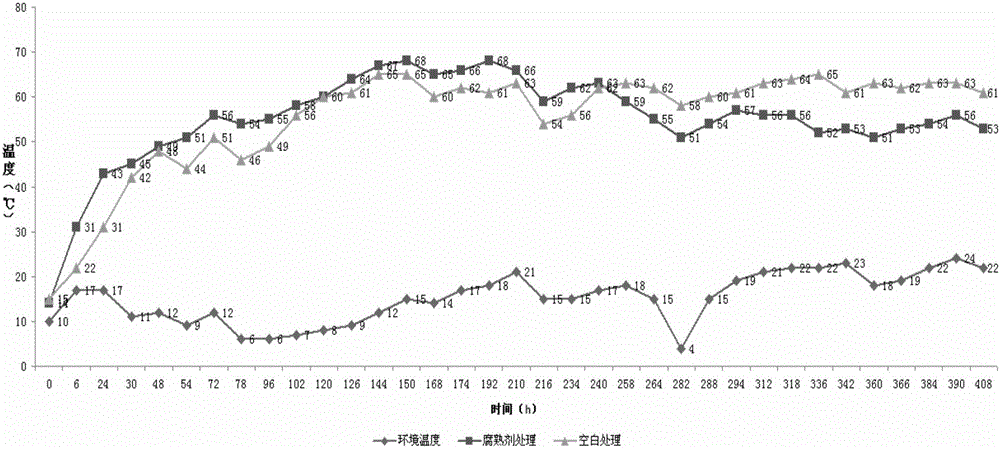

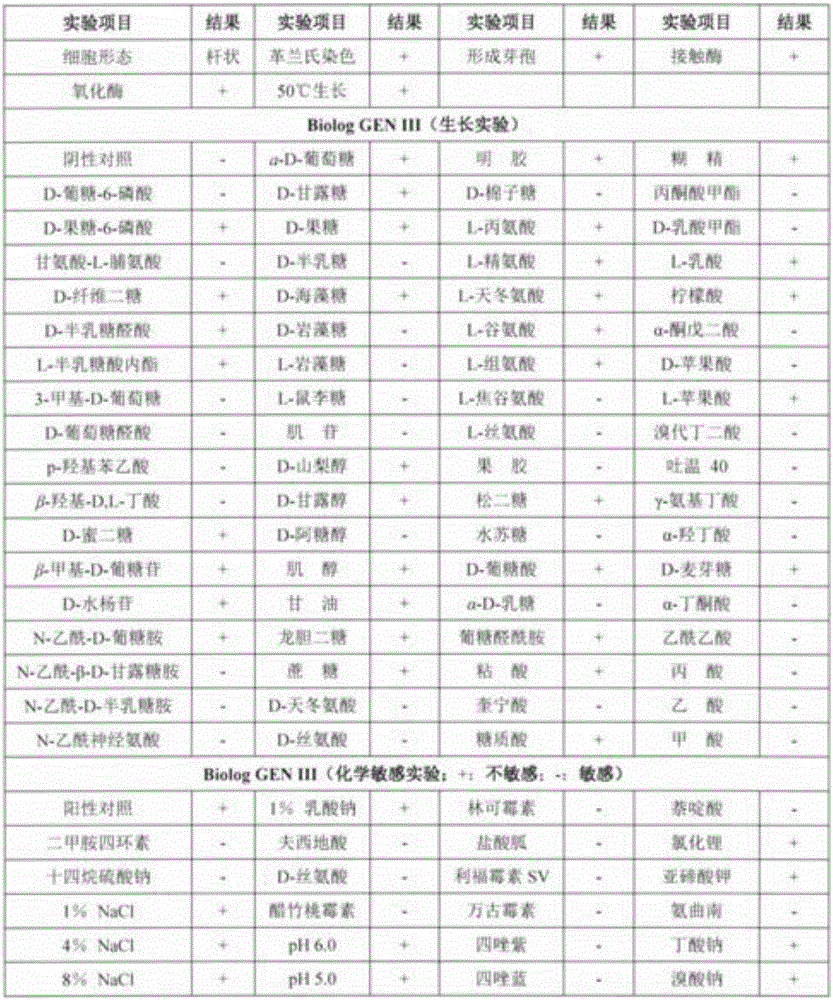

Low-temperature-resistant composting fermentation microbial inoculum with deodorizing function and applications of low-temperature-resistant composting fermentation microbial inoculum

PendingCN106244475AFavorable temperature for fermentationFast heatingBio-organic fraction processingFungiBiotechnologyEffective microorganism

The invention discloses a low-temperature-resistant composting fermentation microbial inoculum with a deodorizing function and applications of the low-temperature-resistant composting fermentation microbial inoculum. The microbial flora contained in the low-temperature-resistant composting fermentation microbial inoculum provided by the invention can tolerate low temperature, and can normally grow at 15-20 DEG C, so that the fermentation air temperature of organic materials in the low-temperature environment is facilitated, in addition, the strains have the mutual promotion effects, therefore, a mutual synergistic effect is generated, and further, decomposing is accelerated. The experiment proves that during the composting process, after the low-temperature-resistant composting fermentation microbial inoculum is added into the organic materials for fermentation, the sum of effective microbes at the composting initial stage is improved, the temperature increase rate of the composted materials is accelerated, the anaerobic fermentation time is shortened, the decomposing process is accelerated, meanwhile, the discharge of sulfur-containing compounds and nitrogen-containing compounds is reduced, the physicochemical properties of the fermentation products are optimized, and in addition, the low-temperature-resistant composting fermentation microbial inoculum has a certain deodorizing function.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

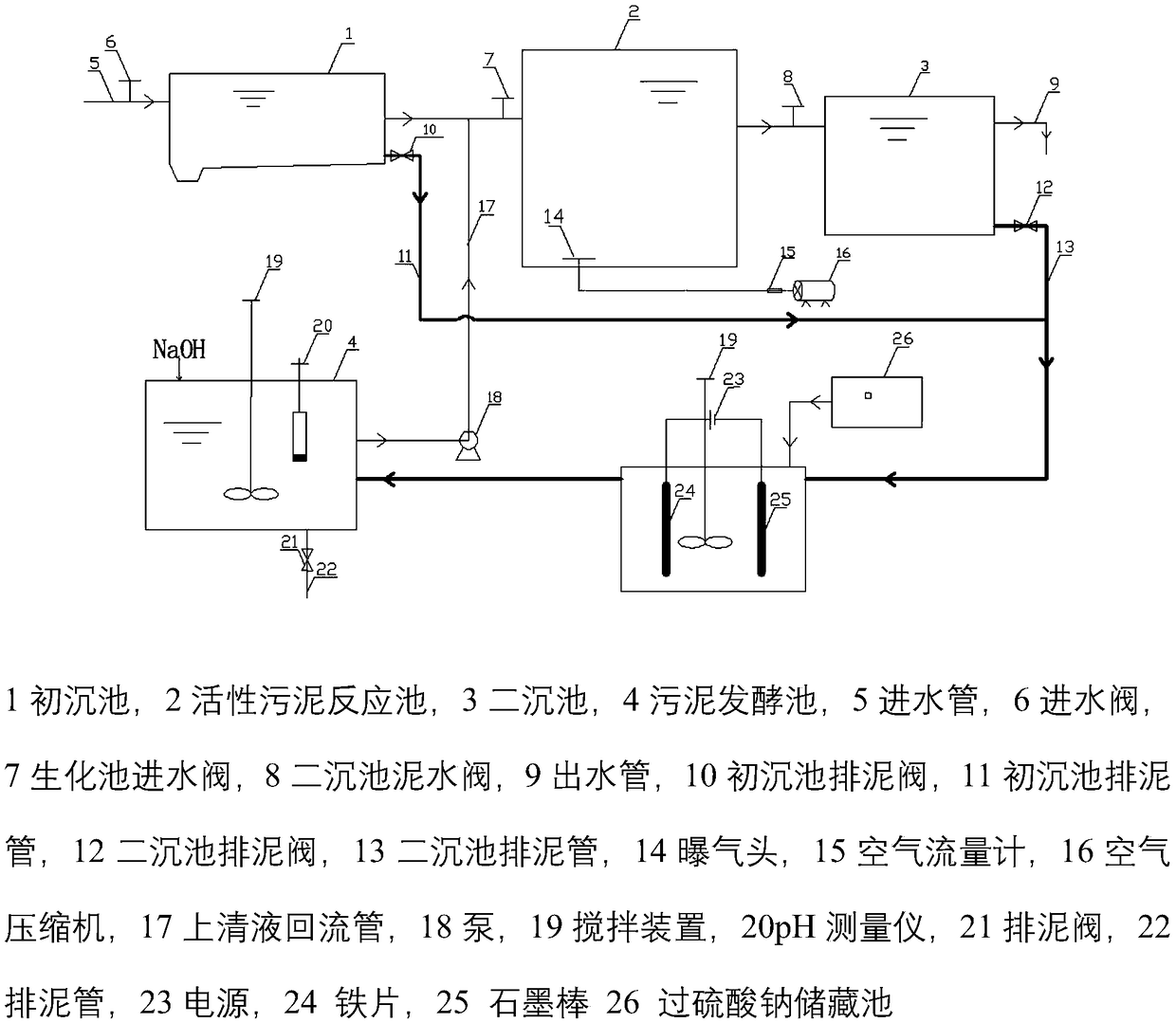

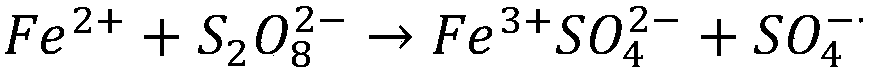

Method of optimizing acid production structure through pretreatment of iron electrode activation of persulfate

InactiveCN109231746AAchieve reductionRealize resourcesFatty oils/acids recovery from wasteFatty substance recoveryElectrochemical responseVolatile fatty acids

The invention discloses a method of optimizing an acid production structure in an anaerobic fermentation acid production process of excess sludge and increasing a short chain fatty acid yield throughpretreatment of iron anode and electricity combined activation of persulfate. The method comprises the steps of: taking sludge as a fermentation substrate, a single-chamber electrolytic tank as a reaction device, an iron sheet as an anode and a graphite rod as a cathode, adding the sludge into an electrochemical reaction tank, adding persulfate into the fermentation substrate at the same time, electrifying for pretreatment, adjusting an initial pH (potential of hydrogen) to 10 for anaerobic fermentation, and obtaining structure optimized short chain volatile fatty acid. The method takes the sludge of a sewage treatment plant as a raw material; an acetic acid yield can be increased to the maximum extent by controlling an iron concentration, a current magnitude, electrifying time and a persulfate concentration in a pretreatment system; and the method contributes to achieving carbon source internal circulation of the sewage treatment plant and promoting sludge reclamation utilization. Atthe same time, the method also has the advantages of simplicity in operation, convenient management and high cost performance.

Owner:HUNAN UNIV

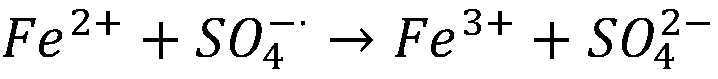

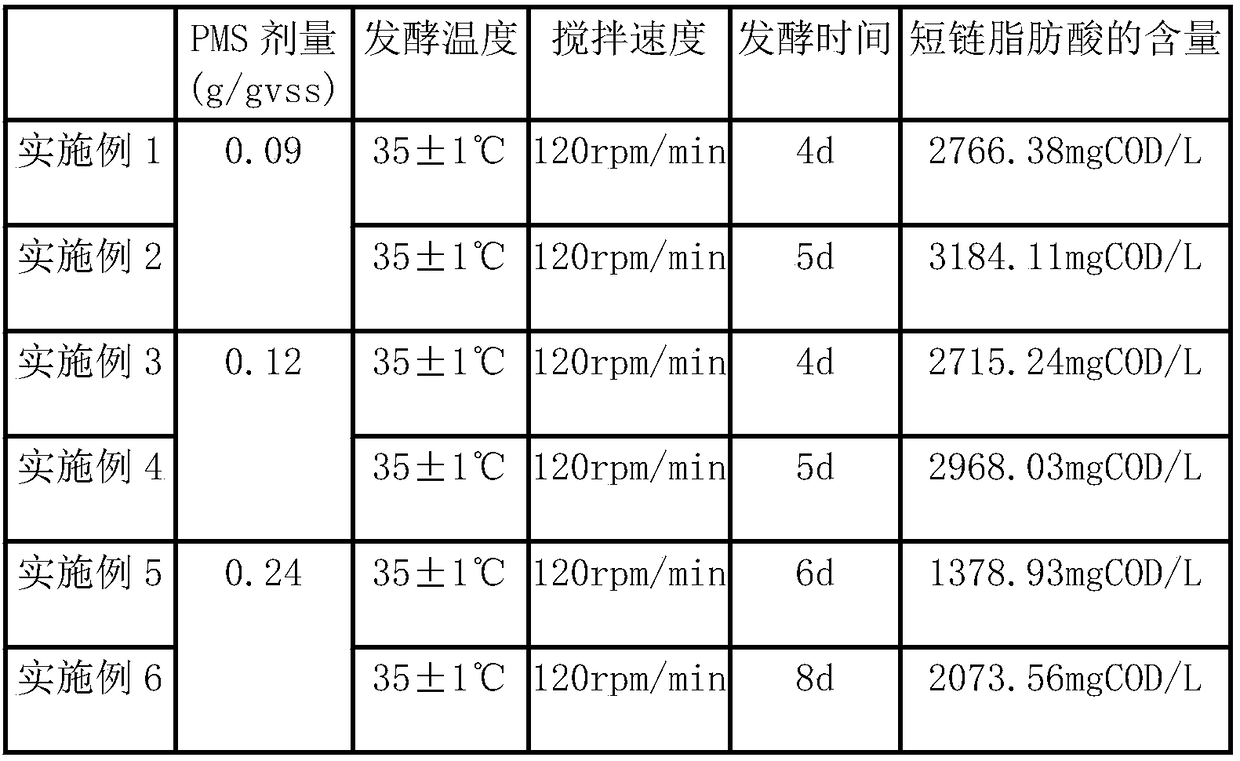

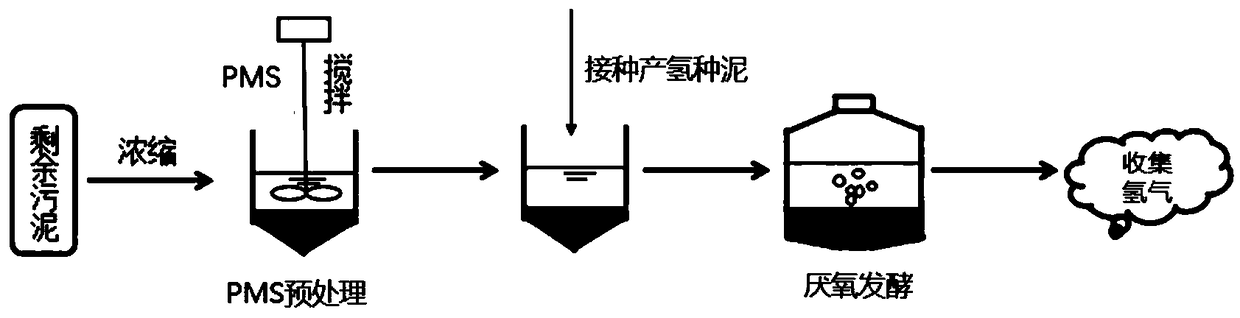

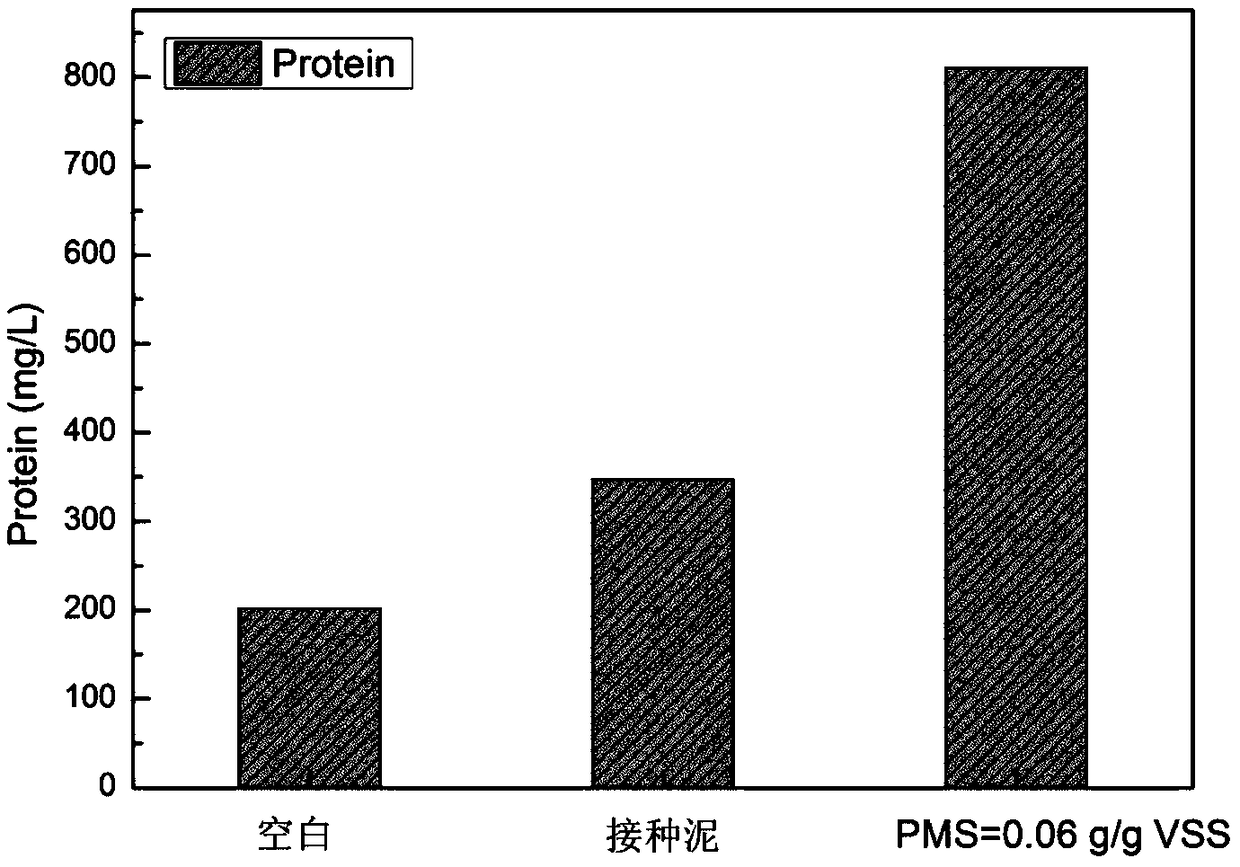

Method for promoting residual sludge anaerobic fermentation to produce fatty acid through potassium peroxymonosulfate sulfate compound salt (PMS)

InactiveCN108441522AIncrease the rate of acid productionShorten the time of anaerobic fermentationFermentationFatty acidFermentation

The invention relates to a method for promoting residual sludge anaerobic fermentation to produce fatty acid through potassium peroxymonosulfate sulfate compound salt (PMS). The method specifically comprises the following steps: (1) treating residual active sludge generated by a secondary sedimentation tank of a municipal sewage treatment plant as a fermentation raw material, and naturally settling to remove liquid supernatant to concentrate and treat to obtain a sludge sample; (2) mixing and pre-treating the sludge sample with potassium peroxymonosulfate sulfate compound salt (PMS), and fermenting under an anaerobic environment to generate fatty acid. After residual sludge is subjected to PMS pretreatment, dissolving of organic substances in sludge is quickened, and activity of acid-consuming microorganisms such as methanogenic bacteria is further inhibited sufficiently, and therefore, the acid yield is greatly increased, and sludge anaerobic fermentation time is shortened; and moreover, the method provided by the invention is simple in operation, and has important environment-friendly ecological significance for reducing, recycling and stabilizing sludge.

Owner:HUNAN UNIV

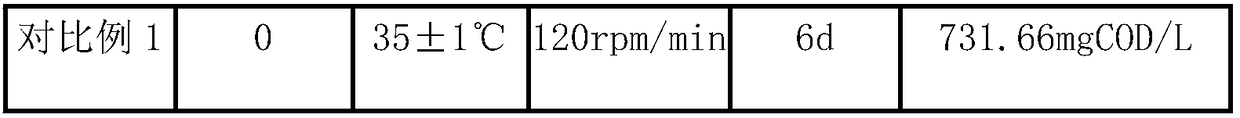

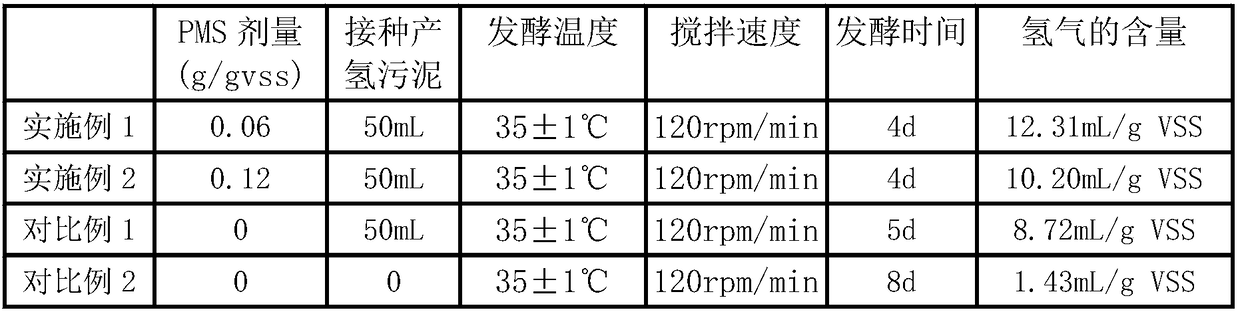

Method for promoting hydrogen production by anaerobic fermentation of remaining activated sludge

InactiveCN108624623AStrong oxidation abilityFacilitated releaseFermentationChemistryMunicipal sewage

The invention relates to a method for promoting hydrogen production by anaerobic fermentation of remaining sludge through potassium peroxymonosulfate (PMS). The methods comprises the following specific steps: (1) with remaining activated sludge produced by a secondary sedimentation tank of a municipal sewage treatment plant as a fermentation raw material, removing supernatant by natural sedimentation and carrying out concentration treatment to obtain a sludge sample; and (2) mixing and preprocessing the sludge sample and PMS, then inoculating a certain volume of hydrogen-producing seed sludge,and fermenting in anaerobic environment to produce hydrogen. After the remaining sludge is pretreated by PMS, the dissolution of organic matter in the sludge is accelerated. The organic matter dissolved after the sludge is cracked provides a rich matrix for hydrogen production by fermentation, thereby improving the hydrogen production, shortening the time of sludge anaerobic fermentation and reutilizing the remaining sludge. The method provided by the invention is simple to operate, has mild reaction conditions, and has good application prospects in environmental control and comprehensive utilization of waste resources.

Owner:HUNAN UNIV

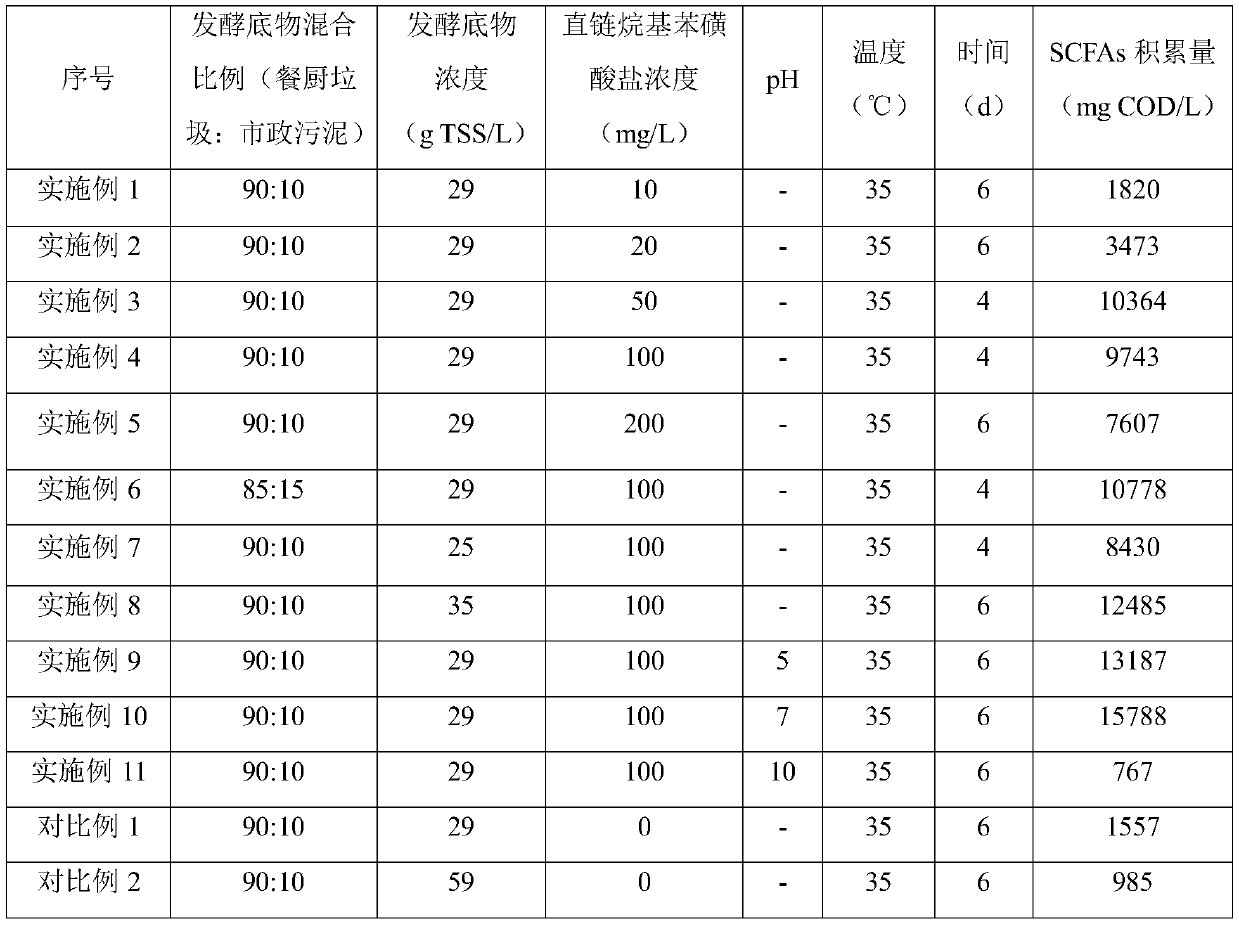

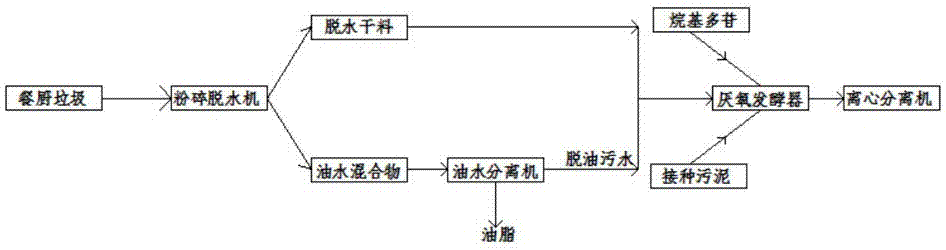

Method for improving resource utilization of kitchen waste

The invention discloses a method for improving the resource utilization of kitchen waste. The method comprises the following steps: (1) grinding and pulping kitchen waste to obtain an anaerobic fermentation substrate; (2) adding civil sludge into the substrate to serve as an inoculating microbe; (3) diluting the fermentation substrate with washing wastewater containing linear alkyl benzene sulfonates to obtain a fermentation system; and (4) performing oxygen removal and sealing on the fermentation system, and performing anaerobic fermentation. The method can improve the characteristics of kitchen waste by adding washing wastewater to realize resource utilization and recycling of the kitchen waste and the like and is favorable to reduction and harmless disposal of washing wastewater and kitchen waste; furthermore, relative to clean water, such as tap water, kitchen waste is diluted with washing wastewater, the solid content of the kitchen waste is reduced, and the treatment cost can bereduced; and the linear alkyl benzene sulfonates can be used for promoting dissolution of complex organic substances and increasing the generation rate and yield of short-chain fatty acids, the anaerobic fermentation time can be remarkably shortened, and the operation cost can be reduced.

Owner:HOHAI UNIV

Method for producing short-chain fatty acid employing combined pretreatment of activated sludge

ActiveCN104445849AIncrease the rate of acid productionShorten the timeFermentationBiological sludge treatmentChemistryGamma ray irradiation

The invention relates to a method for producing a short-chain fatty acid employing combined pretreatment of activated sludge. The method comprises the following steps: (1) carrying out gamma-ray irradiation on activated sludge, so as to prepare gamma-ray irradiated sludge; (2) carrying out ultrasonic treatment on the gamma-ray irradiated sludge, so as to prepare ultrasonic-treated sludge; and (3) adjusting the pH value of ultrasonic-treated sludge, carrying out anaerobic fermentation, so as to prepare the combined pretreated activated sludge. After the activated sludge is subjected to gamma-ray irradiation and ultrasonic treatment, organic matters such as protein and polysaccharide in the sludge dissolved into water can be significantly improved, so that an abundant organic matrix which can be dissolved into water is provided for fermentation and acidogenesis of sludge; the acid production rate of the sludge is improved; the anaerobic fermentation time of the sludge is shortened; and the method has important significance in improvement and optimization of an existing sludge treatment system, energy conservation and consumption reduction, and reduction of the operation cost.

Owner:UNIV OF JINAN

Method for promoting anaerobic fermentation of excess sludge by combining copper sulfate and alkaline pH to produce short-chain fatty acid

ActiveCN104531783AAchieve reductionRealize the purpose of resource utilizationFermentationMicroorganismWastewater

The invention discloses a method for promoting anaerobic fermentation of excess sludge by combining copper sulfate and alkaline pH to produce short-chain fatty acid and belongs to the technical field of environmental protection. According to the method, the excess sludge in a municipal wastewater treatment plant is used as the raw material; firstly, the copper sulfate is added to make the walls of microorganisms in the excess sludge break; secondly, the excess sludge is washed to remove copper ions; lastly, the pH value of the excess sludge is adjusted to be alkaline for anaerobic fermentation. After the excess sludge is pretreated through the copper sulfate, the hydrolysis rate is increased in the anaerobic fermentation process, and the yield of the short-chain fatty acid is increased; besides, the alkaline pH further promotes wall breakage of the microorganisms in the excess sludge and effectively suppresses the activity of methane bacteria produced in the anaerobic fermentation process, so that organic matter in the excess sludge is converted into the short-chain fatty acid to the maximum extent, and meanwhile the short-chain fatty acid is prevented from being converted into methane and is accumulated. The copper sulfate adopted in the method can effectively promote anaerobic fermentation of the excess sludge to produce the short-chain fatty acid at a small dosage, and meanwhile the effect of sludge reduction is achieved.

Owner:BEIJING UNIV OF TECH

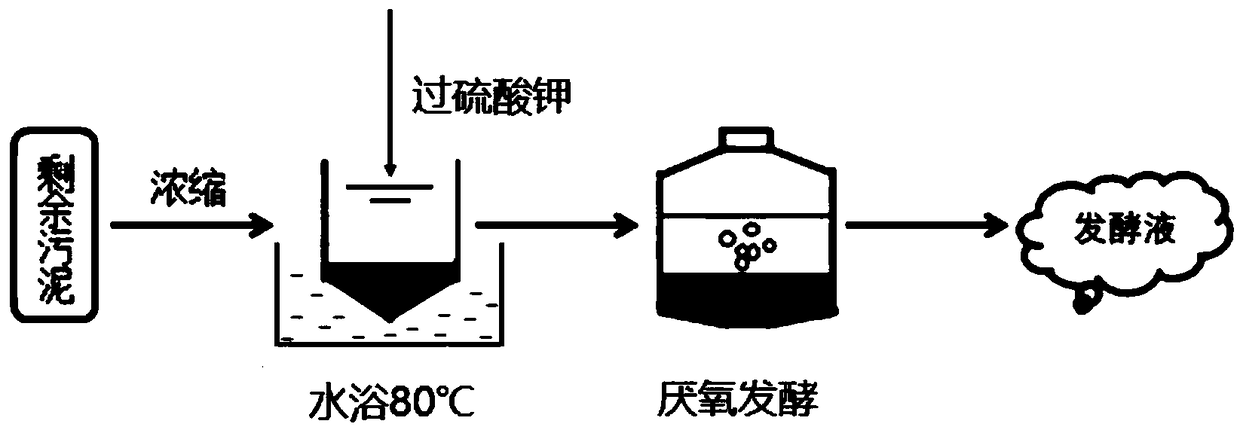

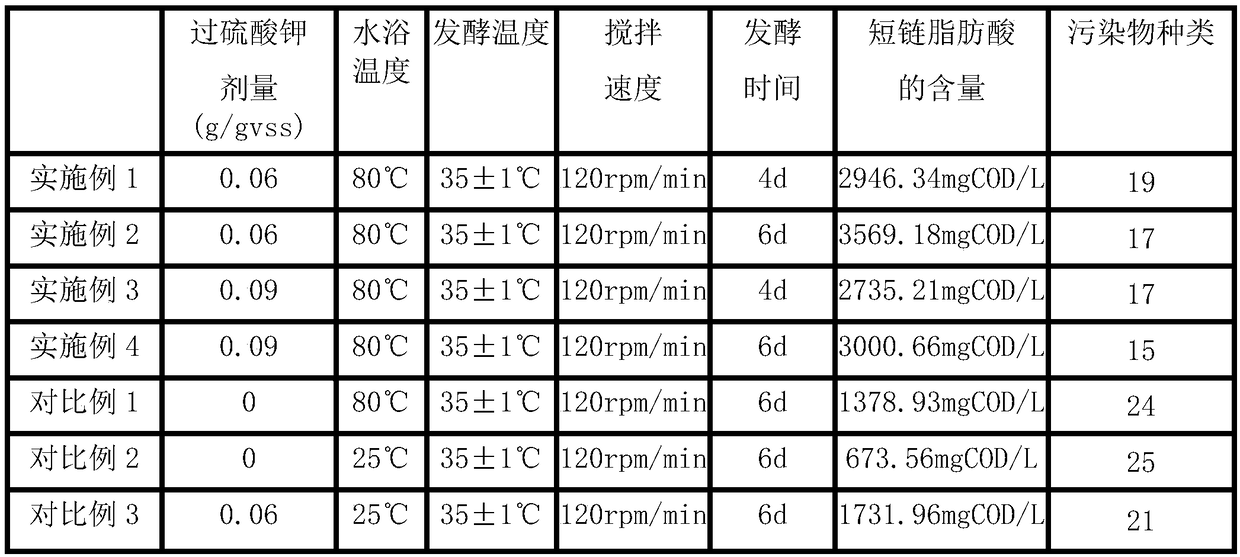

Method for promoting degradation of pollutants in excess sludge and producing fatty acid

InactiveCN108624629AIncrease the rate of acid productionShorten the time of anaerobic fermentationFermentationWater bathsPotassium persulfate

The invention relates to a method for promoting degradation of pollutants in excess sludge and producing fatty acid. The method comprises the following specific steps: firstly, taking excess activatedsludge generated by a secondary sedimentation tank of an urban sewage treatment plant as a fermentation raw material, naturally settling to remove supernate and carrying out concentrated treatment toobtain a sludge sample; secondly, mixing the sludge sample with potassium persulfate, pretreating a mixture in a water bath with the temperature of 80 DEG C for one hour, and fermenting in an anaerobic envirnoment to produce the fatty acid. After the excess sludge is pretreated, dissolution of organic matters in the sludge is accelerated, and the activity of acid-consuming microbes of methanogenic bacteria and the like is sufficiently inhibited, so that acid yield is greatly improved, and the anaerobic fermentation time of the sludge is shortened; meanwhile, kinds and quantity of the pollutants in the sludge are reduced. The method provided by the invention is simple to operate and has important environment-friendly ecological significance for reduction, recycling and stabilization.

Owner:HUNAN UNIV

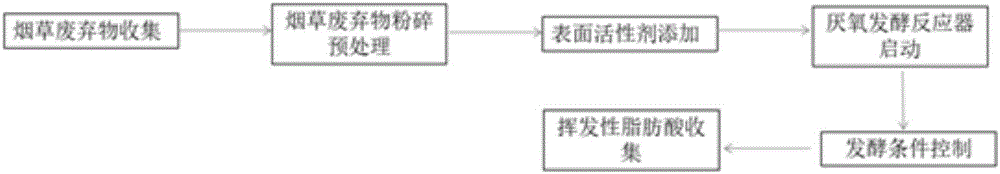

Method for producing short-chain volatile fatty acid by using tobacco waste

InactiveCN106801082AIncrease productionImprove hydrolysis effectFermentationVolatile fatty acidsSludge

The invention discloses a method for producing short-chain volatile fatty acid by using tobacco waste. The method concretely comprises the following steps: stirring and evenly mixing the tobacco waste used as a fermentation substrate with sludge used as an inoculant so as to obtain a fermentation substrate; adding alkyl polyglycoside into the fermentation substrate, and carrying out anaerobic fermentation under the condition of stirring. The method can realize reduction, resource and harmless treatment, and has the advantages of being low in running cost, high in earnings, high in yield of the short-chain volatile fatty acid, and the like.

Owner:CHINA TOBACCO GUANGXI IND

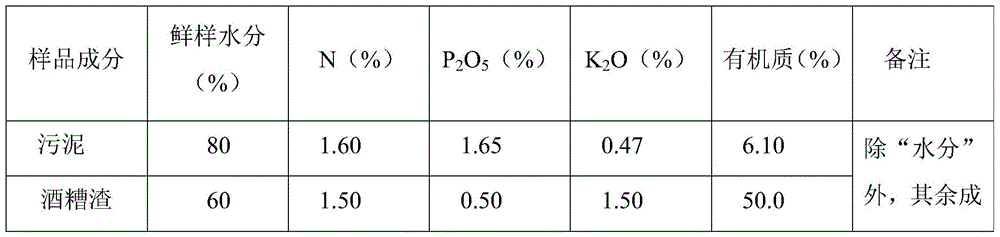

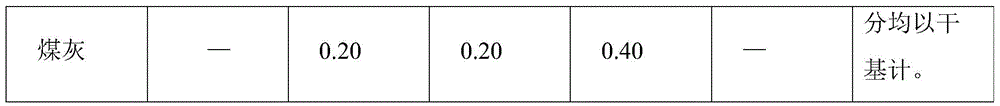

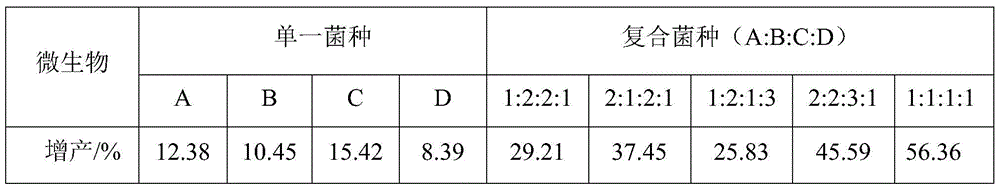

Method for preparing organic compound fertilizer through sludge generated by processing cassava starch

InactiveCN105669286APromote growthImprove stress resistanceAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersBacillus megateriumSludge

The invention discloses a method for preparing an organic compound fertilizer through sludge generated by processing cassava starch. The method includes the steps: 1) uniformly mixing sludge, grain stillage residue and coal ash according to the mass ratio of 2-5:1:1 to obtain a first mixture; 2) inoculating a microbial inoculant being 4-6% in mass percentage, stacking the first mixture into a stereo trapezoid shape, performing aerobic fermentation for 8-15 days to obtain a first fermentation product, wherein the mixture stack is stirred for 1-3 times every day to control the moisture content to be 25-45% and the temperature to be 40-60 DEG C, and the microbial inoculants is composed of bacillus amyloliquefaciens, bacillus mucilaginosus, bacillus subtilis and bacillus megaterium according to the mass ratio of 1:1:1:1; and 3) adding a nitrogen fertilizer, a phosphorous fertilizer and a potassium to the first fermentation product fertilizer with uniform mixing to obtain a second mixture; and 4) stacking the second mixture into a circular conical shape, sealing the second mixture and performing anaerobic fermentation at 25-35 DEG C for 3-8 days to obtain the organic compound fertilizer which has the effect of increasing yield and improving quality of crops.

Owner:广西农垦明阳生化有限公司

Method for promoting sludge to produce organic acid utilizing surface active agent

ActiveCN1814764BAchieve reductionAchieve stabilizationSludge treatmentMicroorganism based processesMicroorganismOrganic acid

This invention relates to a method for promoting sludge to producing organic acid with a surface active agent, which takes the elementary deposition mud, residural sludge or their mixtures of a pollutant water process plant as the raw material to turn the undissolved sludge organics in the mud to organic acid acted by microbials in the mud, the ratio of the volume of the surface active agent and the dry sludge is 0.01: 1-0.3 : 1 and sludge stays for 5 hours-30 days in the reactor, which reduces volume of sludge and pollution to the environment and uses it as the resource.

Owner:TONGJI UNIV

Copper sulfate combined with alkaline ph to promote the method of anaerobic fermentation of excess sludge to produce short-chain fatty acids

ActiveCN104531783BAchieve reductionRealize the purpose of resource utilizationFermentationCombined methodHydrolysis

The invention discloses a method for promoting anaerobic fermentation of excess sludge by combining copper sulfate and alkaline pH to produce short-chain fatty acid and belongs to the technical field of environmental protection. According to the method, the excess sludge in a municipal wastewater treatment plant is used as the raw material; firstly, the copper sulfate is added to make the walls of microorganisms in the excess sludge break; secondly, the excess sludge is washed to remove copper ions; lastly, the pH value of the excess sludge is adjusted to be alkaline for anaerobic fermentation. After the excess sludge is pretreated through the copper sulfate, the hydrolysis rate is increased in the anaerobic fermentation process, and the yield of the short-chain fatty acid is increased; besides, the alkaline pH further promotes wall breakage of the microorganisms in the excess sludge and effectively suppresses the activity of methane bacteria produced in the anaerobic fermentation process, so that organic matter in the excess sludge is converted into the short-chain fatty acid to the maximum extent, and meanwhile the short-chain fatty acid is prevented from being converted into methane and is accumulated. The copper sulfate adopted in the method can effectively promote anaerobic fermentation of the excess sludge to produce the short-chain fatty acid at a small dosage, and meanwhile the effect of sludge reduction is achieved.

Owner:BEIJING UNIV OF TECH

White soy sauce and its production method

ActiveCN104381960BFacilitate the promotion of industrial productionShorten the time of anaerobic fermentationFood scienceWeather exposureBran

Owner:朱守允

Preparation method of hippophae rhamnoides insoluble dietary fibers

PendingCN111449249APromote fermentationPromote growthMicroorganism based processesNatural extract food ingredientsBiotechnologyMicrobiology

The invention relates to a preparation method of hippophae rhamnoides insoluble dietary fibers, and belongs to the technical field of biology. According to the specific technical scheme, hippophae rhamnoides rhizomes, hippophae rhamnoides seeds, male silkworm moths and other raw material are sequentially subjected to anaerobic fermentation, current fermentation and ganoderma lucidum fermentation,and then insoluble dietary fibers are extracted through an enzymolysis method; the insoluble dietary fibers with the hippophae rhamnoides as the main raw material are extracted through the method combining biological fermentation, electrochemistry and enzyme engineering, operation is easy, pollution is little, the purity of the insoluble dietary fibers obtained through the method is obviously improved, and the adsorbability of the produced insoluble dietary fibers in the intestinal tract is enhanced. The method is suitable for large-scale production and popularization.

Owner:SHANXI JINKEHAI BIOLOGICAL PROD

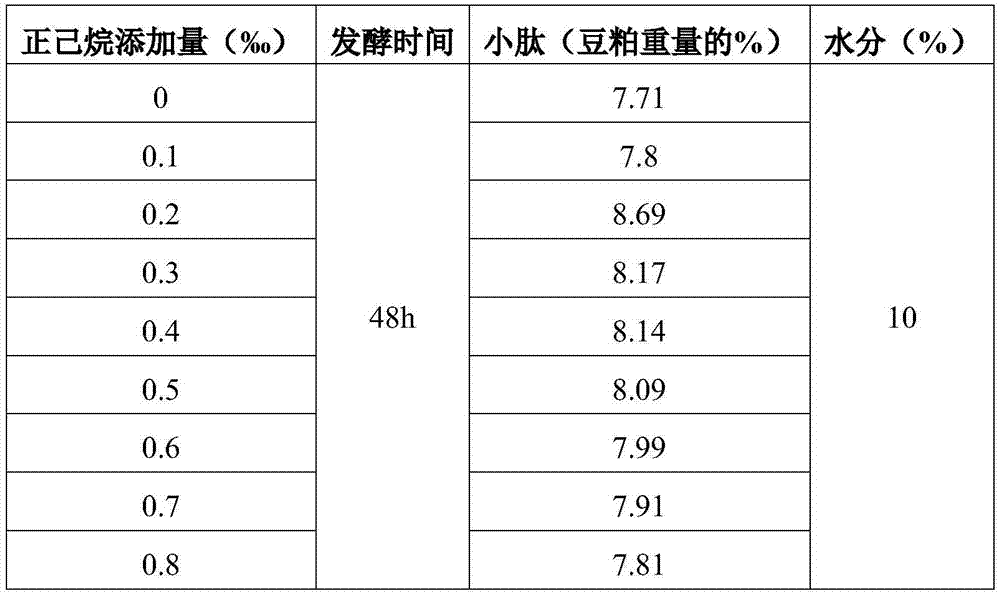

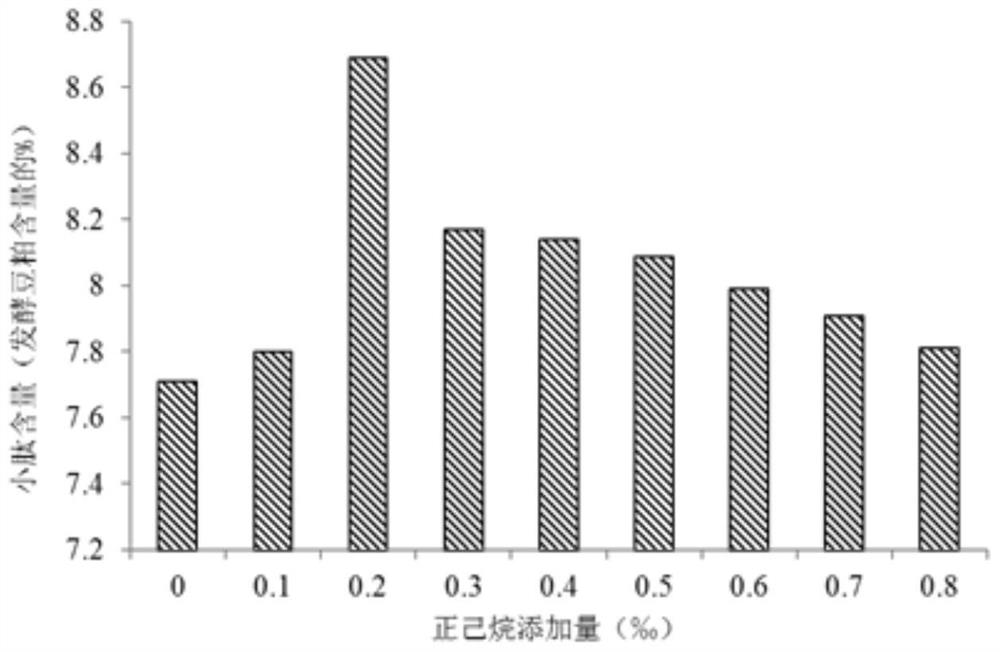

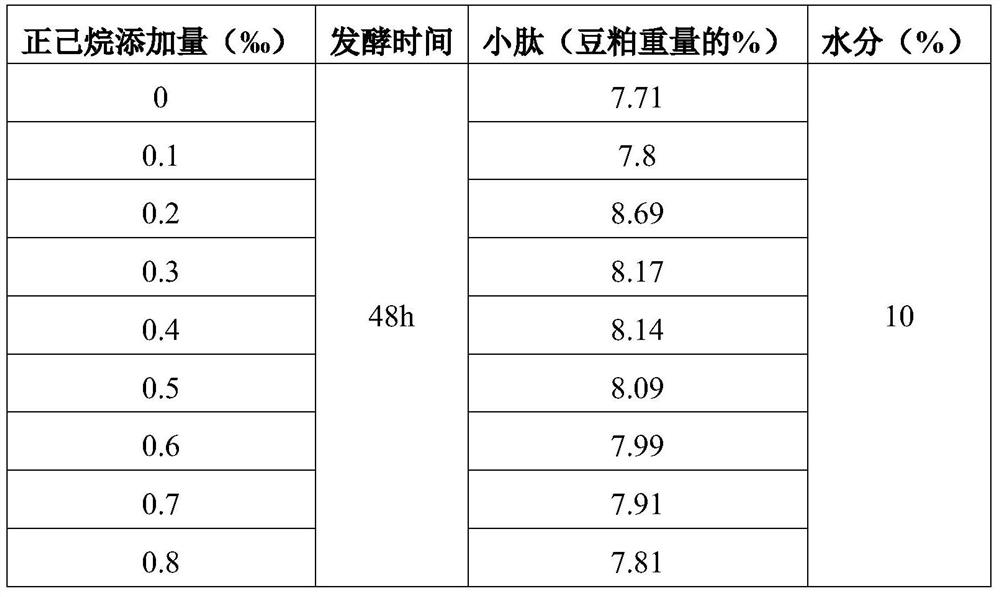

Anaerobic fermentation method, fermentation product and animal feed comprising fermentation product

ActiveCN106929535AShorten fermentation timeEconomic gainAnimal feeding stuffFermentationFodderFermentation

The invention relates to an anaerobic fermentation method, a fermentation product and an animal feed comprising the fermentation product. During anaerobic fermentation, raw materials are improved biotechnologically, and in particular, a feeding value of plant dregs is increased. The anaerobic fermentation method includes the step of mixing the plant dregs with a hydrocarbon compound and an enzyme. By the anaerobic fermentation method, fermentation time in industrial production is shortened effectively and product nutrition value is enhanced.

Owner:益海嘉里(防城港)生物科技有限公司

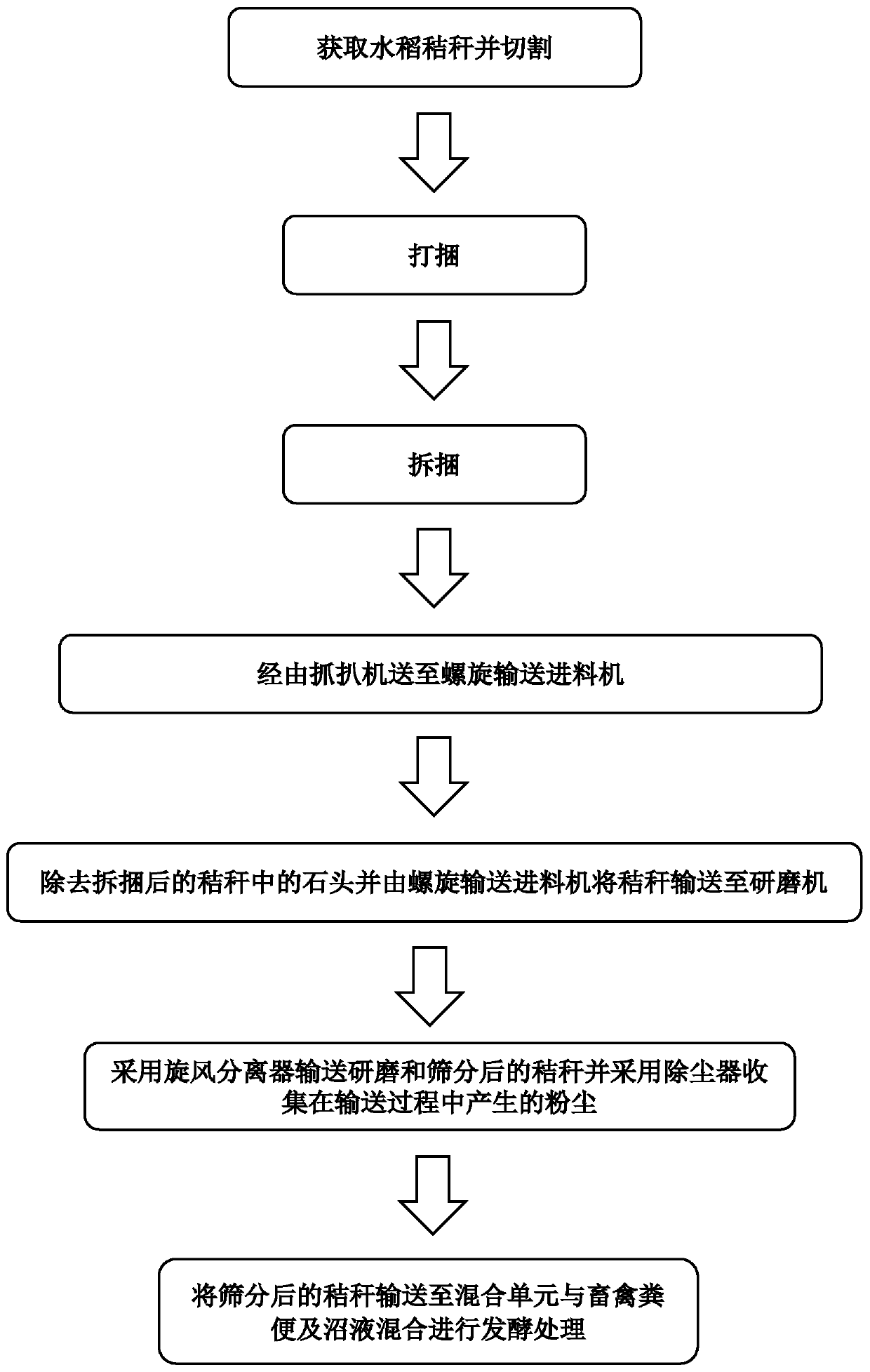

Rice straw pretreatment method for anaerobic fermentation

InactiveCN110229850AFacilitated releaseImprove biogas conversion rateWaste based fuelFermentationRefluxPretreatment method

The invention relates to a rice straw pretreatment method for anaerobic fermentation. The method comprises the following steps: (1) cutting straw into preset length; (2) bundling the cut straw; (3) conveying the bundled straw to a unbundling machine for unbundling; (4) conveying the unbundled straw into a grinder for grinding treatment and screening the ground straw; and (5) conveying the straw subjected to grinding and screening in the step (4) by a cyclone separator, collecting dust generated in the conveying process, so that a large amount of dust is prevented from diffusing into the environment, and after collecting the dust, conveying the straw into a mixing unit through the cyclone separator to be mixed with livestock manure and reflux biogas slurry for anaerobic fermentation. The pretreatment method provided by the invention is beneficial to improving the biogas conversion rate in the subsequent anaerobic fermentation process, shortening the anaerobic fermentation time, effectively reducing the environmental pollution, reducing the anaerobic fermentation cost and saving the labor cost.

Owner:CHINA URBAN CONSTR DESIGN & RES INST CO LTD

A method of combined pretreatment of activated sludge to produce short-chain fatty acids

ActiveCN104445849BIncrease the rate of acid productionShorten the time of anaerobic fermentationFermentationBiological sludge treatmentActivated sludgeGamma ray

The invention relates to a method for producing a short-chain fatty acid employing combined pretreatment of activated sludge. The method comprises the following steps: (1) carrying out gamma-ray irradiation on activated sludge, so as to prepare gamma-ray irradiated sludge; (2) carrying out ultrasonic treatment on the gamma-ray irradiated sludge, so as to prepare ultrasonic-treated sludge; and (3) adjusting the pH value of ultrasonic-treated sludge, carrying out anaerobic fermentation, so as to prepare the combined pretreated activated sludge. After the activated sludge is subjected to gamma-ray irradiation and ultrasonic treatment, organic matters such as protein and polysaccharide in the sludge dissolved into water can be significantly improved, so that an abundant organic matrix which can be dissolved into water is provided for fermentation and acidogenesis of sludge; the acid production rate of the sludge is improved; the anaerobic fermentation time of the sludge is shortened; and the method has important significance in improvement and optimization of an existing sludge treatment system, energy conservation and consumption reduction, and reduction of the operation cost.

Owner:UNIV OF JINAN

Method for producing short-chain volatile fatty acids from kitchen waste and short-chain volatile fatty acids

InactiveCN104498541BIncrease productionGood denitrification and phosphorus removalFermentationVolatile fatty acidsSludge

Owner:HUNAN UNIV

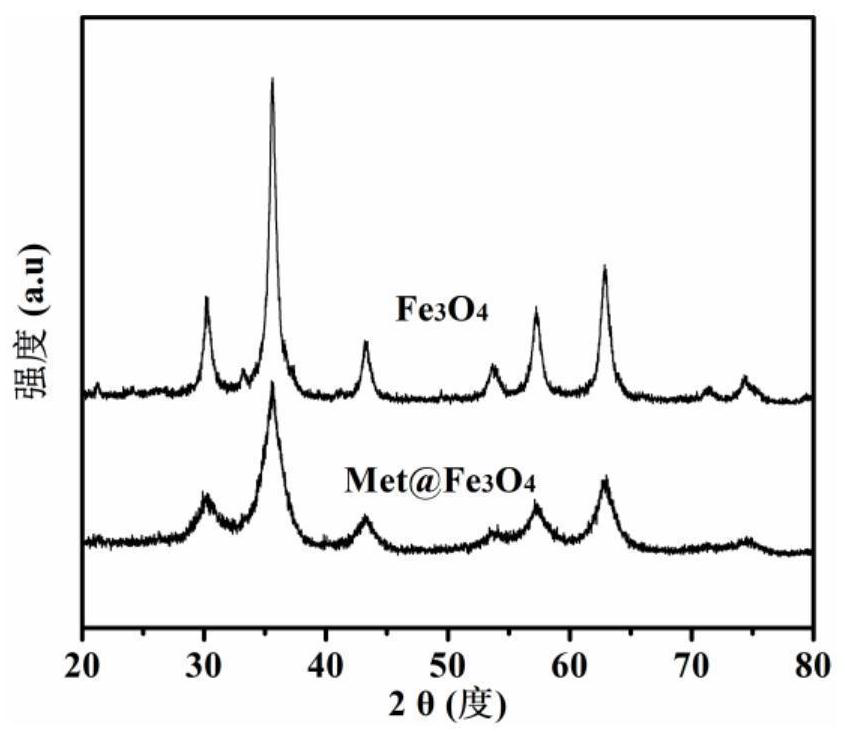

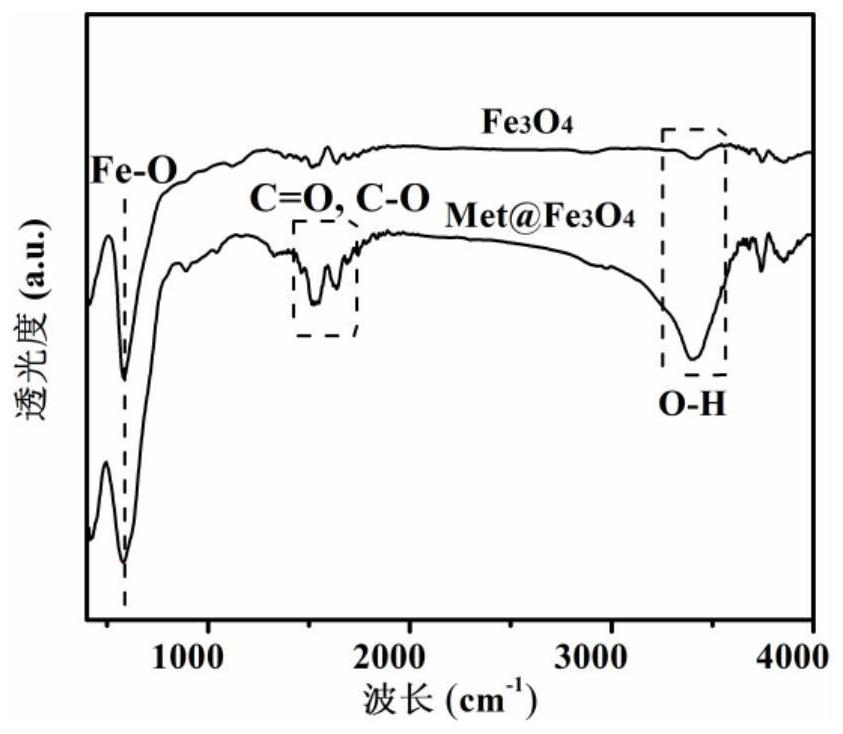

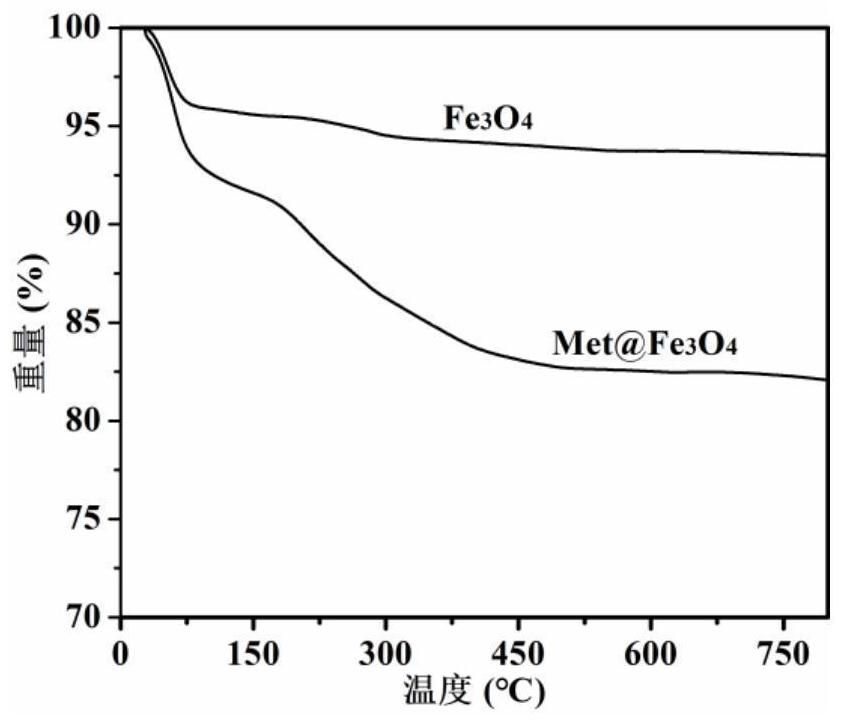

A composite material met@fe 3 o 4 And its preparation method and application

ActiveCN112125345BGood dispersionShorten the time of anaerobic fermentationWaste based fuelFerroso-ferric oxidesWater chlorinationEngineering

The invention discloses a composite material Met@Fe 3 o 4 The preparation method and application thereof belong to the technical field of environmental protection. The steps of the preparation method of the present invention are as follows: adding ferric chloride, ferrous chloride and methionine into a reaction vessel equipped with ultrapure water, fully stirring, and then adding aqueous sodium hydroxide solution into the reaction vessel until the reaction vessel The pH of the system is 11±0.2, and then the reaction is carried out under the condition of a water bath, and the reaction is carried out under the protection of an inert gas. After the reaction, the black solid obtained by centrifugation, washing with water, and vacuum drying is the target composite material Met@Fe 3 o 4 . The present invention passes through methionine (Met) to ferric oxide (Fe) 3 o 4 ) for surface modification to obtain Met@Fe 3 o 4 Composites, the resulting Met@Fe 3 o 4 It has better dispersibility, biocompatibility and conductivity, and its application in the anaerobic fermentation process of acetic acid can not only greatly increase the production of methane, but also significantly increase the production rate of methane and the degradation rate of acetic acid, and shorten the time of acetic acid anaerobic fermentation. Oxygen fermentation time.

Owner:TONGJI UNIV

Method for improving methanogenesis of residual sludge by heat and alkali combined pretreatment

ActiveCN103172242BIncrease productionIncrease the rate of hydrolysisWaste based fuelBiological sludge treatmentSludgeMethanogenesis

The invention belongs to the technical field of environmental protection and relates to a method for improving the methanogenesis of residual sludge by heat and alkali combined pretreatment. According to the method, after the residual sludge is thermally pretreated, the dissolving in water of organic matters such as protein and polysaccharide in the residual sludge can be improved significantly so that abundant water-soluble organic matrixes can be provided for the fermentation of the sludge and the generation of acids; and in addition, after the residual sludge is pretreated under the initial alkaline condition, the dissolving and the dehydrating of the sludge can be promoted further and short chain fatty acids can be produced continuously. Therefore, the residual sludge dehydrating efficiency and the acid generating efficiency can be improved greatly by the combination of thermal pretreatment and the initial alkaline condition so that the yield of methane can be increased to the maximum extent.

Owner:TONGJI UNIV

A method of anaerobic fermentation, fermentation product and animal feed containing the product

ActiveCN106929535BEconomic gainHigh nutritional valueAnimal feeding stuffFermentationNutritionMicrobiology

The invention relates to an anaerobic fermentation method, a fermentation product and an animal feed comprising the fermentation product. During anaerobic fermentation, raw materials are improved biotechnologically, and in particular, a feeding value of plant dregs is increased. The anaerobic fermentation method includes the step of mixing the plant dregs with a hydrocarbon compound and an enzyme. By the anaerobic fermentation method, fermentation time in industrial production is shortened effectively and product nutrition value is enhanced.

Owner:益海嘉里(防城港)生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com