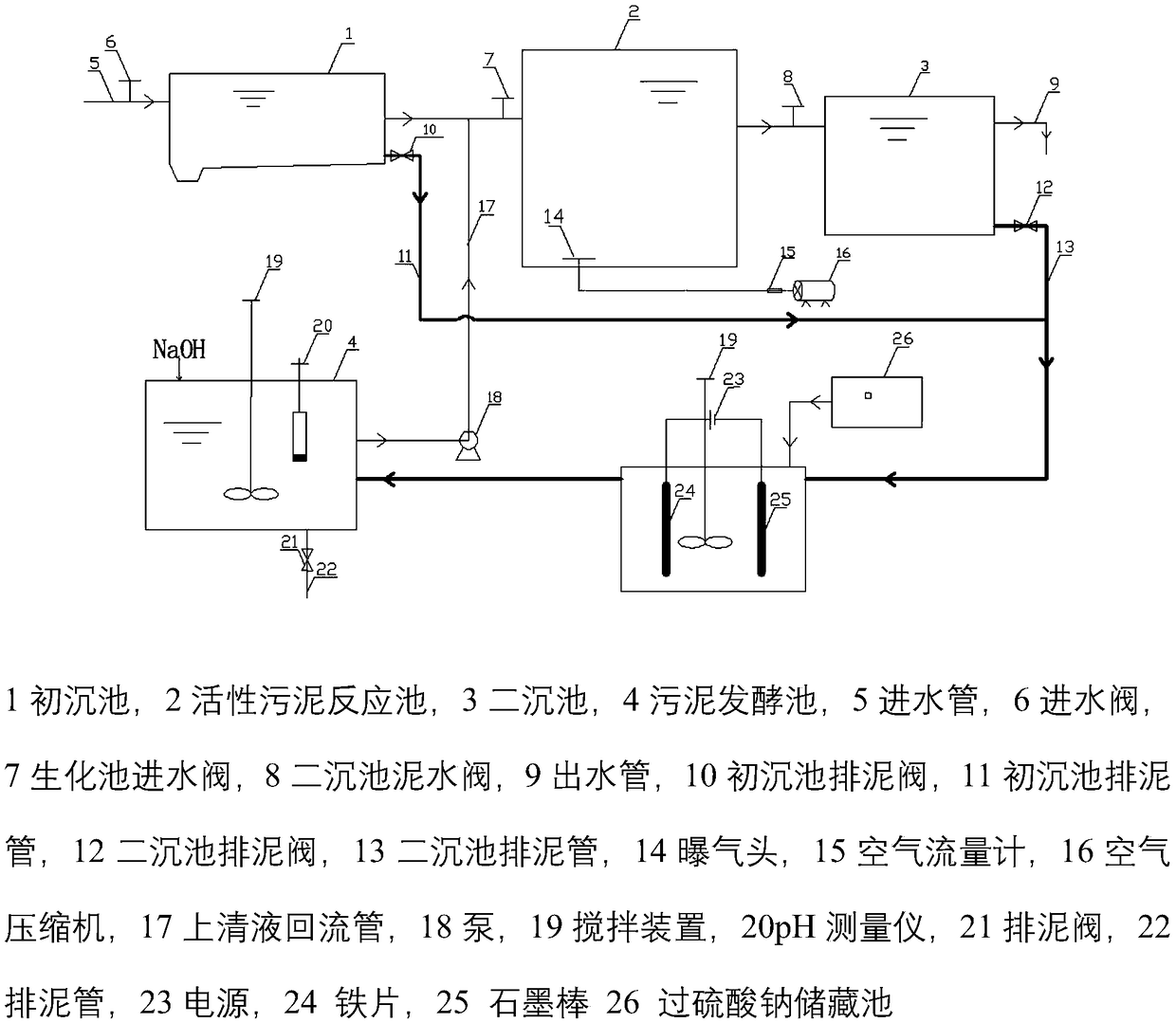

Method of optimizing acid production structure through pretreatment of iron electrode activation of persulfate

A technology for activating persulfate and persulfate, which is applied in biological sludge treatment, fat generation, and recovery of fat oil/fatty acid from waste materials, etc., can solve the problems of long time consumption and low production efficiency of short-chain fatty acids, and achieve resource utilization Recycling, realizing sludge reduction and high acid production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

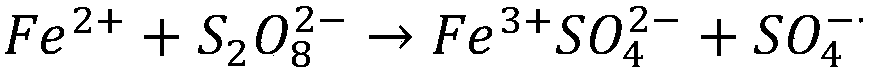

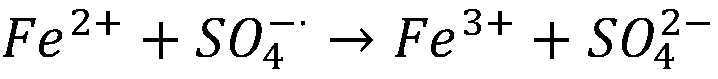

Method used

Image

Examples

Embodiment 1

[0049] The secondary sedimentation sludge of the sewage treatment plant is naturally deposited at 4°C for 24 hours, and the upper liquid is drained as the fermentation substrate. The water content is 98.61%, the TSS is 13.92g / L, the organic matter content is 62% of the total solid content, and the total COD is 9.82g / L. The sludge anaerobic digestion treatment is carried out by using the patented process of this application. In the fermentation system using the above process, the patented iron anode activated persulfate is used for pretreatment, the concentration of persulfate added is 1512mg / L, and the DC power supply is maintained at a constant current state, and the power supply is continuous for 60 minutes. The stirrer continuously stirs, the rotation speed is 150rmp / min, and the room temperature is 20°C. The sludge samples were adjusted to pH 10 before fermentation, and anaerobic fermentation was carried out in a constant temperature incubator at 35°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com