Method for producing short-chain volatile fatty acid by using tobacco waste

A technology for volatile fatty acids and tobacco waste, applied in the field of solid waste treatment, can solve the problems of high toxicity of chemical surfactants, secondary pollution, low biodegradability, etc., and achieve low operating costs, increased output and high income. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

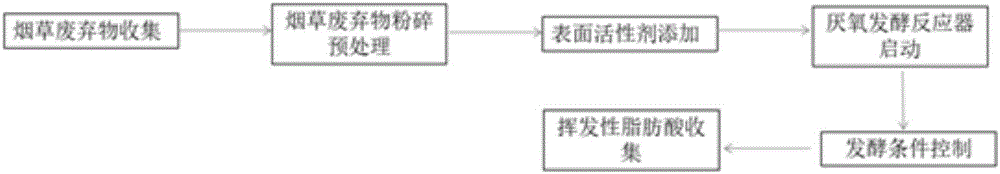

[0033] see figure 1 A method for producing short-chain volatile fatty acids from tobacco waste, specifically comprising the following steps: (1) pre-treating tobacco waste: removing substances unfavorable for fermentation in tobacco waste. Then pulverize it to below 0.3 centimeters with a pulverizer, then mix the pulverized tobacco waste with an appropriate amount of distilled water to control the solid content rate to 15%, VS (volatile solids) / TS (total solids)=95.3%; complete tobacco waste object pretreatment.

[0034] (2) Inoculation sludge: The remaining sludge was taken from the secondary sediment discharge of Nanning No. 1 Sewage Treatment Plant. After testing, the microorganisms in the remaining sludge were mainly hydrolytic and fermentative microorganisms; specifically, they were obligate anaerobic Clostridium Bacteroides, Bacteroides, Butyvibrio, Bifidobacterium. Perform anaerobic culture on the remaining sludge for one month, the temperature of the anaerobic cultur...

Embodiment 2

[0038] A method for producing short-chain volatile fatty acids from tobacco waste, specifically comprising the following steps:

[0039](1) Tobacco waste pretreatment: remove substances that are not conducive to fermentation in tobacco waste. Then pulverize it to below 0.3 centimeters with a pulverizer, then mix the pulverized tobacco waste with an appropriate amount of distilled water to control the solid content rate to 15%, VS (volatile solids) / TS (total solids)=95.3%; complete tobacco waste object pretreatment.

[0040] (2) Inoculation sludge: The remaining sludge was taken from the secondary sediment discharge of Nanning No. 1 Sewage Treatment Plant. After testing, the microorganisms in the remaining sludge were mainly hydrolytic and fermentative microorganisms; specifically, they were obligate anaerobic Clostridium Bacteroides, Bacteroides, Butyvibrio, Bifidobacterium, etc. Perform anaerobic culture on the remaining sludge for one month, the temperature of the anaerobi...

Embodiment 3

[0044] (1) Tobacco waste pretreatment: remove substances that are not conducive to fermentation in tobacco waste. Then pulverize it to below 0.3 centimeters with a pulverizer, then mix the pulverized tobacco waste with an appropriate amount of distilled water to control the solid content rate to 15%, VS (volatile solids) / TS (total solids)=95.3%; complete tobacco waste object pretreatment.

[0045] (2) Inoculation sludge: The remaining sludge was taken from the secondary sediment discharge of Nanning No. 1 Sewage Treatment Plant. After testing, the microorganisms in the remaining sludge were mainly hydrolytic and fermentative microorganisms; specifically, they were obligate anaerobic Clostridium Bacteroides, Bacteroides, Butyvibrio, Bifidobacterium, etc. Perform anaerobic culture on the remaining sludge for one month, the temperature of the anaerobic culture is 35-45°C, the pH is controlled at 7.0±0.5, the anaerobic stirring speed is 100-130r / min, and nitrogen and carbon sourc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com