Anaerobic fermentation method, fermentation product and animal feed comprising fermentation product

An anaerobic fermentation, animal feed technology, applied in animal feed, animal feed, fermentation and other directions, can solve the problem of shortening the fermentation time, and achieve the effect of shortening the fermentation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

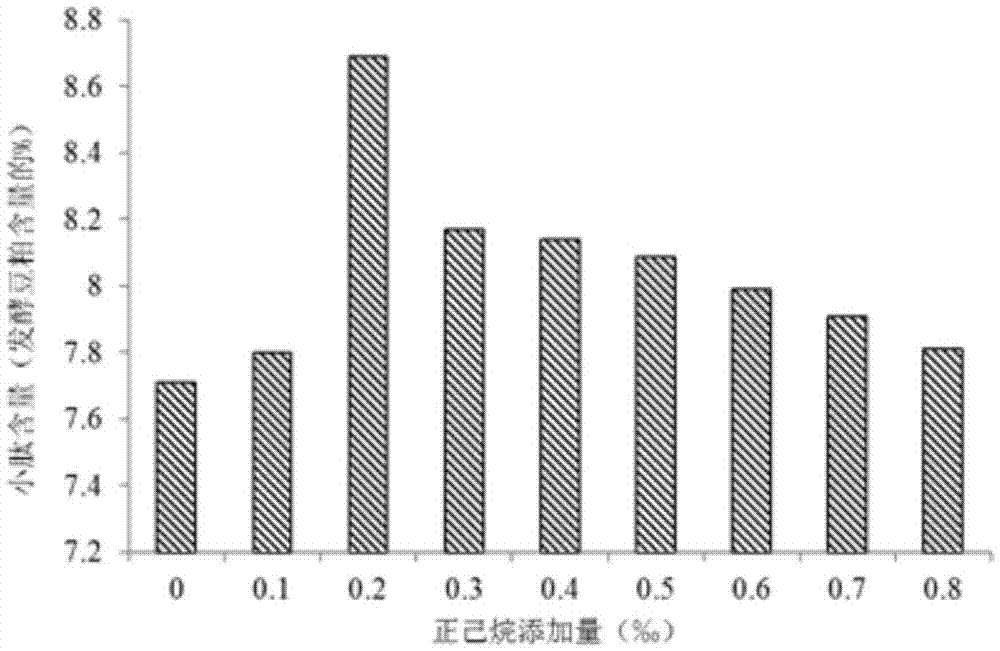

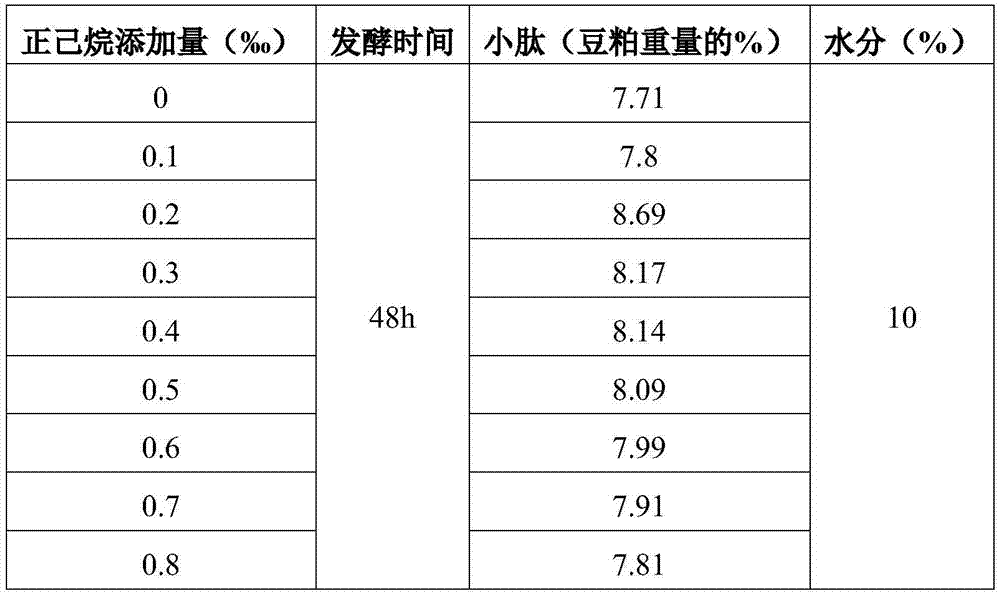

[0078] Effects of different amounts of n-hexane added on fermented soybean meal

[0079] Put 50g of commercial soybean meal into a ziplock bag, add protease at 500U / g soybean meal, mix well, add a certain amount of n-hexane, mix well, add 23g of water, mix well again, put the mixed sample in a constant temperature culture at 40°C After culturing for 48 hours, dry in an oven at 65°C for 6 hours, crush and pass through a 60-mesh sieve to detect acid-soluble proteins. Among them, the content of acid-soluble protein was detected by trichloroacetic acid (TCA) method (GB / T22492-2008).

[0080] Table 1 embodiment 1 test result

[0081]

[0082]From Table 1, it can be seen that using a small amount of n-hexane to participate in the fermentation process can make the content of small peptides in the fermentation product exceed that of the traditional method (i.e. when the amount of n-hexane is 0‰) in a shorter period of time, that is, 48 hours. The level of small peptide content ...

Embodiment 2

[0085] Effect of fermentation time on the quality of fermented soybean meal

[0086] Put 50g of commercial soybean meal into a ziplock bag, add protease at 500U / g soybean meal, mix evenly, add n-hexane with soybean meal weight 0‰ or 0.2‰, mix evenly, add water 23g, mix evenly again, put the mixed sample in After culturing in a constant temperature incubator at 40°C for 48h and 72h, bake it in an oven at 65°C for 6h, crush it through a 60-mesh sieve, and detect acid-soluble proteins. Among them, the acid-soluble protein content was detected by the trichloroacetic acid (TCA) method (GB / T 22492-2008).

[0087] Table 2 embodiment 2 test result

[0088]

[0089] According to the experimental data obtained in Table 2, it can be seen that when 0.2‰ n-hexane is used to participate in the fermentation reaction, except that the fermentation effect has exceeded the fermentation effect of the traditional fermentation method for 48 hours when the fermentation time is 48 hours, the ferm...

Embodiment 3

[0091] Effects of different treatments on the quality of fermented soybean meal

[0092] Take 50g of commercial soybean meal in a ziplock bag, add protease according to 500U / g soybean meal and mix evenly, add 23g of water, mix evenly for the second time and seal, this sample is a blank sample; or take 50g of commercial soybean meal in a ziplock bag, according to the weight ratio Add 0.2‰ of n-hexane, mix evenly, put the mixture in an oven at 60°C for 10 minutes or do not perform this step (corresponding to "no baking" in Table 3 below), then add protease at 500U / g soybean meal and mix evenly, add 23g of water Mix evenly, put the mixed sample in a 40°C constant temperature culture for 24h, then dry it in a 65°C oven for 6h, crush it through a 60-mesh sieve, and detect the acid-soluble protein. Among them, the acid-soluble protein content was detected by the trichloroacetic acid (TCA) method (GB / T 22492-2008).

[0093] Table 3 embodiment 3 test result

[0094]

[0095] It c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com