A composite material met@fe 3 o 4 And its preparation method and application

A composite material and reactor technology, applied in the field of environmental protection, can solve the problems of low electron transfer efficiency, difficult contact with microorganisms, restricting popularization and application, etc., and achieves the effects of shortening the anaerobic fermentation time of acetic acid, strong feasibility and increasing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

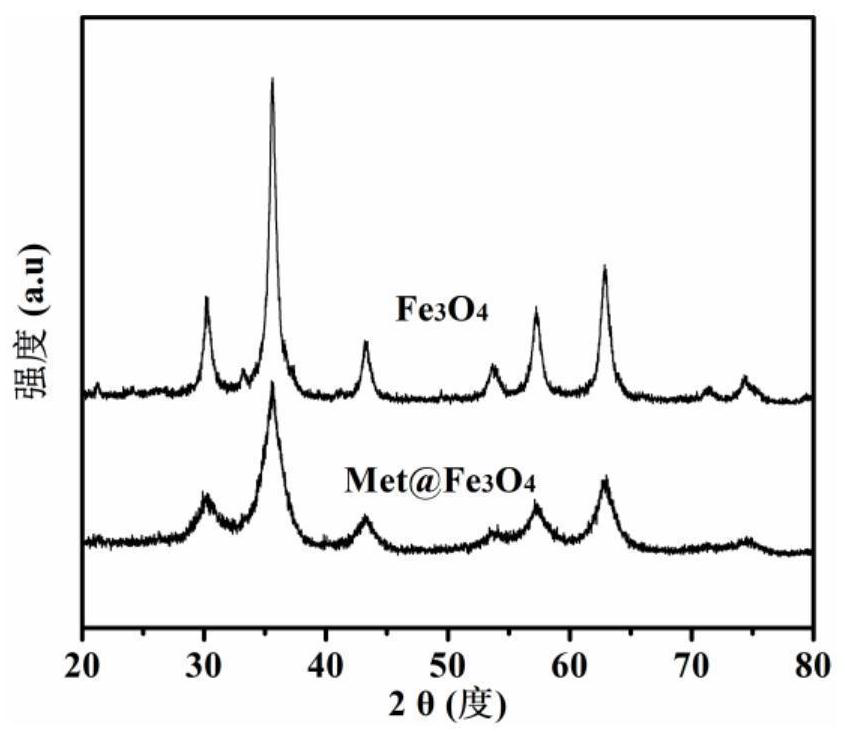

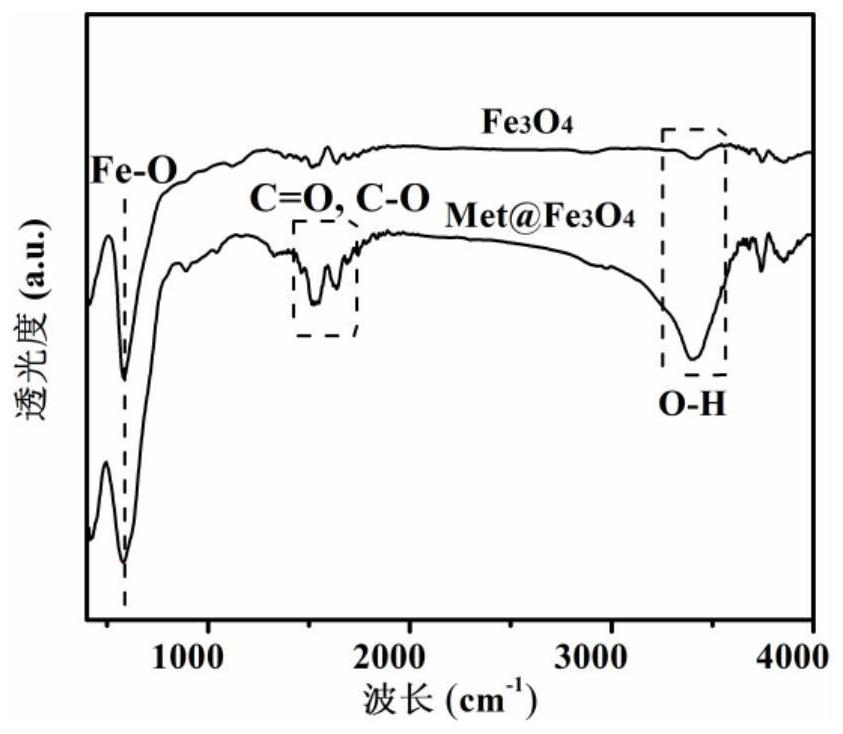

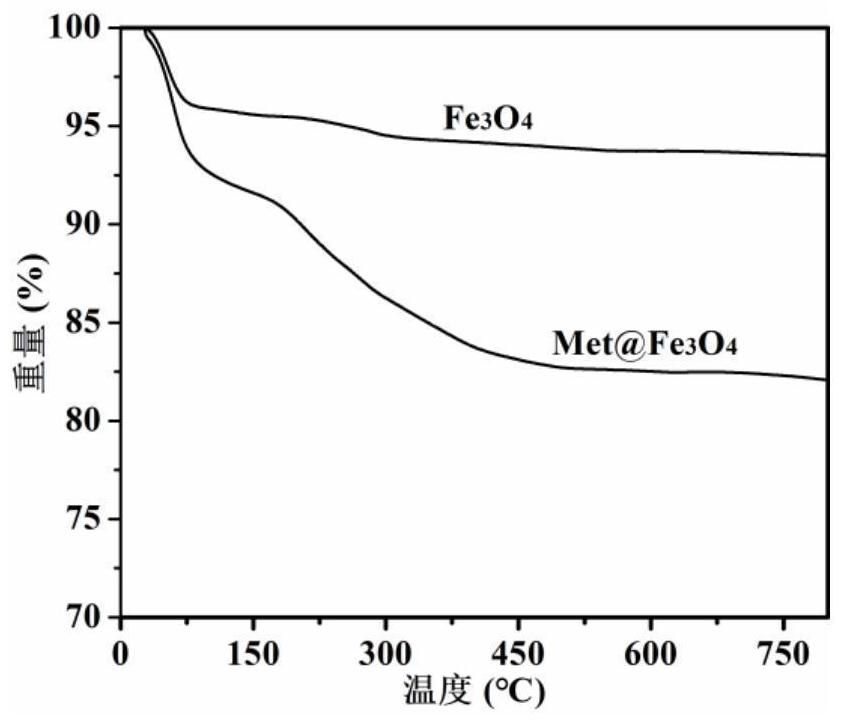

[0032] Composite Met@Fe 3 o 4 The preparation process is carried out under the protection of an inert gas, and the specific preparation steps are: 3.25g ferric chloride, 1.27g ferrous chloride and 2.98g methionine are added to a reaction vessel with 100mL ultrapure water, and at room temperature Stir fully at 150rpm, then add 2M sodium hydroxide aqueous solution to the reaction vessel until the pH of the system in the reaction vessel is 11±0.2, then place the reaction vessel in a water bath at 90°C and stir at a speed of 150rmp React for 10 hours. After the reaction, centrifuge at 4500rmp for 15 minutes to separate the black precipitate, then wash it with ultrapure water 3 times to remove excess methionine groups on the surface of the black precipitate, and finally place the black precipitate in a vacuum at 55°C Dry in a drying oven for 18 hours to obtain a black solid, which is the target composite material Met@Fe 3 o 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com