Rice straw pretreatment method for anaerobic fermentation

An anaerobic fermentation, rice straw technology, applied in fermentation, waste fuel and other directions, can solve the problems of large difference in the size of straw, insufficient pretreatment degree, increase production cost, etc., to improve biogas conversion rate, reduce construction cost and Anaerobic fermentation cost, effect of reducing risk of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1. Synergistic anaerobic fermentation pretreatment method of rice straw

[0027] In this embodiment, rice straw harvested from a paddy field is taken as an example to illustrate the method for synergistic anaerobic fermentation pretreatment of rice straw. In addition to rice straw, the pretreatment method of the present invention can also be used to treat straw-like substances with a water content lower than 25%, such as corn straw, or rice straw, or wheat straw or sunflower straw or a mixture thereof.

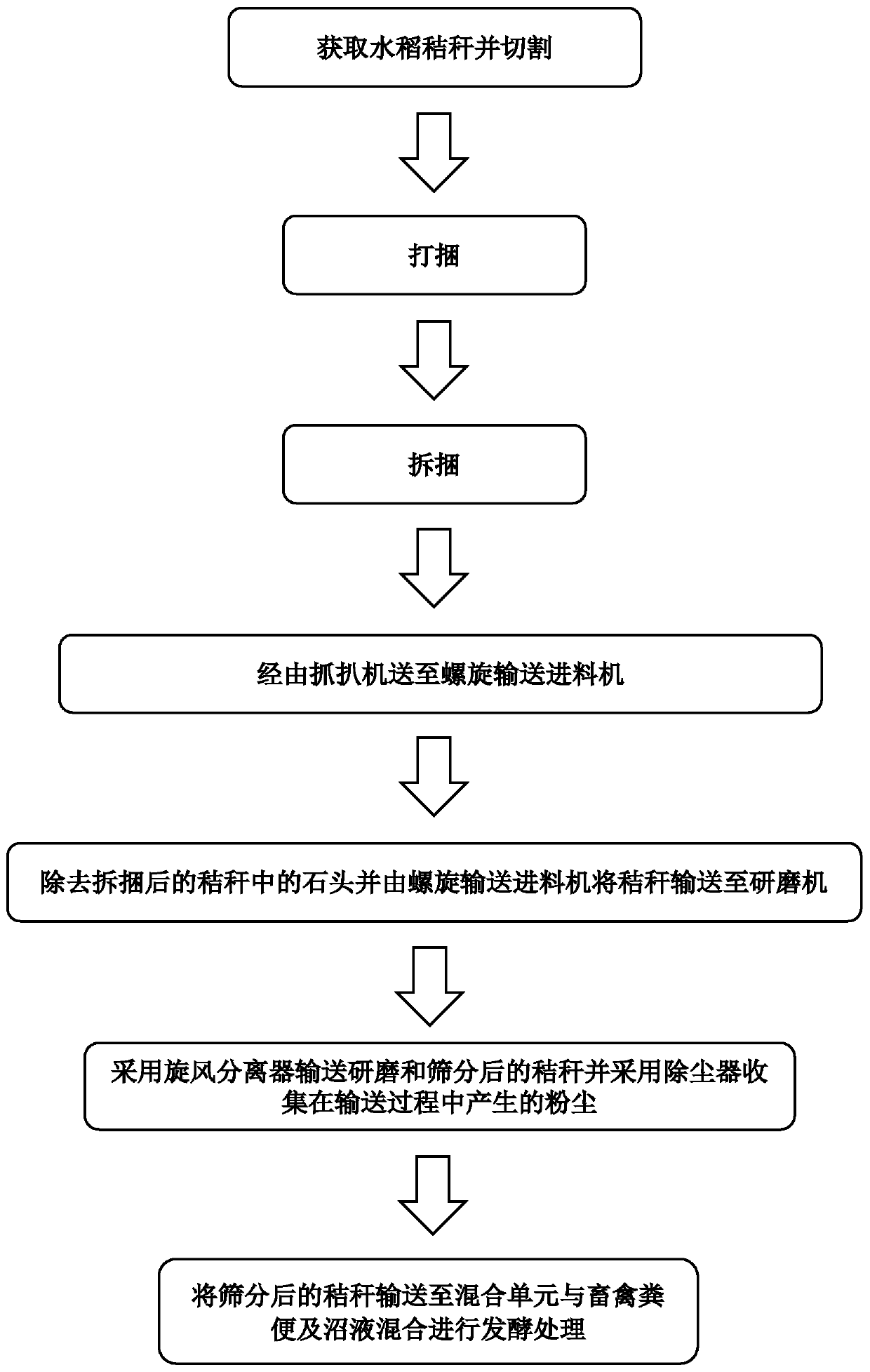

[0028] figure 1 A flow chart of the preprocessing method of this embodiment is exemplarily shown. Such as figure 1 Shown, the pretreatment method for the rice straw of anaerobic fermentation comprises the steps:

[0029] (i) harvesting and cutting: using a combine harvester with a chopping device to harvest rice straw from the paddy field and cut it into rice straw sections with a length of about 10 cm;

[0030] (ii) Bundling: Use a baler to bale the cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com