Patents

Literature

41 results about "Weather exposure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

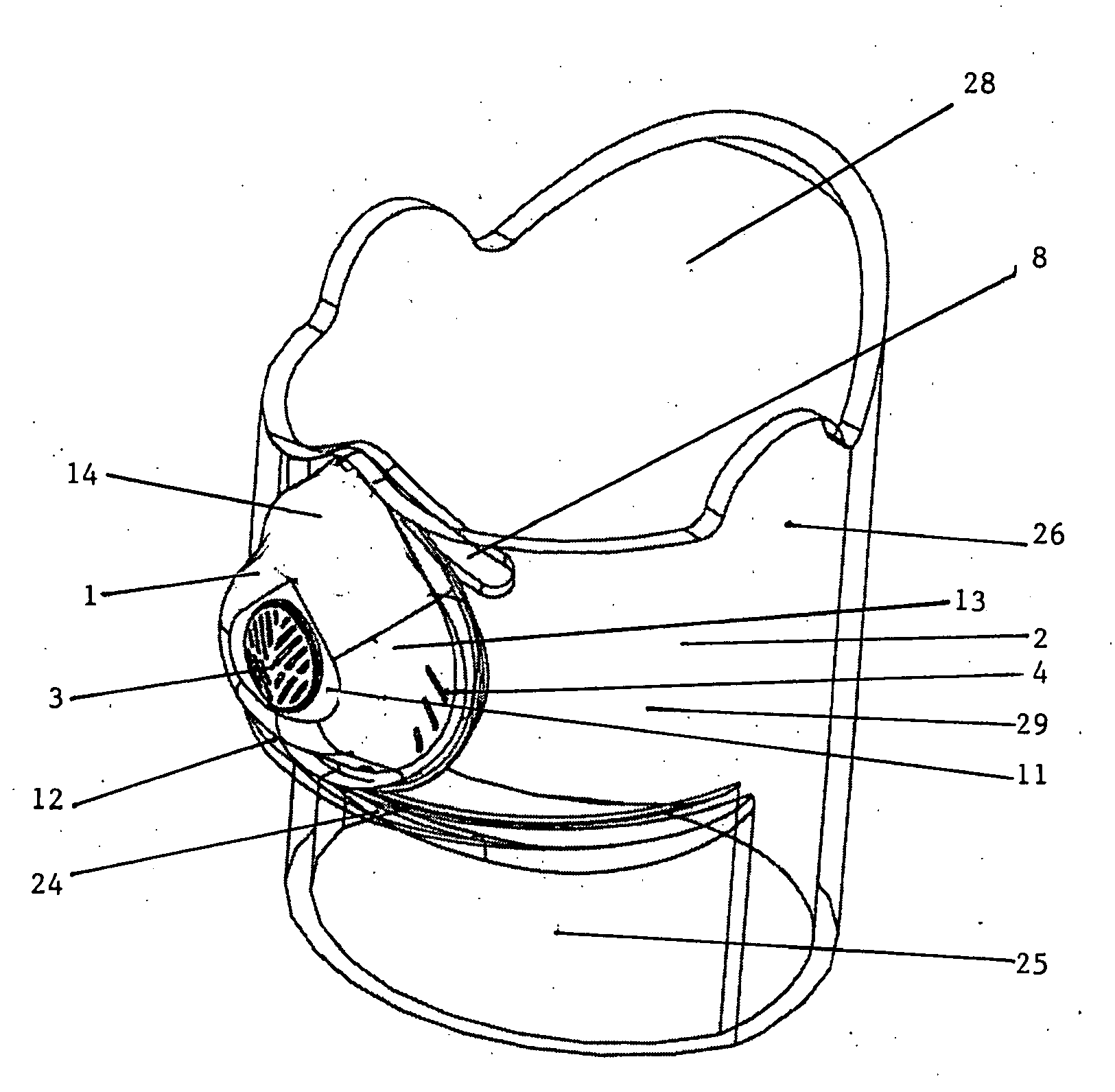

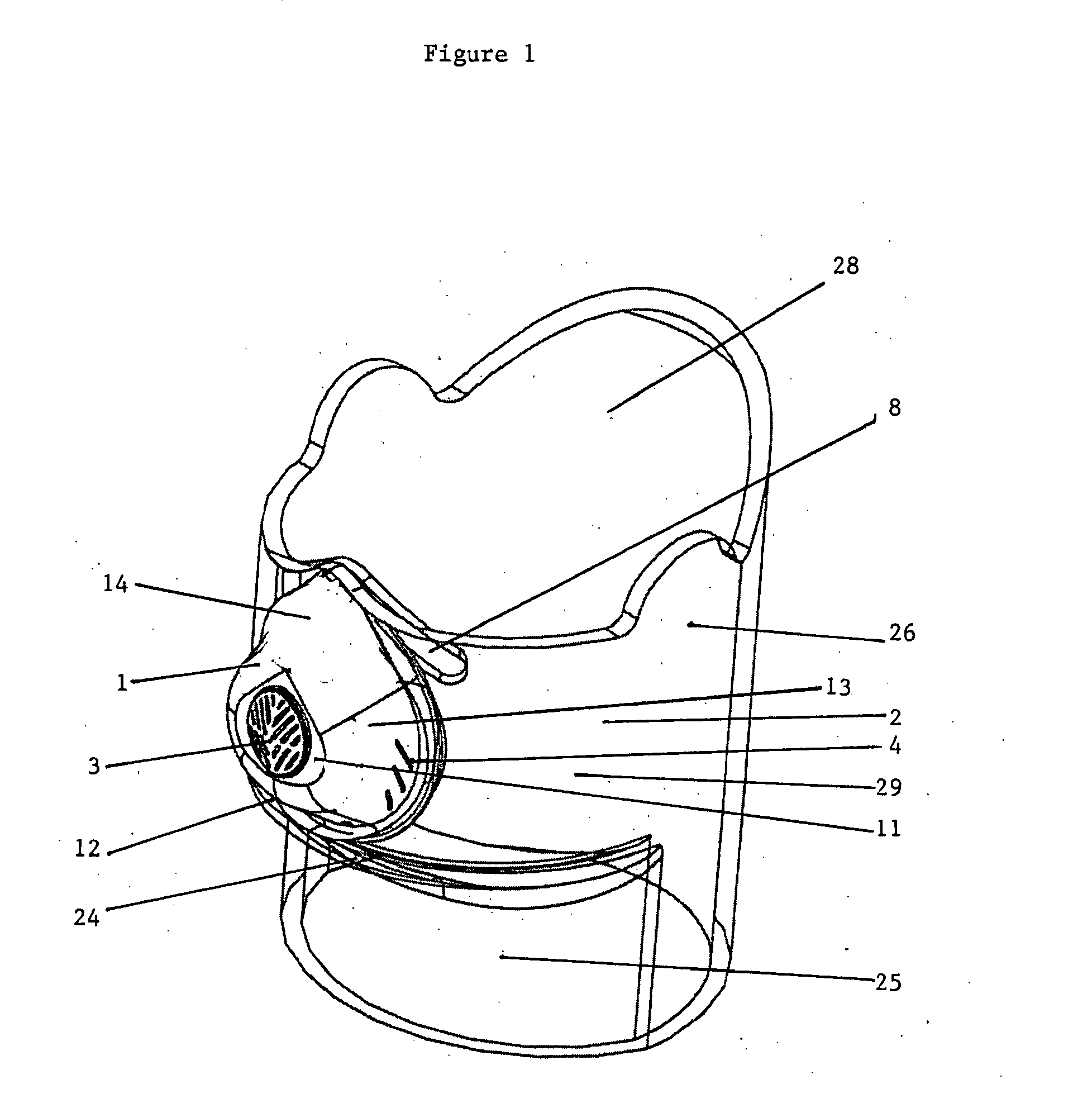

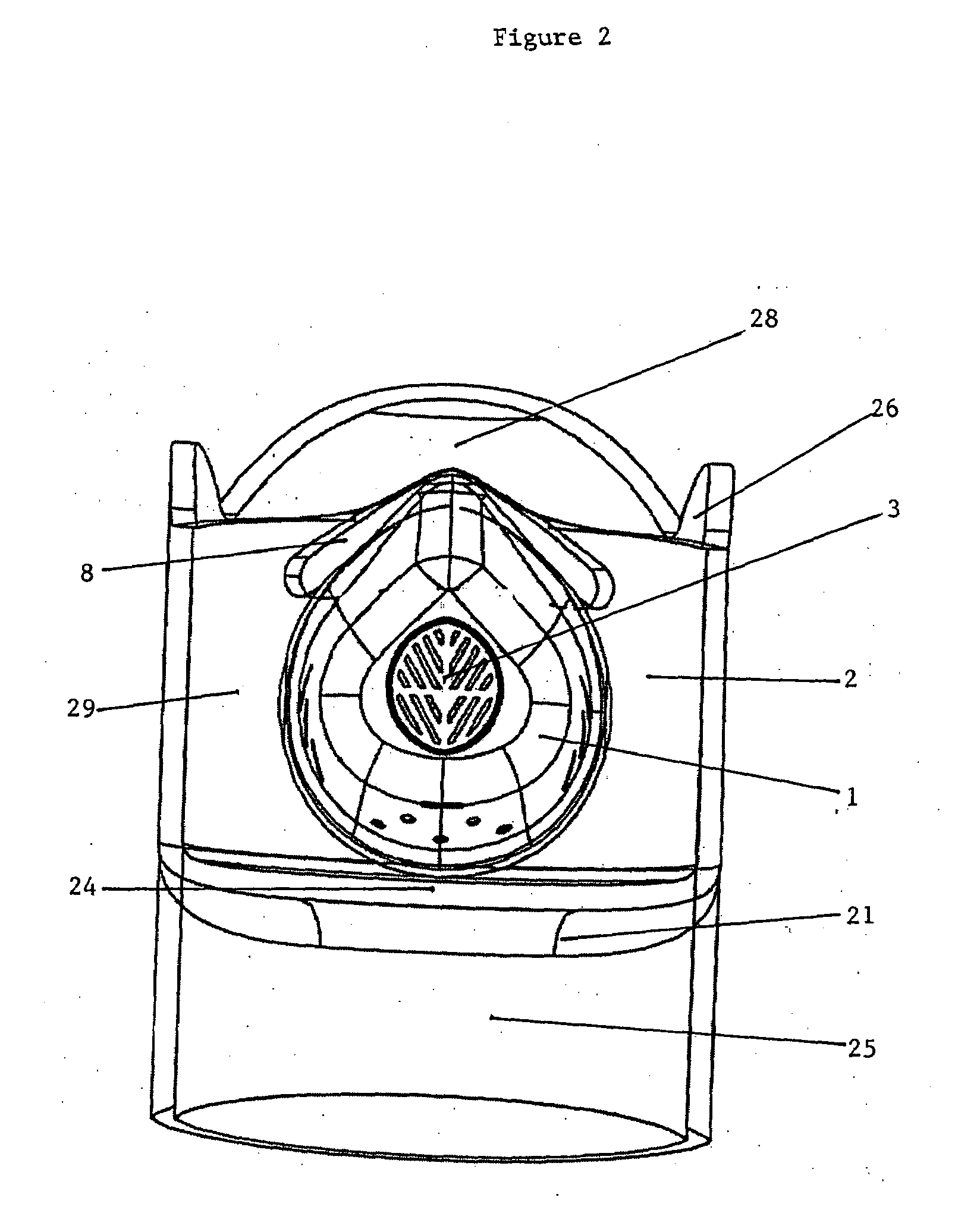

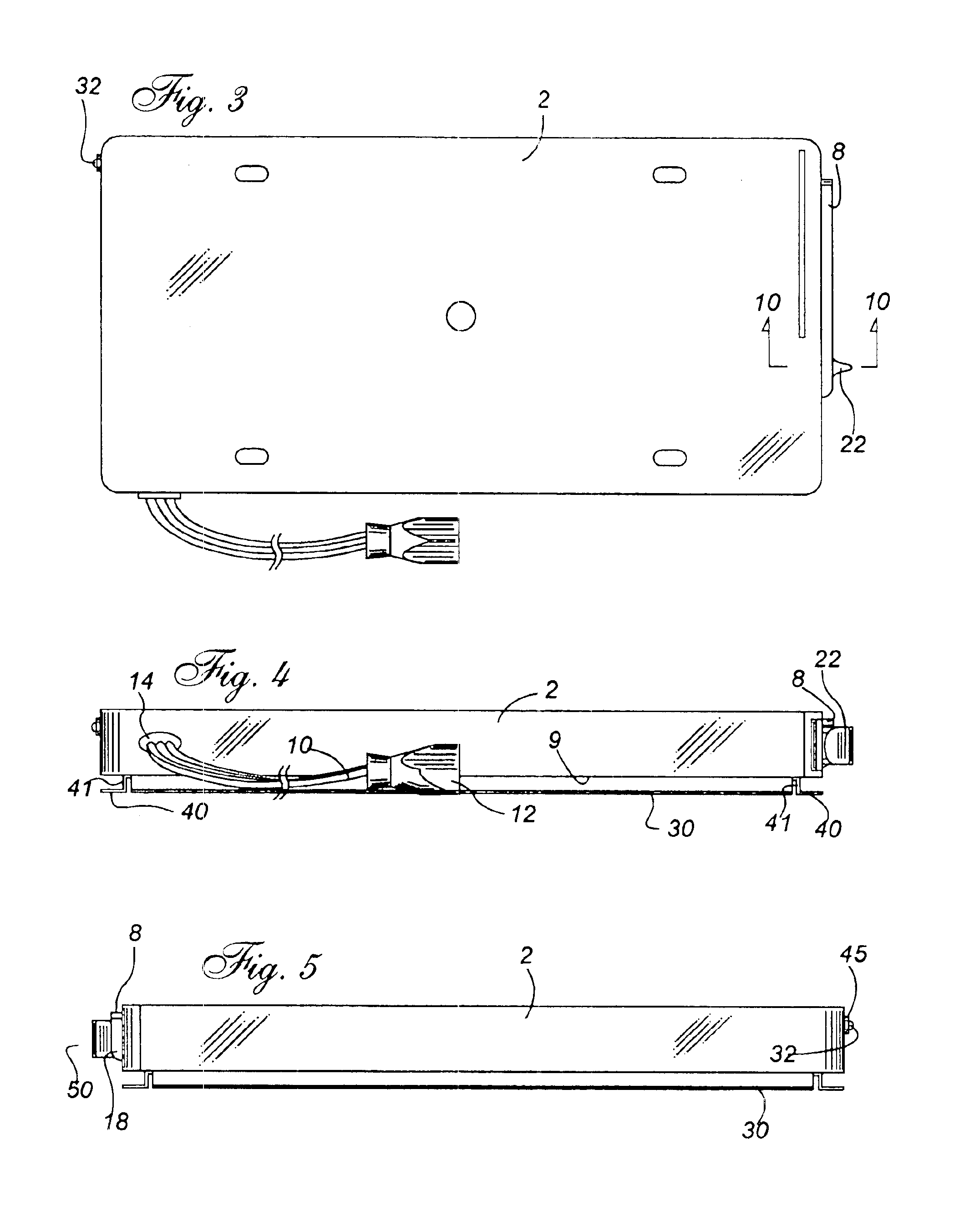

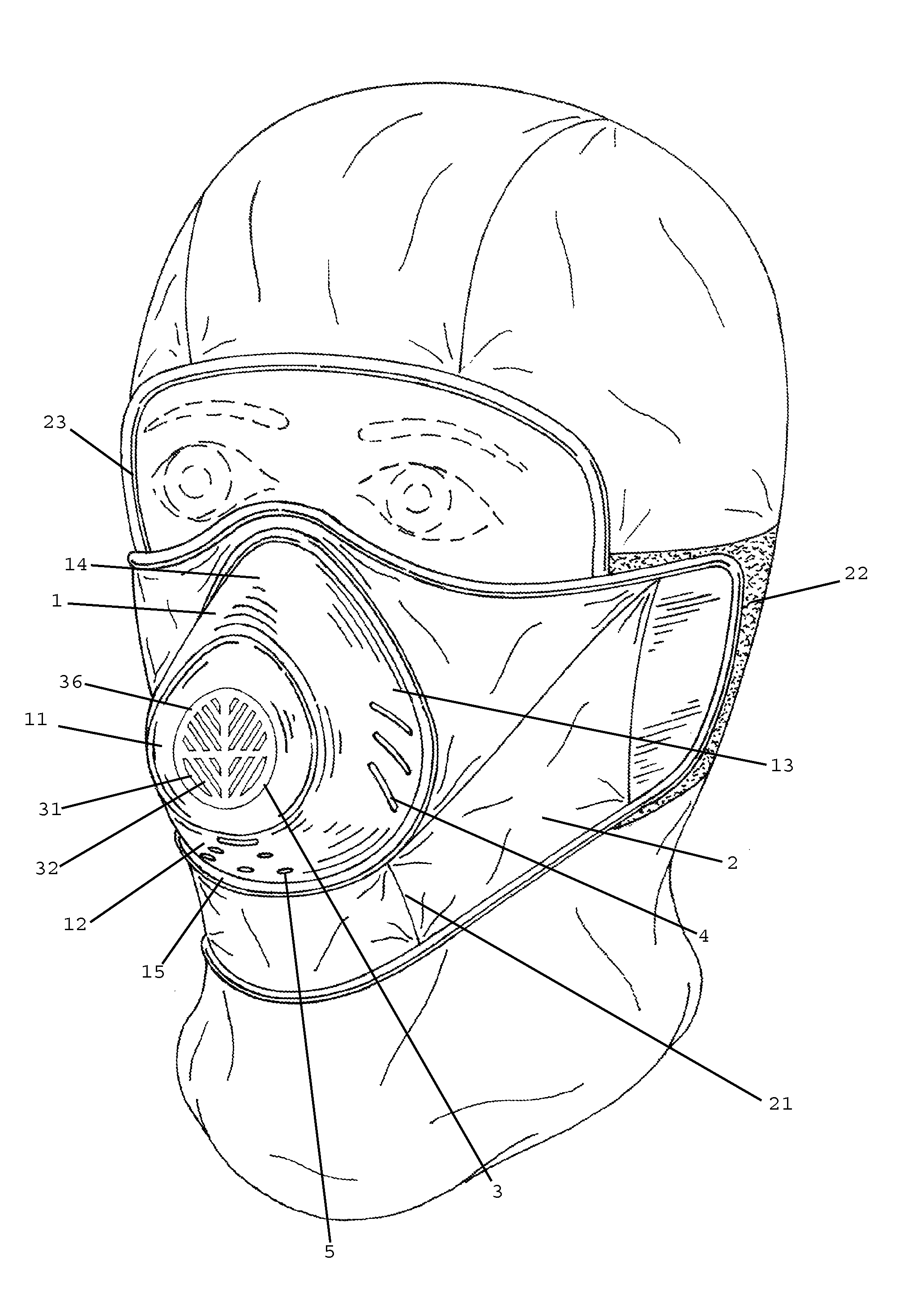

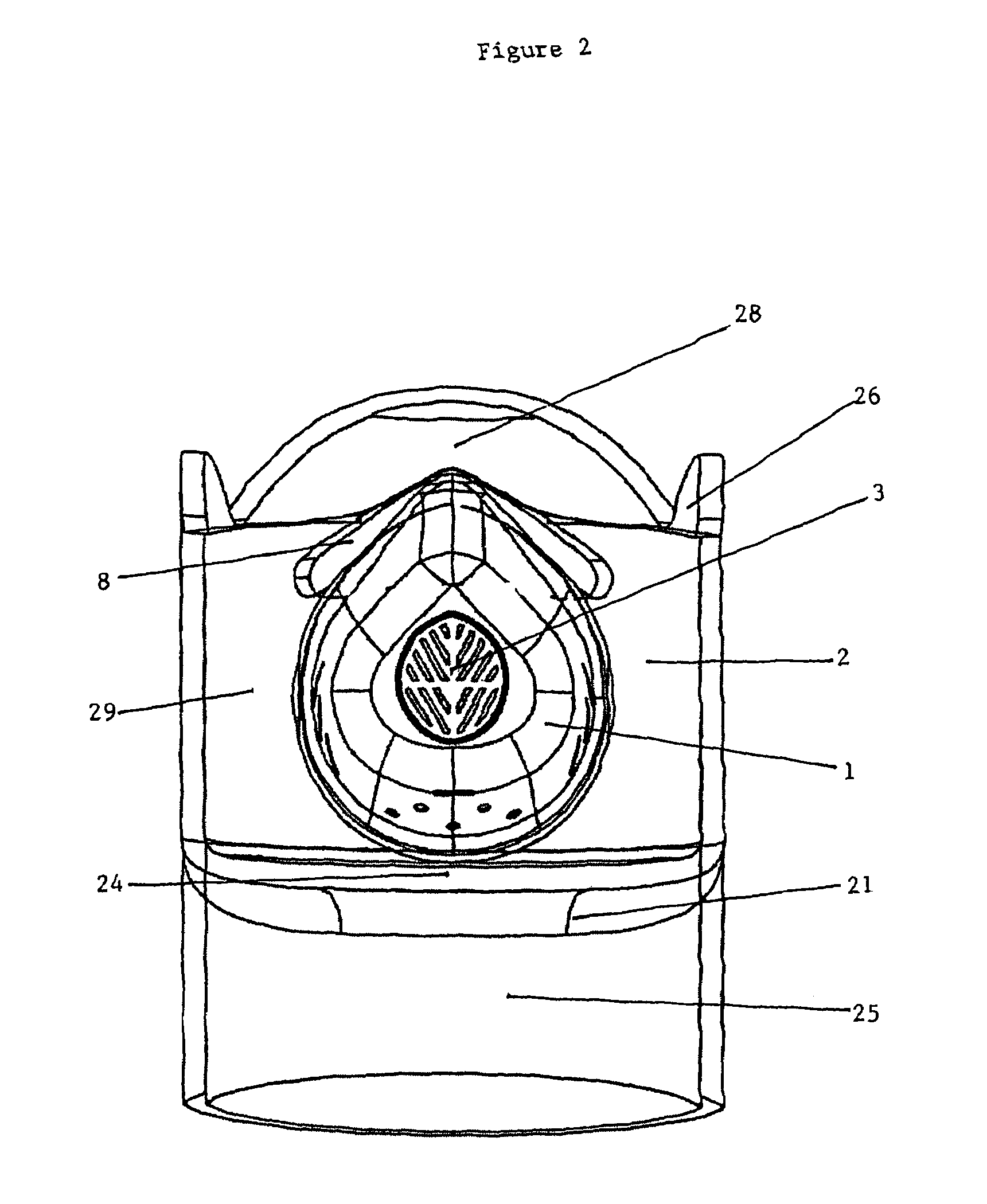

Cold Weather Exposure Mask

ActiveUS20100024826A1Prevent breathing in waterPrevent foggingBreathing masksProtective garmentNoseWeather exposure

A Cold or Inclement Weather Exposure Mask is designed to fit snugly around the face, head, and neck. The mask serves vital needs of warmth, humidity, and air flow. A raised, malleable chamber covering the mouth and nose provides a breathing space to allow normal breathing while keeping the face warm and dry. The chamber is affixed to a fabric panel made of a water and wind resistant, non-irritating, comfortable, and stretchable material. Velcro® or fastening means on the panel holds the mask in place around the wearer. The chamber includes multiple apertures which allow fresh air to pass to the wearer after it is mixed with warm, humid, exhaled air. The apertures also exhaust air and condensation. A raised lip further aids in the removal of condensation. A valve system optionally regulates the flow of air. Colors and pattern selections allow adaptation to all labor and recreation uses.

Owner:TALUS OUTDOOR TECH

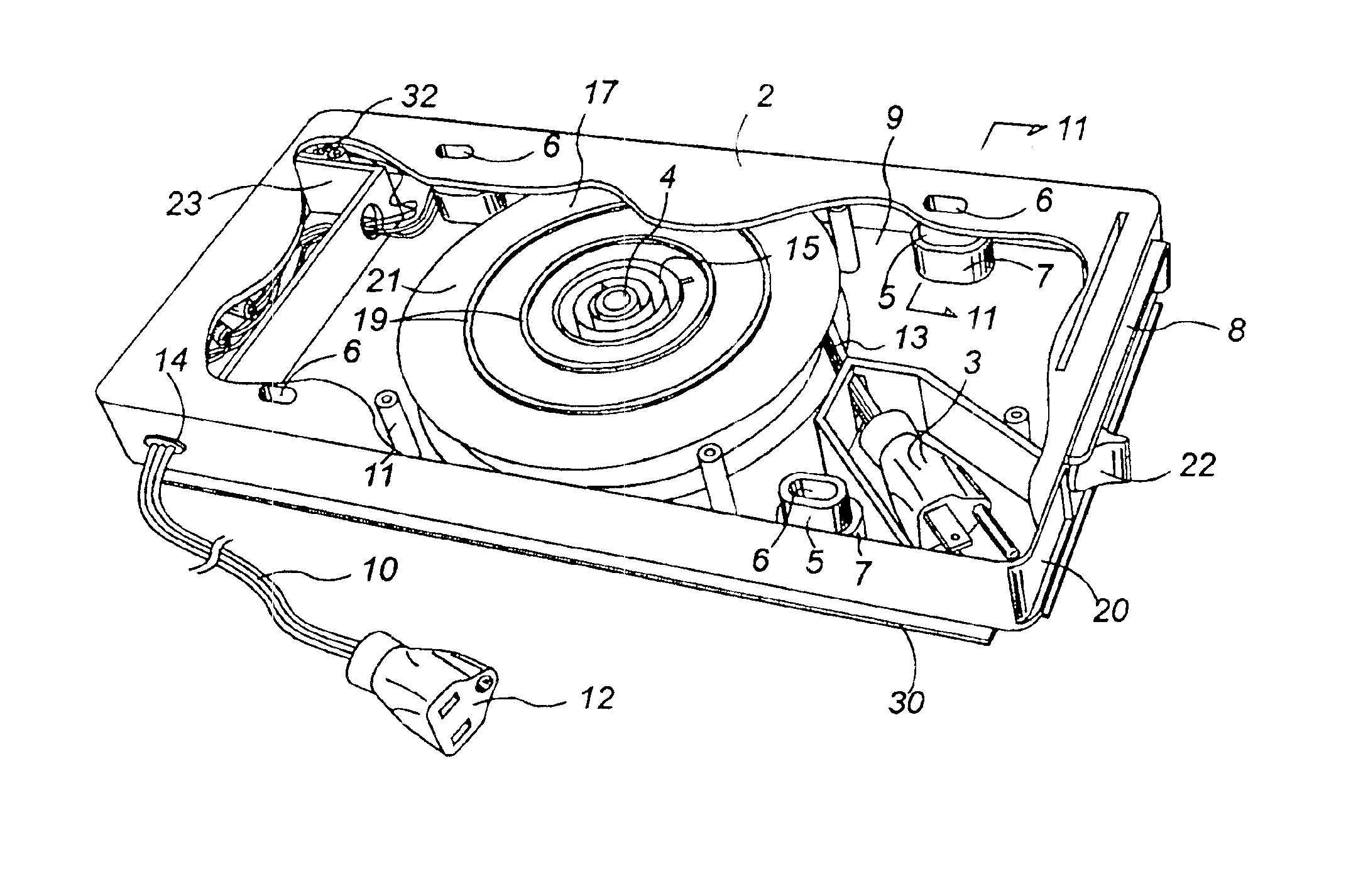

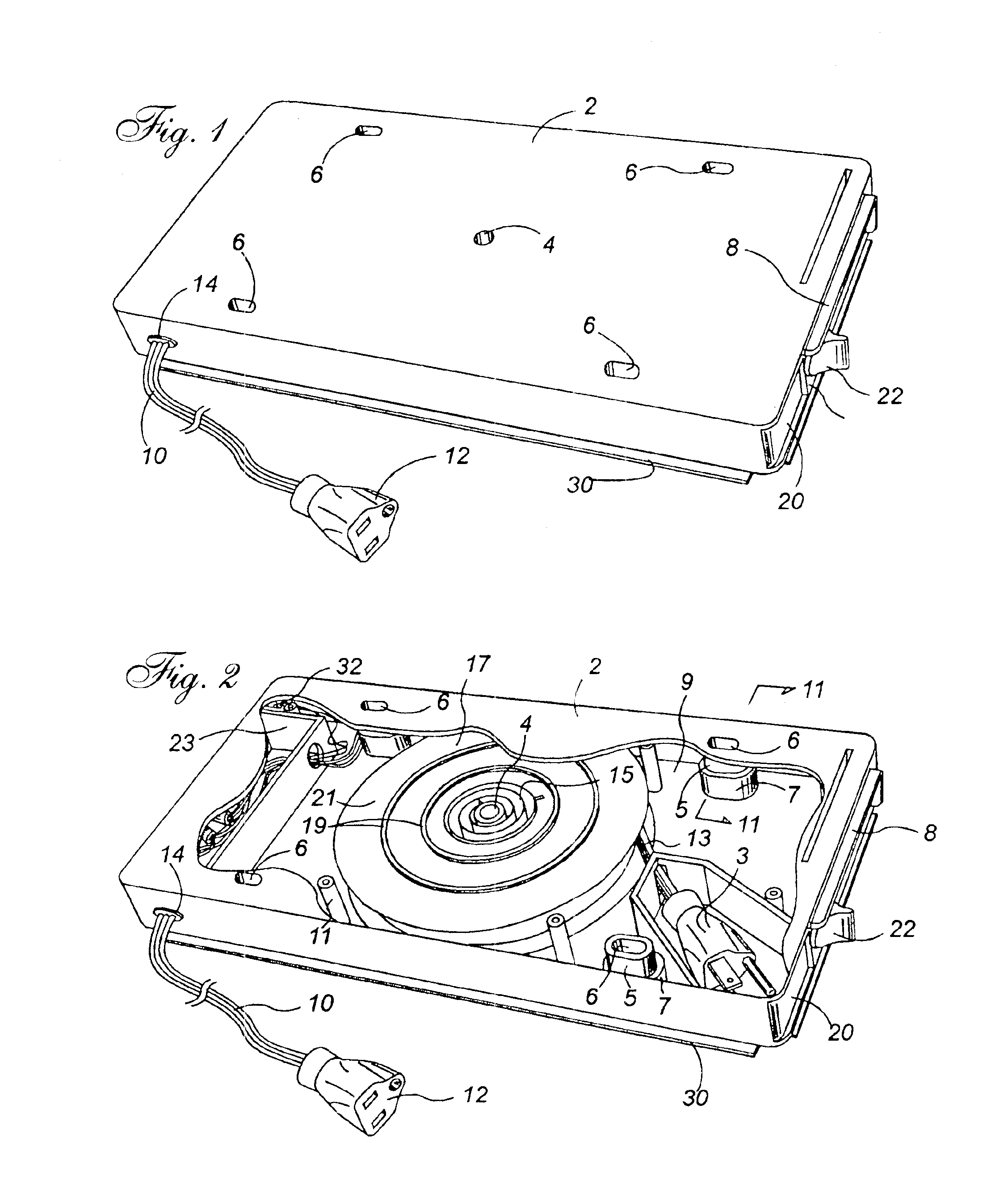

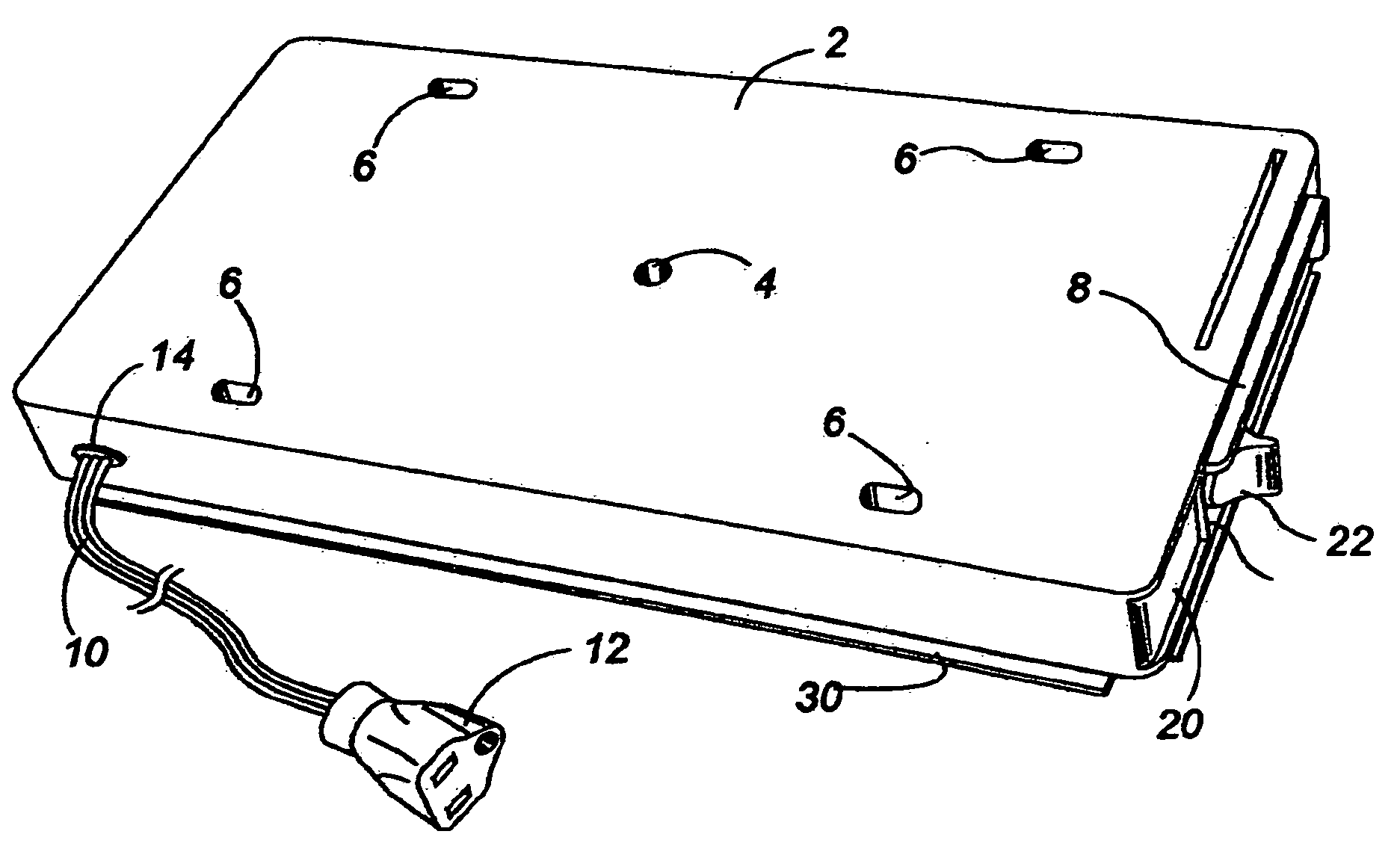

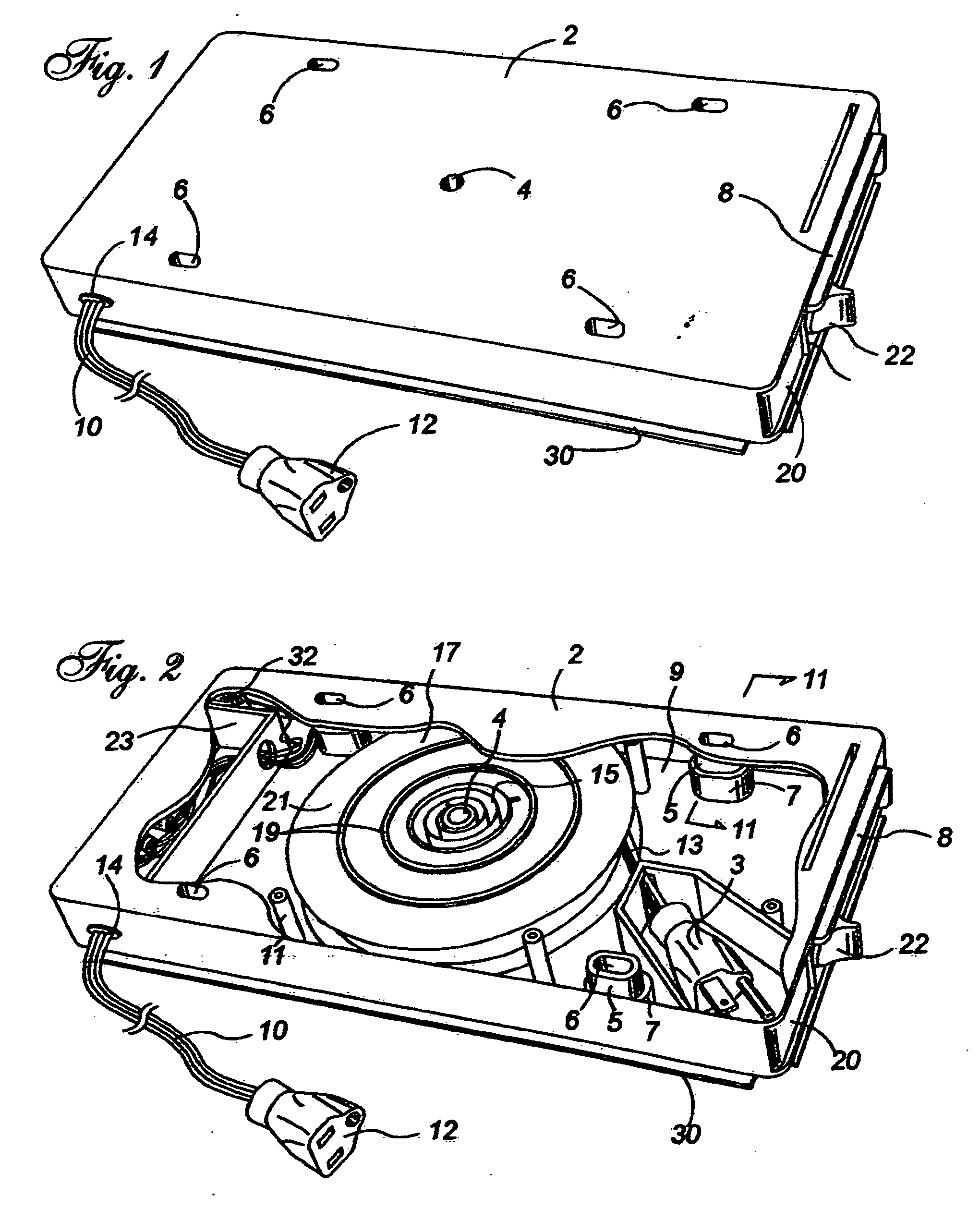

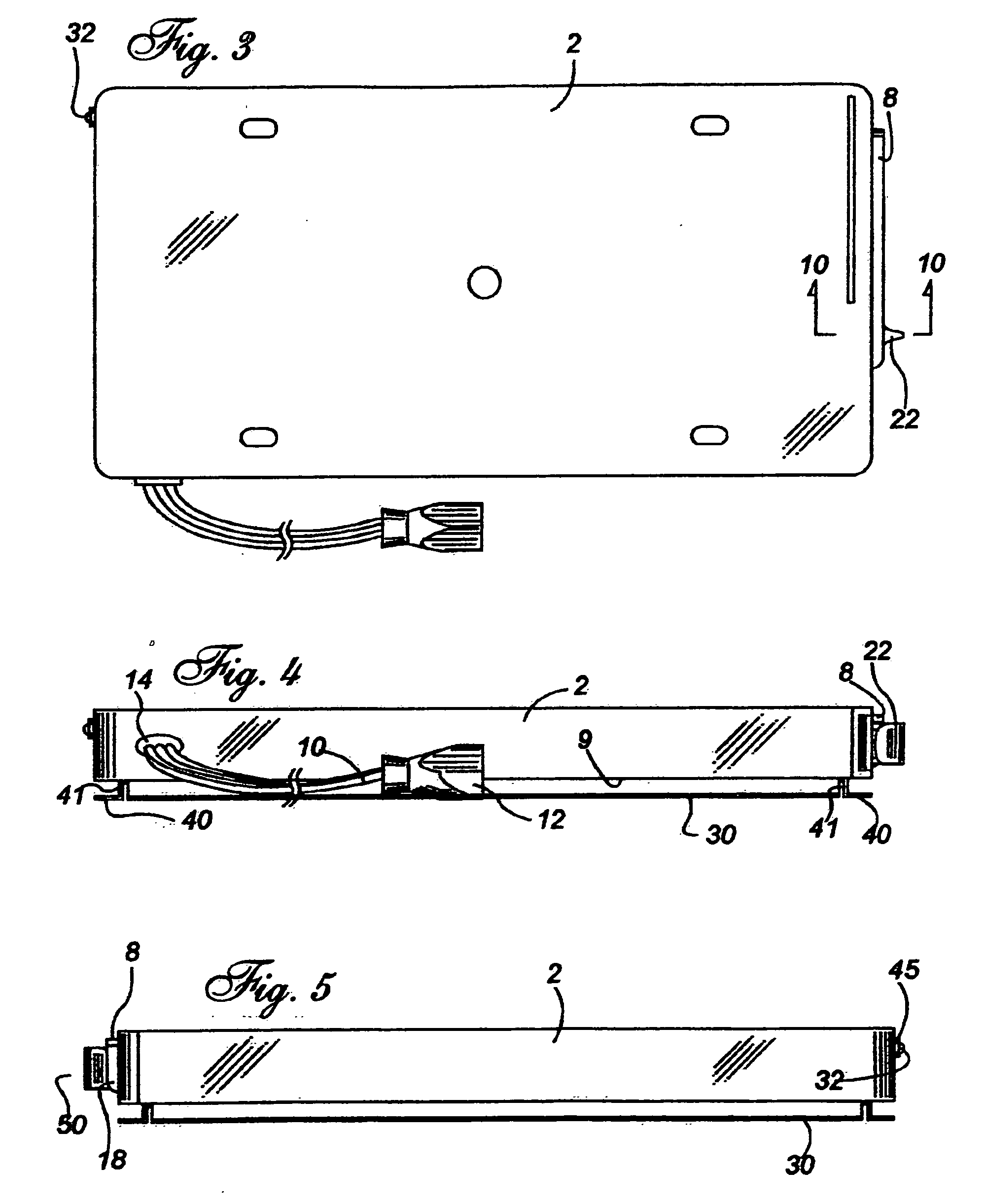

Universal license plate cord winder

InactiveUS6854575B1Increase available lengthAvoid contactCharging stationsElectric vehicle charging technologyWeather exposureElectrical devices

The present invention relates to an improved cord-winding device universally mountable to any front or rear North-American-style license plate bracket, accommodating all electrical devices, which require a 120VAC power supply for a vehicle. The present invention comprises; a housing containing: a reel, a connection box, a male cord housing, a cord hatch and mounting holes, a closure plate and a universal mounting plate. A female receptacle extends from the housing to allow electrical connections to be made in a place away from weather exposure such as engine or rear compartment. The universal license plate cord winder of the present invention can thereby be mounted either from the top or the bottom of housing without compromising the structural integrity of the attachment while maintaining a water tightness required by such a device.

Owner:DESORMEAUX DONALD +2

Cold weather exposure mask

Owner:TALUS OUTDOOR TECH

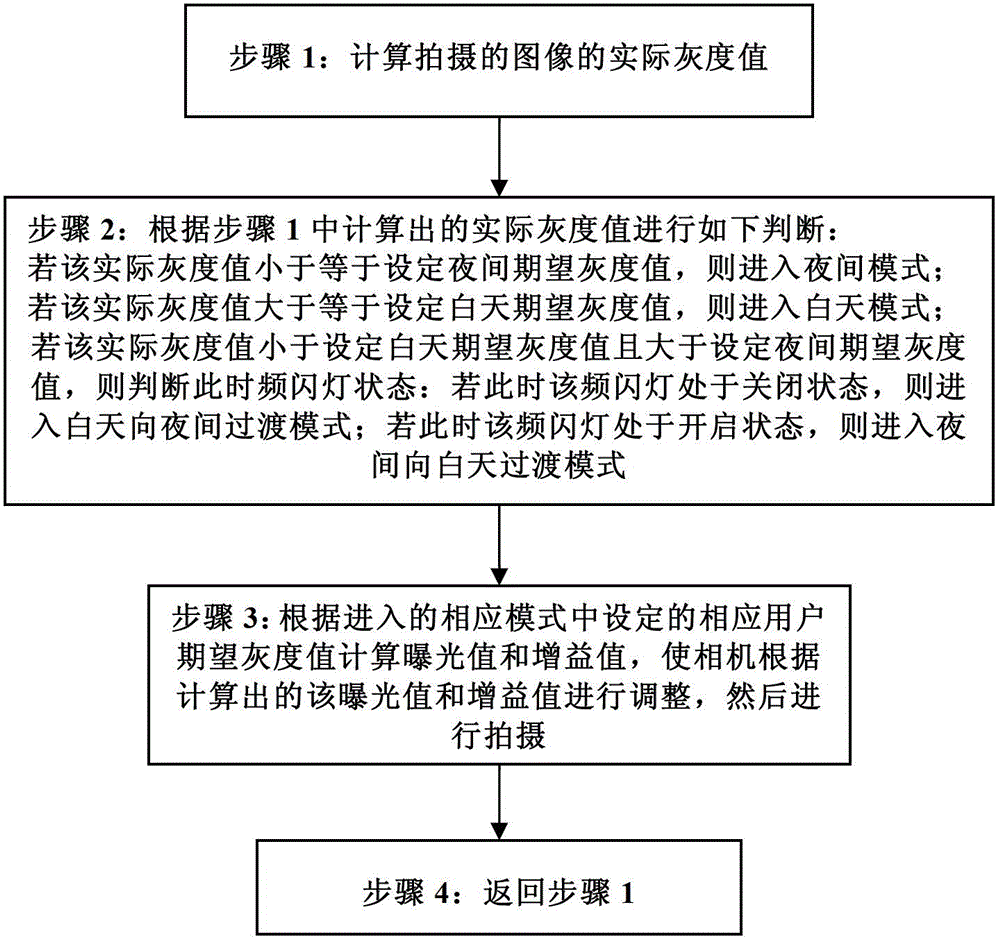

All weather exposure gaining automatic regulation method and system

ActiveCN102724404AImprove the shooting effectImprove image qualityTelevision system detailsColor television detailsAuto regulationValue set

The invention discloses an all weather exposure gaining automatic regulation method and an all weather exposure gaining automatic regulation system. The method comprises the following steps which are repeatedly executed: calculating an actual grey scale value of the shooting image; judging the state according to the calculated actual grey scale value and entering a corresponding mode; and calculating an exposure value and a gain value according to a corresponding user expected grey scale value set in the corresponding mode, adjusting a camera according to the calculated exposure value and gain value, and then shooting. The system comprises a grey scale value computation module, a grey scale value judgment module, a strobe lamp judgment module and an adjustment module. According to the illumination intensity under a shooting environment, the system can enter the corresponding mode, the exposure and gain parameters of the camera can be rapidly and automatically adjusted, so that the grey scale value of an image can achieve the grey scale value expected by a user, the best shooting effect is obtained, and the shooting image quality is improved.

Owner:BEIJING DAHENG IMAGE VISION

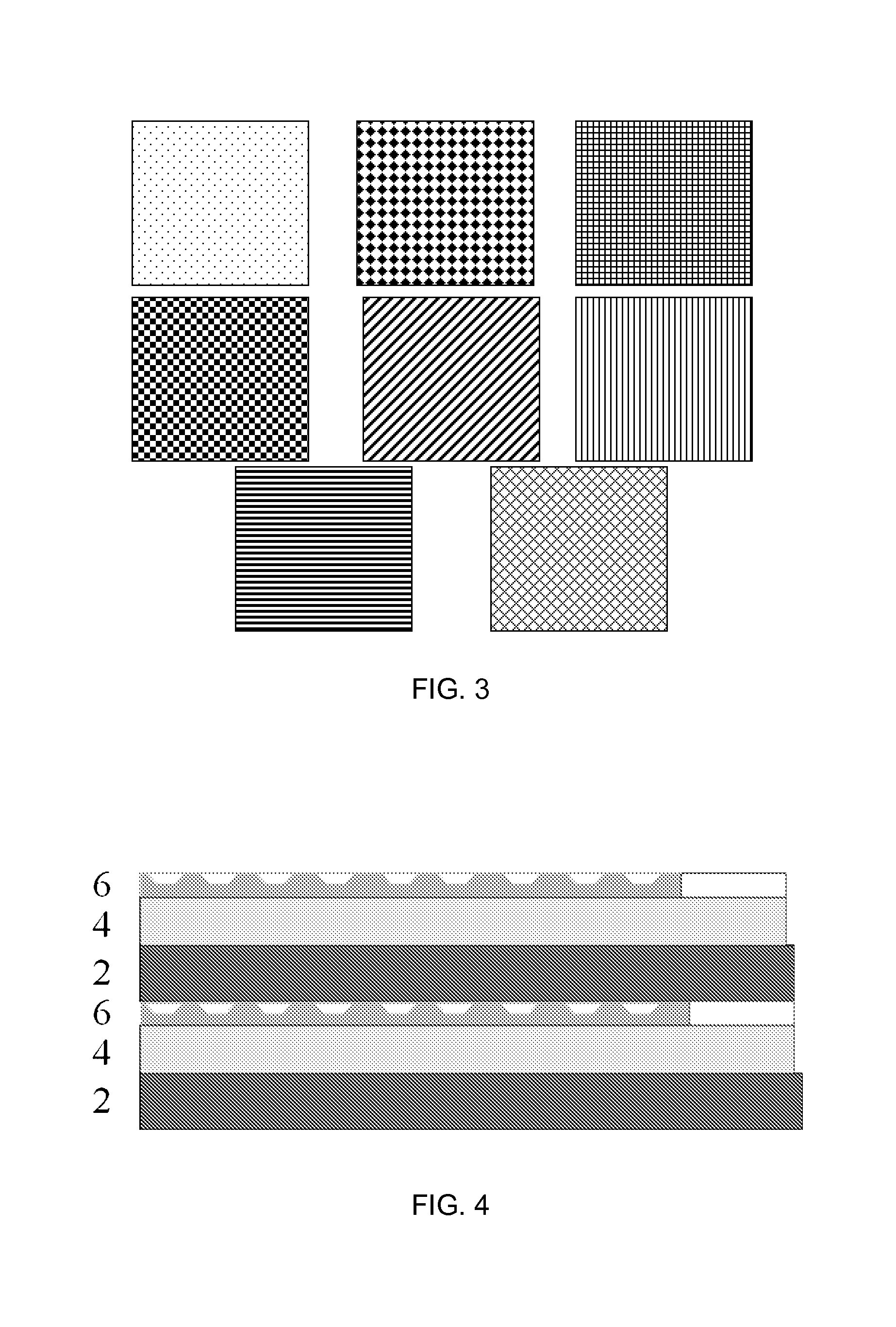

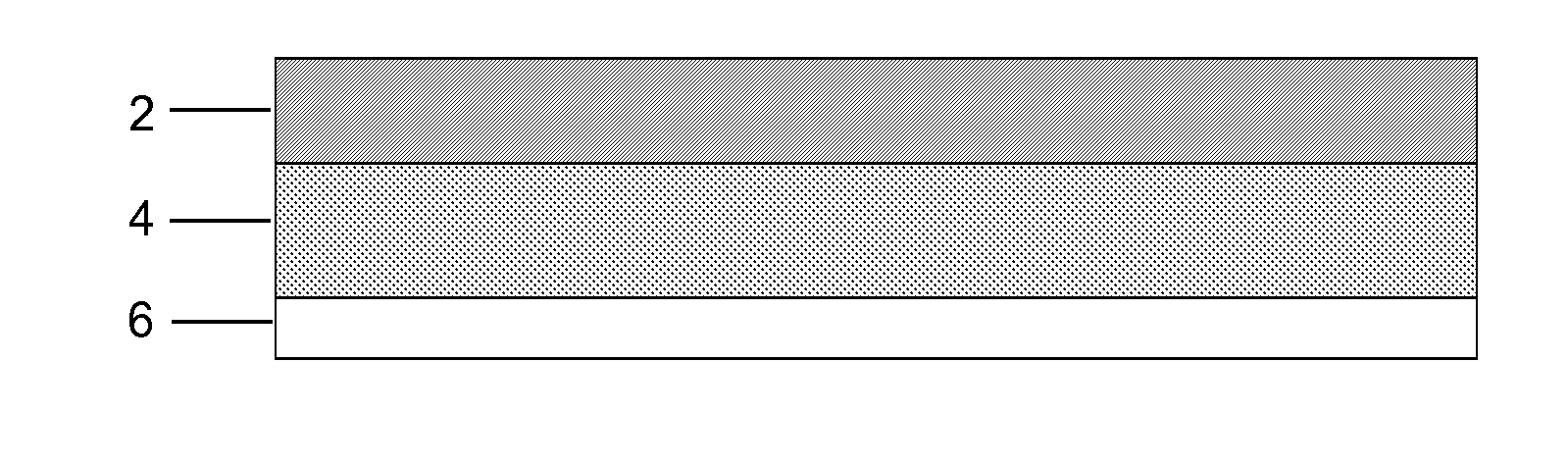

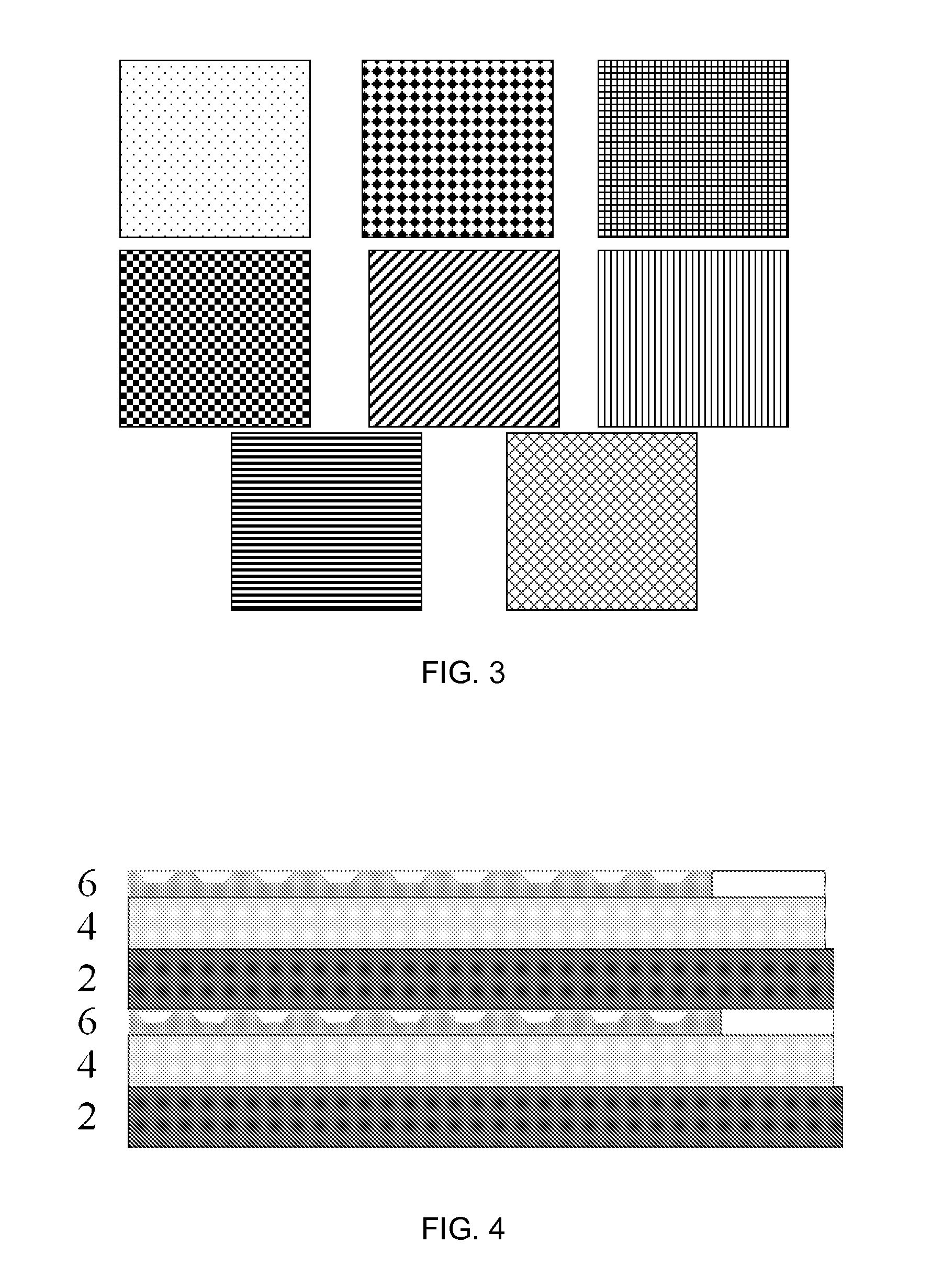

Waterproofing membrane

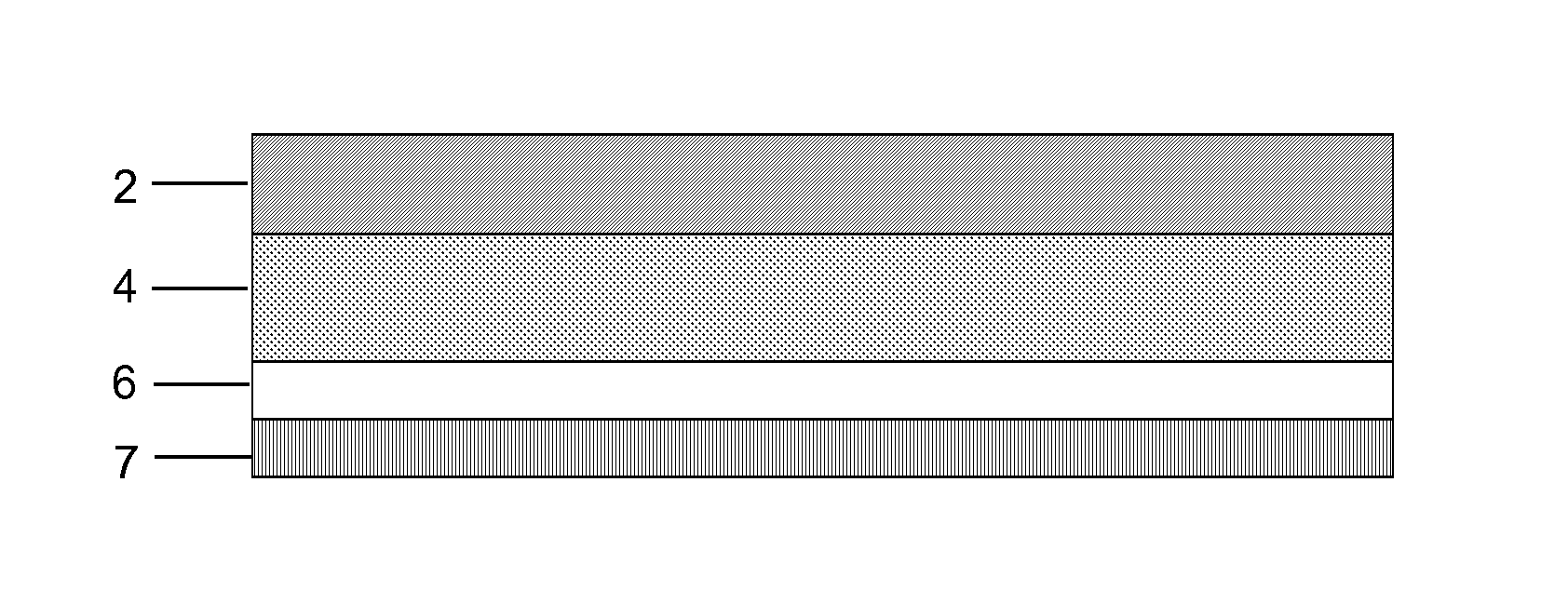

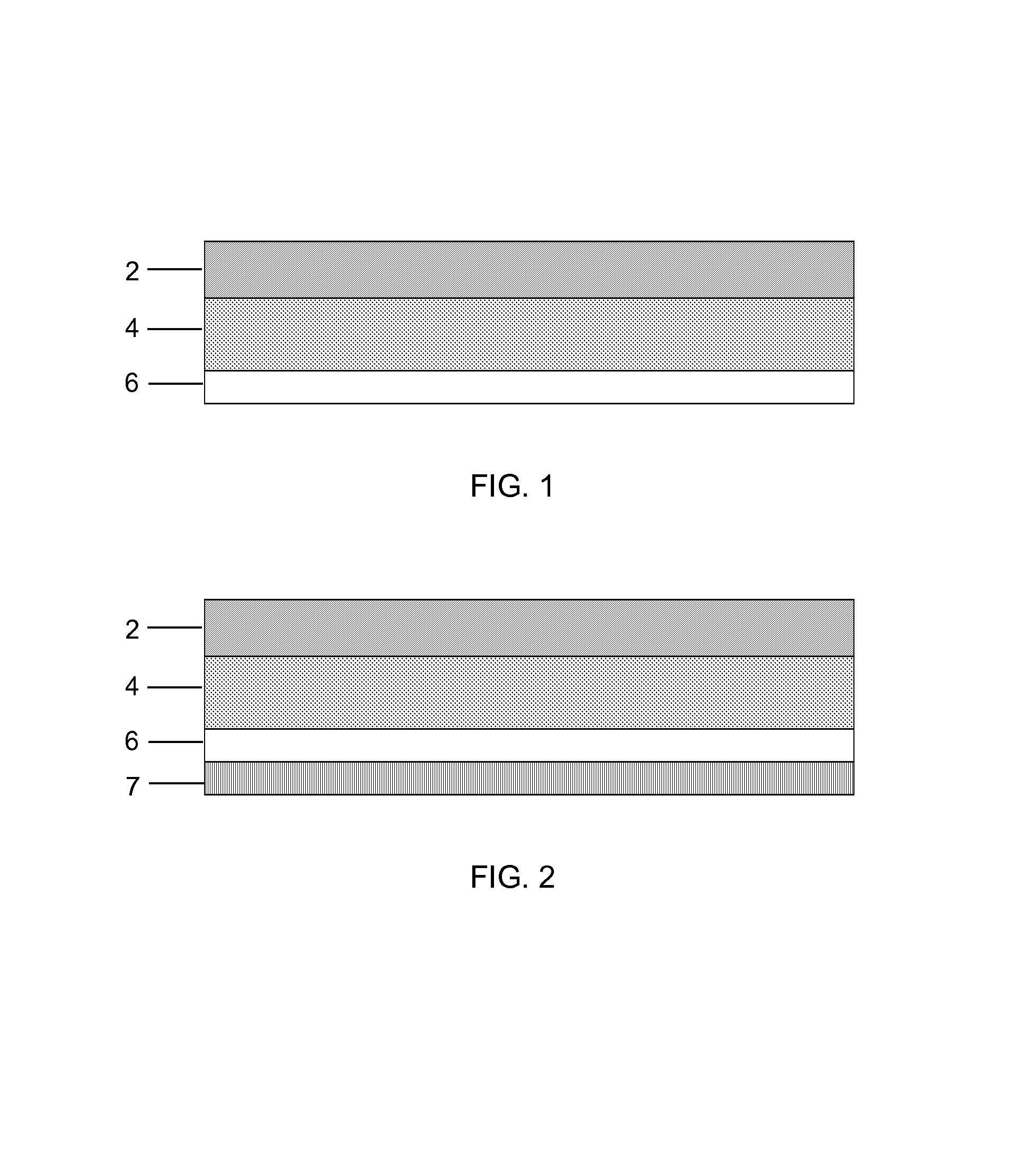

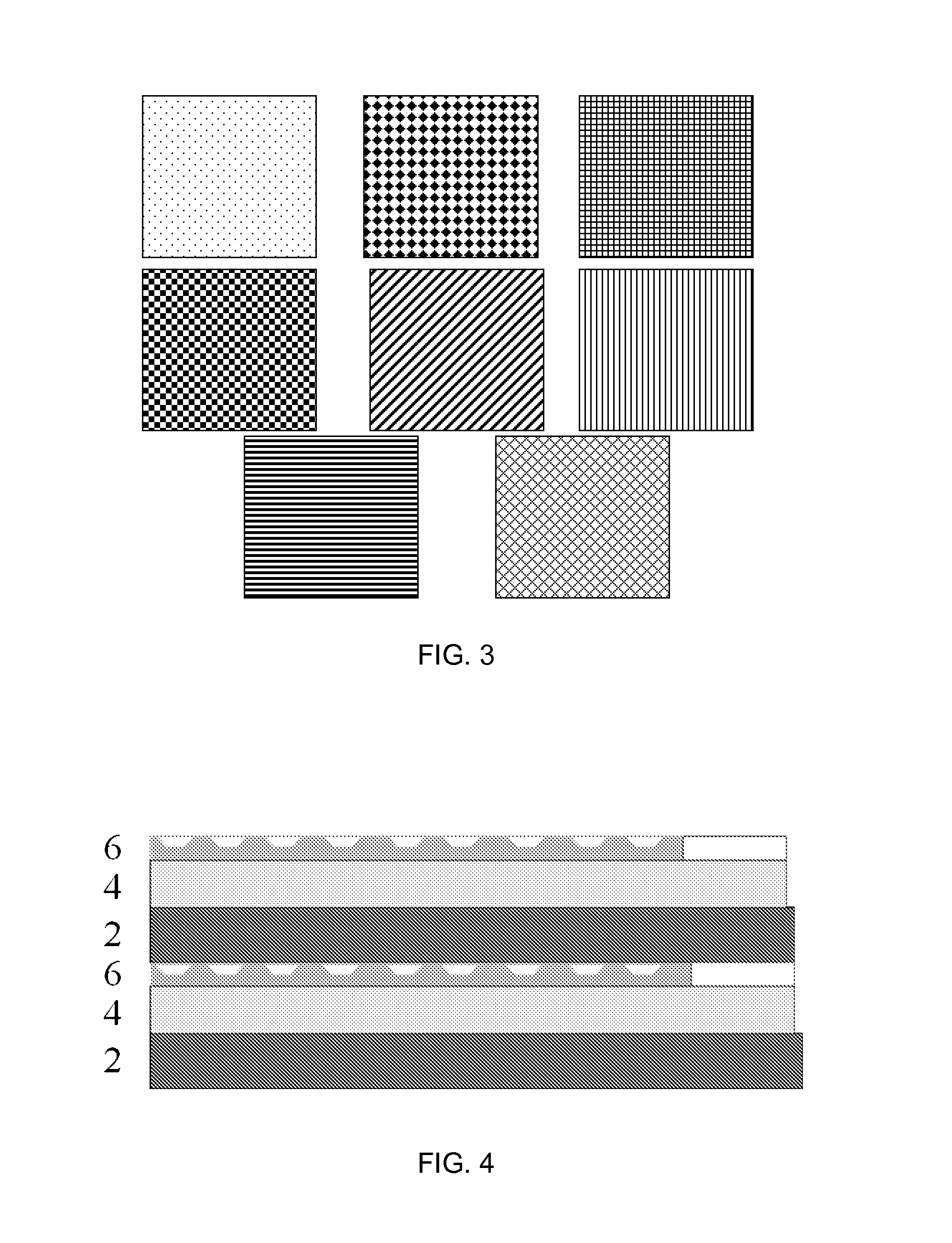

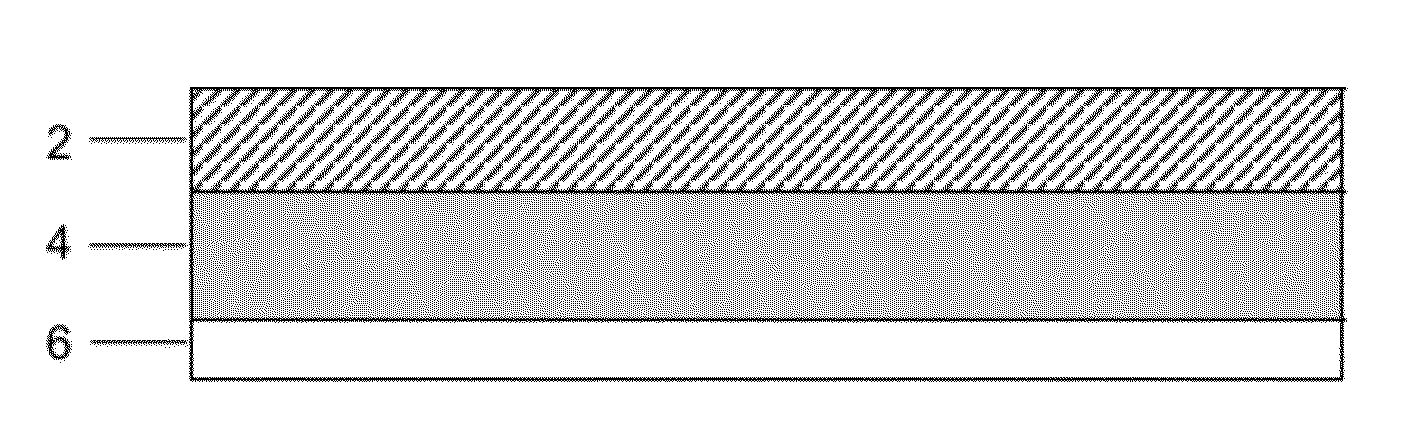

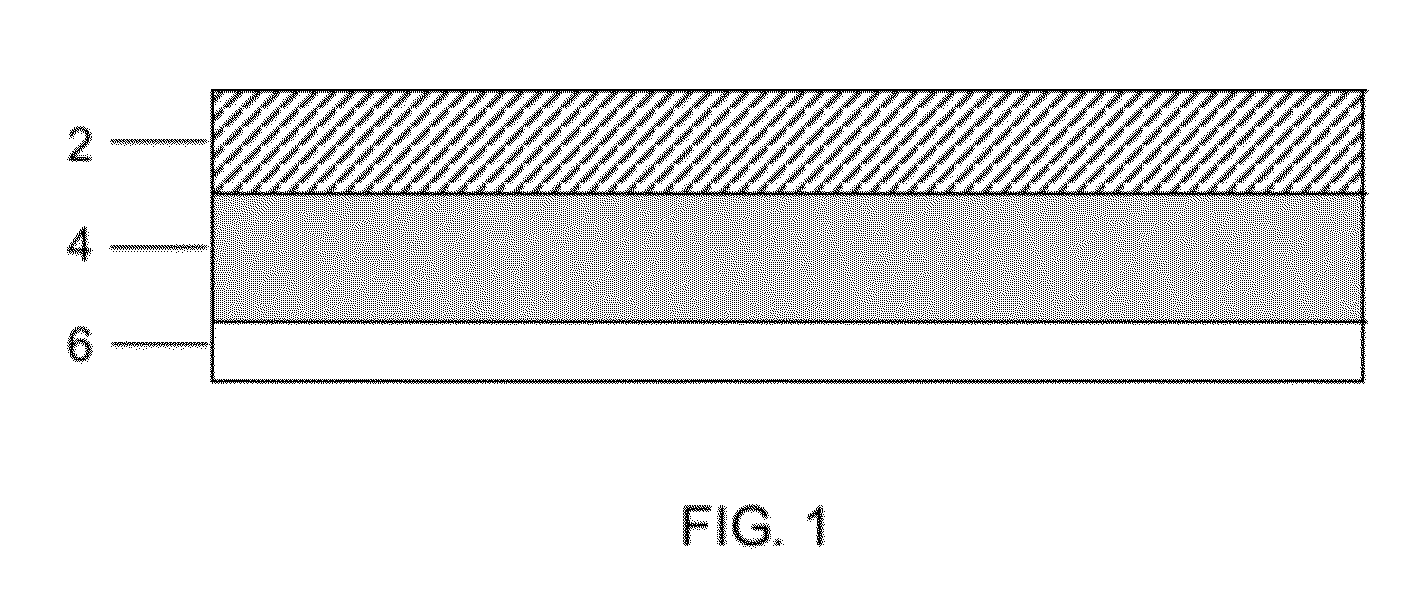

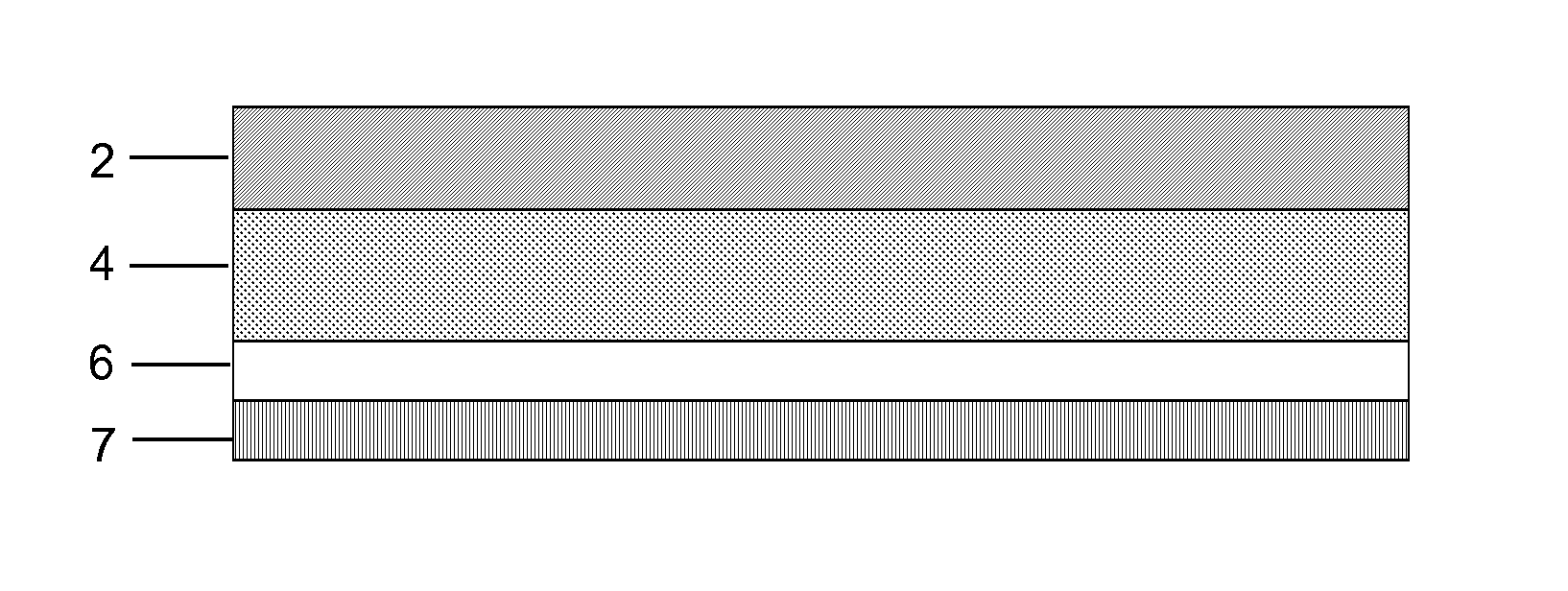

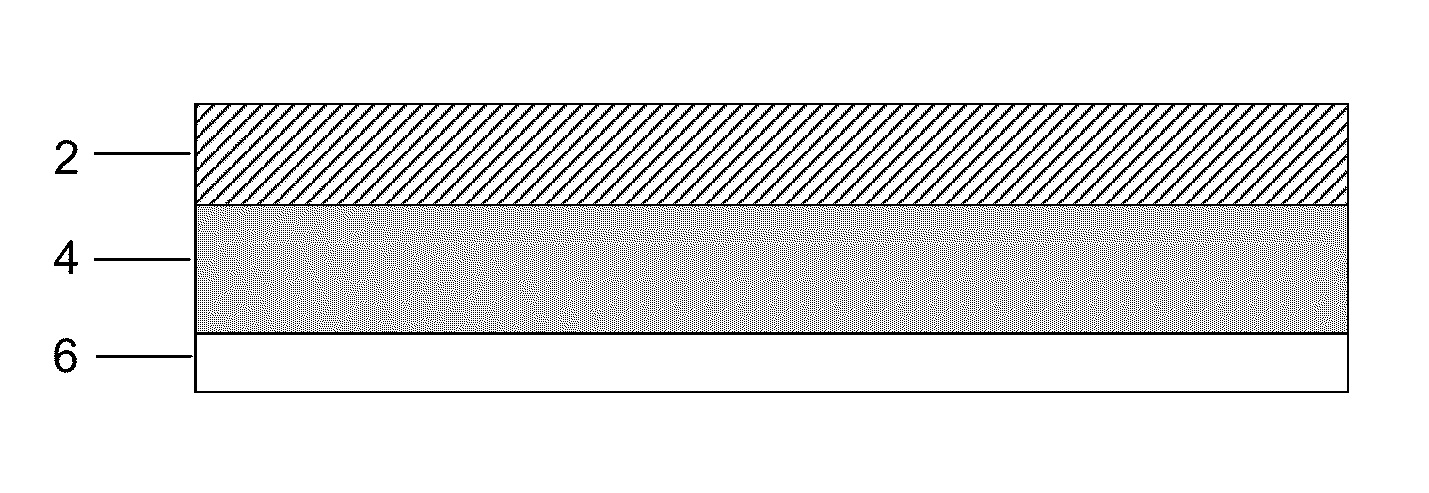

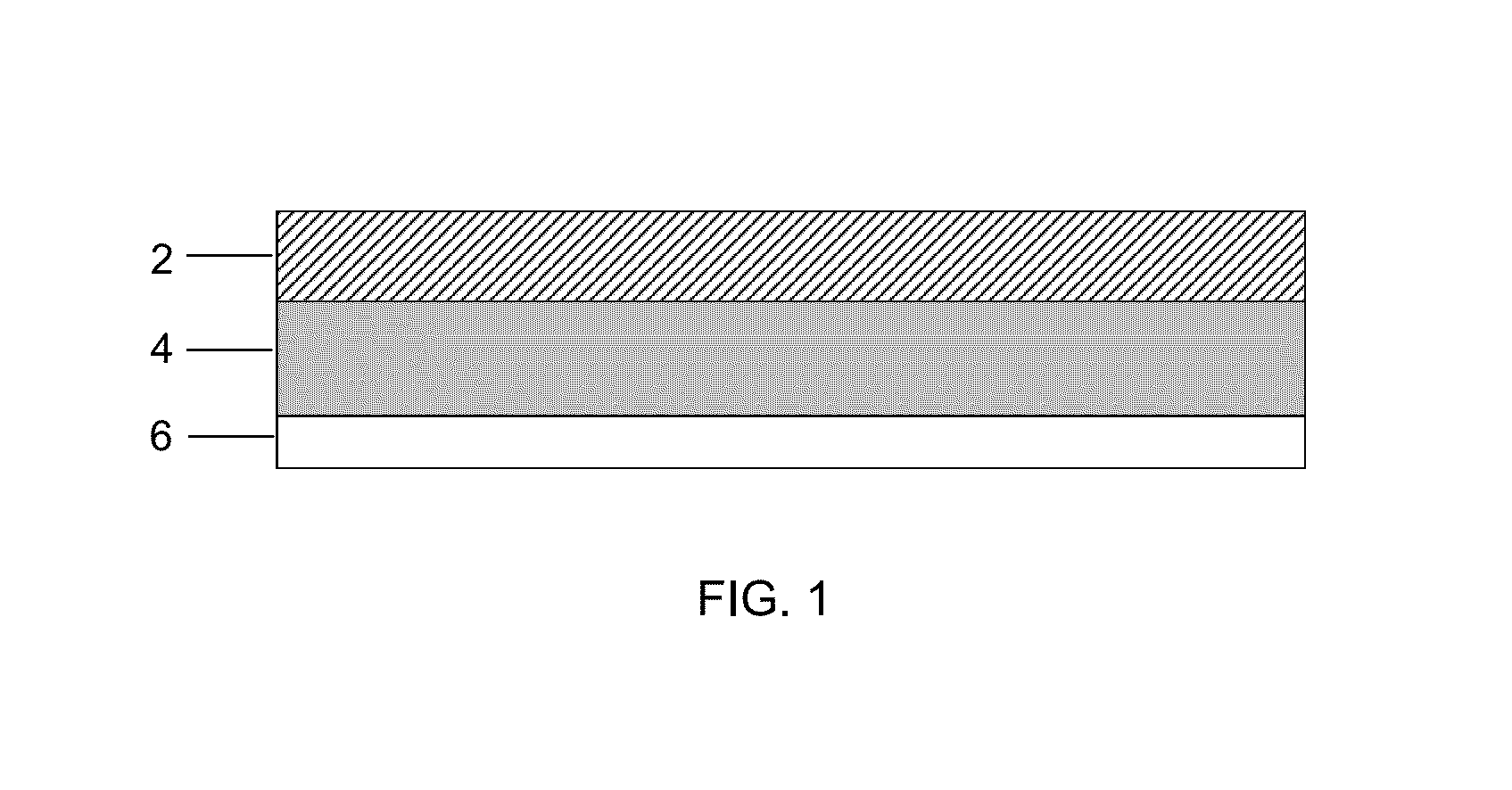

ActiveUS8931228B2High PVCImprove reflectivityRoof covering using tiles/slatesFloorsTectorial membraneAntioxidant

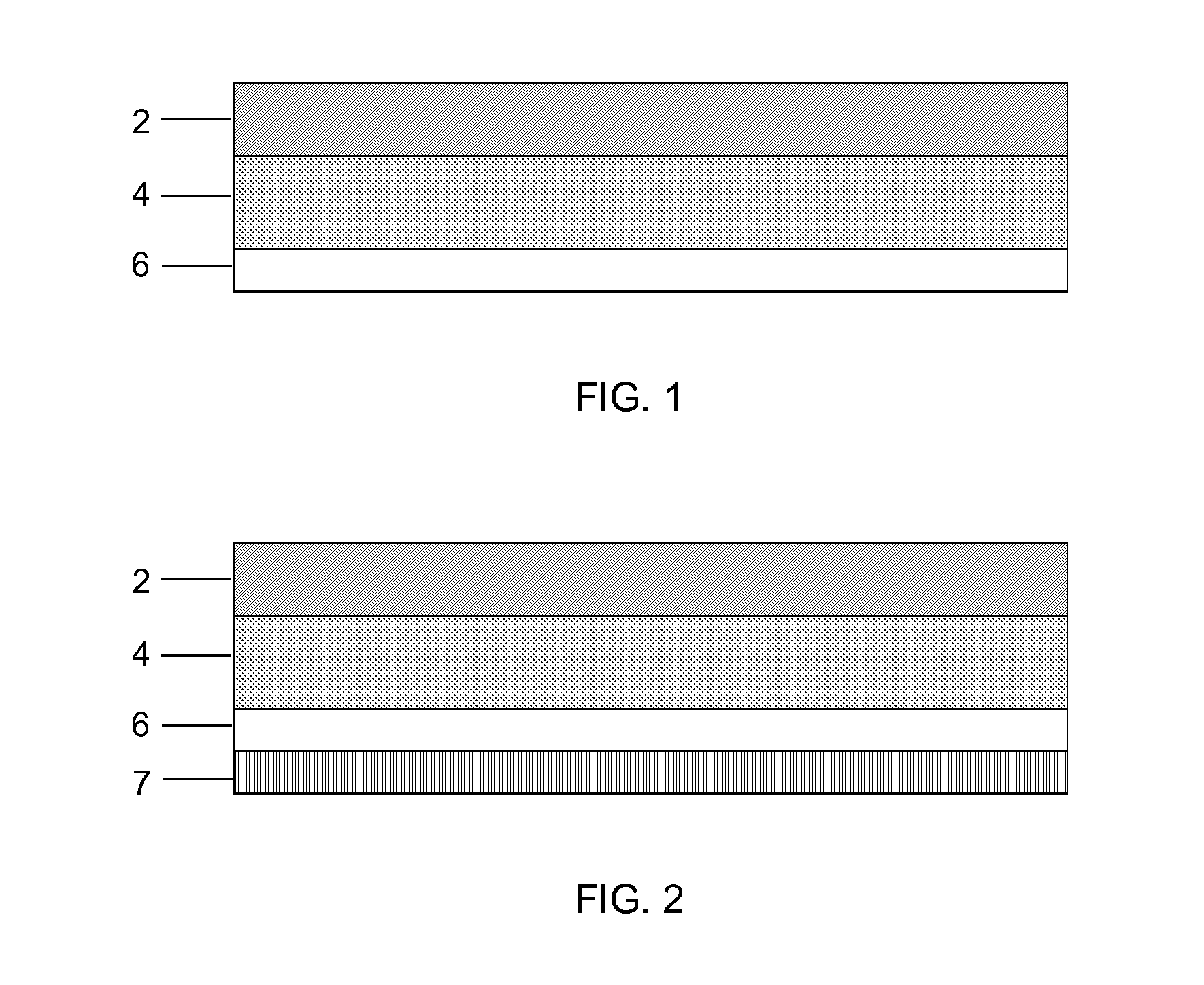

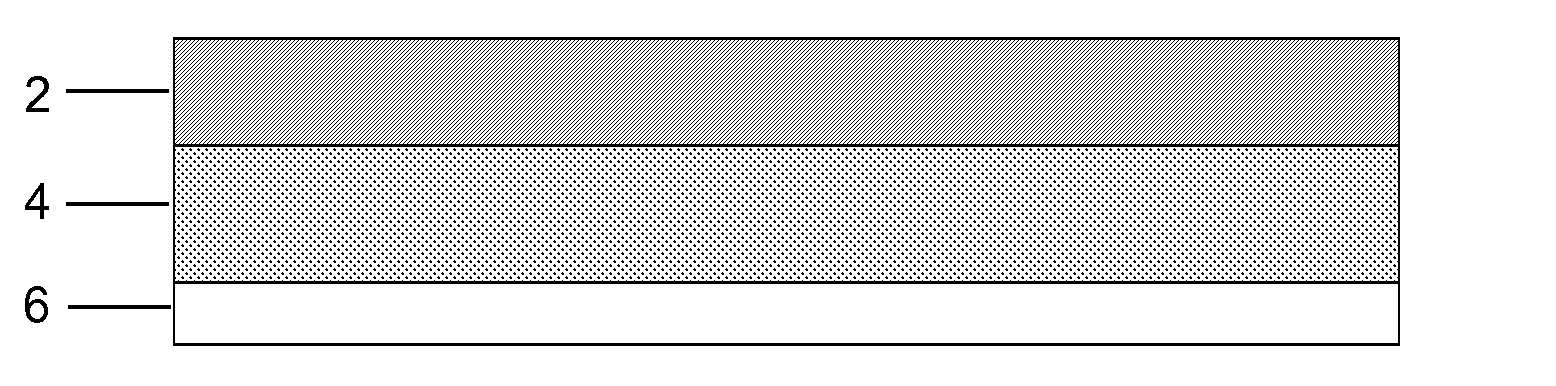

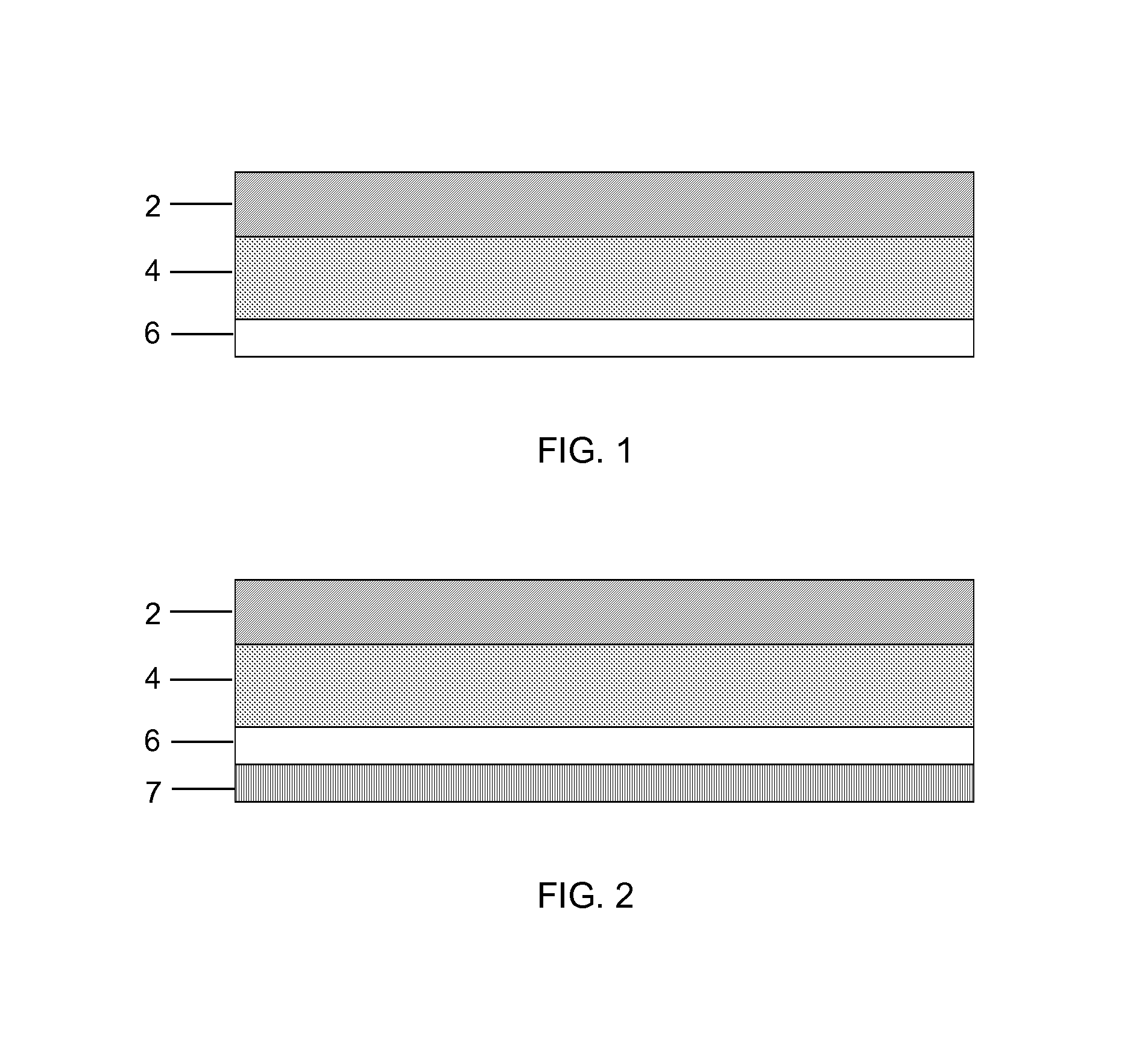

Disclosed is a waterproofing membrane that comprises a carrier sheet, a pressure sensitive adhesive layer on one surface of the carrier sheet, and a protective coating layer on the adhesive layer. The protective coating layer is highly reflective (optionally textured) and operative to bond to concrete cast against it. Preferably, the protective coating layer comprises cement, polymer, and white pigment, and may optionally or additionally include a filler, a UV absorber and an antioxidant. The protective coating layer protects the membrane against weather exposure, tolerates foot traffic and strongly adheres to concrete cast against it. Also disclosed is a waterproofing membrane comprising a carrier sheet, a pressure sensitive adhesive layer, a protective coating layer (as described above), and a highly releasable bonding layer.

Owner:GCP APPL TECH INC

Waterproofing Membrane

InactiveUS20120180933A1Avoid stickingAvoid exposureCovering/liningsWallsTectorial membranePolyvinyl acetate

Disclosed is a waterproofing membrane that comprises a carrier sheet, a pressure sensitive adhesive layer on one surface of the carrier sheet, and a protective coating layer on the adhesive layer. The protective coating layer comprises polyvinyl acetate (PVAc). The protective coating layer protects the membrane against weather exposure, tolerates foot traffic and strongly adheres to concrete cast against it.

Owner:GCP APPL TECH INC

Waterproofing membrane

ActiveUS8931229B2High PVCImprove reflectivityFloorsBridge structural detailsTectorial membraneEmulsion

Owner:GCP APPL TECH INC

Making technology of sun vinegar

The invention discloses a making technology of sun vinegar. The technology includes: 1) porridge cooking: adding water into a pot, pouring rice and glutinous rice, and cooking the rice into 60-70% cooked porridge; 2) vinegar porridge fermentation: pouring the porridge into a vinegar vat, when the temperature of the porridge cools to less than 40DEG C, adding vinegar koji and performing stirring, conducting fermentation at 35-38DEG C for 14-16d, and performing stirring once respectively in the morning and evening every day; 3) making of fermented grains: taking out the vinegar porridge, mixing the vinegar porridge with bran evenly, then placing the mixture into a vinegar slot, and performing covering with a straw mat; 4) turnover of fermented grains and fermentation: at the end of making of fermented grains, turning over the fermented grains once every other day, controlling the fermentation temperature at 37-38DEG C, at the 9-11th day of fermentation, adding salt and turning over the fermented grains evenly, and further conducting fermentation for 5-6 days; 5) jar loading and basking of fermented grains: transferring the vinegar fermented grains into the vat of sunning ground, conducting compaction, performing sealing with salt, and conducting weather exposure for 2 years; 6) vinegar spraying: collecting the vinegar fermented grains, and spraying vinegar by a two-pool set spraying process; 7) vinegar basking: transferring the sprayed vinegar liquid to the sunning ground to conduct weather exposure for 2-3 months; and 8) sterilization and filling: sterilizing the vinegar liquid at a temperature of 95-100DEG C for 15-30min, and then performing canning. The technology provided by the invention is simple, and has no need of inoculation.

Owner:GUIZHOU CHISHUIJINJIANG VINEGAR IND CO LTD

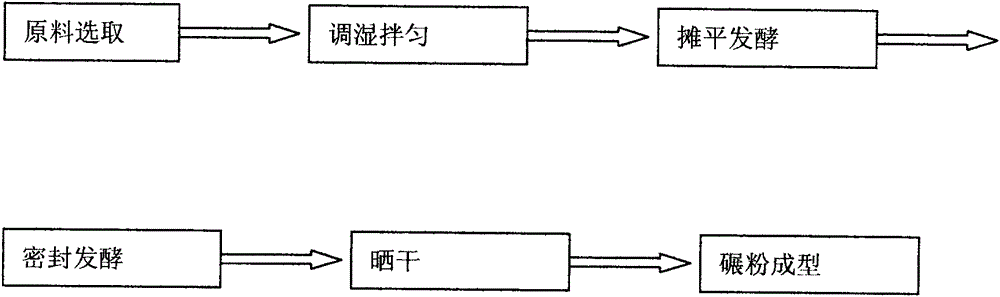

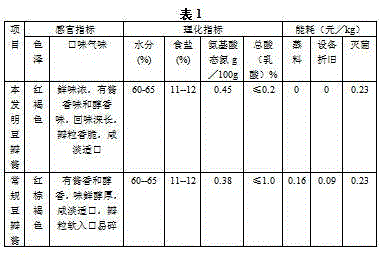

Weather exposure production process of broad bean paste

The invention discloses a weather exposure production process of broad bean paste. The process comprises pretreatment, fermentation and posttreatment. The process specifically comprises the following steps: respectively carrying out screening, grading and removing stone on broad beans and wheat, frying and shelling, removing different color kernels, and grinding and screening the wheat for later use; soaking the broad beans, mixing with the wheat meal and making koji; adding saline water for mixing, arranging the mixture in an outdoor sauce pool, and performing dog-days hot summer weather exposure fermentation to obtain a target product; and packaging, sterilizing, warehousing and preserving the target product. Fast hydrolysis of protease and amylase in the koji is accelerated to generate amino acids and sugar through heat energy of the sun, so that unique sauce and flavor are produced, generation of pigments of the broad bean paste can be promoted, the broad bean paste is red brown due to fermentation within about three months, is oily, glossy, delicious in taste, molten in bean halves, moderate in viscosity and strong in form and does not mildew, the broad bean paste disclosed by the invention is unique in flavor, rich in taste and long in quality guarantee period, and the normal-temperature aftertaste preservation time can be over 36 months.

Owner:CHUXIONG YUNQUAN SAUCE & PICKLE +2

Waterproofing membrane

ActiveUS9394464B2Low penetrationImprove passabilityFilm/foil adhesivesBuilding insulationsTectorial membraneEmulsion

Disclosed is a waterproofing membrane that comprises a carrier sheet, a pressure sensitive adhesive layer on one surface of the carrier sheet, and a protective coating layer on the adhesive layer. The protective coating layer comprises a highly reflective protective coating layer operative to bond to concrete cast against it, particularly one that is produced from an aqueous coating comprising an acrylic emulsion, a filler, and a white pigment. The pigment volume concentration of the filler plus white pigment is greater than or equal to 40% by volume. The protective coating layer protects the membrane against weather exposure, tolerates foot traffic and strongly adheres to concrete cast against it. The protective coating comprises an acrylic polymer with a unique multi-domain morphology (i.e., at least two distinct polymer domains).

Owner:GCP APPL TECH INC

Whole soybean soy sauce process using sauce making method in Zhou dynasty

InactiveCN107927703ADeliciousBright colorFood preservationFood ingredient for microbe protectionWeather exposurePreservative

The invention discloses a whole soybean soy sauce process using a sauce making method in Zhou dynasty. Soybeans are used as protein raw materials, no starchiness raw materials are added, and through steps of cleaning the soybeans, soaking the cleaned soybeans, performing steaming, performing mixing, performing cooling and inoculation, performing koji making in ventilated environment, performing heat preservation and fermentation, and performing weather exposure fermentation, the paste is made. No additives and no preservatives are added, the color, the fragrance and the taste of the soy sauceare greatly improved, and pure natural nutrient substances of the soy sauce are increased to a large extent.

Owner:尧记酱道股份有限公司

Waterproofing Membrane

ActiveUS20130104495A1High PVCImprove reflectivityBuilding repairsRecord information storageTectorial membraneEmulsion

Disclosed is a waterproofing membrane that comprises a carrier sheet, a pressure sensitive adhesive layer on one surface of the carrier sheet, and a protective coating layer on the adhesive layer. The protective coating layer comprises a highly reflective protective coating layer operative to bond to concrete cast against it, particularly one that is produced from an aqueous coating comprising an acrylic emulsion, a filler, and a white pigment. The pigment volume concentration of the filler plus white pigment is greater than or equal to 55% by volume. The protective coating layer protects the membrane against weather exposure, tolerates foot traffic and strongly adheres to concrete cast against it. Also disclosed is a waterproofing membrane comprising a carrier sheet, a pressure sensitive adhesive layer, a protective coating layer, and a highly releasable bonding layer. The preferred highly releasable bonding layer comprises nanoscale silica and a binder.

Owner:GCP APPL TECH INC

License plate cord winder with universal mount and ratchet

InactiveUS20050161548A1Increase available lengthAvoid contactCharging stationsElectric vehicle charging technologyWeather exposureElectrical devices

The present invention relates to an improved cord-winding device universally mountable to any front or rear North-American-style license plate bracket, accommodating all electrical devices, which require a 120 VAC power supply for a vehicle. The present winder includes a storage reel with a spiral coil return spring, a connection box, a male cord housing, a cord hatch and mounting holes, a closure plate and a universal mounting plate. A cord with a female receptacle extends from the housing to allow electrical connections to be made in a place well away from weather exposure such as engine or rear compartment. The universal license plate cord winder can thereby be mounted either from the top or the bottom of housing without compromising the structural integrity of the attachment while maintaining a water tightness required by such a device. A ratchet is provided to control the retraction of the male cord.

Owner:NANEFF ALEXANDER STAIKO +2

Wheat bran sauce

The invention relates to wheat bran sauce. Dry substances consist of 50% of wheat bran, 20% of wheat, 10% of peas, 10% of broad beans and 10% of rice by weight. A manufacturing process is as follows: pure water is assisted for preparing the wheat bran sauce; firstly, an appropriate amount of water is added into the dry substances to humidify and evenly mix the dry substances; then, the mixture is placed in a winnowing fan to be slightly pressed and flattened, and the mixture is covered with vitex negundo branches (with leaves) to be fermented for 10-15 days; after the mixture is covered with the vitex negundo branches (with leaves), the mixture is sealed in a pot for preservation, and the pot is under weather exposure for about 10 days for full fermentation; and a material dough is taken out to be spread and dried in sunshine, and the material dough is ground into powder by a rice mill to obtain finished products. The wheat bran sauce disclosed by the invention has the beneficial effects that the raw materials of the products all come from nature, and chemical additives, such as antiseptic, essence and sweetener, do not need to be added; the wheat bran sauce is fragrant and mellow in mouth feel, the wheat bran sauce is suitable for various crowds, and an excellent way for enabling wheat bran products to strike roots in the hearts of people is provided. The wheat bran sauce has favorable economic benefits and social benefits, and superior food is better provided for the healthy life of people.

Owner:胡宏处

White soybean sauce and production method thereof

ActiveCN104381960AFacilitate the promotion of industrial productionShorten the time of anaerobic fermentationFood preparationWeather exposureBran

The invention relates to the technical field of soybean sauce and a production method thereof, and provides white soybean sauce and a production method thereof. The white soybean sauce is prepared by the following steps: firstly, sequentially mixing soybeans with required amount, oatmeal with required amount and bran with required amount, moistening with water, cooking and cooling; secondly, inoculating and making starter to obtain finished starter; thirdly, adding fermented apple paste, salt and maltose into the starter to prepare soy sauce mash; fourthly, carrying out weather exposure, anaerobic fermentation and soaking to obtain white soybean sauce. Compared with a traditional white soybean sauce production method, the white soybean sauce and the production method thereof have the advantages that the period of anaerobic fermentation is shortened, the whole production cycle is integrally shortened, white soybean sauce can be produced in summer, the production efficiency is improved, and the production cost is reduced; the production method thereof has wide industrial production prospects, and is advantageous to the promotion of industrial production of white soybean sauce.

Owner:朱守允

Calcium carbide dust molded coal

The invention discloses calcium carbide dust briquette and relates to a method for producing briquettes through using calcium carbide dust. The composition of the calcium carbide dust briquette is formed by calcium carbide dust and coke powder, wherein, the volume percentage of the calcium carbide dust is between 50 and 70 percent, the volume percentage of the coke powder is between 50 and 30 percent; during the production, the water with 25 to 35 percent of the total volume of the calcium carbide dust and the coke powder is fully mixed with the calcium carbide dust, then is placed for a period of time to ensure that the gas produced by the water and calcium carbide is completely discharged, and then is added with the coke powder to evenly mix to make a compression molding to dry. The test shows that the average heat calorie of the briquette is 3786 kilocalories which are 30 to 40 percent higher than the prior briquette. The combustion time of the briquette doubles the prior briquette with the same volume. In addition, the calcium carbide dust briquette is waterproof and not afraid of weather exposure, and has no smoke during the combustion and low sulfur content. More importantly, the calcium carbide dust briquette solves the pollution problem caused by the calcium carbide dust to the environment.

Owner:庄芝亮

Production method of raw materials for thick broad-bean sauce

The invention discloses a production method of raw materials for thick broad-bean sauce so as to solve the problems that cooked materials are used for making sauce koji for fermentation in the processing of conventional thick broad-bean sauce, so that much energy is consumed, and pollution in the working procedure of steaming materials is serious. The production method comprises the following steps of treating raw materials, and culturing fermented bean cotyledon koji: transferring treated bean cotyledons into a koji making house, inoculating aspergillus oryzae, and culturing the fermented bean cotyledon koji; performing fermentation with diluted mash: sufficiently and uniformly mixing cultured fermented bean cotyledon koji materials to obtain a mixture, loading the mixture into a fermentation vessel, adding salt water for immersing the fermented koji materials, sealing the fermentation vessel, and performing fermentation under heat preservation condition; and sufficiently and uniformly stirring semi-finished products sauce, loading the stirred semi-finished products sauce into a after-ripening vat, sealing the after-ripening vat, placing the after-ripening vat at outdoors with sufficient sunshine, and performing exposure to sun and after-ripening so as to obtain finished products. According to the production method of the raw materials for the thick broad-bean sauce disclosed by the invention, a steaming link is omitted, and high-temperature fermentation time and weather exposure natural after-ripening time are prolonged, so that the products are rich in nutrition, delicious in mouth feel, high in health, and unique in flavor.

Owner:刘月宝

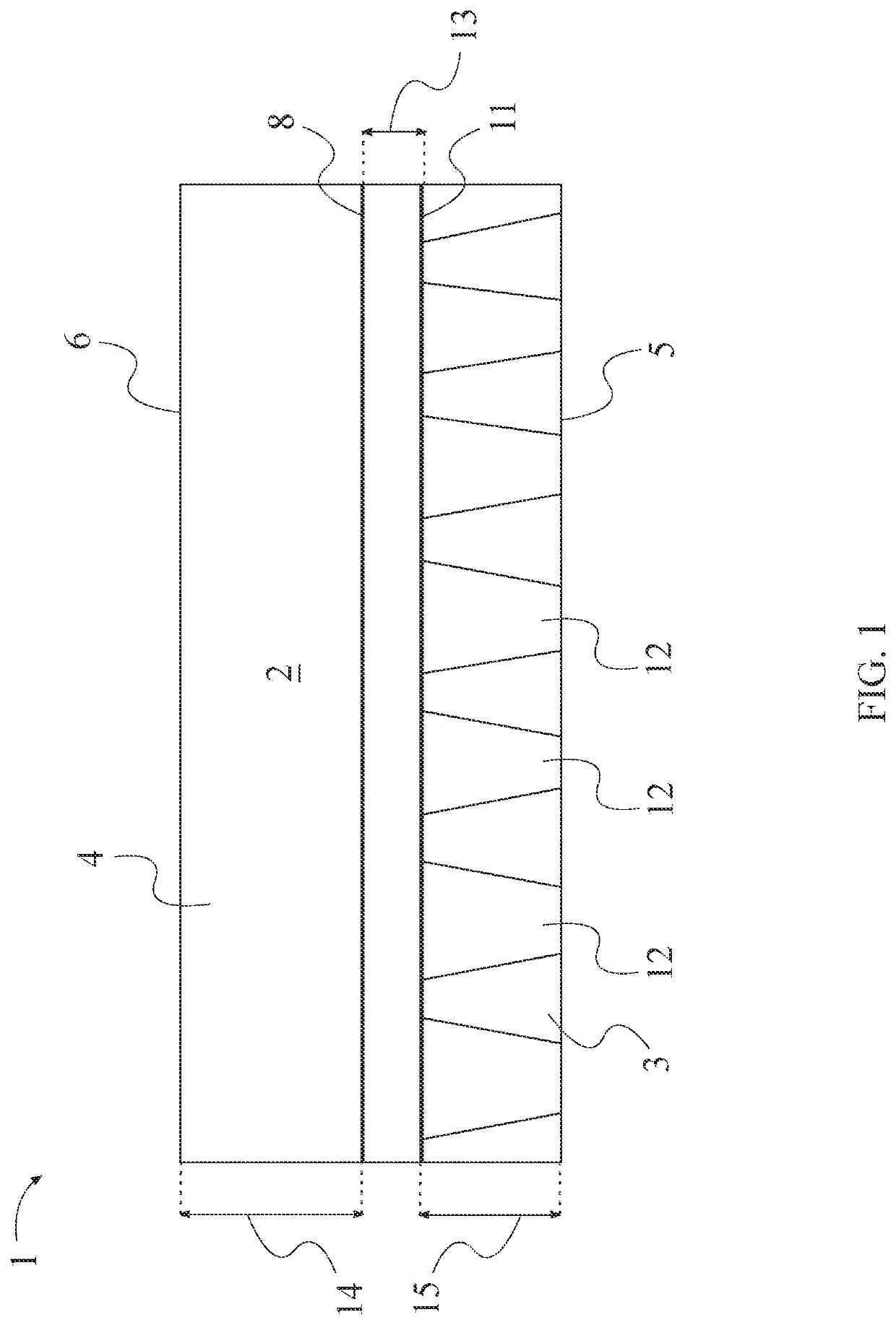

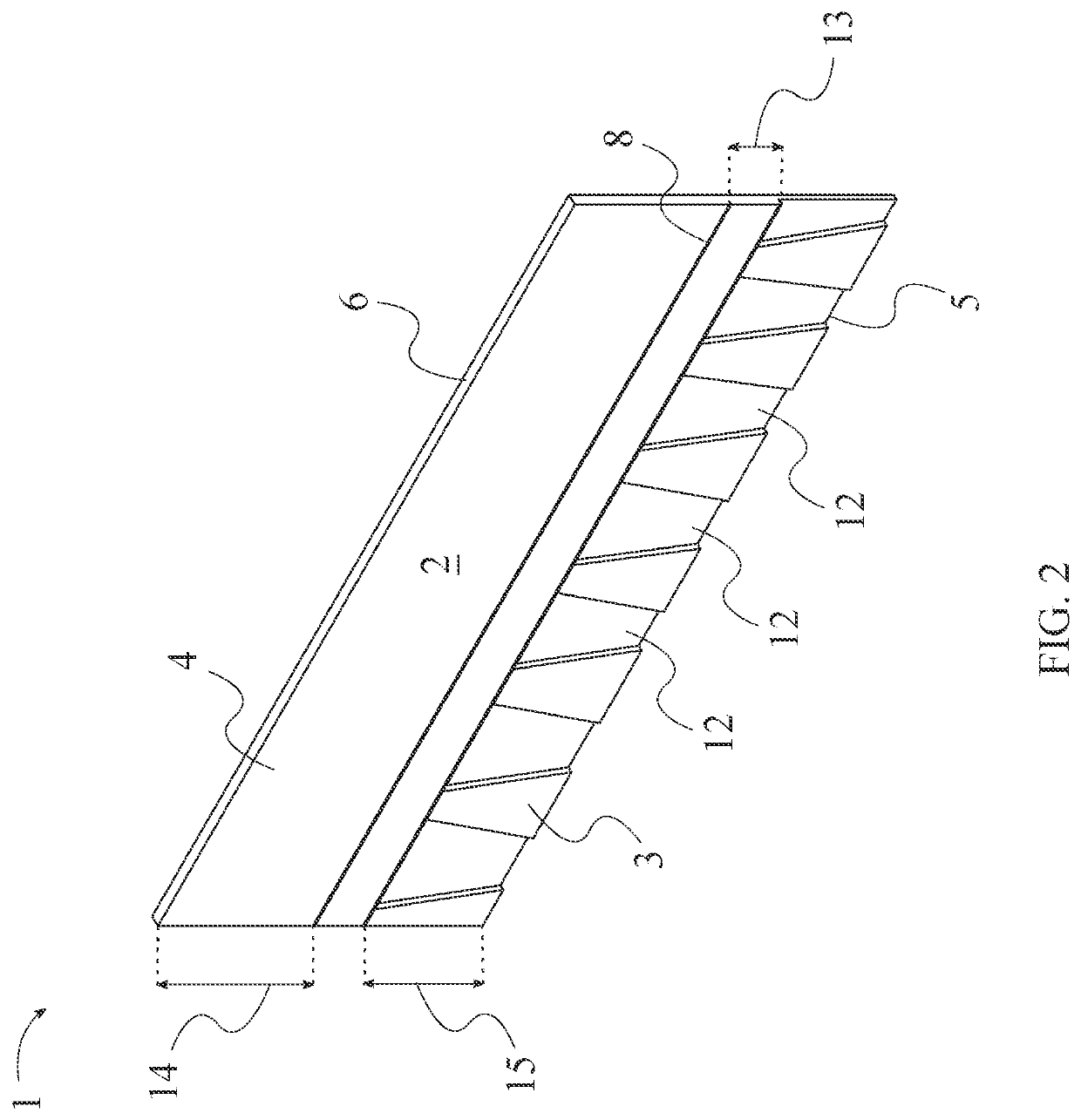

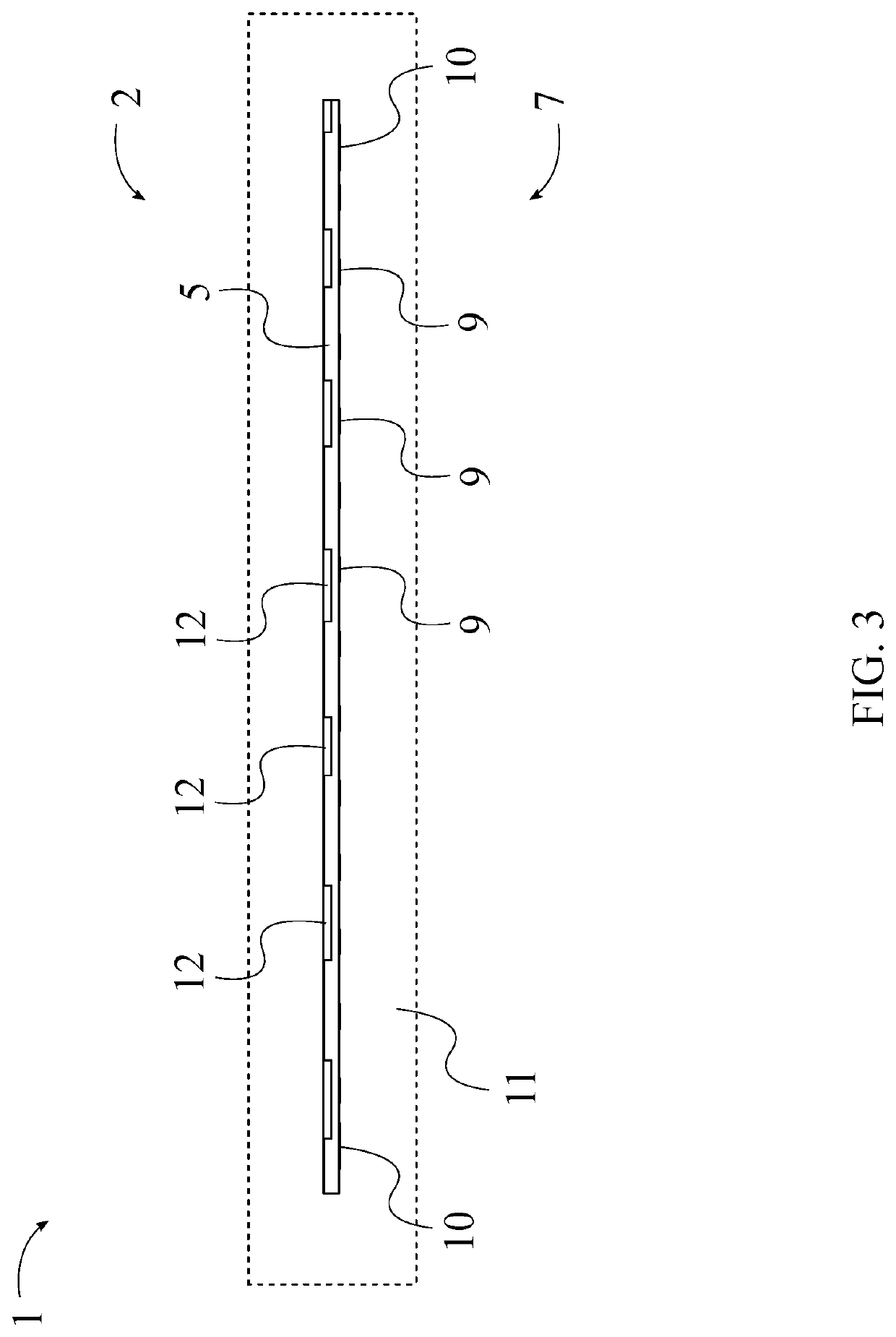

Fastener-protecting roofing shingle

ActiveUS11155996B2Prevent leakageAvoid waterRoof covering using tiles/slatesRoof tileWeather exposure

A fastener-protecting roofing shingle provides a solution for roofing nails or fasteners that become damaged due to weather exposure resulting from damaged roofing shingles. A nailing line is placed above a seamline rather than on or below the seamline, as is conventionally found. By placing the nailing line further from the seamline, which typically borders the exposed and the overlapped sections of a shingle, nails are better-protected from being exposed to the elements, which decreases the chances of failure due to the nail rusting. Due to the shift in the nailing line, a spotted adhesive may be positioned approximately two inches below the nailing line for improved rooftop adherence, and the length of a solid section may be increased. Furthermore, the apparatus directs rainwater straight down the roof. Solid adhesive strips prevent water from pooling or leaking laterally out to the sides and into other layers of shingling.

Owner:DICORCIA WILLIAM P +1

Sun-dried and night-dew production process of bean paste

The invention discloses a weather exposure production process of broad bean paste. The process comprises pretreatment, fermentation and posttreatment. The process specifically comprises the following steps: respectively carrying out screening, grading and removing stone on broad beans and wheat, frying and shelling, removing different color kernels, and grinding and screening the wheat for later use; soaking the broad beans, mixing with the wheat meal and making koji; adding saline water for mixing, arranging the mixture in an outdoor sauce pool, and performing dog-days hot summer weather exposure fermentation to obtain a target product; and packaging, sterilizing, warehousing and preserving the target product. Fast hydrolysis of protease and amylase in the koji is accelerated to generate amino acids and sugar through heat energy of the sun, so that unique sauce and flavor are produced, generation of pigments of the broad bean paste can be promoted, the broad bean paste is red brown due to fermentation within about three months, is oily, glossy, delicious in taste, molten in bean halves, moderate in viscosity and strong in form and does not mildew, the broad bean paste disclosed by the invention is unique in flavor, rich in taste and long in quality guarantee period, and the normal-temperature aftertaste preservation time can be over 36 months.

Owner:CHUXIONG YUNQUAN SAUCE & PICKLE +2

Shrimp sauce fermentation production technology

The invention relates to a shrimp sauce fermentation production technology. The shrimp sauce fermentation production technology comprises the following steps: raw materials are washed, placed in a jar which is placed outdoors for weather exposure for 2 days, the materials are stirred once in the morning and stirred once in the evening, added with salt and stirred after 3-5 days, added with salt once in the morning and in the evening every day, then stirred, and fermented for half of a month; after fermentation, the salt use amount is reduced by 5% for each time, after 1 month, stirring is only performed in the morning, and a small amount of salt is added until the specified salt is used up; then weather exposure is continued; oil refining is started after air-drying in dog days is finished, oil slick on the jar surface is removed firstly during oil refining, then saline water which is boiled and cooled is added, and the use amount is equal to the difference between the weight of the raw materials and the amount of oil slick removed for the first time; then the saline water is added and stirred once in the morning and stirred once in the evening, a basket is placed in the jar, shrimp sauce is filtered into the basket, and the shrimp sauce is taken out; the shrimp sauce sequentially taken out is mixed and boiled to remove impurities and foam, and a shrimp sauce product is obtained. The shrimp sauce fermentation production technology has the benefits of simple operation, low cost, high oil yield, suitability for batch production and good economic benefit.

Owner:张桂华

Food preservative

InactiveCN104544467AHas a killing effectGood antibacterial effectFood preservationAllium sativumSolvent

The invention discloses a food preservative. The food preservative comprises the following raw materials: a bitter melon extracting extract A, a garlic steaming and suction filtering extract B or allicin, or a bitter melon and garlic mixed extract A+B and amino acid polypeptide C; the food preservative is prepared by stirring and mixing the raw materials proportionally to obtain a uniform solution, deodorizing by extracting and washing by using a solvent, and sterilizing and disinfecting, wherein the percentages of the extract A, the extract B and the amino acid polypeptide C by weight are (60-90%), (5-25%) and (5-15%) respectively. The food preservative has a very obvious effect on easily-rotting food and vegetables, such as wax gourds, eggplants, tomatoes, meat and eggs (in summer, after being treated by the food preservative, the food and the vegetables do not deteriorate in more than 10 days in an environment of 37-40 DEG C and complete weather exposure.); the food preservative has excellent bacteriostatic and bactericidal effects which are obviously superior to those of various chemical preservatives widely-used currently at home; the food preservative has an effect of killing gram-negative bacteria and gram-positive bacteria and is a broad-spectrum preservative product; furthermore, the food preservative is simple in production process, relatively low in cost, huge in market and very wide in development prospect.

Owner:邹文

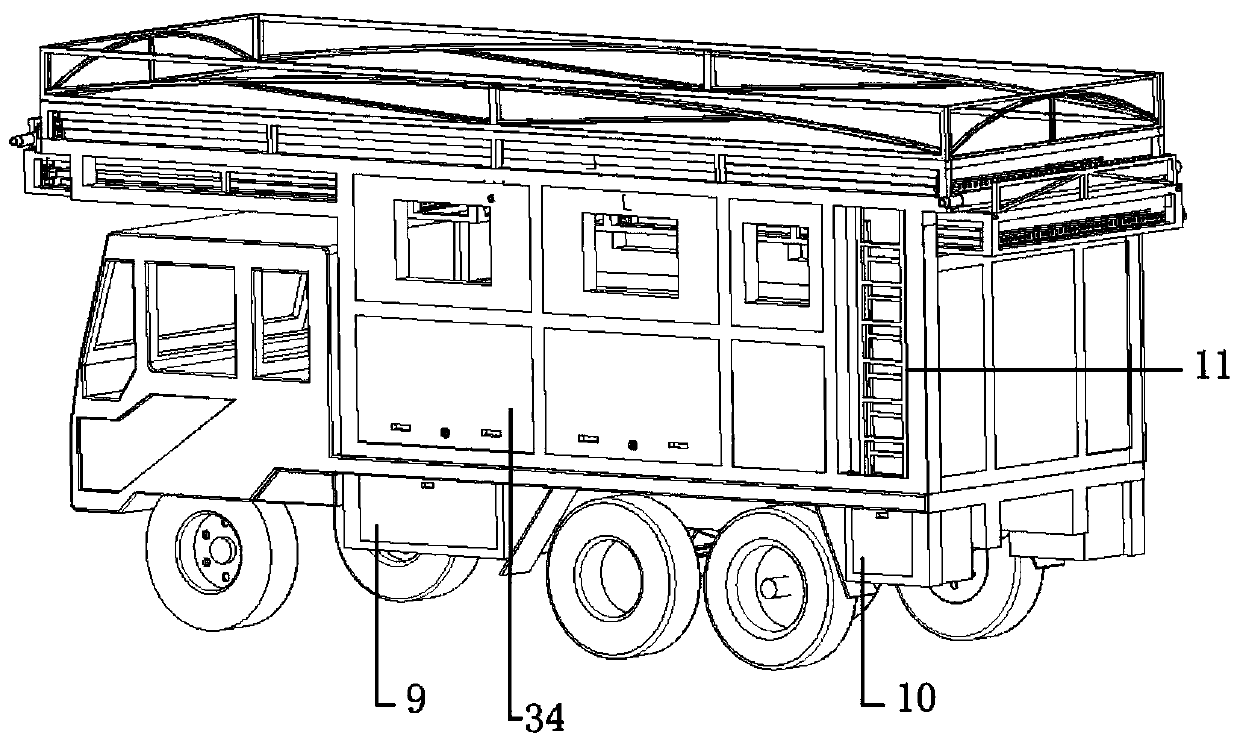

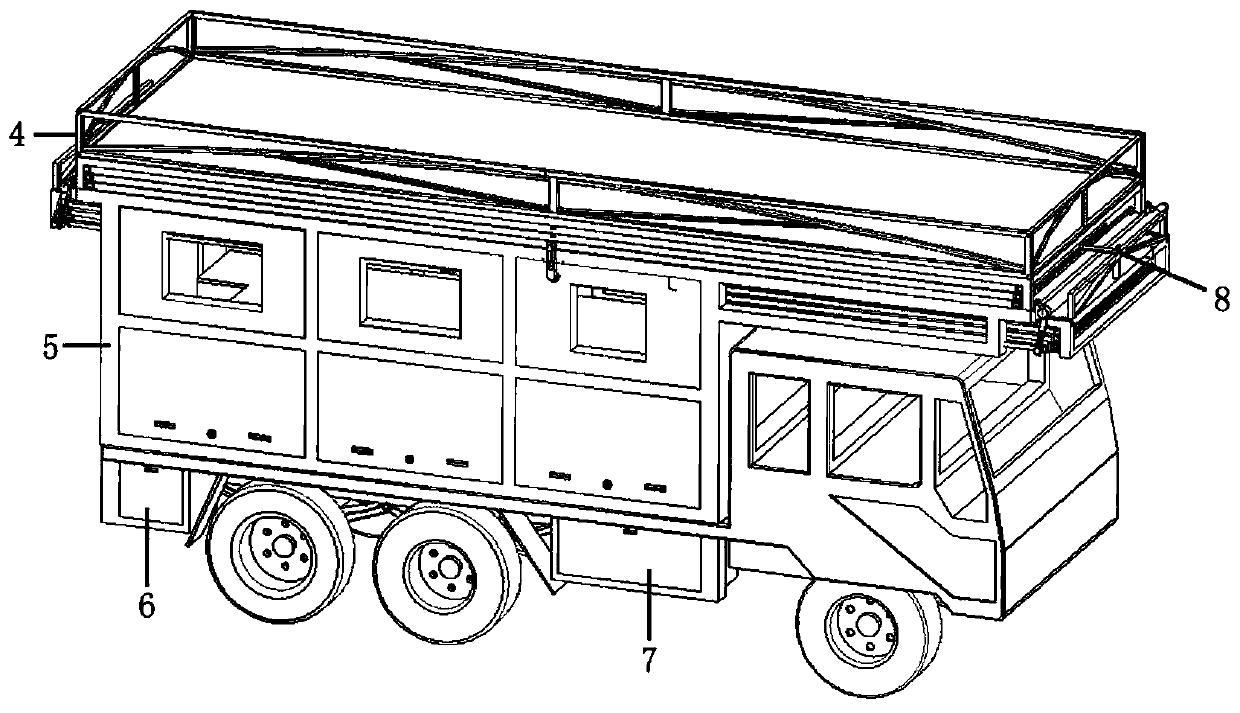

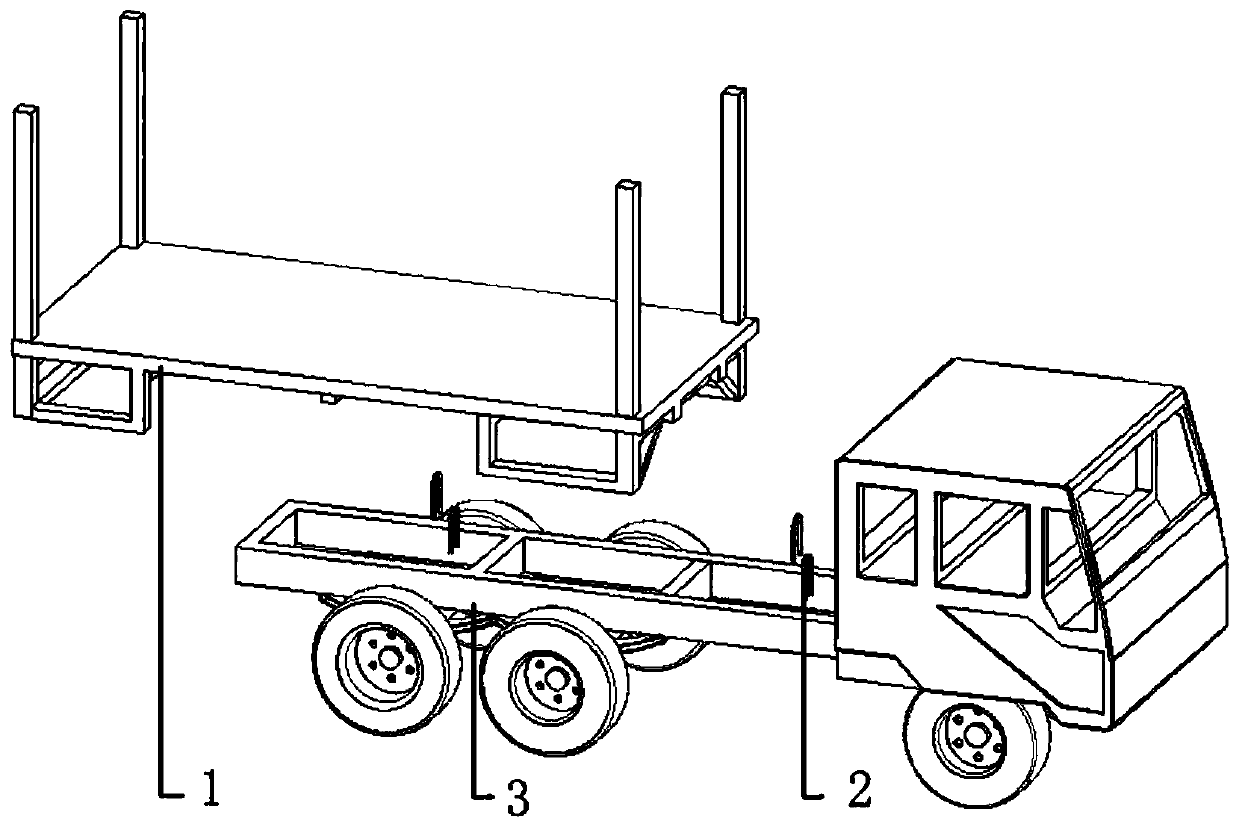

Novel vehicle-mounted equipment field operation repair device

PendingCN111169365AEasy to operateStable structureItem transportation vehiclesServicing equipmentRepair time

The invention discloses a novel vehicle-mounted equipment field operation repair device which can be installed on a vehicle chassis and comprises a hydraulic telescopic maintenance tent, a camouflagenet storage mechanism, a maintenance equipment tool and spare part storage cabinet and a maintainer camping facility. The space layout of equipment loading is optimized; a hydraulic telescopic maintenance tent, a camouflage net storage function, a common spare part storage function, a maintenance equipment tool use function and a maintainer camping function are ingeniously integrated; one equipment rush-repair vehicle has the maintenance function of 2-3 vehicles in the past; under the field operation condition, all elements of field operation repair can be opened or closed by means of the emergency repair vehicle within about 10-15 minutes; the field operation repair tent is simple to operate, stable in structure, convenient and practical, can solve the problems of long field operation repair time, obvious field operation repair tent weather exposure, easiness in damage, inconvenience in disguise of elements and rapid maneuvering transfer in a traditional maintenance guarantee marshalling mode, and can achieve the purpose of rapid equipment maintenance guarantee of troops under field operation conditions.

Owner:中国人民解放军96824部队

Method for Pre-Applied Waterproofing

ActiveUS20160040440A1Avoid stickingAvoid exposureRoof covering using flexible materialsSynthetic resin layered productsTectorial membranePolyvinyl acetate

Disclosed is a waterproofing membrane that comprises a carrier sheet, a pressure sensitive adhesive layer on one surface of the carrier sheet, and a protective coating layer on the adhesive layer. The protective coating layer comprises polyvinyl acetate (PVAc). The protective coating layer protects the membrane against weather exposure, tolerates foot traffic and strongly adheres to concrete cast against it.

Owner:GCP APPL TECH INC

Sweet oil condiment

The invention discloses a sweet oil condiment. The sweet oil condiment is prepared through fermenting two strains, and is prepared in a manner including the steps of processing raw materials, mixing flour and saline water to obtain flour paste, liquifying the flour paste, steaming the liquified flour paste, performing inoculation on the steamed flour paste, and performing heat preservation and fermentation on mixed materials so as to obtain mature soy sauce mash; squeezing the mature soy sauce mash so as to obtain oil materials, performing primary disinfection on the oil materials, blending the oil materials after primary disinfection; and performing secondary disinfection, and discharging sweet oil products. The obtained sweet oil is sweet and fresh, light in color, amber in color, rich in fragrance and pure in flavor. According to the sweet oil provided by the invention, bold innovation is performed on the culture of the strains, the fermentation temperature and the fermentation time in the preparation process of the sweet oil, compared with conventional sweet oil prepared by a conventional technology of weather exposure and natural fermentation, the sweet oil provided by the invention has the advantages that the production cycle is shortened to 20 days from the original 6-12 months, the labor efficiency is improved, the physical labor intensity of workers is alleviated, and all the characteristics of sweet oil products are reserved. According to the sweet oil prepared through heat preservation and fermentation, a liquid enzyme method technology is adopted, the mechanized production and the pipelining production of the sweet oil are realized, and the physical labor intensity of the workers is alleviated. The utilization rate of raw materials is increased, and the labor efficiency is improved. The sweet oil condiment belongs to the innovation of a bio-fermented technique in a brewing condiment trade.

Owner:任佐彬

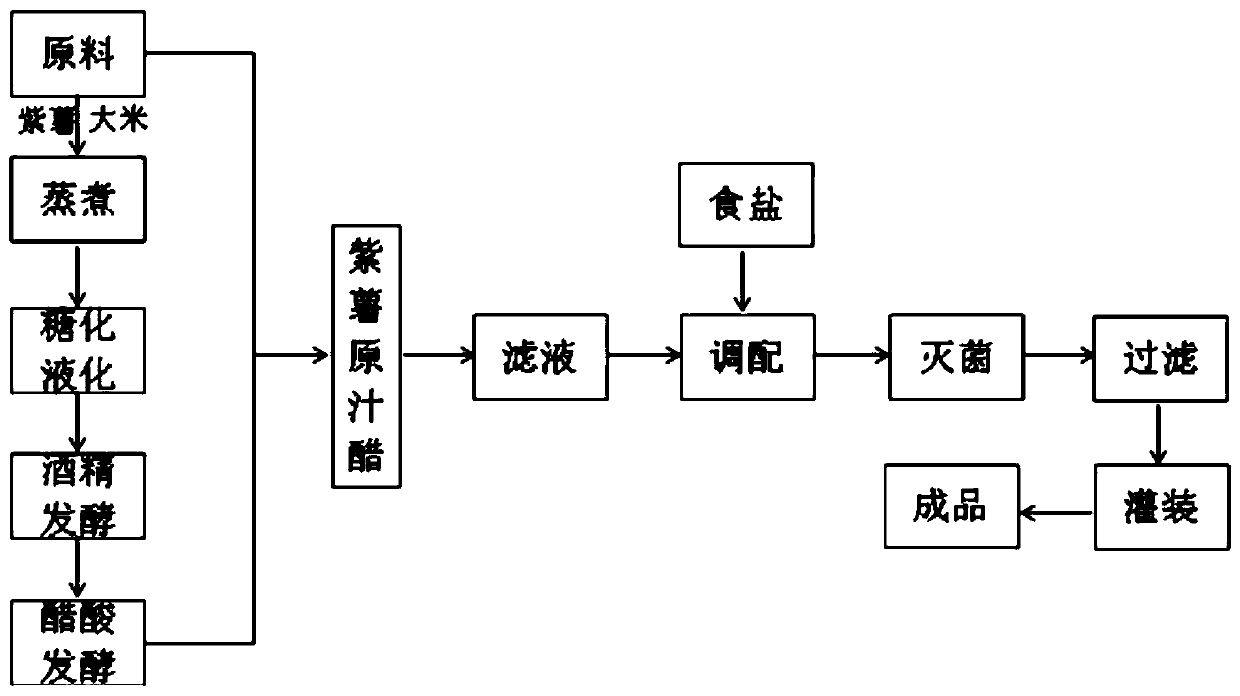

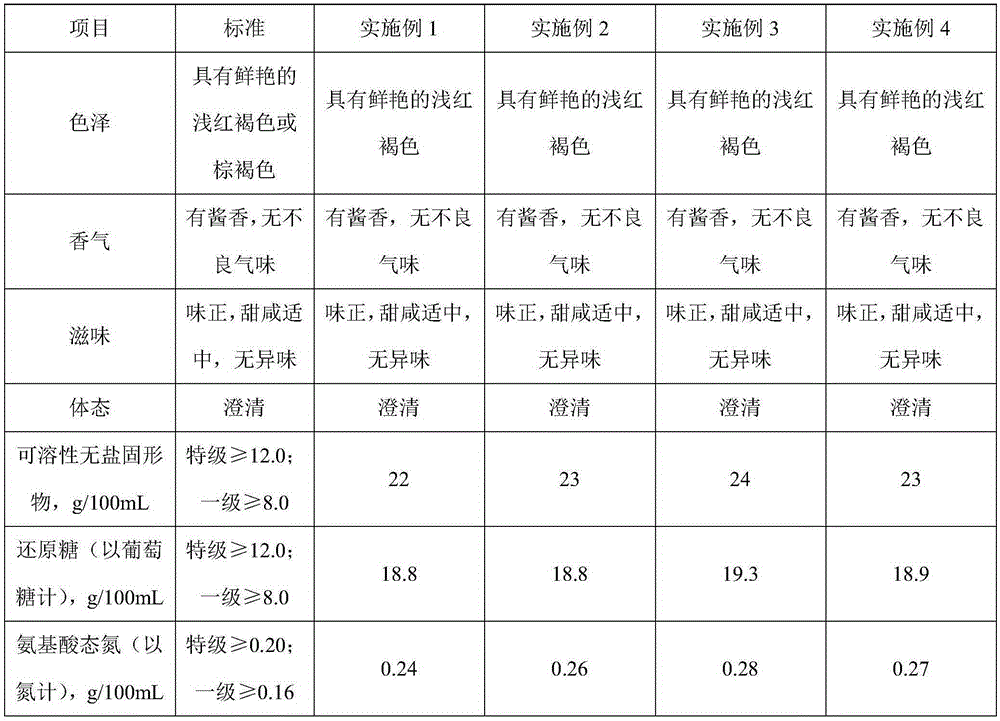

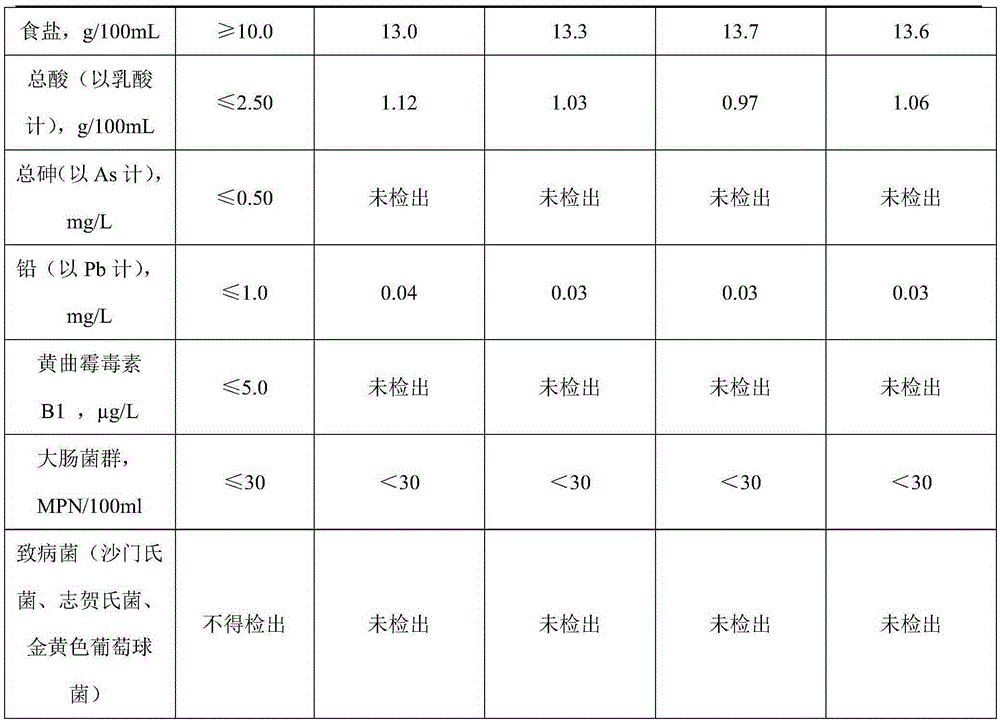

Preparation method of purple sweet potato brewed vinegar

InactiveCN109852528AIncrease appetiteClear and bright colorMicroorganism based processesVinegar preparationBlack yeastFiltration membrane

The invention discloses a preparation method of purple sweet potato brewed vinegar. The preparation method comprises the following steps of using purple sweet potatoes and rice as raw materials, performing crushing, performing mixing, and performing liquifying to obtain mash; performing saccharification at 60-65 DEG C, performing cooling to 34-37 DEG C, adding saccharomyces cerevisiae, and performing fermentation at 30-35 DEG C for 3-5 days so as to obtain wine mash; adding chaff, bran, black yeast and acetic acid bacteria, performing fermentation to obtain vinegar wort, performing acetic acidfermentation for 25-35 days, when the alcoholic strength in the vinegar wort is detected to be less than or equal to 0.5, sprinkling salt, and spraying vinegar so as to obtain purple sweet potato rawvinegar; and performing weather exposure, performing filtration, performing blending with tablet salt, performing high-temperature instantaneous sterilization, and performing filtration membrane filtration so as to obtain the purple sweet potato brewed vinegar finished products. According to the preparation method, the purple sweet potatoes are used as one of main raw materials, the defect that vinegar brewed with purple sweet potatoes as a main raw material is low in alcoholic strength is overcome, and the vinegar high in nutrient value is obtained.

Owner:四川清香园调味品股份有限公司

Shale bronze-imitating sculpture powder

The invention discloses a shale bronze-imitating sculpture powder. The main points of a technical scheme of the invention are as follows: the shale bronze-imitating sculpture powder is composed of shale, acidized zeolite particles, naturally-weathered attapulgite clay, white cement, white carbon black, bronze powder, iron oxide yellow, lemon yellow, rock wool, bronze pearlescent powder and glitter powder. The shale bronze-imitating sculpture powder is prepared through the following steps: subjecting ingredients of a semi-finished shale bronze-imitating sculpture powder to stirring and carrying out milling, then carrying out co-mixing with the ingredients of the shale bronze-imitating sculpture powder under stirring, and carrying out packaging so as to obtain the shale bronze-imitating sculpture powder. By adopting the shale bronze-imitating sculpture powder to manufacture a bronze-imitating sculpture, a bronze-imitating sculpture craft with pure color is obtained after maintenance and hardening; the obtained bronze-imitating sculpture craft has the characteristics of good smooth finish, brightness, high strength, small shrinkage rate, wear resistance and corrosion resistance, can be placed at a variety of places like outdoors, squares, gardens or indoors, is adaptable to weather exposure, and does not deform under exposure to wind and rain; meanwhile, the shale bronze-imitating sculpture powder is applicable to manufacturing of a variety of bronze-imitating sculpture crafts.

Owner:蒋文兰

Montmorillonite bronze-imitative sculpture powder

The invention discloses a montmorillonite imitation bronze sculpture powder. The main point of the technical scheme is that the montmorillonite imitation bronze sculpture powder is composed of naturally weathered bentonite, white cement, acidified bentonite particles, white carbon black, and bronze powder , iron oxide yellow, lemon yellow, rock wool, bronze pearl powder and glitter powder. Firstly, the ingredients of the semi-finished montmorillonite imitation bronze sculpture powder are stirred and ground, and then the ingredients of the montmorillonite imitation bronze sculpture powder are mixed and stirred together, and then packed into the montmorillonite imitation bronze sculpture powder. The imitation bronze sculpture is made of montmorillonite imitation bronze sculpture powder. After maintenance and hardening, it is a bronze-like sculpture handicraft with pure color. It has good finish, bright, high strength, small shrinkage, friction resistance and corrosion resistance. Features, can be placed in various outdoor, square, park or indoor places for a long time, suitable for sun and night dew and wind and rain without deformation, montmorillonite imitation bronze sculpture powder is suitable for making various imitation bronze sculpture crafts.

Owner:XUYI KEYUAN NEW MATERIALS FACTORY

Pumice bronze-imitating sculpture powder

The invention discloses a pumice bronze-imitating sculpture powder. The main points of a technical scheme of the invention are as follows: the pumice bronze-imitating sculpture powder is composed of pumice, acidized zeolite particles, naturally-weathered attapulgite clay, white cement, white carbon black, bronze powder, iron oxide yellow, lemon yellow, rock wool, bronze pearlescent powder and glitter powder. The pumice bronze-imitating sculpture powder is prepared through the following steps: subjecting ingredients of a semi-finished pumice bronze-imitating sculpture powder to stirring and carrying out milling, then carrying out co-mixing with the ingredients of the pumice bronze-imitating sculpture powder under stirring, and carrying out packaging so as to obtain the pumice bronze-imitating sculpture powder. By adopting the pumice bronze-imitating sculpture powder to manufacture a bronze-imitating sculpture, a bronze-imitating sculpture craft with pure color is obtained after maintenance and hardening; the obtained bronze-imitating sculpture craft has the characteristics of good smooth finish, brightness, high strength, small shrinkage rate, wear resistance and corrosion resistance, can be placed at a variety of places like outdoors, squares, gardens or indoors, is adaptable to weather exposure, and does not deform under exposure to wind and rain; meanwhile, the pumice bronze-imitating sculpture powder is applicable to manufacturing of a variety of bronze-imitating sculpture crafts.

Owner:蒋文兰

a sweet oil condiment

The invention discloses a sweet oil condiment which is prepared by fermenting two strains due to modes of raw material treatment, size mixing, liquefying, cooking, inoculating, thermal insulation and fermentation, squeezing, primary sterilization, oil blending, secondary sterilization and discharging. The obtained sweet oil is fresh, sweet, light in color, amber, strong in aroma and pure in flavor. According to the sweet oil provided by the invention, in the preparation process, the strain culture and fermentation temperature and time control are greatly innovated, compared with the original weather exposure, the production period is shortened from 6-12 months to 20 days due to a traditional natural fermentation process, the labor efficiency is improved, the physical labor intensity of workers is alleviated, and all characteristics of the sweet oil product are kept. According to the thermal insulation and fermentation sweet oil, a liquid enzyme process is adopted, so that mechanical and pipeline type sweet oil production is realized, and the physical labor intensity of workers is alleviated. Moreover, the raw material utilization rate is improved, the labor efficiency is improved, and the sweet oil condiment is an innovation of a biological fermentation technology in condiment brewing industry.

Owner:JIANGSU SUQIAN SANYUAN CONDIMENT

White soy sauce and its production method

ActiveCN104381960BFacilitate the promotion of industrial productionShorten the time of anaerobic fermentationFood scienceWeather exposureBran

Owner:朱守允

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com