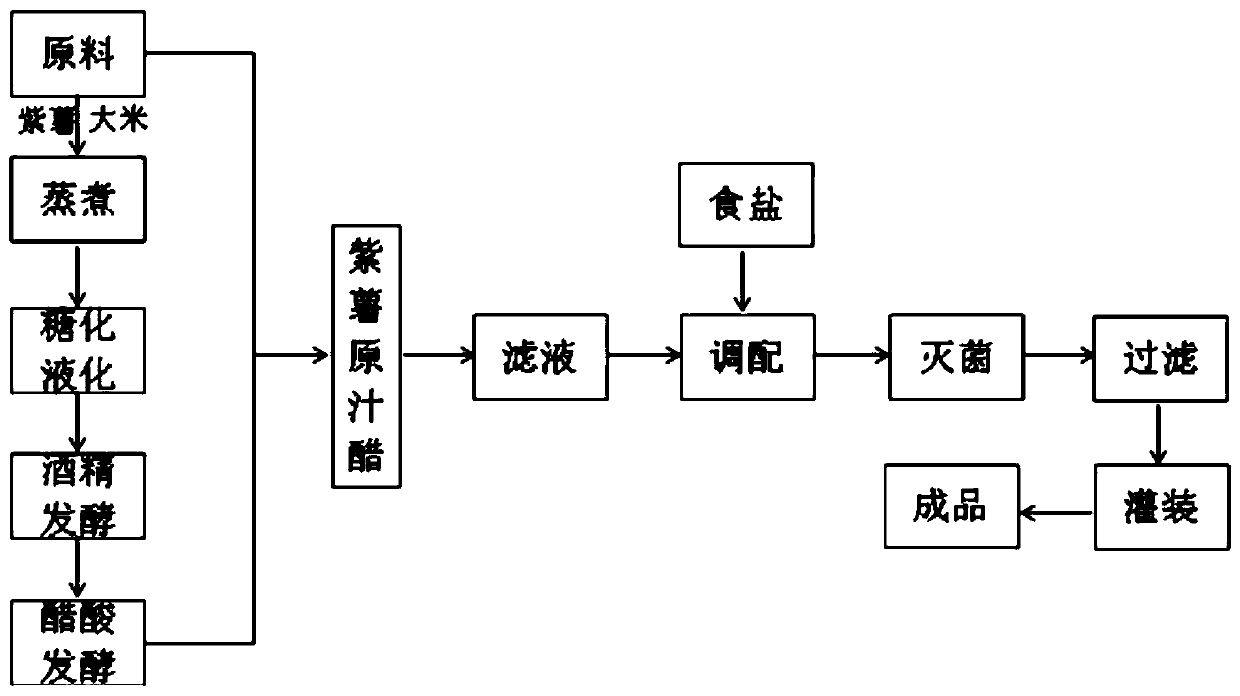

Preparation method of purple sweet potato brewed vinegar

A technology for brewing vinegar and purple potato, which is applied in the preparation of vinegar, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low alcohol content, difficulty in brewing vinegar, etc., achieves high nutritional value, and promotes appetite. , Guarantee the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Grind 50kg of purple sweet potato and 60kg of rice and mix them evenly, add 200kg of water, adjust the pH of purple sweet potato syrup to 6.1, add 0.55kg (0.5% of the mass of purple sweet potato and rice mixture) of α-amylase and cook at 90-95°C After 40 minutes, it was checked with iodine solution, and when it met iodine solution, it turned brownish yellow, completely liquefied, and mash was obtained. Then the mash was cooled to 60° C., 0.55 kg (0.5% of the mass of purple sweet potato and rice mixture) of glucoamylase was added and incubated at a constant temperature of 65° C. for 3 hours to obtain saccharified mash. Cool the saccharified mash to 35° C., add 0.22 kg (0.2% of the mass of purple sweet potato and rice mixture) of Saccharomyces cerevisiae to ferment for 4 days to obtain wine mash. Add 440kg of chaff, 1100kg of bran, and 220kg of black koji to the wine mash, mix well and then add 0.621kg (about 0.3‰ of the mass of the mixture of chaff, bran, black koji and ...

Embodiment 2

[0032] Grind 50kg of purple sweet potato and 50kg of rice and mix them evenly, add 180kg of water, adjust the pH of the purple sweet potato slurry to 6.2, add 0.5% α-amylase in the mixture of purple sweet potato and rice, cook at 90-95°C for 40min, add iodine Liquid inspection, the reaction with iodine solution is brownish yellow, the liquefaction is complete, and the mash is obtained. Then cool the mash to 60° C., add 0.5% glucoamylase of purple potato and rice mixture mass, and incubate at 60° C. for 3 hours to obtain saccharified mash. Cool the saccharified mash to 35°C, add purple sweet potato and Saccharomyces cerevisiae with a mass of 0.2% of the rice mixture, and ferment for 4 days to obtain wine mash; add 420kg of chaff, 840kg of bran, and 140kg of black koji to the wine mash, and mix well Then add acetic acid bacteria with a total mass of 0.3‰ of the mixture of chaff, bran, black koji and wine mash to ferment to obtain vinegar unstrained spirits. After 30 days of ace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com