Production method of jasmine black tea

A production method and technology of flower black tea, which is applied in the production field of jasmine black tea, can solve the problems of lack of taste, monotony, and insufficient aroma of black tea, and achieve the effects of high and long aroma, better aftertaste, and pure, sweet and refreshing taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

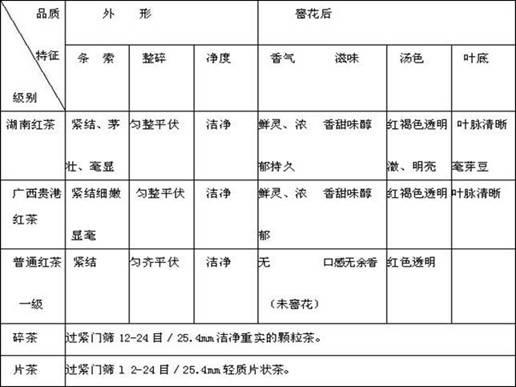

Image

Examples

Embodiment 1

[0030] The production method of jasmine black tea comprises the following steps:

[0031] 1. Withering (langjing). Select fresh tea leaves after sun-drying and the tea leaves cannot be directly greened. They should be withered in an air-conditioned room for 6-20 hours (put them on bamboo mats or rattan mats, the holes are about 0.1-0, and 3 indoors to dry). If it rains, fans are needed Blow-drying, its purpose: First, to ensure the tea leaves after sun-drying have a certain degree of softness, because the leaves of the tea leaves become soft after sun-drying and the stems are still relatively hard; Partial fermentation can achieve the unique taste and aroma of black tea. During the withering process, you can use the palms of both hands to turn the tea leaves, so that the tea leaves rub against each other to damage the tea cells, and the air enters the tea cells to accelerate the fermentation process. Method: After the tea leaves wither in the sun, move them into the witherin...

Embodiment 2

[0042] Directly buy finished dried black tea leaves from the market, and then directly use jasmine flowers to scent the flowers. First, the tea leaves obtained by the above fermentation are dried with hot air for the first time at a temperature of 110-130, 15-30 minutes, or microwave drying for 3 -6 minutes, the first scenting of jasmine flowers, (the volume ratio of tea leaves and jasmine flowers is 1:1-1.2), scenting time 12-16 hours, sieved, sieved broken tea, used to produce black broken tea or as The raw material of tea bricks is then dried for the second time at a temperature of 100-110, 15-30 minutes, or microwaved for 3-6 minutes, and the second time to smell jasmine (the ratio of tea to jasmine is 1:1-1.2), Scented for 12-14 hours, sieved, the sieved broken tea is used to produce black broken tea or as raw material for tea bricks, and then dried for the third time at a temperature of 90-110, 15-30 minutes, or microwave drying 3-6 minutes, smelling jasmine flowers for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com