Production method of raw materials for thick broad-bean sauce

A technology of raw materials and production methods of bean paste, applied in the fields of application, food preparation, food science, etc., can solve the problems of pollution, high energy consumption, etc., and achieve the effects of obvious benefits, simple production methods, and advanced technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

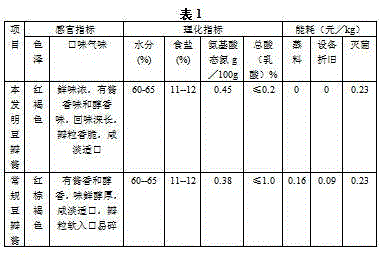

Image

Examples

Embodiment 1

[0022] Embodiment 1-bean adopts broad bean, produces according to the following steps:

[0023] 1. Beans are selected, cleaned, screened, air-selected to remove impurities, peeled, soaked, and drained. Selection refers to the use of physical and mechanical methods to remove impurities and foreign matter; Uniform watercress; soaking refers to soaking the watercress in 30 ℃ water for 3.5 hours, the watercress fully absorbs water, and the watercress has no hard core, then filter out the excess water.

[0024] 2. Dilute mash fermentation: Take 9.0kg of watercress and inoculate Aspergillus oryzae to make koji. Aspergillus oryzae is selected from the purchased Shanghai Niang No. 2 Aspergillus oryzae test tube strain, put the fermented grains into the fermentation tank, and add salt water at a temperature of 60°C to immerse the fermented grains , the amount of salt is 0.1kg, mixed with 9% salt water, the fermentation tank is sealed, kept warm, and fermented at 45°C for 50 days to bec...

Embodiment 2

[0028] Embodiment 2-bean adopts pea, produces according to the following steps:

[0029] 1. Clean and sieve the beans, remove impurities by winnowing, peeling, soaking, and draining. Soaking refers to soaking the watercress in 20°C water for 3 hours. Douban 8.5kg was inoculated with Aspergillus oryzae to make koji. Aspergillus oryzae was selected from the purchased Huyao No. 1 test tube strain of Aspergillus oryzae. The koji fermented grains were put into the fermentation tank, and the temperature was added to immerse the fermented grains in salt water at a temperature of 52 ° C. The amount of salt was 0.15 kg. The concentration is 9.5% salt water, the fermentation tank is sealed, kept warm, and fermented at 40°C for 50 days to become a semi-finished product.

[0030] 2. Stir the semi-finished sauce thoroughly, put it into the post-cooking tank, seal it and place it in the open air with sufficient sunshine for post-cooking for 60 days.

[0031] 3. Add 1.5 kg of vegetable spic...

Embodiment 3

[0032] Example 3. The difference from Example 1 is that soybeans are used as beans, the temperature of the brine in the dilute mash fermentation is 55°C, the concentration is 8.5%, and the heat preservation temperature of the closed fermenter is 38°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com