Method for preparing organic compound fertilizer through sludge generated by processing cassava starch

A technology of tapioca starch and compound fertilizer, which is applied in the direction of organic fertilizer, organic fertilizer preparation, sewage/sludge fertilizer, etc. The effect of healthy growth and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

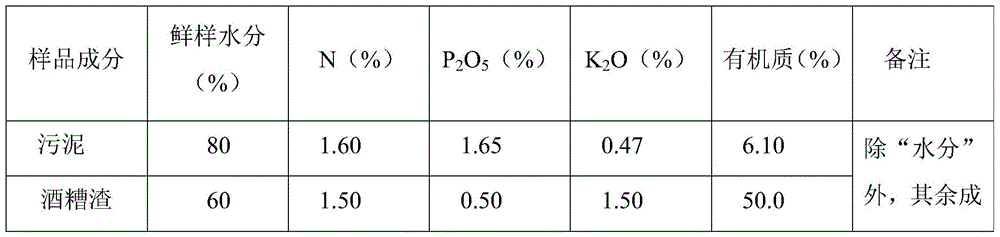

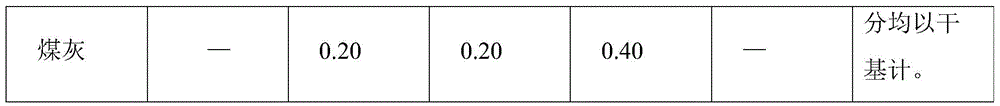

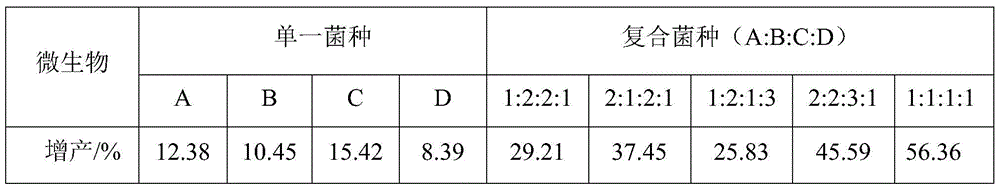

[0031] A kind of method that utilizes the sludge that cassava starch processing produces to prepare organic compound fertilizer, comprises the following steps:

[0032] Step 1. Mix the sludge, distiller's residue and coal ash evenly according to the mass ratio of 2:1:1 to obtain the first mixture, inoculate the first mixture with a microbial agent with a mass fraction of 4%, and stack in a three-dimensional trapezoidal shape Carry out aerobic fermentation for 10 days to obtain the first fermentation product. During the aerobic fermentation, turn the heap 1-3 times a day to control the moisture content at 25%-45%, and the temperature between 40-60°C. The sludge is used to produce cassava The sludge waste obtained by starch, the microbial bacterial agent is composed of Bacillus amyloliquefaciens, Bacillus colloid, Bacillus subtilis and Bacillus megaterium in a mass ratio of 1:1:1:1;

[0033] Step 2: Add mixed fertilizer to the first fermentation product and mix to obtain the sec...

Embodiment 2

[0036] A kind of method that utilizes the sludge that cassava starch processing produces to prepare organic compound fertilizer, comprises the following steps:

[0037] Step 1. Mix the sludge, wine tank slag and coal ash uniformly according to the mass ratio of 4:1:1 to obtain the first mixture, inoculate the first mixture with a microbial agent with a mass fraction of 5%, and stack in a three-dimensional trapezoidal shape Carry out aerobic fermentation for 12 days to obtain the first fermentation product. During the aerobic fermentation, turn the heap 1-3 times a day to control the moisture content at 35%-45%, and the temperature between 40-60°C. The sludge is used to produce cassava The sludge waste obtained by starch, the microbial bacterial agent is composed of Bacillus amyloliquefaciens, Bacillus colloid, Bacillus subtilis and Bacillus megaterium in a mass ratio of 1:1:1:1;

[0038] Step 2. Add mixed fertilizer to the first fermentation product and mix to obtain the secon...

Embodiment 3

[0041] A kind of method that utilizes the sludge that cassava starch processing produces to prepare organic compound fertilizer, comprises the following steps:

[0042] Step 1. Mix the sludge, wine tank slag and coal ash evenly according to the mass ratio of 5:1:1 to obtain the first mixture, inoculate the first mixture with a microbial agent with a mass fraction of 6%, and stack in a three-dimensional trapezoidal shape Carry out aerobic fermentation for 15 days to obtain the first fermentation product. During the aerobic fermentation, turn the heap 1-3 times a day to control the moisture content at 25%-45%, and the temperature between 40-60°C. The sludge is used to produce cassava The sludge waste obtained by starch, the microbial bacterial agent is composed of Bacillus amyloliquefaciens, Bacillus colloid, Bacillus subtilis and Bacillus megaterium in a mass ratio of 1:1:1:1;

[0043] Step 2. Add mixed fertilizer to the first fermentation product and mix to obtain the second m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com