Method for promoting degradation of pollutants in excess sludge and producing fatty acid

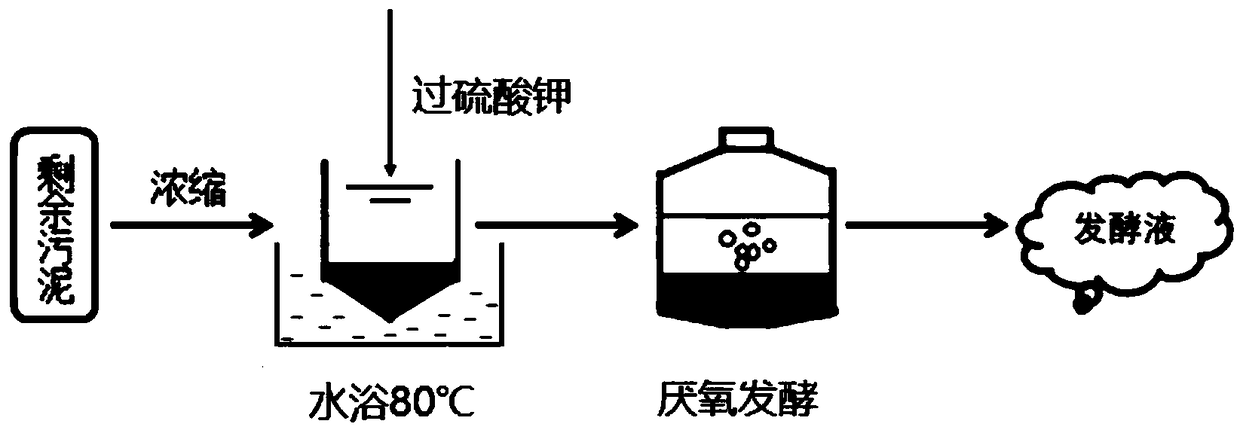

A technology of excess sludge and fatty acid, applied in fermentation and other directions, can solve the problems of slow reaction rate and insignificant degradation effect of organic matter, and achieve the effect of promoting dissolution, shortening time and improving acid production rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

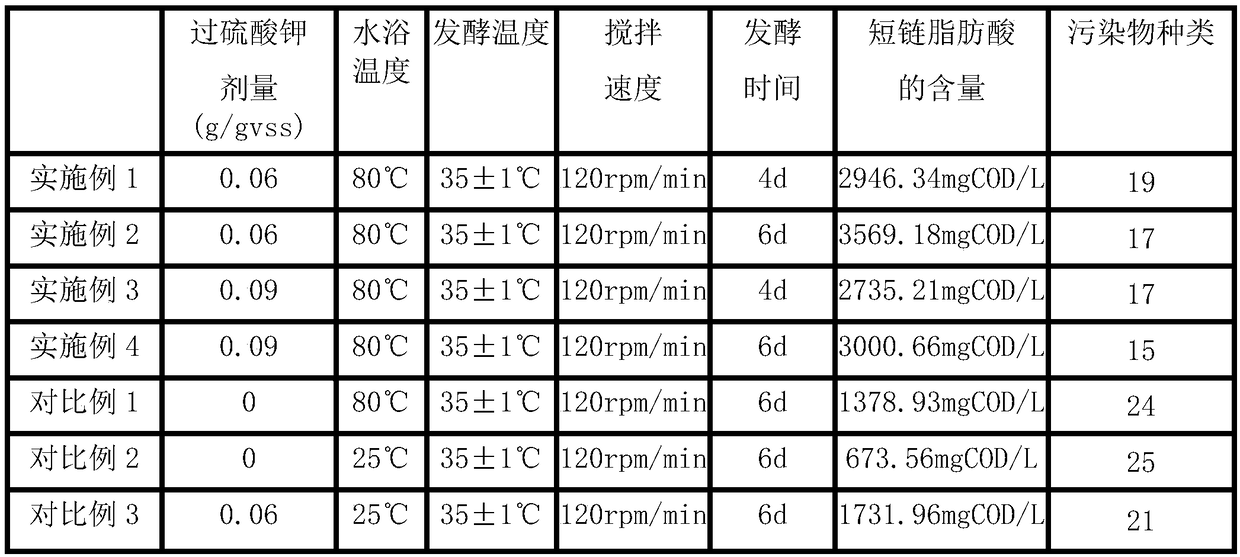

Embodiment 1

[0026] (1) In a plexiglass reactor with a working volume of 5.0L, the excess sludge discharged from the sewage treatment plant was naturally precipitated at 4 °C for 24 hours, and the supernatant was discarded and concentrated to obtain the required sludge sample. Sludge samples as substrates for anaerobic fermentation to produce short-chain fatty acids;

[0027] (2) Add 0.06g / g VSS K to the plexiglass reactor 2 SO 4 , pretreated for 60 min in a water bath at 80 °C with a shaking intensity of 150 rpm. The plexiglass reactor was fed with nitrogen at a rate of 0.5L / min for 1.5min to remove oxygen therein, and the plexiglass reactor was sealed and placed in a shaker for anaerobic fermentation. Through the temperature and the combined action of microorganisms and potassium persulfate in the sludge sample, the organic matter (mainly polysaccharides and proteins) in the sludge sample is converted into short-chain fatty acids, and the sulfate radicals generated oxidize some of the ...

Embodiment 2

[0029] (1) In a plexiglass reactor with a working volume of 5.0L, the excess sludge discharged from the sewage treatment plant was naturally precipitated at 4 °C for 24 hours, and the supernatant was discarded and concentrated to obtain the required sludge sample. Sludge samples as substrates for anaerobic fermentation to produce short-chain fatty acids;

[0030] (2) Add 0.06g / g VSS K to the plexiglass reactor 2 SO 4 , pretreated for 60 min in a water bath at 80 °C with a shaking intensity of 150 rpm. The plexiglass reactor was fed with nitrogen at a rate of 0.5L / min for 1.5min to remove oxygen therein, and the plexiglass reactor was sealed and placed in a shaker for anaerobic fermentation. Through the temperature and the combined action of microorganisms and potassium persulfate in the sludge sample, the organic matter (mainly polysaccharides and proteins) in the sludge sample is converted into short-chain fatty acids, and the sulfate radicals generated oxidize some of the ...

Embodiment 3

[0032] (1) In a plexiglass reactor with a working volume of 5.0L, the excess sludge discharged from the sewage treatment plant was naturally precipitated at 4 °C for 24 hours, and the supernatant was discarded and concentrated to obtain the required sludge sample. Sludge samples as substrates for anaerobic fermentation to produce short-chain fatty acids;

[0033] (2) Add 0.09g / g VSS K to the plexiglass reactor 2 SO 4, pretreated for 60 min in a water bath at 80 °C with a shaking intensity of 150 rpm. The plexiglass reactor was fed with nitrogen at a rate of 0.5L / min for 1.5min to remove oxygen therein, and the plexiglass reactor was sealed and placed in a shaker for anaerobic fermentation. Through the temperature and the combined action of microorganisms and potassium persulfate in the sludge sample, the organic matter (mainly polysaccharides and proteins) in the sludge sample is converted into short-chain fatty acids, and the sulfate radicals generated oxidize some of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com