Activated calcium carbonate for increasing acid production rate of fermentation organic acid and preparation method of activated calcium carbonate

A technology of active calcium carbonate and organic acid calcium, applied in the field of microbial fermentation, can solve the problems of large particle size, prolonged fermentation time, weak pH adjustment ability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

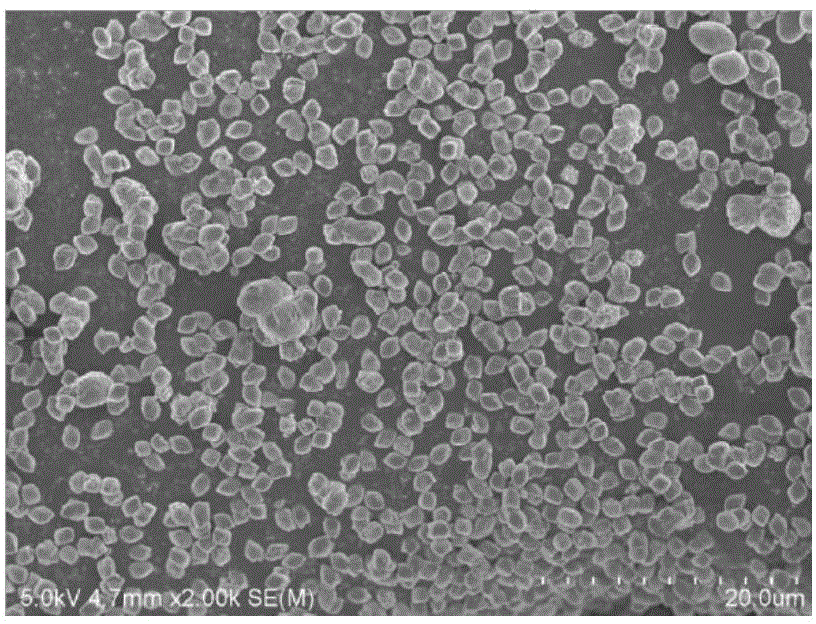

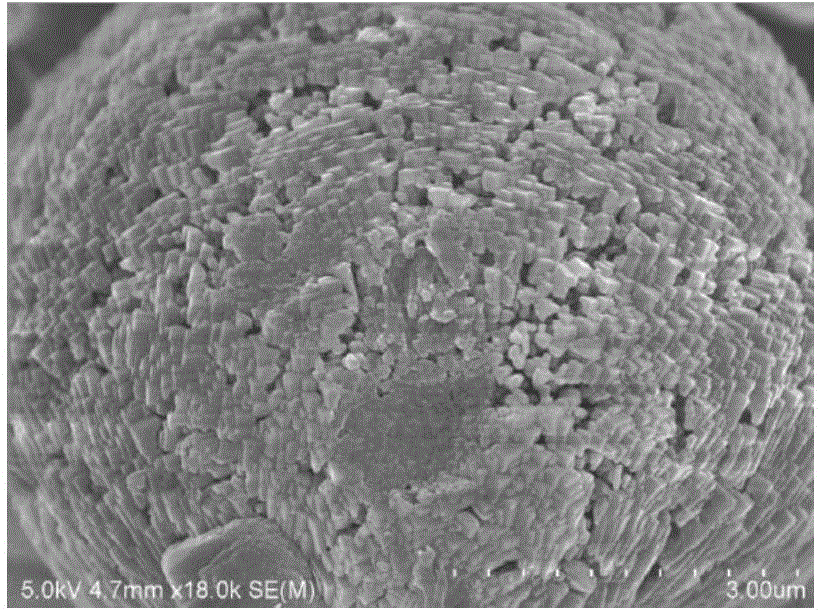

[0057]Preparation of active calcium carbonate to increase the acid production rate of fermented organic acids: Measure 6.6L of fermented liquid with a calcium lactate concentration of 170g / L to remove bacteria, pour it into a fermenter with a volume of 10.0L, and set the temperature to 30°C. The stirring speed is 110r / min; after the temperature is stabilized, add 1350mL of 4.0mol / L ammonium carbonate solution into the preparation container through the feeding system of the fermenter, and seal the preparation container after adding it completely at one time; keep the temperature at 22°C and stir The rotating speed is 110r / min, and after 600min, the reaction is completed; use the method of filtration (with qualitative filter paper as the filter medium) to carry out solid-liquid separation, and the solid obtained is the active calcium carbonate that improves the acid production rate of fermented organic acids, which contains carbonic acid Calcium is about 468g.

[0058] The chara...

Embodiment 2

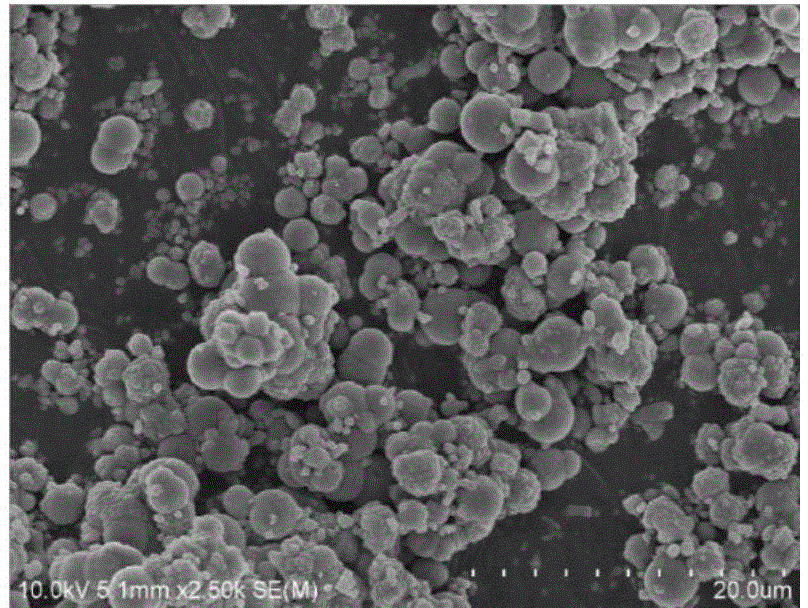

[0061] Preparation of active calcium carbonate to increase the acid production rate of fermented organic acids: Measure 4.1L of fermented broth with a calcium lactate concentration of 220g / L to remove bacteria, pour it into a fermenter with a volume of 7.0L, and set the temperature to 36°C. The stirring speed is 200r / min; after the temperature is stabilized, add 496g of ammonium carbonate solid, the molar ratio of its carbonate group to calcium ion is 1.2:1.0, then seal the feeding port; keep the temperature at 36°C and the stirring speed at 200r / min, After 30min, the reaction was completed; use the method of filtration (with qualitative filter paper as the filter medium) to carry out solid-liquid separation, and the solid obtained is the active calcium carbonate that improves the acid production rate of fermented organic acids, which contains about 400g of calcium carbonate.

[0062] The characteristics of the active calcium carbonate obtained to improve the acid production ra...

Embodiment 3

[0066] Preparation of active calcium carbonate to improve the acid production rate of fermented organic acids: Measure 4.7L of fermented liquid with a calcium lactate concentration of 190g / L without bacteria removal, and pour it into a fermenter with a volume of 7.0L. This fermenter has two Set the ventilation pipeline, the gas outlet is located at the bottom of the fermentation tank, set the temperature at 30°C, and the stirring speed at 300r / min; after the temperature stabilizes, introduce carbon dioxide gas and ammonia gas at the same time, and use a carbon dioxide mass flow meter to measure the input and discharge of fermentation The amount of gas in the tank is adjusted by pH feedback to adjust the rate of ammonia gas introduction; when the amount of carbon dioxide reacted reaches 4.33mol, stop the introduction of carbon dioxide, use ammonia gas to adjust the pH of the liquid to 8.0, stop ventilation, and react after 60 minutes It took a total of 7 hours to complete; the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com