A kind of Aspergillus niger seed continuous culture and method for producing citric acid thereof

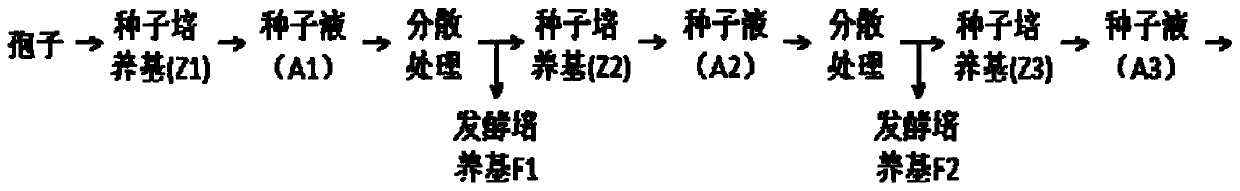

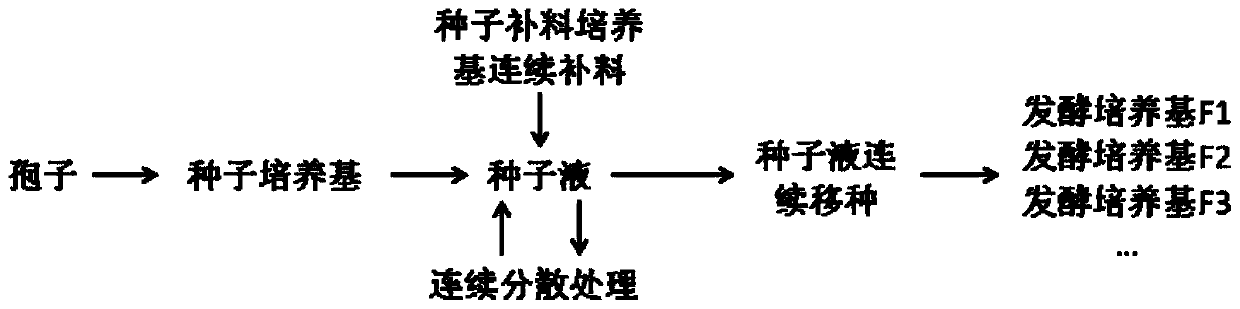

A technology of Aspergillus niger spores and Aspergillus niger, which is applied in the field of continuous cultivation of Aspergillus niger seeds and the production of citric acid, which can solve the problems of slow growth of multicellular filamentous bacteria and easy loss of mycelium balls, and reduce the auxiliary time of starting and stopping , Auxiliary time saving, stable fermentation index effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Corn flour and tap water are mixed evenly in a mass ratio of 1:3, and Ca(OH) 2 Adjust the pH of the slurry to 6.0, and add α-high-temperature amylase according to the amount of 20U / g corn flour; after spraying and liquefying, the iodine test turns light brown to obtain a qualified corn liquefaction liquid; pass 80% of the corn liquefaction liquid through the plate frame Filter and remove the filter residue to obtain corn syrup.

[0039] Start-up stage: the corn liquefaction solution and ammonium sulfate are prepared into a seed medium (total sugar 100g / L, C / N is 20), after sterilization and cooling, Aspergillus niger spores are inoculated into the seed medium, and the final concentration of spores is 9*10 5 cells / mL, cultured for 16 hours at a temperature of 35°C, an air volume of 0.2vvm, a tank pressure of 0.05Mpa, and a stirring speed of 100rpm to obtain a seed liquid.

[0040] Continuous stage: The corn liquefaction liquid and ammonium sulfate are prepared into a se...

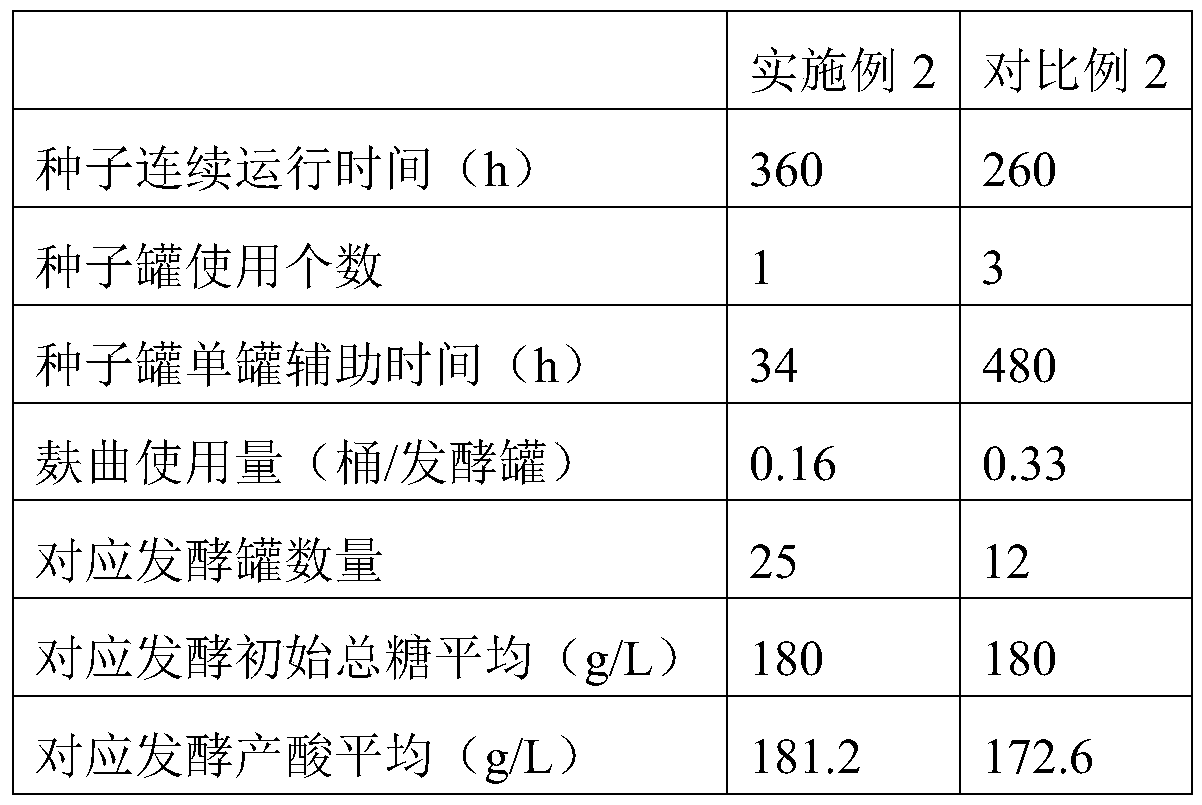

Embodiment 2

[0044] Corn flour and tap water are mixed evenly in a mass ratio of 1:3, and Ca(OH) 2 Adjust the pH of the slurry to 6.0, and add α-high-temperature amylase according to the amount of 20U / g corn flour; after spraying and liquefying, the iodine test turns light brown to obtain a qualified corn liquefaction liquid; pass 80% of the corn liquefaction liquid through the plate frame Filter and remove the filter residue to obtain corn syrup. Cassava flour and tap water are mixed evenly in a mass ratio of 1:3, and Ca(OH) 2 Adjust the pH of the slurry to 6.0, and add α-high temperature amylase according to the amount of 20U / g cassava flour; after jet liquefaction, the iodine test turns light brown to obtain a qualified cassava syrup.

[0045] Start-up stage: The corn liquefaction solution and urea are prepared into the seed medium (total sugar 140g / L, C / N is 30), after sterilization and cooling, the Aspergillus niger spores are inoculated into the seed medium, and the final concentrat...

Embodiment 3

[0050] Corn flour and tap water are mixed evenly in a mass ratio of 1:3, and Ca(OH) 2 Adjust the pH of the slurry to 6.0, and add α-high-temperature amylase according to the amount of 20U / g corn flour; after spraying and liquefying, the iodine test turns light brown to obtain a qualified corn liquefaction liquid; pass 80% of the corn liquefaction liquid through the plate frame Filter and remove the filter residue to obtain corn syrup. Wheat starch and tap water are mixed evenly in a mass ratio of 1:3, and Ca(OH) 2 Adjust the pH of the slurry to 6.0, and add α-high temperature amylase according to the amount of 20U / g wheat starch; after jet liquefaction, the iodine test turns light brown to obtain qualified wheat sugar liquid.

[0051] Start-up stage: Prepare corn liquefaction liquid and soybean meal powder to make seed medium (total sugar 180g / L, C / N is 40), inoculate Aspergillus niger spores into the seed medium after sterilization and cooling, the final concentration of spo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com