Method for promoting hydrogen production by anaerobic fermentation of remaining activated sludge

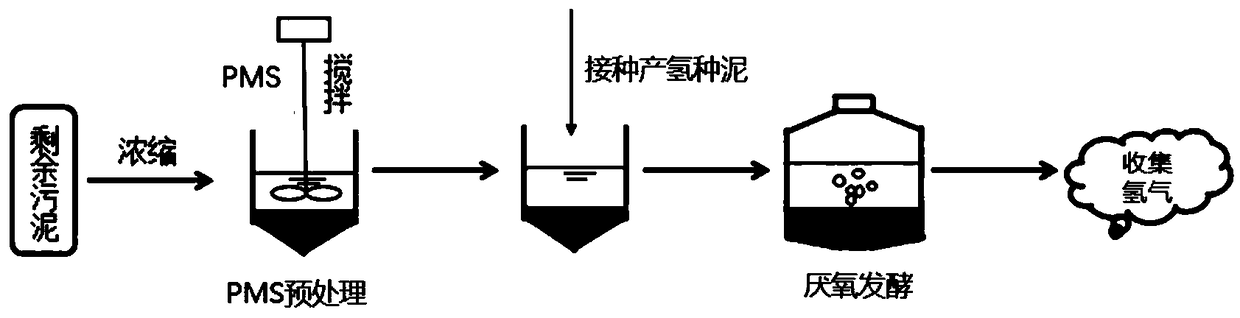

A technology for excess sludge and sludge is applied in the field of anaerobic fermentation of sludge pretreated with potassium hydrogen persulfate compound salt to produce hydrogen, which can solve the problems of serious secondary pollution, complex process control, large energy consumption, etc. The effect of processing cost, improving hydrogen production rate and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a plexiglass reactor with a working volume of 5.0L, the remaining sludge discharged from the sewage treatment plant was naturally precipitated at 4°C for 24 hours, and the supernatant was discarded and concentrated to obtain the required sludge sample. Sludge samples are used as substrates for anaerobic fermentation to produce hydrogen;

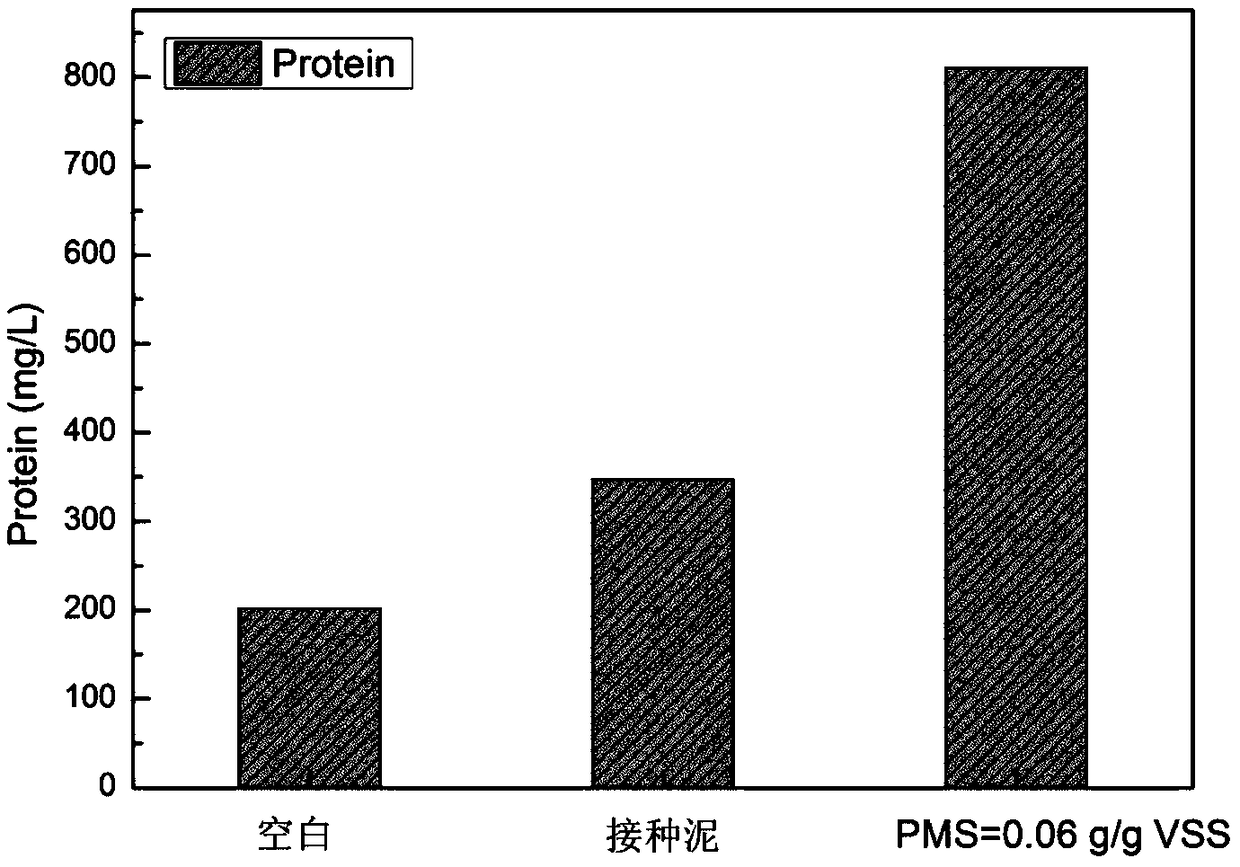

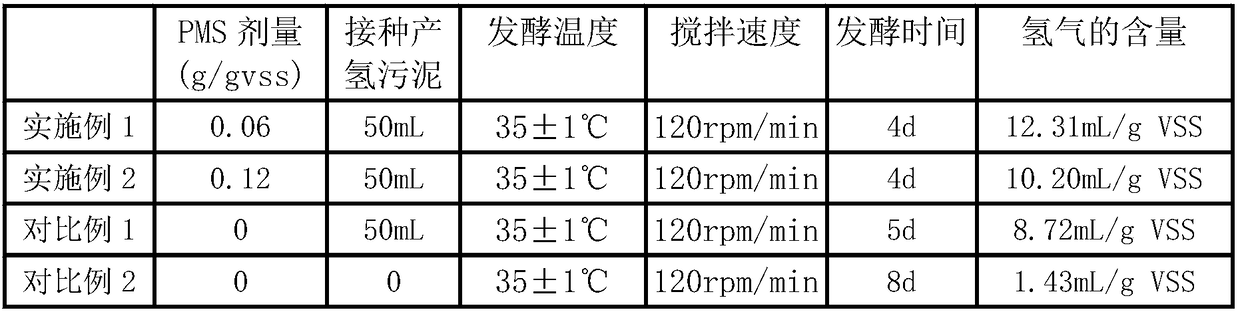

[0028] (2) Get 500 mL of the fermentation substrate obtained in step (1) in the anaerobic reactor, add 0.06 g / g VSS potassium monopersulfate compound salt (PMS), and stir rapidly at 300 rpm for 5 min earlier with a magnetic stirrer, Stir again at 150rpm for 100min to fully mix the agent with the sludge. Inoculate 50ml of hydrogen-producing seed slime into the anaerobic reactor, fill the anaerobic reactor with nitrogen for 1.5min to remove the oxygen in it, seal the anaerobic reactor and put it into a shaker for anaerobic fermentation to produce hydrogen. Among them, the shaker fermentation temperature is 35±1°C, the oscillation...

Embodiment 2

[0030] (1) In a plexiglass reactor with a working volume of 5.0L, the remaining sludge discharged from the sewage treatment plant was naturally precipitated at 4°C for 24 hours, and the supernatant was discarded and concentrated to obtain the required sludge sample. Sludge samples are used as substrates for anaerobic fermentation to produce hydrogen;

[0031] (2) Get 500mL of the fermentation substrate obtained in step (1) in the anaerobic reactor, add 0.12g / g VSS potassium peroxymonosulfate compound salt (PMS), and stir rapidly at 300rpm earlier with a magnetic stirrer for 5min, Stir again at 150rpm for 100min to fully mix the agent with the sludge. Inoculate 50ml of hydrogen-producing seed slime into the anaerobic reactor, fill the anaerobic reactor with nitrogen for 1.5min to remove the oxygen in it, seal the anaerobic reactor and put it into a shaker for anaerobic fermentation to produce hydrogen. Among them, the shaker fermentation temperature is 35±1°C, the oscillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com