Assembly type steel rib reinforcing cell concrete composite floor slab and production method thereof

A concrete and prefabricated technology, applied in floors, building components, ceramic molding machines, etc., can solve the problems of poor thermal insulation and sound insulation, high material consumption, cumbersome construction, etc., and achieve good thermal performance, good frost resistance, Good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

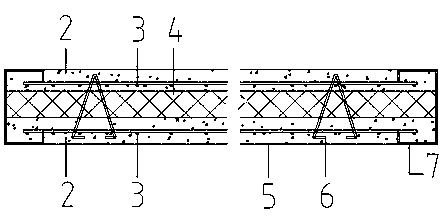

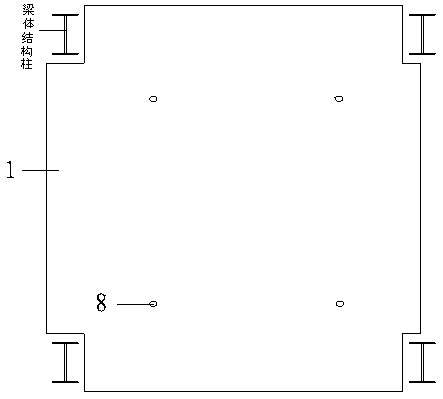

[0016] Such as Figure 1 ~ Figure 2 As shown, the composite floor is prefabricated according to the structural requirements. The prefabricated steel reinforced microporous concrete composite floor 1 is composed of lightweight microporous concrete 2, thermal insulation polystyrene board 4 with a bulk density of 18kg / m3 and steel mesh 3 of ∮4@50 It is placed in the light steel keel frame 7 and is integrally composited without gaps. The surface of the light steel keel frame 7 is sprayed with galvanized coating, the surface of the tripod and the steel mesh is sprayed with epoxy coating anti-rust paint, and the polystyrene insulation board 4 is a flame-retardant polystyrene foam board.

[0017] Lightweight microporous concrete is lightweight microporous concrete paste 2 with LC10 strength grade. Lightweight microporous concrete paste 2 uses 400~500kg of new early-strength quick-hardening cement (application number: 200510094428.1) as the cementing material, 320~400kg of quick-hard...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com