Method for rehabilitating concrete surface injury using high-strength abrasion-proof basalt fibre mortar

A basalt fiber and concrete surface technology, which is applied in building maintenance, bridge maintenance, sea area engineering, etc., can solve the problems of poor cement matrix adhesion, low strength and modulus, and high cost of steel fiber, and achieve good bonding performance and chemical Good stability and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1 uses the method for repairing concrete surface trauma with high-strength wear-resistant basalt fiber mortar, and its method steps are as follows:

[0022] Treatment of spalling concrete on the surface of the lock chamber wall:

[0023] 1. Use mechanical methods to chisel the repaired surface, then blow it with high-pressure gas, rinse the surface with water, and finally spray the repaired surface with water to moisturize and maintain for 24 hours;

[0024] 2. Preparation of high-strength wear-resistant basalt fiber mortar: After fully mixing 700kg of cement, 1050kg of sand, 182kg of water, 4.9kg of high-efficiency water reducer β-naphthalenesulfonic acid formaldehyde condensate and 1.06kg of basalt fiber, it is made by fully stirring ;

[0025] 3. Brushing the adhesive: First, paint the repaired surface with the acrylic milk paste adhesive, and evenly brush the adhesive on the adhesive layer with a paint brush, and then paint the basalt fiber mortar prepar...

Embodiment 2

[0028] 1. Raw materials

[0029] The cement adopts No. 425 cement;

[0030] The sand is coarse quartz sand with a fineness modulus of 3.7 to 3.1, and the particles larger than 5mm are screened out;

[0031] High-efficiency water reducer is β-naphthalenesulfonate formaldehyde condensate

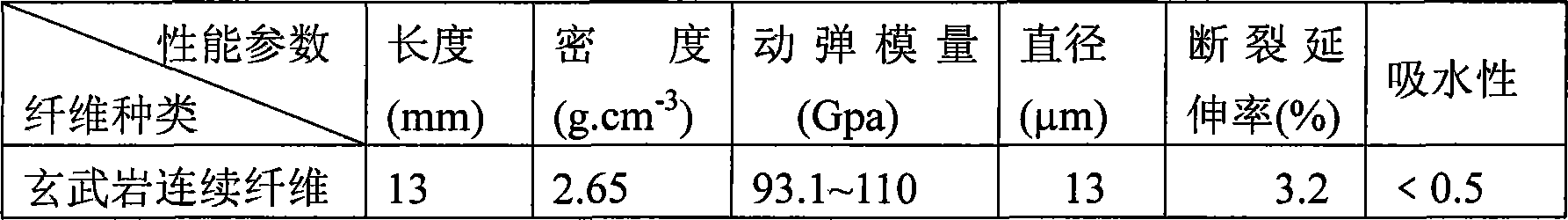

[0032] Basalt fiber properties:

[0033] Table 1 Performance parameters of basalt continuous fiber

[0034]

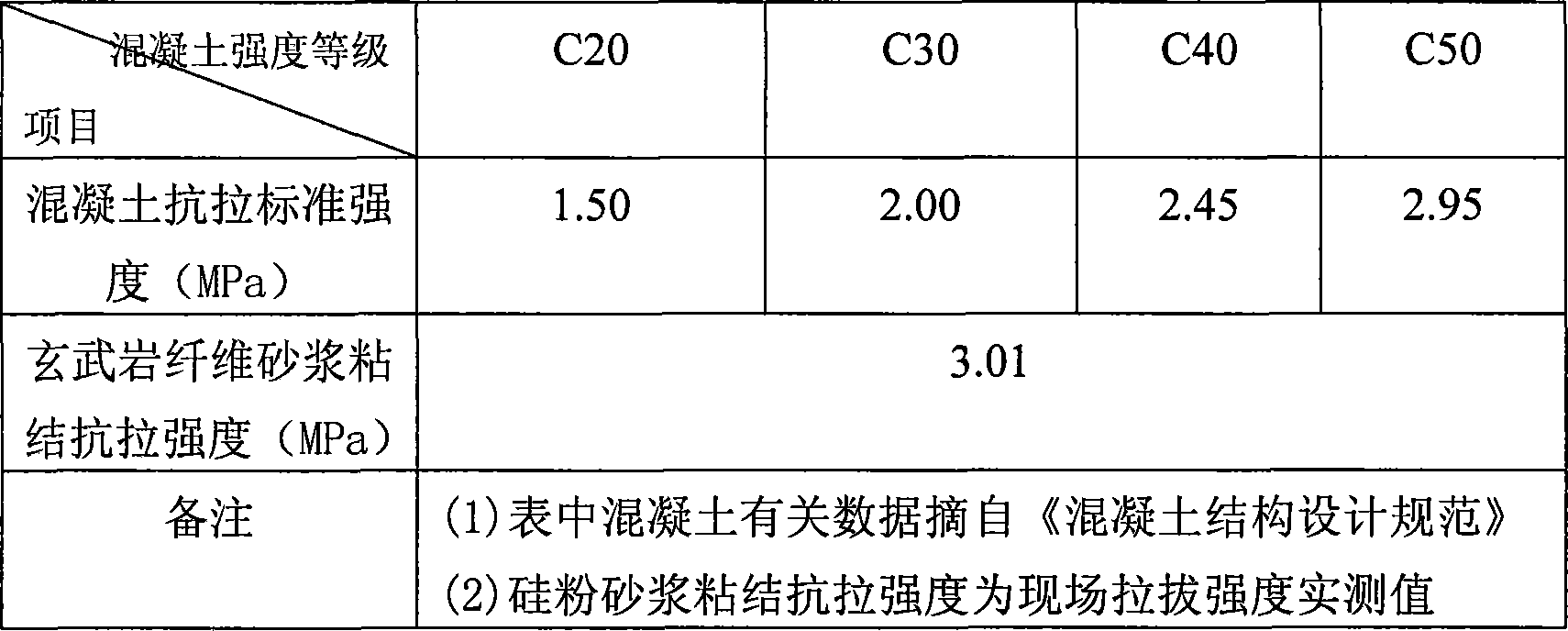

[0035] 2. Performance index of basalt fiber mortar

[0036] The test performance of basalt fiber mortar and its blank sample is shown in Table 2:

[0037] Table 2 Test performance of basalt fiber mortar

[0038] performance

blank sample

28d compressive strength (MPa)

68.2

81.1

28d flexural strength (MPa)

10.2

14.3

Shrinkage rate×10-4(%)

1d

3.886

2.121

28d

8.215

7.684

28d tensile strength (MPa)

4.78

5.75

Bond strength between 28d and ...

Embodiment 3

[0043] Treatment of spalling concrete on the surface of the lock chamber wall:

[0044] 1. Use mechanical methods to chisel the repaired surface, then blow it with high-pressure gas, rinse the surface with water, and finally spray the repaired surface with water to moisturize and maintain for 24 hours;

[0045] 2. Preparation of high-strength wear-resistant basalt fiber mortar: After fully mixing 700kg of No. 425 cement, 1050kg of sand, 182kg of water, 4.9kg of β-naphthalenesulfonate formaldehyde condensate superplasticizer and 1.06kg of basalt fiber, fully stir Uniformly made, ready to use;

[0046] 3. Brushing the adhesive: First, paint the repaired surface with the acrylic milk paste adhesive, and evenly brush the adhesive on the adhesive layer with a paint brush, and then paint the basalt fiber mortar prepared above to repair the concrete surface after a little dry .

[0047] 4. Painting and maintenance, the painting steps are one coating, two leveling and three calender...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com