Semi-flexible pavement injection grout

A semi-flexible pavement and mud technology, applied in the field of materials, can solve problems such as pinholes, linear cracks, surface cracks, etc., and achieve the effects of improving road performance, prolonging service life, and reducing dry shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

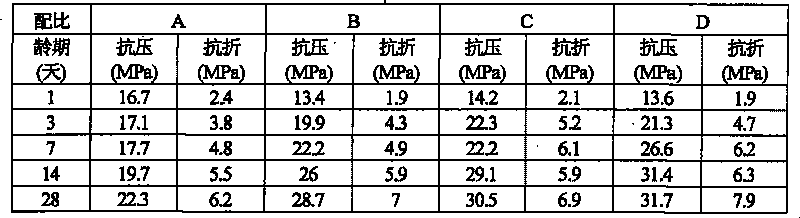

Embodiment 1

[0031] Taking the preparation of semi-flexible pavement perfusion cement slurry 100kg of the present invention as an example, the raw materials used and their mass proportions are:

[0032] Qinling 42.5# cement 59.4072kg

[0033] Water 33.5807kg

[0034] TH-928 polycarboxylate superplasticizer 0.637kg

[0035] UEA expansion agent 6.37kg

[0036] ZY-99 type triterpene saponin air-entraining agent 0.0051kg

[0037] Its preparation method is as follows:

[0038] Take water, Qinling 42.5# cement, TH-928 polycarboxylate water reducer, UEA expansion agent and ZY-99 type triterpene saponin air-entraining agent according to the mass parts proportioning of the present invention, and water, TH-928 polycarboxylate Water reducer and ZY-99 type triterpene saponin air-entraining agent are mixed to make a mixed liquid, then Qinling 42.5# cement and UEA expansion agent are put into a mixing pot, stirred evenly with a mixer, added the mixed liquid, stirred until uniform, and prepared Fill...

Embodiment 2

[0040] Taking the preparation of semi-flexible pavement pouring cement slurry 100kg of the present invention as an example, the raw materials used and their proportioning ratio are as follows:

[0041] Qinling 42.5# cement 54.0064kg

[0042] Water 37.3kg

[0043]TH-928 polycarboxylate superplasticizer 0.662kg

[0044] UEA expansion agent 7.944kg

[0045] ZY-99 type triterpene saponin air-entraining agent 0.0876kg

[0046] The preparation method is the same as that of Example 1, and the cement slurry is poured into the semi-flexible pavement.

Embodiment 3

[0048] Taking the preparation of semi-flexible pavement pouring cement slurry 100kg of the present invention as an example, the raw materials used and their proportioning ratio are as follows:

[0049] Qinling 42.5# cement 65.6958kg

[0050] Water 33.1kg

[0051] TH-928 polycarboxylate superplasticizer 0.001kg

[0052] UEA expansion agent 1.2032kg

[0053] ZY-99 type triterpene saponin air-entraining agent 0kg

[0054] The preparation method is the same as that of Example 1, and the cement slurry is poured into the semi-flexible pavement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com