Coal ash solidifying agent for coal ash building materials

A technology of fly ash and binder, which is applied in the field of building material production, can solve the problems of large dry shrinkage and non-freeze-resistant fly ash binder, etc., achieves low dry shrinkage, promotes rational utilization, and is easy to use raw materials. the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of fly ash consolidation agent for fly ash building materials, the raw material of described fly ash consolidation agent comprises clinker, granulated blast furnace slag, gypsum, lime, crystal nuclide, described clinker, The ratio of parts by weight of granulated blast furnace slag, gypsum, lime and crystal nuclide is:

[0040] Clinker 10~30

[0041] Granulated blast furnace slag 50~70

[0042] Gypsum 10~20

[0043] Lime 5~15

[0044] Crystal nuclides 2~5.

[0045] The clinker is a semi-finished product obtained by using limestone, clay and iron raw materials as the main raw materials, which are prepared into raw meal in an appropriate proportion, burned until part or all of them are melted, and cooled. The main components are CaO, SiO 2 、Al 2 o 3 and Fe 2 o 3 , and CaO, SiO in clinker 2 、Al 2 o 3 and Fe 2 o 3 It does not exist as a single oxide, but a collection of various minerals formed by chemical reactions of two or more oxides at high temperat...

Embodiment 2

[0062] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. The content of the example will not be repeated here.

[0063] The weight and number ratio of described clinker, granulated blast furnace slag, gypsum, lime, crystal nuclide is:

[0064] Clinker 10

[0065] Granulated blast furnace slag 70

[0066] plaster 10

[0067] lime 15

[0068] Crystal nuclides 5.

[0069] In this example, the clinker comes from the sales branch of Beijing Shuangshan Cement Clinker Co., Ltd., the granulated blast furnace slag comes from Shougang slag, gypsum and lime are commercially available products, and the crystal nuclei are products of Beijing Hengshengran Building Materials Technology Co., Ltd. , currently available in the market.

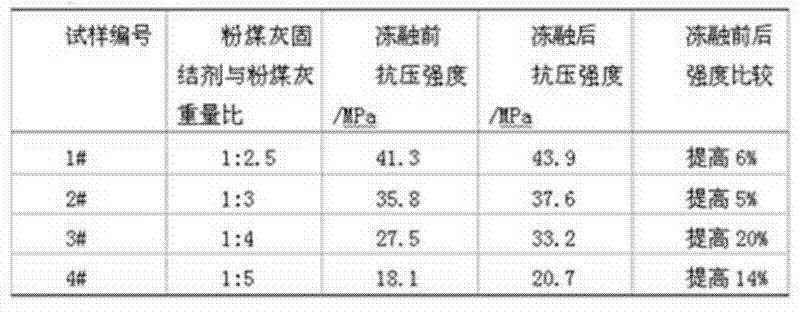

[0070] The test method is th...

Embodiment 3

[0074] This embodiment is an improvement made on the basis of Embodiment 1. For the same part as Embodiment 1 in this embodiment, please refer to the content disclosed in Embodiment 1 for understanding, and the content disclosed in Embodiment 1 should also be used as this embodiment. The content of the example will not be repeated here.

[0075] The weight and number ratio of described clinker, granulated blast furnace slag, gypsum, lime, crystal nuclide is:

[0076] Clinker 30

[0077] Granulated blast furnace slag 50

[0078] plaster 20

[0079] lime 5

[0080] Crystal Nuclides 2.

[0081] The source of each raw material in the present embodiment is the same as in Example 2.

[0082] The test method is the same as in Example 1.

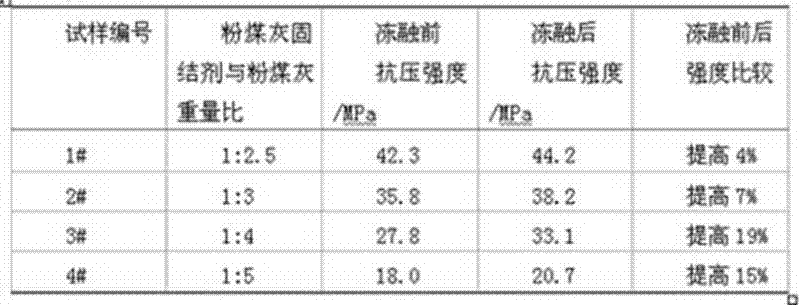

[0083] The experimental data is shown in the table below:

[0084]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com