Soft soil foundation curing agent and construction method for curing soft soil foundation

A kind of technology of soft soil foundation and construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further describe the present invention, a kind of soft ground curing agent of the present invention and the construction method for curing soft ground will be further described below in conjunction with examples. However, the present invention is not limited to the Examples.

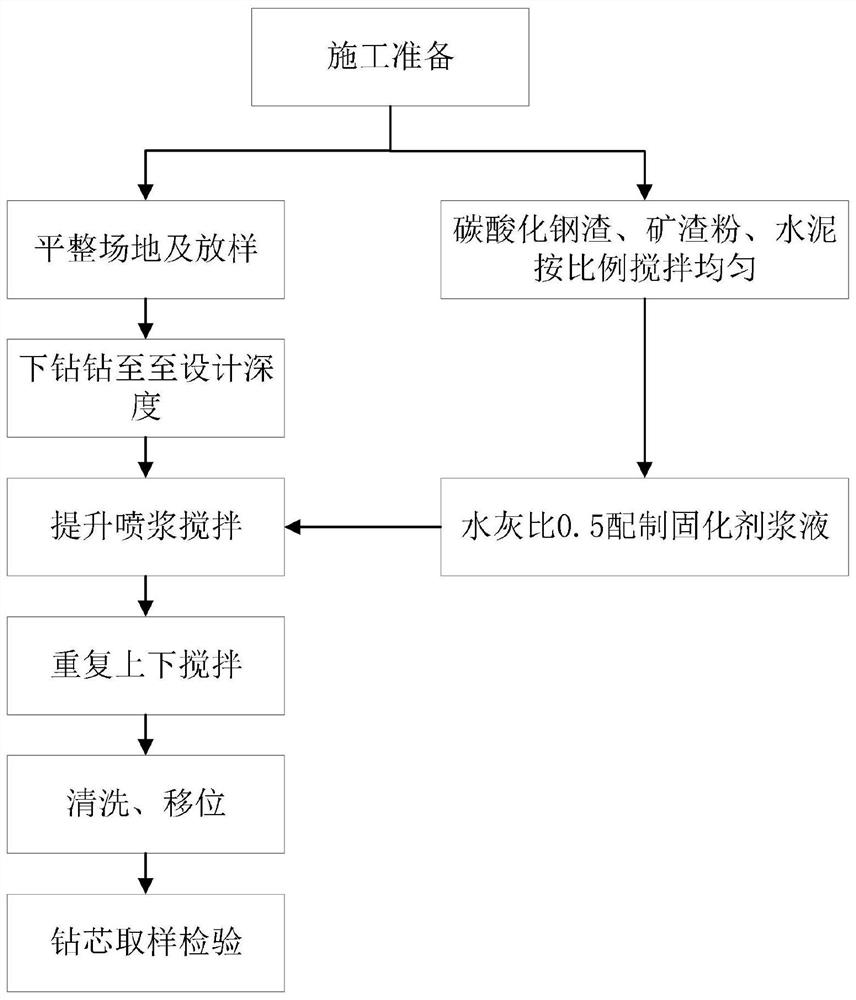

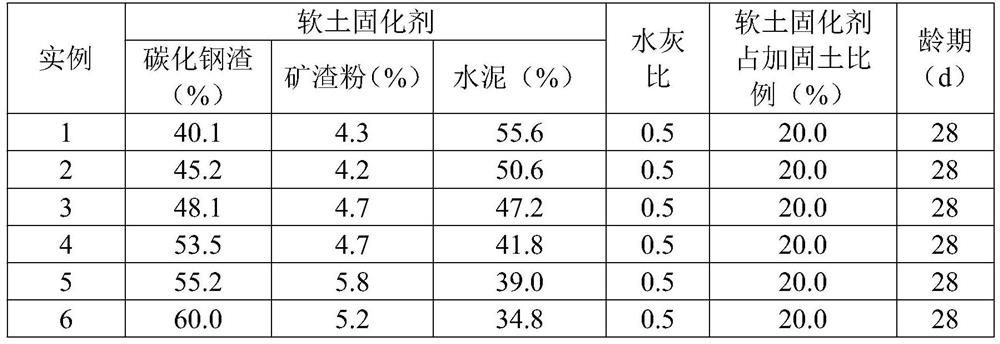

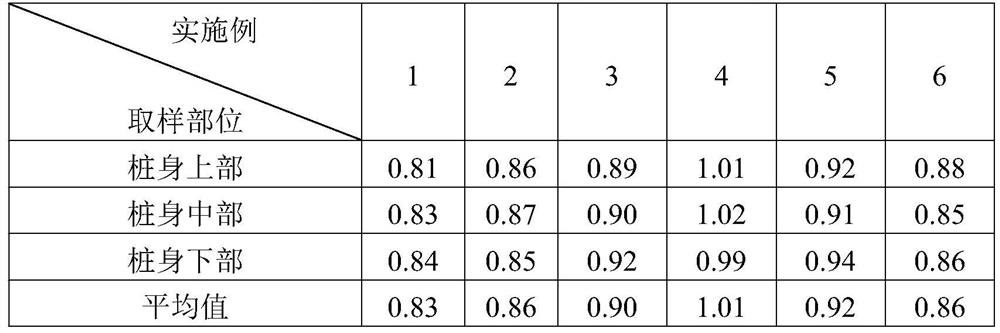

[0037] The solidifying agent for soft ground of the present invention comprises the following mass percentages of each component in raw materials: 40.1%-60.0% of carbonated steel slag, 4.2%-5.8% of slag powder, and 34.2%-54.1% of cement. The particle size of the carbonated steel slag needs to be controlled, preferably below 2 mm, and the finer the particle size, the better the effect. The cement is 42.5 grade ordinary Portland cement. The soft soil curing agent is prepared with dry materials, and the soft soil foundation curing agent slurry is prepared at a water-cement ratio of 0.5. The carbonated steel slag is mainly composed of iron oxide, calcium oxide, desulfurized gypsum, alumin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com