In-site tensioning system and method for reinforcing slab plate of integral prestress fiber board

A fiberboard, prestressed technology, applied in building maintenance, building reinforcements, processing of building materials, etc., can solve the problems of large beam slotting area, cumbersome force transmission of tensioning system, not direct, etc., to achieve anti-seismic and anti-fatigue. Good performance, reduced reinforcement workload, and reduced slotting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

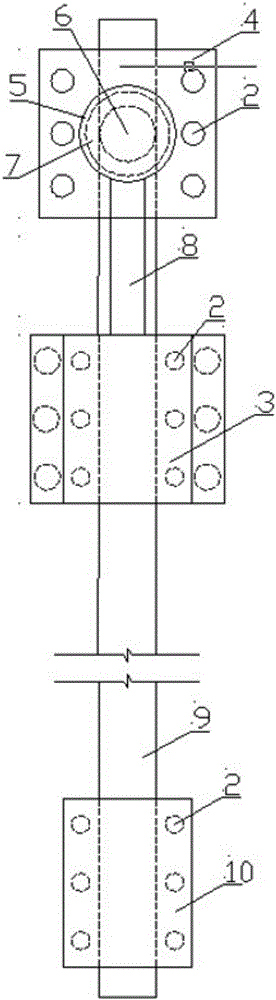

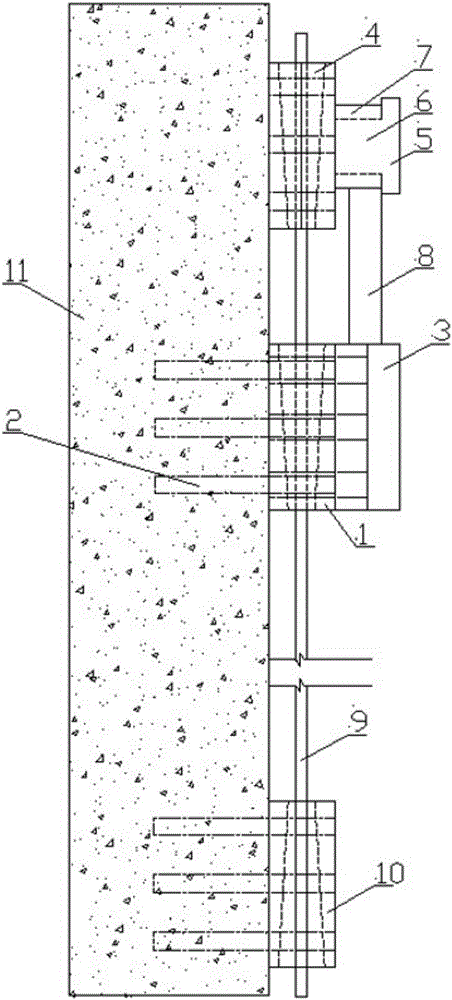

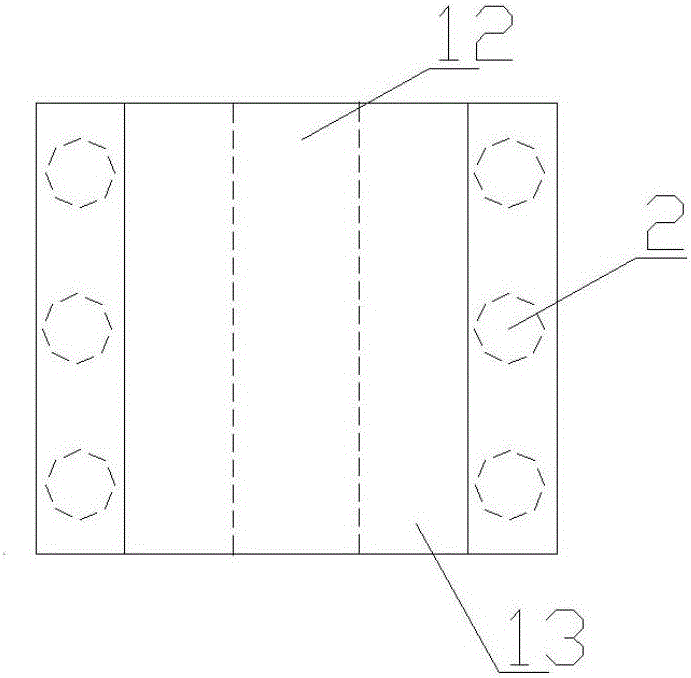

[0033] like figure 1 , figure 2 As shown, an in-situ tensioning system for beams and slabs reinforced with integrated prestressed fiberboards includes tension end anchors 1 and fixed end anchors 10 respectively anchored on beams or slabs, and is connected with tension end anchors 1 The convex hydraulic jack 3 also includes a two-part clamp 4, a cylinder 6 with a column cap 5 is welded to the upper surface of the clamp 4, and a sleeve 7 nested outside the cylinder 6 is connected by a push rod 8 On the convex hydraulic jack 3; one end of the fiberboard 9 is clamped by the clip-type clamp 4 at the tension end, and the other end is anchored to the anchor 10 at the fixed end. The tension end anchor 1 is composed of an anchor cup and a clip, and there are two sets of threaded holes on the anchor cup, one set of holes is used for planting bars to anchor on the beam, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com