Method for assembling prefabricated part reinforcing column through concrete

A technology of concrete prefabrication and prefabrication, which is applied in building maintenance, construction, building construction, etc. It can solve the problems of long construction period templates, high reinforcement costs, and damage to original components, so as to reduce the number of templates and binding steel bars and ensure the durability of the structure Sexuality, the effect of avoiding further destruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

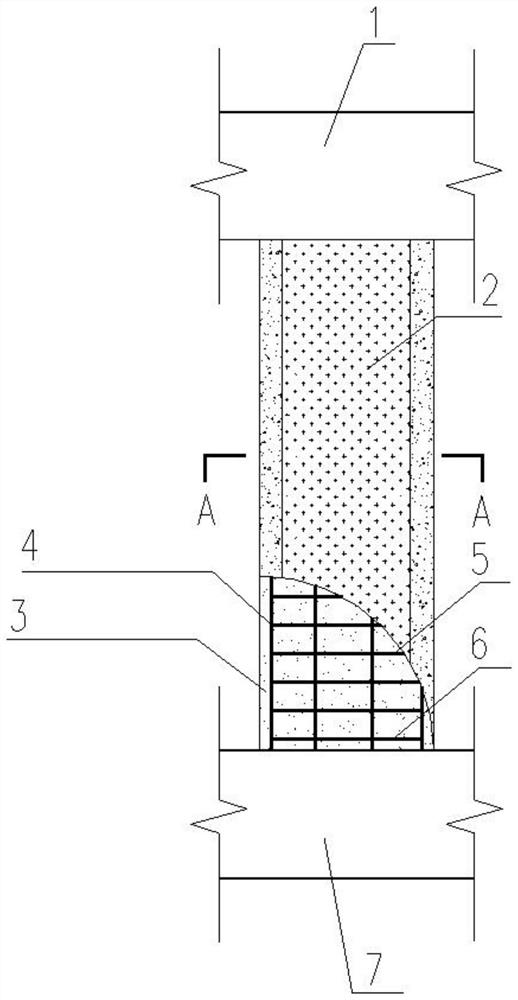

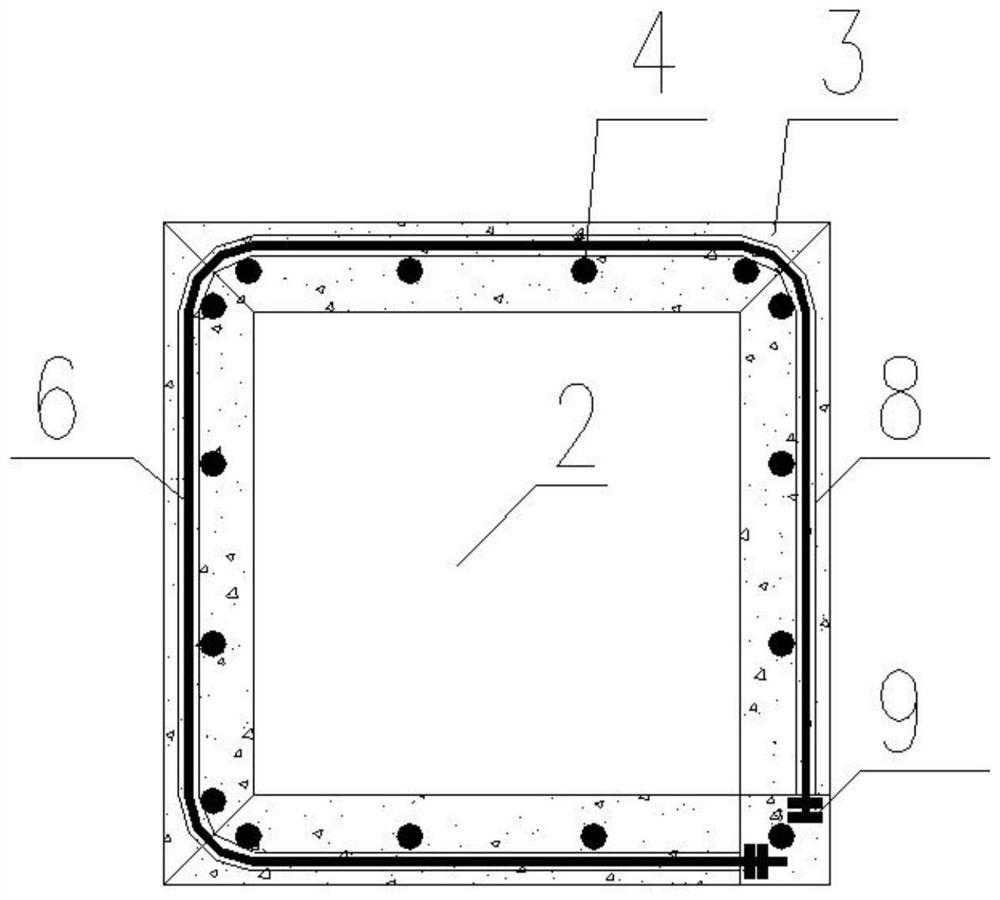

[0033] This embodiment relates to a method for reinforcing a column by assembling prefabricated parts with concrete, which specifically includes the following steps: for the implementation process, see figure 1 shown;

[0034] Step 1: The upper end of the concrete column 2 is provided with an upper frame beam 1, and the lower end is provided with a lower frame beam 7; before the concrete column 2 is reinforced, firstly, the stucco layer on the surface of the member is removed to the concrete base, and the oil stains and floats on the surface are removed. Slurry, and polished to a solid base; uneven parts should be polished or repaired. Remove surface dust, clean and apply interface agent.

[0035] Step 2: After preparing the adhesive according to the product instructions, use a spatula to spread it on the surface of the treated base and the surface of the concrete prefabricated part at the same time, with a thickness of 3mm.

[0036] Step 3: Paste the concrete prefabricated ...

Embodiment 2

[0042] This embodiment relates to a method for reinforcing a column by assembling prefabricated parts with concrete, which specifically includes the following steps: for the implementation process, see figure 1 shown;

[0043] Step 1: The upper end of the concrete column 2 is provided with an upper frame beam 1, and the lower end is provided with a lower frame beam 7; before the concrete column 2 is reinforced, firstly, the stucco layer on the surface of the member is removed to the concrete base, and the oil stains and floats on the surface are removed. Slurry, and polished to a solid base; uneven parts should be polished or repaired. Remove surface dust, clean and apply interface agent.

[0044] Step 2: After preparing the adhesive according to the product instructions, use a spatula to spread it on the surface of the treated base and the surface of the concrete prefabricated part at the same time, with a thickness of 3mm.

[0045] Step 3: Paste the concrete prefabricated ...

Embodiment 3

[0051]This embodiment relates to a method for reinforcing a column by assembling prefabricated parts with concrete, which specifically includes the following steps: for the implementation process, see figure 1 shown;

[0052] Step 1: The upper end of the concrete column 2 is provided with an upper frame beam 1, and the lower end is provided with a lower frame beam 7; before the concrete column 2 is reinforced, firstly, the plaster layer on the surface of the member is removed to the base layer, and the oil stains and laitance on the surface are removed , and polished to a solid base; the uneven parts should be polished or repaired. Remove surface dust, clean and apply interface agent.

[0053] Step 2: After preparing the adhesive according to the product instructions, use a spatula to spread it on the surface of the treated base and the surface of the concrete prefabricated part at the same time, with a thickness of 3mm.

[0054] Step 3: Paste the concrete prefabricated part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com